Ee 483 TC

Ee 483 TC

Uploaded by

mnvijaybabuCopyright:

Available Formats

Ee 483 TC

Ee 483 TC

Uploaded by

mnvijaybabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Ee 483 TC

Ee 483 TC

Uploaded by

mnvijaybabuCopyright:

Available Formats

OPERATION AND MAINTENANCE MANUAL

EE483TC & EE483TCI Power Generation Engine

Pub. No : M190456 : 01 Nov 2012

Downloaded from www.Manualslib.com manuals search engine

CONTENTS

Section Details Page No

Introduction-Operation & Maintenance

Part I 2

Manual

Part II Eicher Engine - General Information 3

Engine Familiarization

3 General Information 4

3.1- Engine Identification 4

3.2- Engine Nomenclature 5

3.3- Engine orientation and Parts

6 to 8

Illustration

Part III 3.4- Technical Specification- Engine 9 to 10

3.5- Engine Systems and Function 11

3.5.1- Air Intake and Exhaust System 11 to 13

3.5.2- Lubrication System 14 to 17

3.5.3- Fuel System 17 to 19

3.5.4- Cooling System 20 to 21

Part IV Engine Electrical System 22 to 23

Part V Safety Guidelines 24 to 25

Part VI Recommended Routine Checks By user 26 to 28

Part VII Engine Inspection and Maintenance 29 to 38

Part VIII Trouble Shooting Guidelines 39 to 47

Downloaded from www.Manualslib.com manuals search engine

PART I-INTRODUCTION - OPERATION & MAINTENANCE MANUAL

We are glad to introduce us as VE Commercial Vehicles Ltd (VECV), manufactures of EICHER EE483TC and

EE483TCI Power Generation Engine owned by you. VECV is committed to being the leader in customer

satisfaction in India and emerging markets. We put our best efforts to maintain global quality levels by

understanding and fulfilling customer needs.

This manual presented to you gives a comprehensive understanding on Construction, operation and

Maintenance aspects of Engine for the intended application.

These Engines meets current prevailing emission norms.

Due care has been taken in preparing this manual. However due to Continuous improvements product

specifications and illustrations are likely to undergo change without any prior notice.

For any further information, please write to:

PRODUCT SUPPORT

NON AUTOMOTIVE ENGINES

VE Commercial Vehicles Limited

(A Volvo Group and Eicher Motors Joint Venture)

102, Industrial Area No. 1 Pithampur 454775 Dist. Dhar (M.P.) India

Phone: (07292) 402633

Fax: (07292) 402611

PUBLICATION NO: M190456:00 REVISION NO: 01

PUBLICATION MONTH: NOVEMBER’2012 REVISION DATE: 01/11/2012

Downloaded from www.Manualslib.com manuals search engine

PART II: EICHER ENGINE GENERAL INFORMATION:

Eicher EE483TC Engines manufactured by VE Commercial Vehicles Ltd (VECV) are direct injection, four

Strokes, Water cooled, and Turbo charged Diesel Engines designed to suit Power Generation application.

Eicher EE483TCI Engines manufactured by VE Commercial Vehicles Ltd (VECV) are direct injection, four

Strokes, Water cooled, Turbo charged, Intercooled Diesel Engines designed to suit Power Generation

application.

The engines are eco-friendly, reliable and fuel efficient meets prevailing statutory emission standards.

While we, at manufacturing and testing have taken due care to ensure trouble free performance, as an

engine owner and user, proper up keep of engine, use of genuine parts, use of Genuine oil and Lubricants,

use of Genuine Coolant and adherence to scheduled and preventive maintenance shall derive the best out of

your engine resulting in Value for investment.

Downloaded from www.Manualslib.com manuals search engine

PART III: ENGINE FAMILIARIZATION

3. GENERAL

This part provides details about engine identification, engine Sl No nomenclature, Orientation, technical

specifications and various Systems of engine.

3.1 ENGINE IDENTIFICATION.

Engine is identified with the engine nameplate fitted on flywheel housing on left hand side of the engine

when viewed from front. Engine name plate contains the information as shown in the figure 1, 2 and 3.

Engine Sl No is also punched on the Cylinder block as shown in the figure 4.

Fig- Fig 2 – EE483TC-48 Kw

1- EE483TC-38 Kw

Engine Sl No Punched on Cylinder Block

Fig-4

Fig-3-EE483TCI-59 Kw

Downloaded from www.Manualslib.com manuals search engine

3.2 ENGINE NOMENCLATURE:

G- Identification for Power

EE 4 83 C D B A 100000 G Generation Engine

Running Serial number

Month of production (A to M), A= Jan

& M = Dec.

Note: “I” is omitted

Year of production (A to W), A= 2010

W=2028.

Note: “I” is omitted

Type of fuel used

(D=Diesel)

Version: N=NA (Naturally aspirated)

C= TCI (Turbo Charged intercooled)

T=TC (Turbo Charged)

Swept Volume per cylinder

83=0.83 Litres

No. of Cylinders (4 or 6)

EICHER

Downloaded from www.Manualslib.com manuals search engine

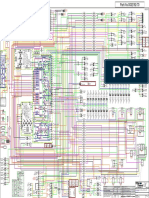

3.3 ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TC -TURBO CHARGED ENGINE):

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25 26

1 Radiator 14 Strip-Support radiator

2 Radiator Cap 15 Shroud Radiator

3 Hose- Radiator In 16 Guard Fan Radiator

4 Tank Condenser 17 Fan Cooling Radiator

5 Bracket – Radiator Support 18 Pipe- Fuel filter to Fuel injection pump

6 Cushion-Radiator Support Bracket 19 Stop Solenoid

7 Cap Oil Filler 20 Feed pump

8 Pipe- Turbo to Intake Manifold 21 Pipe fuel- Feed Pump to fuel filter

9 High Pressure Pipe 22 Fuel injection Pump

10 Rocker Cover 23 Oil Sump

11 Hose- Turbo out 24 Starter Motor

12 Hose Breather 25 Dip Stick

13 Air cleaner Assembly 26 Flywheel

Downloaded from www.Manualslib.com manuals search engine

ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TC -TURBO CHARGED ENGINE) CONTD:

27 28 29 30 31 32 33

34 35 36 37 38 39 40 41 42 43 44 45 46

27 Hose – Air cleaner 37 Pedestal- Rear for Transportation

28 Switch-Choke Air Cleaner 38 Hose- turbo charger in

29 Pipe- Lubrication Turbocharger 39 Turbo charger

30 Manifold- Exhaust 40 Filter Oil – Main

31 Cooler- Oil 41 Bend Exhaust

32 Manifold- Intake 42 Filter- By Pass

33 Switch Cum Sensor- Water Temperature 43 Pedestal – Front

34 Pipe- Air Cleaner to Turbo 44 Sensor-oil Pressure

35 Housing flywheel 45 Alternator- Battery charging

36 Engine Identification plate 46 V Belt- Engine/Alternator/Water pump

Downloaded from www.Manualslib.com manuals search engine

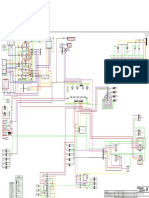

ENGINE ORIENTATION AND PARTS ILLUSTRATION (EE483TCI -TURBO CHARGED INTERCOOLED ENGINE):

1 2 3 4 5 6 7 8

1 Hose-Air Filter to Pipe TC in B 5 Intercooler Assy

2 Pipe TC in B 6 Hose – Thermostat to Radiator

3 Hose- Intercooler Outlet 7 Pipe-Turbo Charger to Intercooler inlet

4 Pipe TC in A 8 Hose-Pipe Intercooler inlet to Intercooler in

Downloaded from www.Manualslib.com manuals search engine

3.4 ENGINE TECHNICAL SPECIFICATIONS:

Details

Parameters Unit

40 Kva 50 Kva 62.5 Kva

Engine Manufacturer Name VE Commercial Vehicles Ltd

Engine Make Make EICHER

Engine Model Model EE483TC EE483TC EE483TCI

Emission Compliance Standard CPCB1 – As Per GSR 448 (E) 12.07.2004

No of Cylinders Nos. 4

Engine Configuration Configuration Inline / 4 Stroke

Turbo Charged

Engine Aspiration Type Turbo Charged

Inter cooled

Engine Fuel Type High Speed Diesel

Combustion Chamber Type Type Direct injection

Cylinder Bore X Stroke Mm 100 X 105

Engine Displacement Litres 3.3

Compression ratio Ratio 17:1 ± 0.5 mm

38 (52) @ 48 (65) @

Engine Rated Output Kw ( HP) @ RPM 59 (80) @ 1500

1500 1500 RPM

Ambient /

Standard Operating 25°C / 40 % / 1000 mbar

Relative Humidity

Conditions

/ Altitude

Engine Deration Applicability Above 4000 feet

Rating Standard Standard IS10000

10 % over load Permissible for 1 Hour in Every

Overload Permissibility

12 Hours of Operation

Governing Standard Standard BS5514 / IS 10000

Governing Class Class A1

Engine Low Idling Speed RPM 700 ± 50

Engine Fly Up Speed RPM 1560 ± 10

Engine Firing order Sequence 1-3-4-2

Direction of Rotation Direction Anti Clock wise when viewed from Flywheel End

Flywheel Standard SAE J 620 SAE 10 SAE 11.5

Flywheel Housing Standard SAE J 620 SAE 3 SAE 2

Lubrication Method Method Oil Pump Forced feed system

Oil Pump Type Gear Type

Oil Filter-Main Type / Nos. Paper Type / Single

Oil Filter-By Pass Type Spin on Type Paper

Oil Cooler Type Shell Type

API CH4-SAE 15W40 / EICHER Premium Diesel

Specification / Engine Oil

Engine Lubricating Oil Grade /

Recommendation

Downloaded from www.Manualslib.com manuals search engine

Details

Parameters Unit

40 Kva 50 Kva 62.5 Kva

% of Fuel < 0.15 %

Lubricating Oil Consumption

Consumption

Minimum Lubricating Oil

Bar 1.5

Pressure @ Low Idle

Max Lubricating Oil Pressure

Bar 5.5

@ Fly up Speed

Fuel Injection Pump Make/Type Bosch / Inline

Fuel Filter Type / Nos. Cartridge type / 2 Nos.

Cooling Method Method Liquid Cooling / Forced Circulation

Centrifugal

Water Pump Type

Specification / JIS-K-2234-94 / EICHER GENUINE RADIATOR

Coolant

Recommendation COOLANT

Engine Cooling Fan Type Pusher

Electrical System V 12

Starter Motor Make / V / Kw Bosch / 12 / 1.9 Kw Bosch / 12 / 3.2

Battery Charging Alternator Make / V / Amps Bosch / 14 / 49

Shut off Solenoid Type Energise to Stop

Switch – Low Oil Pressure Applicability Yes

Switch – High Coolant

Applicability Yes

Temperature

Switch- Air Cleaner Choke Applicability Yes

Sensor-Water temperature Applicability Yes (Integral Design with Switch)

Sensor-Lubricating Oil

Applicability Yes

Pressure

10

Downloaded from www.Manualslib.com manuals search engine

3.5 ENGINE SYSTEMS AND ITS FUNCTION:

As we all know, Diesel engine is a prime mover developing useful power. Air and fuel is required to produce

power. Lubrication is necessary for the moving parts of the engine. Continuous cooling is required to

dissipate heat generated during combustion. Electrical system is required for engine starting, battery

charging and sensing of critical engine operating parameters.

The construction of Eicher diesel engine is divided in to five parts as below.

1 Air intake and Exhaust System

2 Lubrication System

3 Fuel System

4 Cooling System

5 Electrical System

The below section provides details of function, key components and working principle of respective system

to understand better about Engine aspects.

3.5.1 AIR INTAKE AND EXHAUST SYSTEM

TURBO CHARGED INTERCOOLED ENGINES:

The function of air system is to supply clean, cool and sufficient quantity air required for proper combustion

of the fuel which results in designed power output of the engine and maintains emissions as per statutory

norms.

Air intake system facilitates cleaning of air, induction of air, compression of air through turbocharger and

cooling by intercooler.

Air is sucked from atmosphere and passed through the Air filter to restrict dust and other foreign particles

from entering into air intake system. Clean air is then induced and compressed by the turbocharger

compressor wheel. Turbocharger increases the temperature of the air. This high temperature air is then

passed through an intercooler which decreases its temperature. As air inducted cools down its density is

11

Downloaded from www.Manualslib.com manuals search engine

further increased. Due to more air with desired density of air inducted into the engine there will be complete

combustion resulting in:

• Increase in power and torque without increasing the size of the engine.

• Improves fuel economy.

• Reduce engine noise.

• More complete combustion resulting in cleaner emission

TURBO CHARGED ENGINES:

In turbo charged engines, intercooler will not be present. The Compressed air from turbo charger will be

directly inducted into the combustion chamber. The combustion parameters will be designed to suit the air

temperature inducted in to the combustion chamber and accordingly desired quantity of fuel will be

supplied to ensure better fuel economy and complete combustion to achieve emission characteristics.

AIR FILTER:

Air filter is fitted on the Suction Side. It is paper cartridge dry type air filter comprising of inner and outer

element. Air filter prevents dust and other foreign particles entering into the air inlet system. The restriction

Indicator fitted on the filter gives indication when air filter gets clogged.

Do not run the engine with clogged air filter. Clogged air filter reduces

power output, fuel efficiency; higher exhaust emissions and affects

engine performance.

Air filter outer element shall be cleaned whenever the restriction

indicator gives indication. There are limitations for cleaning as

frequent cleaning affects air filter filtration efficiency. Follow the

recommendation for cleaning procedures and permissible number of

cleaning.

The inner element should not be cleaned and it should be replaced.

Never run the engine without air filter. Running without air filter will cause foreign object entering into air

system and results in turbocharger and engine failures.

TURBO CHARGER:

The exhaust gases discharged from the combustion chamber are driven out through the exhaust manifold

into the turbo charger and accelerated in the turbine housing to turn the turbine wheel driving away the

Exhaust gases through the muffler to the atmosphere.

Simultaneously, the compressor wheel mounted on the same shaft spins at the designed speeds. The

centrifugal action draws air from air cleaner and builds up the boost pressure in the intake system.

12

Downloaded from www.Manualslib.com manuals search engine

SILENCER:

Silencer is used to reduce the noise of exhaust gas /

Smoke.

The exhaust gas is sent through a number of small holes

provided inside the silencer which results in sudden

expansion of exhaust gases.

This results in reduction in exhaust noise.

For specific applications like Power Generation residential

mufflers are used to achieve reduction in noise levels.

INTER COOLER (APPLICABLE FOR TURBO CHARGED INTERCOOLED ENGINES):

Compressed hot air from turbocharger flows through the

tubes of intercooler.

Pusher type radiator cooling fan charges Cold air through the

intercooler fins carries away the heat from compressed hot air

flowing through the intercooler tubes thereby reducing the

temperature of air to the designed temperature levels. This

compressed cold air rushes in to the combustion chamber.

13

Downloaded from www.Manualslib.com manuals search engine

3.5.2 LUBRICATION SYSTEM:

The engine has a forced lubrication system. The main functions of the Lubrication systems are as follows:

• Lubricates moving engine parts by forming a thin film of oil between components and prevents

metal to metal contact

• This oil film is capable of absorbing shocks in Con-rod Bearings and Gear train

• Flowing oil absorbs heat and cools engine parts

• Oil also collects carbon & metal particles formed during engine operation and flows it to the oil pan

• Oil neutralizes the acids and alkali produced during engine operation & prevents corrosion

• Seals compression by forming a thin oil film on cylinder liner walls

ENGINE OIL FLOW PATH:

14

Downloaded from www.Manualslib.com manuals search engine

SCHEMATIC DIAGRAM OF LUBE OIL FLOW:

22

1. Oil Strainer 4B. Bypass valve 8C. Timing gear 15. Auxiliary gallery

2. Oil Pump 5. Main oil gallery 9. Connecting rod bearing 16. Oil jet for piston cooling

2A. Relief valve 6. Engine oil pressure switch 10. Camshaft bushing 17 Piston

3. Oil cooler 7. Bypass filter 10A. Camshaft bushing no.1 18 Con rod bushing

3A. Bypass valve 7A. Restriction orifice 11. Rocker bushing 19. vacuum pump

3B. Regulator valve 8. Crankshaft main bearing 12. Push rod 20. Turbocharger

4. Filter element 8A. Crankshaft main bearing no. 1 13. Tappet 21. Oil sump

4A. Oil bypass alarm 8B. Idler bushing 14. Pressure control valve 22.Fuel Pump

The oil required for lubricating the engine parts is sucked by the oil pump from the sump through the

strainer.

The pressurised engine oil is then sent to oil cooler, where the oil is cooled and then it is sent to the oil filter

for filtration.

The filtered oil is then sent to all engine parts through main oil gallery. By pass oil filter is provided for fine

filtration.

LUBE OIL PUMP:

The oil pump is of gear type and is driven by the skew gear

mounted on the camshaft.

The oil pump cover also serves as the oil filter head, requiring no

oil pipe.

Engine oil is pressurised to the required pressure by the oil pump

and sent to various parts for lubrication and cooling.

15

Downloaded from www.Manualslib.com manuals search engine

OIL COOLER:

Shell type oil cooler facilitates heat dissipation from engine

lubricating oil and maintains engine lubricating oil temperature and

viscosity to the desired levels.

The Pressurised oil from oil pump is sent into the oil cooler for

cooling the hot engine oil. The coolant from the cylinder block is

passed through oil cooler element, which takes away the heat from

the engine oil.

LUBE OIL FILTER:

The full flow barrel type paper filter removes carbon and fine metal

particles formed during normal operation of engine. The filtered oil

is sent to Main oil gallery.

BY PASS FILTER:

The Spin on type by pass filter mounted on engine block through

adopter which has a small orifice is used for fine filtration of

lubricating oil.

The bypass filter allows a portion of main gallery oil to flow

through it & back to the oil pan through an adopter having a small

orifice.

During replacement the whole filter to be replaced

TURBO CHRAGER LUBRICATION:

Oil from oil main gallery flows through the oil tube to bearing housing

of turbocharger to lubricate bearing and is returned through the

outlet tube at the bottom of the bearing housing through the crank

case and to the oil pan.

16

Downloaded from www.Manualslib.com manuals search engine

FUEL INJECTION PUMP LUBRICATION:

Oil from oil gallery flows through benzo tube to FIP & lubricates

camshaft and governor mechanism and then drained to the oil

sump from the FIP gear side of FIP housing.

Pipe Lubrication - FIP

3.5.3 FUEL SYSTEM:

The function of fuel system is to feed the engine with clean and sufficient quantity of fuel as per designed

requirements.

Fuel Tank Feed pump Fuel Filter Fuel Injection Pump Injection

Nozzle Return line Diesel tank

The fuel system consists of the injection pump, fuel filter, injection nozzle, injection pipe and other parts. Fuel

is fed from the fuel tank through suction pipe to the feed pump of the fuel injection pump assembly and then to

the fuel filter, injection pump and injection nozzle.

The excess fuel is returned from the Nozzle to injection pump and to the fuel tank.

17

Downloaded from www.Manualslib.com manuals search engine

WATER SEPARATION FROM FUEL:

The air moisture trapped inside the fuel tank gets condensed during night time, becomes water and mixes

with diesel. If this water is allowed to flow through the fuel system it can damage the FIP and nozzle.

Since the engines are used for power generation application which is operated under stationery condition,

the fuel tank acts as water separator. The foreign particles in fuel are collected as sediments in fuel tank

bottom and water in fuel are collected at the bottom of the fuel tank. Ensure periodical draining of water

from fuel tank through the drain plug provided in the fuel tank.

Ensure periodical cleaning of Fuel tank to make it free from Sediments.

Do not top up fuel in fuel tank when the engine is under operation as the process will allow sediments and

water to float and gets carried away along with fuel. Always top up fuel in fuel tank when the engine is not in

operation. Wait for few minutes and allow sometime for sediments and water to settle at the bottom of the

fuel tank before starting the engine.

FEED PUMP:

The feed pump is driven by the Fuel injection pump

camshaft.

The priming pump allows manual lift of fuel when the

injection pump is stationary. It may be used when bleeding

the system.

The gauze filter removes large particles of dust from the fuel

lifted from the fuel tank, preventing the feed pump from

getting clogged. The filter must be washed in clean diesel

periodically.

FUEL FILTER:

The fuel from the feed pump is supplied to fuel filter for filtration. The dual filter is of element type and

replaceable individually.

18

Downloaded from www.Manualslib.com manuals search engine

Fuel from feed pump flows into the outer side of the filter housing and filtered by the element and supplied

to the fuel injection pump. The above diagram shows the flow path of fuel in fuel filter.

FUEL INJECTION PUMP:

The Bosch in line type fuel injection pump is used. The injection

pump, that forces fuel into the injection nozzle under pressure is

provided with a mechanism to increase or decrease the amount of

fuel. It has one plunger and delivery valve for each cylinder.

The plunger pushed up by the camshaft and pushed back by the

plunger spring, moves up and down in the plunger barrel on a

predetermined stroke to feed fuel under pressure. In doing so it

opens and closes the suction and discharge ports to adjust the fuel

injection rate.

The Constant speed governor of the fuel injection pump is capable of holding rated speed steadily

irrespective of variation in loads.

INJECTION NOZZLE:

The injection nozzles are of the hole type. The fuel delivered from

the injection pump enters the nozzle holder. When it reaches the

specified pressure value, the fuel overcomes the spring force to push

up the needle valve of the nozzle tip, spraying from the injection

orifice at the end of nozzle into the cylinder.

The injection pressure can be adjusted by increasing or

decreasing the number of washers in the spring.

19

Downloaded from www.Manualslib.com manuals search engine

3.5.4 COOLING SYSTEM:

The function of the cooling system is to absorb and dissipate heat generated during combustion thereby

maintaining engine coolant temperature as per designed parameters. To ensure the same the engine is

cooled by forced circulation of coolant by the water pump. Radiator cooling fan driven by the V Belt from the

water pump pulley charges cold air through the radiator fins which carries away the heat from the coolant.

This continuous process of circulation and heat dissipation ensures the operating temperature of the engine

is maintained.

The coolant temperature around the combustion chamber should be maintained at optimum levels for

satisfactory performance of the engine. It takes more time to achieve the desired operating temperatures at

low ambient temperatures, engine warm up periods and light loading conditions. Hence a thermostat is

installed in the cooling system which controls the coolant temperature around the combustion chamber to

the desired level all times during engine operation.

WATER PUMP:

The water pump is of centrifugal type and it is

driven by the V-belt from the crankshaft

pulley. A unit seal is installed between the

impeller and Water pump to prevent leakage

of coolant. There is drain hole provided at the

bottom of the water pump case which

ensures that coolant, should it leak from the

unit seal, does not enter the bearings. The

water pump is mounted on the timing gear

case provided with a suction pipe and swirl

chamber. Pressed into one end of the water

pump shaft is the impeller with backward

blades which feeds coolant under pressure

into the engine.

20

Downloaded from www.Manualslib.com manuals search engine

THERMOSTAT:

The thermostat is of a bottom bypass configuration, has a

valve controlled by a special wax enclosed in a pellet. The

wax changes from solid to liquid as it is heated, involving

volumetric change for regulating the flow of coolant.

The changes in the valve position with varying coolant

temperatures regulate the flow rate of coolant into the

radiator and water pump (bypass side), thus controlling

coolant temperature

RADIATOR:

The radiator, with a tube-and-corrugated-fin type core, not

only cools the engine coolant but also separates vapour

from liquid water and regulates pressure in the cooling

system.

The radiator is of simple closed type, equipped with a

pressure cap. The reservoir tank is open to atmosphere. The

coolant overflowing from the radiator is therefore stored in

the reservoir full with coolant at all times.

RADIATOR PRESSURE CAP:

The pressure cap regulates the pressure in the cooling system. When the pressure builds up exceeding the

predetermined level, the pressure valve compresses the pressure spring relieving the excessive pressure to

the atmosphere. As the coolant temperature falls forming a vacuum in the radiator, the vent valve opens to

admit air into the radiator, thus preventing the radiator from being deformed by the vacuum.

21

Downloaded from www.Manualslib.com manuals search engine

PART IV- ENGINE ELECTRICAL SYSTEM:

12 V, Negative Earthing Electrical systems is used on the engine. Electrical systems consist of the following

and its usage is discussed as below.

Sl Name of Operating Usage Illustration

No Component Voltage

1 Starter Motor 12V Engine Starting

Battery

Battery Charging / W Point Signal

2 Charging 12V

for RPM Sensing

Alternator

1.Signal to Engine Control Unit /

Temperature Gauge for Coolant

temperature indication

Temperature

2.Signal to Engine Control Unit /

3 Sensor Cum 12V

Stop Relay for Stopping the

Switch

Engine in the event of High

Coolant Temperature

3. NO – Normally open

Signal to Engine Control Unit /

4 Pressure Sensor 12V Gauge oil pressure for oil pressure

indication

22

Downloaded from www.Manualslib.com manuals search engine

1.Signal to Engine Control Unit /

Stop Relay for Stopping the

5 Pressure Switch 12V engine in the event of Low

Lubricating Oil Pressure

2. NC-Normally Closed

1.Signal to Engine Control Unit /

Stop Relay for Stopping the

Engine in the event of Air Cleaner

6 Choke Switch 12V

Element Clogging leading to High

Intake air restriction

2.NO-Normally Open

Engine Normal stopping through

Key Switch/ Stops the engine

based on the command received

Engine Stop

7 12V from Stop relay in the event of

Solenoid

Low Lubricating Oil Pressure, High

Coolant Temperature and High Air

restriction

Proper earthing, recommended Voltage, proper Crimping of wiring connections and avoiding loose

connection is mandatory for satisfactory performance of electrical system.

The basic engine is supplied with the above features for integration to Engine control unit / Instrumentation.

The Equipment manufacturers are requested to refer engine manufacturer for necessary details.

23

Downloaded from www.Manualslib.com manuals search engine

PART V-SAFETY GUIDELINES

This section laid guidelines for safety of personal and equipment. Safety should be the utmost priority during

installation, operation and maintenance of the engine and equipment.

General safety instruction, accident prevention regulations and safety precaution defined by law must be

observed.

Use of personal protective equipment must be worn during installation, operation and maintenance of the

engine and equipment.

ACCIDENTAL STARTING

Accidental starting of the engine can cause severe injury or death when working on engine. Safety must be

observed when working on engine.

Disconnect the battery before start of work negative (-) lead first. While reconnecting battery leads

connect negative (-) last.

Use lock out/tag out procedures when doing maintenance work on the engine In case engine is under

remote start/ stop operation.

ROTATING PARTS

Never operate equipment without guards and electrical enclosures. Rotating parts like Flywheel, Pulleys and

radiator fan can cause severe injury or death.

ELECTRICAL SHOCK

Never touch electrical terminals with bare hands or metal tools, always cut off the power and use insulated

handled tools. Electric shock can cause severe injury or death.

Always open the outgoing circuit breaker or isolator before starting any maintenance work on engine.

Never make contact when standing in water or wet shoes.

Never ground live terminals. It can cause electrocution.

Loose wiring is a hazard for spark and short circuit. Electrical wiring should be done properly using gland and

cable harnesses.

24

Downloaded from www.Manualslib.com manuals search engine

HOT SURFACES

While running engine and exhaust system surface are at elevated temperature contact with them can cause

severe burn injury.

Always wear personnel protective equipment (PPE’s) when working on hot surfaces. Start working on engine

when it cools down.

HANDLING ENGINE FLUIDS

Most Chemicals used in engines such as old engine oil, corrosion inhibiters; coolants and adhesives are

hazardous to health. Direct contact to Skin will cause allergy. Use of personnel protective equipment (PPE’s)

is recommended when using. Storage of the same should be done as per suppliers recommendations. Oral

consumption of these fluids can cause death.

Exhaust emitted from the engine exhaust is poisonous and inhalation of the same can cause harm. Always

provide proper ventilation of exhaust gases to the atmosphere.

Never smoke or permit flame near flammable fluids.

High pressure fluids can cause severe injury when pipes burst. Care should be taken when working with high

pressure fluids. Always release pressure before working on pressurized systems. Use safety goggles and

personnel protective equipments (PPE’s) while working.

HEAVY EQUIPMENT HANDLING/LIFTING

During handling heavy equipment always use proper lifting techniques. Lifting hooks should always be used.

Unbalanced load can cause injury to personal and damage to equipment.

Always use proper lifting arrangements. Check slings condition and capacity before using them.

Do not stand under the lifted loads.

Always lift load from the specified lifting points of the equipment.

Use soft/nylon slings of adequate capacity to prevent damage of equipment.

Always check operation of the crane/lifting tools before start of work.

25

Downloaded from www.Manualslib.com manuals search engine

PART VI: RECOMMENDED ROUTINE CHECKS BY USER

While all due care has been taken to ensure trouble free performance of the engine, a few simple routine

checks by the actual user will help to identify and fix the issue at right time which will avoid major

breakdown and down time of the equipment. It is recommended to monitor as below at regular intervals

and immediately report to authorized service centre if any abnormality noticed for necessary rectification.

DETAILS ACTIVITY

Engine Lubricating Oil Inspect for Leakage and Correct / Top up if required

Inspect for Looseness, Cracks / Damage and Correct if

V Belt

required

Inspect for Leakage and correct if Required

Coolant

Inspect for Level and top Up If required

All Rubber Hoses Inspect for Cracks / Damage and Correct If required

Instruments & Gauges Inspect for Proper Operation and correct if required

ENGINE LUBRICATING OIL CHECKING:

Ensure the equipment is placed on flat surface before checking the oil level. Do not check the oil level

immediately after stopping the engine. Allow 15 minutes after stopping the engine so that all the oil is

completely drained to the oil sump. The Engine oil level shall be checked through DIPSTICK of the engine.

Always ensure the level is maintained to the full level mark. Do not mix up different brands of oil.

Never operate the engine with oil level at Low level marks.

If any oil leakages noticed from any parts or location of the engine, report to the authorized service centre

and correct the same.

26

Downloaded from www.Manualslib.com manuals search engine

COOLANT CHECKING AND TOPPING UP:

Keep observing the reservoir tank coolant level and top up with genuine

recommended coolant to the maximum Level mark.

RUBBER HOSES:

Perform visual checks of all rubber hoses for cracks / damage. Report to the authorized service centre and

correct if necessary.

INSTRUMENTS & GAUGES:

All the instruments and gauges are critical for monitoring the operating parameters of the engine. The Hour

meter feature records the operating hours of the engine which is critical for planning scheduled

maintenance.

Any abnormality shall be immediately reported to the authorized service centre and corrected as required.

V BELT:

V BELT Main which connects Engine Crank pulley/Battery charging alternator/water pump/ Fan Radiator is

used for driving water pump for effective Coolant circulation, battery charging alternator for delivering

Battery Charging DC out Put and W Point Signal to Engine Control Unit for RPM and Hour Indication and

driving radiator cooling fan for keeping the coolant temperature within designed parameters.

Operating the engine with belts in loose condition will result in belt slippage affecting coolant circulation,

Engine cooling performance, and battery charging alternator output and improper RPM and Hour reading.

Excessive tension will result in cracks/damage to belts and more stress on bearings affecting components

reliability.

Whenever any abnormality is observed, it is recommended to correct the defects through the authorized

service centre.

27

Downloaded from www.Manualslib.com manuals search engine

ENGINE STARTING CARE:

During Starting of the engine, long cranking and holding the ignition key in on condition keeping starter

motor engaged with flywheel ring gear for longer period will affect the life of starter motor. The precautions

are as below.

Release the ignition key immediately once engine firing noise is heard.

If engine does not start, do not hold the ignition key more than 10 seconds.

Re crank after 1 minute. If Engine does not start in three attempts, Check and correct the

issue.

28

Downloaded from www.Manualslib.com manuals search engine

PART VII: ENGINE INSPECTION & MAINTENANCE

Needless to say, any equipment needs scheduled and preventive maintenance care. Engine being a prime

mover also needs attention at right time in order to ensure trouble free performance of the equipment. By

strictly adhering to the following Scheduled & preventive maintenance, use of genuine spares, Lubricants

and coolant will deliver satisfactory performance of the engine and avoid down time of the equipment.

INSPECTION & MAINTENANCE SCHEDULE

LEGEND: C-CLEAN / D – DRAIN / I – INSPECT, ADJUST, CORRECT, REPLACE, TOP UP IF REQUIRED / L – LUBRICATE /

R – REPLACE / T – TIGHTEN TO SPECIFIC TORQUE

SL PART NAME ACTIVITY

Every 2500 Hrs

Every 4000 Hrs

Every 1000 Hrs

Every 1500 Hrs

Every 2000 Hrs

Every 3000 Hrs

Every 500 Hrs

NO

Engine- Lubricating Replace at Specified interval / 6 Months

1 R

Oil Whichever occurs earlier

Filter – Lubricating Oil Replace at Specified interval / 6 Months

R

Main Whichever occurs earlier

Filter-Lubricating Oil Replace at Specified interval / 6 Months

R

By Pass Whichever occurs earlier

2

Replace at Specified interval / 6 Months

Filter- Fuel R

Whichever occurs earlier

Filter- Gauze Feed

Clean C

Pump

Clean Primary Cartridge Whenever Choke Indicator Provides alarm

3 Filter- Air Primary Replace with new Primary Cartridge after two cleanings or 24 Months Whichever

Occurs earlier

Replace with new Safety Cartridge during 3rd replacement of Primary Cartridge or 24

4 Filter-Air Safety Months whichever occurs earlier

Caution: Safety Cartridge Should not be cleaned

Replace Coolant at Specified Interval / 24

5 Coolant I R

Months Whichever occurs earlier

Inspect Belt tension and adjust if required I

6 Engine – V Belt Replace at Specified interval / 24 Months

R

whichever occurs earlier

Inspect and Adjust Valve Clearance if required

7 Valve Clearance I

Inspect and retighten Cylinder Head Bolts

Rubber Hoses-Air

intake / Turbo Replace at Specified Interval / Every 24

8 I

Charger/Intercooler/ Months Whichever occurs earlier

Radiator

Inspect for Leakage. Correct and Replace if

required

9 Fuel Hoses I R

Replace at Specific interval/ Every 24 Months

Whichever Occurs earlier

It is always recommended to carry out the above maintenance activities at the authorized service centre as it

needs skilled, trained manpower to perform the job.

29

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE ACTIVITY CARE:

Before starting the scheduled / preventive maintenance activity, ensure the engine is started and run for

around 15 minutes to confirm the engine starting ability, abnormal noise, vibrations, oil leakage, fuel

leakage, function of electrical instruments and gauges. This will facilitate in better understanding of the

engine before proceeding for the maintenance activity.

ENGINE LUBRICATING OIL REPLACEMENT:

Always perform engine lubricating oil replacement when the engine is in warm condition to ensure complete

draining of lubricating oil from oil sump.

The following steps shall be followed:

Ensure equipment is positioned on flat surface.

Unscrew the oil drain plug and drain the oil in tray.

Install and retighten the Drain Plug.

Ensure to replace the Copper Gasket of the drain plug

with new.

Fill with recommended quantity of EICHER GENUINE

lubricating oil through the Filler Cap.

Drain Plug

Allow 10 Minutes to facilitate oil to reach the oil Sump.

Reconfirm the oil level through dip stick after starting

Oil Filler Cap and stopping of the engine. If found less top up to the

level. Ensure sufficient time is allowed as discussed

above before checking the oil level.

CAUTION!

Necessary care shall be taken while working as high

temperature will result in burns.

Do not mix different brands of oil.

Clean the surface thoroughly.

Do not dispose the used oil on the ground as it is

hazardous to environment safety. Always collect, store

and dispose the old used oil in a container and dispose as per safety rules.

30

Downloaded from www.Manualslib.com manuals search engine

ENGINE LUBRICATING OIL RECOMMENDATION:

DETAILS ENGINE

EICHER EE683TCI

SPECIFICATION

API CH4 /CI4 SAE15W40

EICHER GENUINE OIL & LUBRICANTS EICHER PREMIUM DIESEL ENGINE OIL

QUANTITY REQUIRED FOR REPLACEMENT

11 LITERS (Including Filters)

DURING SCHEDULED MAINTENANCE

ENGINE MAIN OIL FILTER REPLACEMENT:

Unscrew the drain plug and remove oil from main oil filter casing.

After draining retighten the drain plug. Ensure to replace the Copper

gasket.

Unscrew the centre bolt and remove the filter casing along with

element.

Remove the used main oil filter element and clean the housing. Damage

and discard the same to avoid misuse.

Insert the centre bolt in its location of the casing.

Secure the spring driving through the centre bolt.

Locate the new filter element driving through the centre bolt.

Secure main oil filter o’ring with new and ensure its seating in its

location.

Tighten the centre bolt to specific torque (3 to 3.5 Kgf m / 29 to 34 N m).

CAUTION!

Cleaning and reuse of element is not recommended.

31

Downloaded from www.Manualslib.com manuals search engine

ENGINE BY PASS FILTER REPLACEMENT:

Remove used spin on type by pass filter by using bypass

filter wrench (Part No153801).

Damage and Discard the same.

Apply oil film on the bypass filter gasket before fitment

Fit the new bypass filter by fully tightening with the hand

and then using bypass filter wrench.

After ensuring complete tightness tighten filter by rotating

90°.

ENGINE FUEL FILTER REPLACEMENT:

Unscrew the drain plug and drain diesel in a clean

container. Pour back the fuel in the fuel tank.

Unscrew the centre bolt and remove the fuel filter

casing along with filter.

Remove the old O’ring from its location and discard

the same.

Clean the fuel filter casing with clean diesel.

Install the drain plug and tighten to 0.8 to 1.5 Kgf m (8

to 15 Nm) torque. Replace the copper gasket with

new.

Install the fuel filter O’ring with new in its location.

Install new fuel filter element in the filter housing.

Secure the fuel filter housing on the filter head and

tighten to 2.5 Kgf m torque (25 Nm).

Ensure the copper gasket is replaced with new.

Bleed the fuel system through Hand primer of feed pump. Wipe and clean any spilled diesel fuel as it can

cause fire.

32

Downloaded from www.Manualslib.com manuals search engine

ENGINE FUEL FEED PUMP GAUZE FILTER CLEANING:

Since the fuel from fuel tank is passed first through feed pump, due to

suction process foreign particles / dust from Fuel if allowed through the

fuel system affects the reliability of Fuel injection pump components.

Hence a gauze filter (Baby Filter) is provided at the inlet side of fuel pump

which filters any foreign particles/dust that is being is passed through it.

Remove the filter by unscrewing the Banjo Bolt and clean with diesel as

per recommendation.

Feed Pump Gauze Filter

ENGINE AIR FILTER ELEMENT INSPECTION AND CLEANING:

Remove the Air cleaner assy cover.

Loosen the nut and remove the Primary air

filter element.

Remove air cleaner safety cartridge.

Visually inspect both the filters for clogging /

tear of element.

If there are thin portions in the filter paper,

replace the element. If the sealing of the air

filter element is found damaged, replace

element.

If there is dry dust on the element, clean the dust by blowing 7 Kg/cm² or

lower compressed air against the element.

Blow the compressed air from inside the element up and down along the

frills of the filter paper and clean the whole element evenly.

After the element has been cleaned, put an electric lamp inside the element

to check for damage and pin holes.

If the element is contaminated with moist soot, replace it regard less of the

specified replacement frequency.

33

Downloaded from www.Manualslib.com manuals search engine

CAUTION! :

Do not strike the element or strike it against a hard object to remove dust.

Primary Element Should be removed for cleaning only when Choke switch provides alarm.

Clean only the primary filter element. The safety Element should never be cleaned but only

replaced at the recommended intervals.

Frequent cleaning of elements will only result in damage to the paper, sealing washers and

rings and wing nut which will ease the entry of unfiltered air into the engine. It will thus

reduce the air cleaning efficiency of the element leading to serious engine damage.

CHOKE INDICATOR:

The choke indicator functioning shall be confirmed after starting the engine and

closing the inlet port of air cleaner assy gradually to increase negative pressure. The

Choke switch will covert to NC and send signal to the stop relay there by

commanding the stop solenoid to shut off the engine.

If it does not stop the engine then replace the Choke switch.

Choke Switch

ENGINE COOLANT REPLACEMENT:

In order to prevent corrosion of the cooling system, it is

recommended to add coolant at a ratio 50:50 of quantity

of water.

A drain cock is provided at the bottom tank of the radiator

for draining coolant from the engine.

Unscrew the drain cock and drain the coolant. Secure the

drain cock in its position after draining.

Remove Pressure cap and fill the recommended coolant as

per ratio through the Pressure cap opening.

Allow sufficient time for the coolant to get filled as air will

be removed from the engine slowly during the coolant refilling process.

With pressure cap removed from the radiator, allow the engine to run at idle with coolant temperature of

90°C to bleed the system completely.

After the system is bled with air, add recommended coolant to radiator as required.

34

Downloaded from www.Manualslib.com manuals search engine

ENGINE COOLANT RECOMMENDATION:

DETAILS ENGINE COOLANT

SPECIFICATION JIS-K-2234-94

EICHER GENUINE OIL & LUBRICANTS EICHER GENUINE RADIATOR COOLANT

1: 1 by Volume i.e. 50% COOLANT & 50 %

USAGE RECOMMENDATION

WATER

40 Kva 50 Kva 62.5 Kva

COOLANT CAPACITY ( LITERS)

14.8 17 17

Refer to “Engine Technical Specification” for Qty of Coolant Required for the respective Engine

CAUTION! :

Be sure to use EICHER Genuine Coolant

Never Mix it with any other coolant, anti-freezes or anti rusts.

Ensure that the caps of the radiator assembly and that of coolant are tightened.

BELT TENSION CHECKING AND ADJUSTMENT:

As shown in figure, press the V belt and check whether

there is a deflection of 10-15 mm.

In case the deflection is less or more than the above value

then loosen two bolts of alternator which is shown in the

figure with arrows.

With the help of a long rod move the

alternator assembly in required direction and

retighten the two bolts.

35

Downloaded from www.Manualslib.com manuals search engine

INSPECTION AND ADJUSTMENT OF VALVE CLEARENCE:

Valve clearance adjustment should be performed when the engine is cold. The engine was warm while

performing the maintenance activities as the engine was started before starting the maintenance activities.

The engine will become cooler by the time lubricating oil and filter replacements were completed.

Inspect and adjust the valve clearance when the engine is cold by using the following procedure.

1 Remove the inspection cover on the flywheel housing.

You will observe a pointer is fitted on the flywheel

housing and also access to the flywheel periphery.

2 Remove the Rocker cover.

3 Crank the engine with cranking handle (Standard tool) in

the direction of engine rotation (Anti clockwise when

viewed from Flywheel End).

4 Align the TDC Mark with the pointer.

5 Check the cylinder no 1 valves for freeness (The Push rod

of No 1 Cylinder not pushing the intake and exhaust valves). This confirms that Cylinder No 1

piston is at TDC position of the compression stroke.

6 Perform valve clearance adjustment as per the table given below. The nominal value is 0.4 mm.

36

Downloaded from www.Manualslib.com manuals search engine

7 Install the specified thickness gauge

between the rocker and valve cap to check

for clearance.

8 If the valve clearance is out of nominal

value, loosen the lock nut and turn the

adjusting screw to the extent that the

thickness gauge moves slightly tight.

9 After adjustment hold the adjusting screw

in position with a screw driver and tighten

to secure the lock nut.

10 Recheck the valve clearance with the

thickness gauge.

11 Rotate the engine one full turn and bring

the Cylinder no 4 piston to compression

stroke and perform the valve clearance

adjustment for other Cylinder as per table

given above.

12 Assemble the rocker cover assembly.

ENGINE STARTING AFTER MAINTENANCE:

Before starting the engine, ensure tightness all fasteners, Lubricating oil level and coolant level. The fuel

systems needs bleeding of air and proceed as below.

The feed pump has a hand primer arrangement for the purpose.

Turn the feed pump primer counter clockwise until it becomes loose.

Loosen the air plug of the fuel filter.

Move the hand primer up and down by hand to feed fuel until air bubbles do

not come out from the fuel filter air plug.

When no air bubbles come out along with fuel, tighten the air plug. Press the

hand primer down and turn clockwise until it fits into its position.

Wipe out spilled fuel around the fuel filter and floor.

Actuate Starter to discharge air from Fuel Injection Pump.

37

Downloaded from www.Manualslib.com manuals search engine

After bleeding the air check for performance of engine on load, Oil leaks, Coolant leaks, Engine noise level

and for any other abnormalities before handing over to the end user.

38

Downloaded from www.Manualslib.com manuals search engine

PART VIII: ENGINE TROUBLE SHOOTING GUIDLINES:

Sl no Symptom Probable Cause Remedy

Inadequate fuel quantity Add Fuel

Poor Quality of fuel or oil

Change fuel or Oil

used

Bleed the system.

If trouble persists Check for

Loose Piping & Connectors

Air trapped in fuel system Restriction for fuel flow due to

blockage in fuel pipes

Possibility of air being sucked

in from the feed pump

Water trapped in fuel system Drain water from fuel tank, fuel filter

Fuel leakage from injection Repair/ Replace Cracked or loose

Pump piping pipes and other parts

Feed Pump defective Repair

Fuel Pipes, feed pump gauze

filter, fuel filter, air cleaner Clean/Replace

clogged

Incorrect fuel injection timing Reset

1 Engine Difficult to Start

Incorrect Valve Clearance Reset

Injection Nozzles not clean Clean

Injection pressure not ok Rectify

Injection Spray Pattern Poor Repair / Replace Nozzle

Low engine Compression

(Worn out piston and

Repair / Replace worn out parts

sleeve/valve seat leakage/

cylinder head gasket leakage)

Ignition key defective Replace

Starter Motor defective Repair / Replace

Check for:

Fuel injection Pump defective Starting delivery

Variation between cylinders

Battery Discharged Recharge Battery

39

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Incorrect fuel or oil used Change fuel or oil

Idling speed setting not ok Adjust idling stopper bolt

Bleed the system.

If trouble persists Check for

Loose Piping & Connectors

Air trapped in fuel system Restriction for fuel flow due to

blockage in fuel pipes

Possibility of air being sucked

in from the feed pump

Water trapped in fuel system Drain water from fuel tank, fuel filter

Fuel Pipes, feed pump gauze

filter, fuel filter, air cleaner Clean/Replace

clogged

2 Idling Not Smooth

Incorrect fuel injection timing Reset

Incorrect Valve Clearance Reset

Injection Nozzles not clean Clean

Injection pressure not ok Rectify

Injection Spray Pattern Poor Repair / Replace Nozzle

Low engine Compression

(Worn out piston and

Repair / Replace worn out parts

sleeve/valve seat leakage/

cylinder head gasket leakage)

Incorrect Engine control

Reset

adjustment

Bleed the system.

If trouble persists Check for

Loose Piping & Connectors

Air trapped in fuel system Restriction for fuel flow due to

blockage in fuel pipes

Possibility of air being sucked

in from the feed pump

3 Loss of Power Output

Water trapped in fuel system Drain water from fuel tank, fuel filter

Fuel Pipes, feed pump gauze

filter, fuel filter, air cleaner Clean/Replace

clogged

Incorrect fuel injection timing Reset

40

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Incorrect Valve Clearance Reset

Injection Nozzles not clean Clean

Injection pressure not ok Rectify

Injection Spray Pattern Poor Repair / Replace Nozzle

Low engine Compression

(Worn out piston and

Repair / Replace worn out parts

sleeve/valve seat leakage/

cylinder head gasket leakage)

Air cleaner Clogged Clean/Replace

3 Loss of Power Output Air leakage in intake System Repair

Muffler or Exhaust pipe

Repair/Replace

clogged

Feed Pump delivery quantity

Rectify

and Pressure low

Air restriction in intake

Rectify

system

Turbo Charger - Gas leak at

Overhaul at Manufacturer authorized

turbine inlet / exhaust

service centre

manifold joint

Excessive dirt built up on

Overhaul at Manufacturer authorized

turbo charger compressor

service centre

wheel or diffuser vanes

Insufficient oil supply to

Check and rectify

turbo charger

Air cleaner / Muffler not in

Correct or replace defective parts

good condition

Engine oil level is not Ok Restore Proper level

Incorrect fuel injection timing Reset

Incorrect Valve Clearance Reset

4 Black Smoke

Improper fuel used Change fuel

Restricted Exhaust system Check and rectify

Clean nozzles and adjust injection

pressure if required. Check spray

Injection Nozzles defective

pattern and change Nozzle if required

41

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Check / Correct or Replace.

Defective Cylinder head

gasket

Worn Valve and Valve Seat

Poor Compression Pressure

Valve Spring set

Worn or damaged piston ring

Excessive clearance between

piston and cylinder sleeve

Restricted air duct from

turbo compressor to intake Rectify

manifold

Restricted air duct from air

Rectify

cleaner to turbo charger

Air leak between Intake

Retighten manifold Nuts

manifold and engine

Gas leak at Turbo charger

turbine inlet / Exhaust Retighten Mounting nuts

manifold joint

Excessive dirt build up on

Overhaul at manufacturer authorized

compressor wheel and or

service centre

diffuser vanes

4 Black Smoke Foreign body damage on Find out the cause of entry of foreign

compressor or turbine particles and rectify.

Find out the cause of entry of foreign

Turbine housing flap particles and rectify.

damaged Overhaul at manufacturer authorized

service centre

Insufficient oil supply to

Check and rectify

turbocharger

Air filter clogged Clean/ Replace

Restricted turbo charger oil

Rectify / Check Quality of fuel

drain line

Turbo charger bearing Overhaul at manufacturer authorized

housing sludge or coked service centre

Worn Engine Piston rings or

Replace

Liners

Burnt Valves and or Piston Replace

Turbo Charger Piston ring Overhaul at manufacturer authorized

sealing defective service centre

Turbo charger bearing Overhaul at manufacturer authorized

defective service centre

Improper fuel used Change fuel

Improper Exhaust

5

Colour

Engine oil level not Ok Restore Proper Level

42

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Full Load stopper on

Adjust and tighten the stopper bolt

governor control lever loose

Excessive Valve clearance Adjust

Incorrect fuel injection timing Reset

Clean nozzles and adjust injection

Injection Nozzle defective pressure if required. Check spray

pattern and change Nozzle if required

Improper Exhaust

5 Air cleaner or muffler not in

Colour Correct or replace defective parts

good condition

Check / Correct or Replace.

Defective Cylinder head

gasket

Worn Valve and Valve Seat

Poor Compression Pressure

Valve Spring set

Worn or damaged piston ring

Excessive clearance between

piston and cylinder sleeve

Adjust belt tension. Check for damage

Fan belt loose

and cracks

Add Coolant and if level continues to

Coolant level incorrect reduce inspect for leakages, loose

hose, clamps and damaged hoses

Radiator fins Clogged Clean and correct core bends if any

Thermostat defective Replace

Radiator Cap Pressure Valve

Replace

defective

Water Pump Impeller

Replace

damaged / Malfunction

6 Engine Over Heating

Inferior Engine oil quality Change oil

Low engine oil level Replenish

Flush Cooling system and change

Coolant Contaminated

coolant

Oil Cooler defective Repair

Oil Pump defective Repair

Cylinder head gasket leaky Replace

Air cleaner or muffler clogged Replace

43

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

6 Engine Overheating Engine overloaded Avoid Overload

Piping’s and hoses not

Rectify

securely installed

Injection Pump, water Pump

and other auxiliaries not in

Check and adjust

good condition or improperly

Engine Noise- Comes installed

from outside the

Adjust belt tension and replace if

engine V Belt Loose or damaged

damaged

Crankshaft pulley not

Rectify

installed properly

Alternator bearing worn out Replace

Incorrect valve clearance Adjust

Valve Spring deteriorated

Replace

or damaged

Valve and Valve seat contact

Noise comes from Rectify

improper

rocker cover and

Oil Supply to rocker shaft

neighbourhood Rectify

inadequate

Injection opening pressure

Repair/Replace

low

7

Injector spray pattern poor Repair / Replace

Noise comes from Gear

Timing gear backlash not ok Replace gear

case & Neighbour hood

Excessive ply in camshaft Rectify

Piston, Piston ring and

Replace

cylinder sleeve worn out

Connecting rod small end and

Replace

big end bush worn out

Main bearing worn out Replace

Noise comes from

cylinder head & Crank Excessive crankshaft end ply Correct by using correct thrust washer

Case

Piston pin worn out Replace

Loose flywheel or crankshaft Rectify

Worn Cam and tappet Replace

Inferior quality of fuel (Low

Use correct fuel

cetane number)

44

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Injection Pump Coupling

Align timing marks and retighten bolts

loose

Noise from around the Injection pump piping

Rectify / Replace

injection pump cracked or loose connection

Injection timing incorrect Reset

Clamping bolts & nuts of

intake & exhaust System Tighten

loose

Turbo charger bearing Rectify through manufacturer’s

7 defective authorized service centre

Foreign body damage on Rectify through manufacturer’s

compressor or turbine authorized service centre

Noise in Intake and

Turbine housing / flap Find out the cause of entry of foreign

Exhaust System

damage particles and rectify the same

Insufficient Oil Supply to

Check and rectify

turbocharger

Exhaust Pipe or muffler

Repair or Replace

damage

Air leakage in intake /

Rectify

exhaust system

Oil cooler defective Repair

Check for leaks or oil trapped in.

Incorrect oil level Repair trouble spot and restore oil

level

Oil Viscosity not Ok Change oil with correct viscosity

Oil Pressure switch / Gauge

Replace

defective

Oil Pressure too low

Oil filter clogged Replace

Oil Strainer Clogged Clean

8

Oil Pump defective Rectify

Connecting rod bearing worn

Replace

out

Oil Temperature high Rectify

Oil Pump relief valve faulty Repair/Reset

Oil Pressure too high Oil Main gallery clogged Clean

Oil Pump Joints loose or

Repair/Replace

Piping Cracked

45

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Improper Engine oil Viscosity Use correct grade of oil

Check for oil Leaks – Oil

filter/Oil cooler/Oil Repair leaks

Pan/Piping’s/Rocker cover

Lines in cooling system Repair leaks of oil cooler, water jacket

leaking etc

Bearings worn Replace

Front or Rear Crankshaft oil

Repair defective parts or replace

seals leaking

Dirty air cleaner Clean

Valve stem seal worn Replace

Excessive Oil

9

Consumption Valve to Valve guide

Replace

clearance not ok

Piston ring and groove worn Replace Piston rings or Piston

Piston and sleeve worn Replace Piston or sleeve

Turbo charger bearing Overhaul at manufacturer authorized

housing sludge or coked service centre

Excessive dirt build up on

Overhaul at manufacturer authorized

turbocharger compressor /

service centre

diffuser vanes

Turbo charger sealing Overhaul at manufacturer authorized

defective service centre

Turbo Charger Bearing Overhaul at manufacturer authorized

defective service centre

Fuel leakage from Piping’s Rectify

Improper fuel being used Use correct fuel

Incorrect setting of idling

Reset

speed

Incorrect Engine control

Excessive fuel Reset

10 adjustment

consumption

Incorrect fuel injection timing Reset

Incorrect Valve clearance Adjust

46

Downloaded from www.Manualslib.com manuals search engine

Sl no Symptom Probable Cause Remedy

Injection Nozzles defective.

Check for Clean Nozzle/Adjust injection pressure

Injection Pressure/Spray if incorrect/Replace nozzles tip or

Condition/Seat tightness Nozzle if required

Excessive fuel

10

consumption

Engine Overloaded Avoid overloading

Repair/Calibrate FIP from Bosch

Defect in FIP

authorized service centre

47

Downloaded from www.Manualslib.com manuals search engine

Regd. Office & Works : 102, Industrial Area No.1, Pithampur - 454 775. Distt. Dhar (M.P.) India. Tel.: 91 - 7292 - 402633. Fax : 07292 - 402611 Website : eicher.in\eth

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 2012 Chevrolet Sonic 1.8L Motor LUWDocument612 pages2012 Chevrolet Sonic 1.8L Motor LUWPatricio Valencia100% (1)

- Workshop Manual SL90 SeriesDocument110 pagesWorkshop Manual SL90 Seriesfreddy yagual89% (18)

- Iveco - Euro Trakker 4 - 5 - Manual PDFDocument1,702 pagesIveco - Euro Trakker 4 - 5 - Manual PDFFranciscoOliveira92% (93)

- Timberjack Skidder-BrochureDocument24 pagesTimberjack Skidder-BrochureBassie100% (1)

- DG Set ManualDocument58 pagesDG Set ManualAMIT VIJAYVARGI100% (1)

- Ee694 Power Generation Engine CPCB II - 100 Kva & 125 Kva Pub No.m190514-00Document52 pagesEe694 Power Generation Engine CPCB II - 100 Kva & 125 Kva Pub No.m190514-00eichermgupta71% (7)

- Greaves Cotton LTD.: Spare Parts CatalogueDocument62 pagesGreaves Cotton LTD.: Spare Parts Cataloguenithin100% (1)

- 3H.3025 Ispl Book For 3R1040 Engine For Power GenerationDocument99 pages3H.3025 Ispl Book For 3R1040 Engine For Power GenerationDevidas Jaiswal50% (2)

- 4g11 Tg2 Engine Parts BookDocument64 pages4g11 Tg2 Engine Parts Bookrahmeds123100% (4)

- 1AL 485 - G1 TG2 TAG3 EngineDocument30 pages1AL 485 - G1 TG2 TAG3 Engineajay67% (3)

- Price List APB IEB - MRP Apr 2021Document141 pagesPrice List APB IEB - MRP Apr 2021dev baid100% (3)

- Ashok Leyland CA PARTS LISTDocument1,368 pagesAshok Leyland CA PARTS LISTRas-Sherwin A. Jalani100% (1)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument91 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya Anam100% (2)

- Bliss Broucher New PDFDocument8 pagesBliss Broucher New PDFganapati hegfeNo ratings yet

- Parts Catalogue - MDIDocument47 pagesParts Catalogue - MDIsengottaiyan86% (7)

- Dv8.5005 Ispl Book For Dv8 Engine For Power GenerationDocument135 pagesDv8.5005 Ispl Book For Dv8 Engine For Power GenerationMECHO STORE100% (1)

- 6h.5255-6k1080ta Engine For Power Generation 125kvaDocument118 pages6h.5255-6k1080ta Engine For Power Generation 125kvanilesh asthana75% (4)

- Aluw04d EngineDocument6 pagesAluw04d EngineDhaval Waghela100% (1)

- Al 485 - g1 Tg2 Tag3 Tag4 EngineDocument32 pagesAl 485 - g1 Tg2 Tag3 Tag4 Enginerahul mehta100% (2)

- Mahindra DG - 2Document44 pagesMahindra DG - 2sengottaiyan100% (3)

- Spare Parts Catalogue PDFDocument156 pagesSpare Parts Catalogue PDFprasadmvk100% (5)

- Mahindra Blazo 25 9s Bogie Parts CatalogueDocument391 pagesMahindra Blazo 25 9s Bogie Parts CatalogueBhomesh Kumawat100% (1)

- 07 - CMO - 965 - AL6DTIG4 - 160KVA - Parts CatalogueDocument80 pages07 - CMO - 965 - AL6DTIG4 - 160KVA - Parts CatalogueTiago Freire100% (1)

- Spare Part Catalog cv01 6sl 9088tDocument85 pagesSpare Part Catalog cv01 6sl 9088tparahu arief100% (2)

- 3R1040 Spare Parts PDFDocument90 pages3R1040 Spare Parts PDFSergio Ramos Rivera100% (2)

- Location:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDocument23 pagesLocation:-Fleetguard Filters Pvt. Ltd. - After Market Price List W.E.F. 18Th June 2018 Distributor Name: - Address: - Office Contact No. For Queries / Order Booking: - Distributor Contact PersonDadasaheb More100% (3)

- (MDI Series) - This Catalogue Is Updated As On 1st September, 2008Document46 pages(MDI Series) - This Catalogue Is Updated As On 1st September, 2008rahul mehta100% (2)

- Parts PDFDocument96 pagesParts PDFviraj arjun ghadage100% (2)

- Mahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationDocument3 pagesMahle Air Filter (Primary) For Ashok Leyland: Industrial FiltrationSurajPandey100% (2)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument85 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedPlr. Baswapur100% (3)

- Kirloskar Engine EA10 & EA20Document34 pagesKirloskar Engine EA10 & EA20Niten Gupta100% (1)

- Part Manual DG 380-KVA PDFDocument128 pagesPart Manual DG 380-KVA PDFMd Akhtar100% (1)

- Ashok Leyland DG - 03 - CMO - 904A - AL4DTG3-2 (62.5KVA) Parts CatalogueDocument82 pagesAshok Leyland DG - 03 - CMO - 904A - AL4DTG3-2 (62.5KVA) Parts Cataloguesengottaiyan100% (6)

- 5 - 7.5 KVA DG - 1125GR - Mahindra - PartsDocument26 pages5 - 7.5 KVA DG - 1125GR - Mahindra - Partsradhakishan pawar100% (4)

- Fleetguard Filters Pvt. Ltd. After Market Price List (HCV / LCV) W.E.F. 21-May-2021Document11 pagesFleetguard Filters Pvt. Ltd. After Market Price List (HCV / LCV) W.E.F. 21-May-2021dev baid100% (6)

- Cropton Graeves 160kva DG Parts CatlogueDocument51 pagesCropton Graeves 160kva DG Parts CatlogueFariyad Ansari100% (2)

- Tata BS4 5890Document233 pagesTata BS4 5890mzplus chikhli67% (3)

- Greaves Rhs65xlDocument54 pagesGreaves Rhs65xlNiten GuptaNo ratings yet

- Kirloskar 6R1080TA PAGE 1-10Document10 pagesKirloskar 6R1080TA PAGE 1-10Niten Gupta50% (2)

- 2R1040 Spare Parts Manual PDFDocument84 pages2R1040 Spare Parts Manual PDFmanoj_doshi_1100% (2)

- 6R1080TA Spare PartsDocument87 pages6R1080TA Spare PartsHarneak Singh Gujral67% (6)

- Cummins New Price ListDocument1,930 pagesCummins New Price ListAwaish KhanNo ratings yet

- Koel MRP Oct 20Document151 pagesKoel MRP Oct 20dulichandNo ratings yet

- NEW August 13 ALWD618-42D Genset Engine - Parts CatalogueDocument21 pagesNEW August 13 ALWD618-42D Genset Engine - Parts Cataloguerahul mehta100% (1)

- Kirloskar Parts Cata LougeDocument77 pagesKirloskar Parts Cata LougePlr. Baswapur100% (2)

- TATA 407 SpecificationDocument10 pagesTATA 407 Specificationbaisankit100% (3)

- Volvo Eicher Domestic CatalogueDocument6 pagesVolvo Eicher Domestic CatalogueDipesh50% (4)

- INDEX - Parts Catalogue - September-2015 PDFDocument2 pagesINDEX - Parts Catalogue - September-2015 PDFVivek100% (2)

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument101 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya Anam100% (1)

- Ashok Leyland ALU 400Document2 pagesAshok Leyland ALU 400Naveen Chaudhary100% (3)

- Eicher ManualDocument93 pagesEicher Manualkajay9550% (12)

- 6R1080T Spare Parts PDFDocument86 pages6R1080T Spare Parts PDFSamir Khan100% (2)

- KG 545 EmsDocument32 pagesKG 545 EmsRoyston fernandes0% (2)

- Chota ChilliDocument1 pageChota ChilliRishu ranaNo ratings yet

- Spare Part Catalog - cv01 6sl 9088tDocument85 pagesSpare Part Catalog - cv01 6sl 9088tbabaisandip100% (6)

- DV SeriesDocument101 pagesDV SeriesManish Kumar100% (2)

- Presentacion de Cargador 980g.Document50 pagesPresentacion de Cargador 980g.Cristian NeiraNo ratings yet

- SERV1847 - TXT3 - EngineDocument65 pagesSERV1847 - TXT3 - Enginefrezgi birhanu100% (4)

- DE18 Instruction Manual (Maintenance)Document161 pagesDE18 Instruction Manual (Maintenance)diegoNo ratings yet

- 1070-Instruction Book HATZ 2G40HDocument27 pages1070-Instruction Book HATZ 2G40HNicolae HincuNo ratings yet

- Technical Manual 8.1 L Diesel Engines - Base EngineDocument500 pagesTechnical Manual 8.1 L Diesel Engines - Base Enginejohnsaad15No ratings yet

- V04-De18 Instruction Manual (Operation)Document109 pagesV04-De18 Instruction Manual (Operation)RM Haroon67% (3)

- Dc17a Instruction Manual (Operation) ) V00aDocument103 pagesDc17a Instruction Manual (Operation) ) V00aPalmNo ratings yet

- Hydraulic Breaker PDFDocument69 pagesHydraulic Breaker PDFRofie Tritho100% (1)

- Refrigerant Weight CalculatorDocument4 pagesRefrigerant Weight CalculatormnvijaybabuNo ratings yet

- GMK Manitowoc Training Catalog 2019Document32 pagesGMK Manitowoc Training Catalog 2019mnvijaybabu100% (1)

- GMK Manitowoc Training Catalog 2019Document32 pagesGMK Manitowoc Training Catalog 2019mnvijaybabu100% (1)

- TUV&IICS4 1 Offshore Crane Sep19 KwanDocument5 pagesTUV&IICS4 1 Offshore Crane Sep19 KwanmnvijaybabuNo ratings yet

- Dse7110 Mkii Dse7120 Mkii Data SheetDocument2 pagesDse7110 Mkii Dse7120 Mkii Data Sheetmnvijaybabu100% (1)

- Pharmacy - Pre Q Pharm 5 6 Years - 27!02!2018Document8 pagesPharmacy - Pre Q Pharm 5 6 Years - 27!02!2018mnvijaybabuNo ratings yet

- eDocument8 pagesemnvijaybabuNo ratings yet

- Piston & Crankshaft - S130Document4 pagesPiston & Crankshaft - S130mnvijaybabuNo ratings yet

- DENSO Brushless Alt SpecsDocument1 pageDENSO Brushless Alt SpecsmnvijaybabuNo ratings yet

- Basic Hydraulic SystemsDocument128 pagesBasic Hydraulic Systemsbeau04297% (37)

- Bendix E-7 Dual Brake Valve: DescriptionDocument8 pagesBendix E-7 Dual Brake Valve: DescriptionmnvijaybabuNo ratings yet

- Enduron Low SAPSDocument3 pagesEnduron Low SAPSmnvijaybabuNo ratings yet

- Transmision Allison PDFDocument1,130 pagesTransmision Allison PDFmnvijaybabu100% (3)

- Powertrain Diagnostics Development ValidationDocument3 pagesPowertrain Diagnostics Development ValidationmnvijaybabuNo ratings yet

- M10 Tower Light PDFDocument2 pagesM10 Tower Light PDFmnvijaybabu0% (1)

- Tj114pe5a enDocument4 pagesTj114pe5a enmnvijaybabuNo ratings yet

- CB 13Document2 pagesCB 13mnvijaybabuNo ratings yet

- Service Manual: Chassis, Mast & Options DP100N DP120N DP135N DP150N DP160NDocument41 pagesService Manual: Chassis, Mast & Options DP100N DP120N DP135N DP150N DP160NmnvijaybabuNo ratings yet

- Nitrogen Gas Charging Kits Brochure WEBDocument12 pagesNitrogen Gas Charging Kits Brochure WEBmnvijaybabuNo ratings yet

- Mechanical Engineering: Academic Regulations Course Structure AND Detailed SyllabusDocument48 pagesMechanical Engineering: Academic Regulations Course Structure AND Detailed SyllabusmnvijaybabuNo ratings yet

- Part # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalDocument1 pagePart # Is 0032192-70: Eldorado Eldorado Eldorado Eldorado National National National NationalmnvijaybabuNo ratings yet

- Course Electric System Backhoe Loaders KomatsuDocument46 pagesCourse Electric System Backhoe Loaders Komatsumnvijaybabu100% (9)

- 4 Troubleshooting GuideDocument25 pages4 Troubleshooting GuidemnvijaybabuNo ratings yet

- Advantage SchematicDocument1 pageAdvantage SchematicmnvijaybabuNo ratings yet

- O497ag MilDocument88 pagesO497ag MilmnvijaybabuNo ratings yet

- RH 120eDocument8 pagesRH 120eSawadogo Gustave NapinguebsonNo ratings yet

- Diagrama Electrico 950hDocument17 pagesDiagrama Electrico 950hJose Carmona67% (3)

- Jenbacher: 4.1 Checklist For Alarm MessagesDocument32 pagesJenbacher: 4.1 Checklist For Alarm MessagesAqeel Ahmad100% (4)

- Argo Atv Operator's ManualDocument76 pagesArgo Atv Operator's ManualForum PompieriiNo ratings yet

- BMW - M3 - V8-4.0 - E92 - Manual Part2Document700 pagesBMW - M3 - V8-4.0 - E92 - Manual Part2Mariluz Fonseca Prieto100% (2)

- Maintenance Manual Intervals For ForkliftDocument15 pagesMaintenance Manual Intervals For ForkliftMoataz SamiNo ratings yet

- MTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetDocument2 pagesMTU 400 KW 8V1600G80S EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- MF8925 ManualDocument670 pagesMF8925 ManualGedas Pocius83% (6)

- Case Cx210 Crawler Excavator Shop ManualDocument20 pagesCase Cx210 Crawler Excavator Shop Manualjohn100% (66)

- 3 160428055251Document30 pages3 160428055251arifNo ratings yet

- Santa FE 2002 2.7LDocument202 pagesSanta FE 2002 2.7LMarcelo Ravena Ulloa100% (1)

- 360 - 460 - 510 Series Tractors: Service ManualDocument210 pages360 - 460 - 510 Series Tractors: Service ManualNicusor BuleteanuNo ratings yet

- BCA Sheet KSBDocument65 pagesBCA Sheet KSBbumatio latiNo ratings yet

- R300LC 9SDocument204 pagesR300LC 9Sazze bouz100% (4)

- 8w-Detc Maintenance ManualDocument87 pages8w-Detc Maintenance Manualarun100% (1)

- 3408E-3412E Engine ControlsDocument138 pages3408E-3412E Engine Controlsgerardogusi100% (18)

- Maintenance Chart For QSM15 POWER CAR - Updated - Latest - Final - 1Document2 pagesMaintenance Chart For QSM15 POWER CAR - Updated - Latest - Final - 1SSE ACCNo ratings yet

- Manual - de - Taller - Aprilia Sport City 125Document159 pagesManual - de - Taller - Aprilia Sport City 125David CardosoNo ratings yet

- Haynes Ford Sierra Service and Repair ManualDocument20 pagesHaynes Ford Sierra Service and Repair Manualmerri100% (66)

- Porsche 911 Carrera (Type 993) Service Manual: 1995-1998 - Complete IndexDocument13 pagesPorsche 911 Carrera (Type 993) Service Manual: 1995-1998 - Complete IndexBentley Publishers0% (3)

- 03 SPARE PARTS MaK - 9M20CDocument357 pages03 SPARE PARTS MaK - 9M20Ccamilo.provoste.manNo ratings yet

- D2876 LE 201 Standard Scope of SupplyDocument4 pagesD2876 LE 201 Standard Scope of SupplyncthanhckNo ratings yet