MiniTec Conveyors

MiniTec Conveyors

Uploaded by

g.subhadeep6890Copyright:

Available Formats

MiniTec Conveyors

MiniTec Conveyors

Uploaded by

g.subhadeep6890Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

MiniTec Conveyors

MiniTec Conveyors

Uploaded by

g.subhadeep6890Copyright:

Available Formats

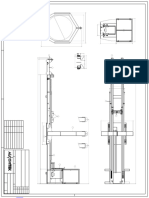

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

00.0

028/

0

BELT CONVEYORS

286 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

BELT CONVEYOR 00.0

104/

0

The belt conveyor module in our MiniTec CADmenue construction software designs your belt conveyor auto-

matically according to your requirements. Furthermore it calculates the deflection, suggests the number of

supports and generates the respective part list - within a few minutes. Assembly can be carried out quickly

and easily as a result of our proven components.

Motor arrangement

Plug-on motor Flanged motor

Subconstuctions

Height-adjustable Standard

MINITEC PROFIL SYSTEM 287

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

REQUEST

00.0 FOR OFFER: BELT CONVEYORS AND ROLLER TRACKS

105/

0

Standard dimension

Axial distance A mm

Belt width L mm

Conditions of usage

Goods to be conveyed

Weight/piece kg

Total belt load kg

Temperature °C

Subconstuction

Charging side height He mm

Discharging side height Ha mm

Number of supports Pcs.

Height adjustable sup. from mm to mm

No. of lateral guide support Pcs. (max. distance: 1000 mm)

Lateral guide one side both sides

Floor anchor Yes No

Rollers Yes No

Feet Yes No

Options

Belt PVC PU

Supporting sheet Aluminium Inox

Drive

Motor arrangement Flanged Plug-on motor

Motor Type Part no.

Speed m/min.

Adjustable speed from m/min. up to n m/min.

Company Please call me back

Name Please send me an offer

Phone no.

Fax no.

288 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

MOTOR ATTACHMENT KIT Ø 16 Part N° 29.5030/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Motor plate and cover, steel, powder - Belt-conveyors made of MiniTec - Screw flange plate on basic frame;

coated, grey aluminium profiles mount housing with bearing

- Housing with self aligning - Suitable for attachment of spur wheel - Insert belt driving cylinder; on the

back-geared motors; flange Ø 120 mm opposite side use conveyor bearing

- Chain wheel bored for motor-shaft Part N° 21.0993/0

Ø 16 - Belt driving cylinder Part N° 29.5022/0

and belt tensioning cylinder Part N° - Mount motor and chain wheels and

- 2 chain wheels with driving chain 21.0994/0 tension chain

- Fixing kit - Mount cover

Weight 3,060 kg

MOTOR ATTACHMENT KIT Ø 20 Part N° 29.5031/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Motor plate and cover, steel, powder - Belt-conveyors made of MiniTec - Screw flange plate on basic frame;

coated, grey aluminium profiles mount housing with bearing

- Housing with self aligning - Suitable for attachment of spur wheel - Insert belt driving cylinder; on the

back-geared motors; flange Ø 120 mm opposite side use conveyor bearing

- Chain wheel bored for motor-shaft Part N° 21.0993/0

Ø 16 - Belt driving cylinder Part N° 29.5022/0

and belt tensioning cylinder Part N° - Mount motor and chain wheels and

- 2 chain wheels with driving chain 21.0994/0 tension chain

- Fixing kit - Mount cover

Weight 3,060 kg

MINITEC PROFIL SYSTEM 289

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

SWIVEL PLATE Part N° 29.5001/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Steel, powder coated, grey - Attachment of the subconstruction on - Fasten at the conveyor profiles at the

MiniTec belt conveyor subconstruction with fixing kit from

- Fixing kit supply schedule

- Also suitable for inclined belt conveyors

Weight 0,377 kg

- The swivel plate is also used as a

counterbearing to tighten the belt

- Range: ± 35°

SUPPORT ROLLER KIT Part N° 29.5002/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Support roller kit, PVC - MiniTec belt conveyor systems - Preassemble the profile roller support

on the conveyor supports; use the

- Ball bearings on both sides - As a support for the lower side of long angles

belt conveyors

- Two profile supports - Clip the support roller in fixing kit

- We recommend to install one support

- 2 mounting angles roller for each intermediate support on - Slide the roller in appropriate position

the belt conveyor and tighten the screws

- Fixing kit

- Use this support roller kit only with belt

Weight 0,487 kg width > 115 mm

Please specify dimension L (belt width)

290 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

BELT TENSIONING CYLINDER 45 Part N° 21.0994/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium - MiniTec belt conveyor systems - Insert the axle in the conveyor bearing

assembly bore

- Turned spherically - Use suitable conveyor bearing Part N°

21.0993/0 - The cylinder is fixed axially by the self-

- Journal Ø 17 aligning ball bearings

Weight 4,800 kg/m - The self-aligning ball bearings

compensate light misalignments

Please specify dimension L (belt width)

BELT DRIVING CYLINDER 45 Part N° 21.0995/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Steel, zinc-plated - MiniTec belt conveyor systems - Insert belt driving cylinder in conveyor

bearing with bore Part N° 21.0993/1

- Turned spherically - Use suitable conveyor bearing Part N°

21.0993/0 - Mount on opposite conveyor bearing

- Journal max. Ø 17 Part N° 21.0993/0

Weight 15,300 kg/m - The self-aligning ball bearings

compensate light misalignments

Please indicate belt width L and

dimensions A, B, C, D and E (if < 17 mm)

MINITEC PROFIL SYSTEM 291

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

BELT DRIVING CYLINDER 45 FOR MOTOR KIT Part N° 29.5022/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Steel, zinc-plated - Can only be used with the MiniTec belt - Insert the belt driving cylinder in the

conveyor kit Part N° 29.5030/0orPart bearing housing on the motor side

- Turned spherically N° 29.5031/0

- Mount the conveyor bearing Part N°

- Axle Ø 17, driving side suitable for 21.0993/0 on the opposite side

fastening the chain wheel of motor

attachment kit - The self-aligning ball bearings

compensate light misalignments

Weight 15,300 kg/m

Please specify dimension L (belt width)

BELT DRIVING CYLINDER 45 FOR PLUG-ON MOTOR Part N° 29.5023/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Steel zinc-plated - MiniTec belt conveyor systems DSGM - Insert the belt driving cylinder in the

with torque support conveyor bearing for plug-on motor

- Turned spherically Part N° 29.5029/0

- Suitable for MiniTec plug-on motor

- Axle Ø 14, driving side suitable for with torque support - Mount the conveyor bearing Part N°

fastening the plug-on motor 21.0993/0on the opposite side

Weight 15,300 kg/m

Please specify dimension L (belt width)

292 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

BELT TENSIONING CYLINDER 90 Part N° 21.0982/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium with shaft made of steel - MiniTec belt conveyor systems - Insert axes in the bore of the self-

aligning bearings of the conveyor

- Turned spherically - Use suitable conveyor bearing Part N° bearing

21.0985/00

- Axle Ø 25 - The cylinder is fixed axially by the self-

aligning ball bearings

Weight 15,800 kg/m

- The self-aligning ball bearings

Please specify dimension L (belt width) compensate light misalignments

BELT DRIVING CYLINDER 90 Part N° 21.0981/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium with shaft made of steel - MiniTec belt conveyor systems - Insert belt driving cylinder in conveyor

bearing with bore Part N° 21.0985/10

- Turned spherically - Use suitable conveyor bearing Part N°

21.0985/0 and Part N° 21.0985/1 - Mount on opposite conveyor bearing

- Axle max. Ø 25 Part N° 21.0985/00

Weight 16,200 kg/m - The self-aligning ball bearings

compensate light misalignments

Please indicate belt width L and

dimensions A, B, C, D and E (if < 25 mm)

MINITEC PROFIL SYSTEM 293

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

CONVEYOR BEARING 45 Part N° 21.0993/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium GD, powder coated, grey - Bearing for belt-tensioning cylinders - Pretighten at the profile groove

- Self-aligning ball bearing with Ø 17 - If swivel plates Part N° 29.5001/0 for

mm, both sides sealed support fastening are used, they serve

as counter bearing for tightening

Weight 0,275 kg purpose; if not, use multi block or

angles

Please specify dimension L (belt width)

- Tighten the conveyor belt by

unscrewing the set screw, if necessary

reset the tool as often as needed

- Firmly tighten the conveyor bearing

- Recommended locking torque: 25 Nm

CONVEYOR BEARING 45 WITH BORE Part N° 21.0993/1

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium GD, powder coated, grey - Bearing for belt-tensioning cylinders - Pretighten at the profile groove

- With bore for shaft end (add on motor) - Attachmant of plug-on motors or chain - If swivel plates Part N° 29.5001/0 for

wheels on shafts; max. Ø 17 mm support fastening are used, they serve

- Self-aligning ball bearing with bore Ø as counter bearing for tightening

17 mm, both sides sealed purpose; if not, use multiblocks or

angles

Weight 0,268 kg

- Tighten the conveyor belt by

unscrewing the set screw, if necessary

reset the tool as often as needed

- Firmly tighten the conveyor bearing

- Recommended locking torque: 25 mm

294 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

CONVEYOR BEARING 45 FOR PLUG ON MOTOR Part N° 29.5029/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium GD, powder coated, grey - MiniTec belt-conveyors with plug on - Fasten the torque support on thread M8

motor (hollow shaft) - Preassemble conveyor bearing at profile

- Self-aligning ball bearing Ø 17 mm, end

both sides sealed - If swivel plates Part N° 29.5001/0for

floor fastening are used, they serve as

- With thread M8 for torque support counter bearing for tightening purpose;

if not. use multiblock or angles

- Fixing kit - Tighten the conveyor belt by

unscrewing the set screw , if necessary

Weight 0,269 kg reset the tool as often as needed

- Firmly tighten the conveyor bearing

- Recommended locking torque: 25 Nm

CONVEYOR BEARING 90 Part N° 21.0985/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium GD, powder coated, grey - Bearing of belt-tensioning cylinders 90 - Preassemble conveyor bearing at profile

in MiniTec belt-conveyors end

- Self -aligning ball bearing with bore Ø

25 mm, both sides sealed - As counter bearing for tightening of

connection plate 32 x 90 or 45 x 90

Weight 0,900 kg

- Tighten the conveyor belt by

unscrewing the set screw, if necessary

reset the tool as often as needed

- Firmly tighten the conveyor bearing

- Recommended locking torque: 25 Nm

MINITEC PROFIL SYSTEM 295

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

CONVEYOR BEARING 90 WITH BORE Part N° 21.0985/1

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium GD, powder coated, grey - Bearing of belt driving cylinders in - Preassemble conveyor bearing on

MiniTec belt-conveyors profile end

- With bore for shaft end (add on motor)

- Attachment of motors, chain wheels or - As counter bearing for tightening use

- Self-aligning ball bearing with bore Ø belt pulleys on shaft, Ø max 25 mm connecting plate 32 x 90 or 45 x 90

25 mm, both sides sealed

- Tighten the conveyor belt by

Weight 0,900 kg unscrewing the set screw, if necessary

reset the tool as often as needed

- Firmly tighten the conveyor bearing

- Recommended locking torque: 25 Nm

SUPPORTING SHEET Part N° 29.5010/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium, anodized - Support for conveyor belts - Screw with counter sunk screws M6 x

16 and square nut M6 on profile

- Thickness: 2 mm - For MiniTec conveyor systems

- bored, ready for use

Weight 5,400 kg/m2

296 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

CONVEYOR BELT PVC Part N° 29.5014/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS

- PVC, black - For MiniTec belt conveyor systems - Pull belt over belt driving cylinder and

belt tensioning cylinder

Please specify dimension L (belt width) - High performance conveyor belts,

and dimension EL (endless length) seamless welded - Mount belt tensioning cylinder and

belt driving cylinder and tighten belt

- Special designs possible upon request:

e.g. picking surface, struts etc. Calculation of endless length EL:

- For cylinder 45: EL = 2 x A + 165 mm

- For cylinder 90: EL = 2 x A + 305 mm

CONVEYOR BELT PU Part N° 29.5015/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS

- PU, blue - For MiniTec belt conveyor systems - Pull belt over belt driving cylinder and

belt tensioning cylinder

Please specify dimension L (belt width) - High performance conveyor belts,

and dimension EL (endless length) seamless welded - Mount belt tensioning cylinder and

belt driving cylinder and tighten belt

- Special designs possible upon request:

e.g. picking surface, struts, etc. Calculation of endless length EL:

- For cylinder 45: EL = 2 x A + 165 mm

- For cylinder 90: EL = 2 x A + 305 mm

MINITEC PROFIL SYSTEM 297

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

LATERAL GUIDE Part N° 29.5024/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Aluminium, E6/EV1 - Adjustable lateral guide for MiniTec belt - Slide the M8 square nuts with spring

conveyors steel sheet into the groove

- Sliding profile PE

- Recommended length: axial distance A - Screw the lateral guide on the distance

Weight 0,414 kg + 40 mm bolt

- Other designs on request - Secure plastic rail with square nut and

set screw, bore requested

LATERAL GUIDE SUPPORT 70 Part N° 29.5025/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS

- PA 6 GF, grey - Adjustable lateral guides for MiniTec - Fasten support on lateral profiles

belt conveyors

- Distance bolt, stainless Steel - Set the height H and tighten the screws

- Other designs on request

- Securing against torsion AL GD - Mount the lateral guide Part N°

- We recommend: approx. 500 mm 29.5024/0

- Fixing kit distance between the supports

- Adjust lateral distance bolt

Weight 0,137 kg

298 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

LATERAL GUIDE SUPPORT 140 Part N° 29.5028/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS

- PA 6 GF, grey - Adjustable lateral guides for MiniTec - Fasten support on lateral profiles

belt conveyors

- Distance bolt, stainless steel - Set the height H and tighten the screws

- Other designs on request

- Securing against torsion AL GD - Mount the lateral guide Part N°

- We recommend: approx. 500 mm 29.5024/0

- Fixing kit distance between the supports

- Adjust lateral distance bolt

Weight 0,142 kg

BEARING ASSEMBLY FOR TRANSPORT ROLLERS Part N° 21.1056/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Housing PA with slide-bearing - Roller conveyors at any length - Attachment of the roller support on all

profiles possible

- Axle bolt, steel - Drive via round belt Ø 5 mm possible

- Mount roller support

- Roller support, PA 6 - The rollers can be replaced individually

- Press bearing assembly into the tube

- Fixing kit

- Insert axle bolt

- For transport rollers of 60 - 1000 mm

- Clip in transport roller

Weight 0,420 kg

Load max. (roller) 20 kg

MINITEC PROFIL SYSTEM 299

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

BEARING ASSEMBLY S Part N° 21.1722/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Housing steel with ball bearing - Roller conveyors at any length - Attachment of the roller support on all

profiles possible

- Securing clip, steel - The rollers can be replaced individually

- Mount roller carrier

- Roller support, PA 6

- Press bearing assembly into the tube

- Fixing kit

- Insert shaft Ø 8 and secure with

- For transport rollers of 60 - 1000 mm securing clip

Weight 0,420 kg - Clip in transport roller

Load max. (roller) 33 kg

DRIVING BELT PU Part N° 21.1050/7

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- PU, green - Drive of transport rollers via groove in - Strip driving belt over driving shaft

bearing assembly

- Ø = 5 mm - Lay driving belt in groove of transport

- Usuable with bearing-assembly only roller

- Length = 550 mm Part N° 21.1056/0

- Bind rollers at insufficient places with

driving belt NBR Part N° 21.1050/1 to

Part N° 21.1050/6; see page 301

- Clip roller in roller support

300 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

DRIVING BELT NBR Part N° 21.1050/1

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- NBR, black - Attachment of transport rollers at - Insert belt in groove of the first roller

insufficient places via groove in bearing and clip roller in the bearing

- Ø = 5 mm assembly from roller to roller

- Strip belt over second roller and clip in

- A = 80 mm roller support

For other length see selection table on

the right

SUPPORT BEARING 20 Part N° 50.0128/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Pillow block, steel, zinc-plated - Driving of roller-conveyors with driving - With fixing kit from supply schedule

belts

-Fixing kit - Lead shaft trough bearing and secure

with set screw

- Bore Ø 20 mm

Load:

dyn. C 975 N

Weight 0,190 kg

MINITEC PROFIL SYSTEM 301

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

TRANSPORT ROLLER PVC Part N° 21.1717/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Completely mounted transport roller, - Producing of roller conveyors with or - Clip in roller support

PVC-tube without drive

- As roller support we recommend door

Please indicate dimension L - Drive possible via driving belt Ø 5mm catch Part N° 21.1756/1

- The rollers can be replaced individually

TRANSPORT ROLLER AL Part N° 21.1716/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Transport roller completely assembled, - Producing of roller conveyors with or - Clip in roller support

Alu-tube without drive

- As roller support we recommend door

Please indicate dimension L - Drive possible via driving belt Ø 5mm catch Part N° 21.1756/1

- The rollers can be replaced individually

302 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

TRANSPORT ROLLER S PVC Part N° 21.1719/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Transport roller completely assembled, - Producing of roller conveyors without - Clip in roller support

PVC-tube drive

- As roller support we recommend door

- With ball bearings and shaft catch Part N° 21.1756/1

Please indicate dimension L

TRANSPORT ROLLER S AL Part N° 21.1718/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- Transport roller completely assembled, - Producing of roller conveyors without - Clip in roller support

Alu-tube drive

- As roller support we recommend door

- With ball bearings and shaft catch Part N° 21.1756/1

Please indicate dimension L

MINITEC PROFIL SYSTEM 303

TURN-KEY SOLUTIONS BELT CONVEYORS AND ROLLER CONVEYORS

TUBE AL 50 X 2 Part N° 20.1041/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- AlMgSi 0,5 F22, natural - Transport rollers at any length for - Use bearing assembly S Part N°

driven or non-driven roller conveyors 21.1722/0or bearing assembly for

- Recommended tube length: max. 1000 transport roller Part N° 21.1056/0

mm

Weight 0,820 kg/m

Length 6 m

Please indicate desired tube length

TUBE PVC 50 X 2 Part N° 20.1050/0

TECHN. DATA/ITEMS SUPPLIED APPLICATIONS ASSEMBLY

- PVC, blue - Transport rollers at any length for - Use bearing assembly S Part N°

driven or non-driven roller conveyors 21.1722/0or bearing assembly for

- Recommended tube length: max. 1000 transport roller Part N° 21.1056/0

mm

Weight 0,420 kg/m

Length 3 m

Please indicate desired tube length

304 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS LONGITUDINAL STOPS

00.0

029/

0

LONGITUDINAL STOPS

MINITEC PROFIL SYSTEM 305

TURN-KEY SOLUTIONS LONGITUDINAL STOPS

LONGITUDINAL

00.0 STOPS

106/

0

MiniTec longitudial stops are proven turn-key solutions based on MiniTec standard elements of the MiniTec

profile system. Its modular structure enables optimum solutions for any kind of application. All stops are

equipped with a height-adjustable foot including bores for floor mounting. Connection to the machine via

adaptor plate with fixing bores. Digital LCD display attached directly to the machine at operators height.

Simple dimension modifications, e.g. for saw blade thickness or distance between stop and tool can be car-

ried out via display

Standard lengths up to 6000 mm Slide guide: Input for motor drive:

(measuring length:5500 mm), other Linear guide LR with 4 precision bea- Input terminal with foil keyboard and

dimensions on request rings, clearance adjusted, shafts Ø 12 LCD-display, fixed in switch-box plate

mm , hardened special steel Cf 53, at operator height next to the machi-

Width carrying rollers: 200-600 mm Mat. no. 1.1213 ne.

Distance between carrying Slide clamping:

rollers: 200 mm Motor drive: automatically at stop

Height adjustment: ±100mm position,

manual drive: via switch (pneumatic)

Standard height: 850 mm

or via clamping lever.

Standard connection: right

Length measuring: magnetic tape Motor drive:

AC-motor with positioning control

Measuring accuracy: ±0.15 mm system, integrated in housing. Displa-

Measuring display: LCD cement speed: 0.6 m/s

306 MINITEC PROFIL SYSTEM

TURN-KEY SOLUTIONS LONGITUDINAL STOPS

LONGITUDINAL STOPS 00.0

107/

0

First cuts can easily be carried out:

The top of the stop can be swung

out of the conveyor by 180°.

Adjustable measuring length com-

pensation including scale,

L = 400 mm, fixed onto slide.

Motorized drive with stationary Manual handwheel drive with sta- Manual slide displacement with

display, integrated in the switch- tionary 230 V - display battery-driven digital display on

box slide

DATA REQUIRED LONGITUDINAL STOPS

Dimensions

Measuring length Lm mm

Roller distance A mm

Roller width B mm

Height H mm

Load dN

Control

Drive motoric handwheel manual

Stop right left

MINITEC PROFIL SYSTEM 307

You might also like

- Instruction Manual: Soil Ec Humidity Temperature Three-In-OneDocument12 pagesInstruction Manual: Soil Ec Humidity Temperature Three-In-OneMohamed IbrahimNo ratings yet

- Session 7 Linear Asset ManagementDocument17 pagesSession 7 Linear Asset ManagementSam MakNo ratings yet

- MK Conveyor TechnologyDocument308 pagesMK Conveyor TechnologyironalejanNo ratings yet

- PLC Programmers ManualDocument344 pagesPLC Programmers ManualPaun AlNo ratings yet

- 13 1 2 Part Feeding DeviceDocument41 pages13 1 2 Part Feeding Devicedavid mierNo ratings yet

- Mathcad Leaf SpringDocument3 pagesMathcad Leaf SpringsharanietNo ratings yet

- 002 Emesb-Msa-Mtn-001 Heat Exchanger ProcedureDocument6 pages002 Emesb-Msa-Mtn-001 Heat Exchanger ProcedureAin TieyNo ratings yet

- Guia Practica Inventor 11 PDFDocument181 pagesGuia Practica Inventor 11 PDFJose Manuel Merodio BarbadoNo ratings yet

- Check WeigherDocument57 pagesCheck WeigherozmenNo ratings yet

- JoyPad User Manual 2.0 PDFDocument64 pagesJoyPad User Manual 2.0 PDFnelusabieNo ratings yet

- Motor Stepper Nema 17Document1 pageMotor Stepper Nema 17LailatulNo ratings yet

- Semi-Automatic Painting Machine For Door and Flat SheetsDocument11 pagesSemi-Automatic Painting Machine For Door and Flat SheetsIJRASETPublicationsNo ratings yet

- FCS-13USN Carton Taping Machine Operation Manual: Machine Model Date IssueDocument14 pagesFCS-13USN Carton Taping Machine Operation Manual: Machine Model Date IssueTheodora StefanNo ratings yet

- Aluminum ProfileDocument21 pagesAluminum ProfileceeyesmeNo ratings yet

- Shell and Tube Heat ExchangerDocument6 pagesShell and Tube Heat ExchangernithansaNo ratings yet

- Alvey Palletizer Brochure LR PDFDocument6 pagesAlvey Palletizer Brochure LR PDFtintucinbNo ratings yet

- User Manual 1.0 PDFDocument18 pagesUser Manual 1.0 PDFnelusabieNo ratings yet

- 90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorDocument7 pages90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorImpel IntralogisticsNo ratings yet

- InventorCAM 2016 IMachining Getting StartedDocument39 pagesInventorCAM 2016 IMachining Getting Startedspeedtunning100% (1)

- Despiece 25T-6100x1600EDocument1 pageDespiece 25T-6100x1600ECalidad ServiciosHLBNo ratings yet

- Asymptote: The Vector Graphics LanguageDocument178 pagesAsymptote: The Vector Graphics Languagemartin_salazar5856No ratings yet

- Conveyor Systems Maintenance Manual XS, XL, XM, XH, XK, XBDocument43 pagesConveyor Systems Maintenance Manual XS, XL, XM, XH, XK, XBTamal Tanu RoyNo ratings yet

- 04 - Assembly Line Balancing PDFDocument19 pages04 - Assembly Line Balancing PDFMangesh JoshiNo ratings yet

- Mechanical Scissor Jack Project 4 YearsDocument65 pagesMechanical Scissor Jack Project 4 YearslatiyohannesNo ratings yet

- Leaf Spring Design and EngineeringDocument4 pagesLeaf Spring Design and EngineeringAnonymous YkDJkSqNo ratings yet

- Welcome To Kushal Foods PVT LTD KANPUR Dehat, Uttar PradeshDocument31 pagesWelcome To Kushal Foods PVT LTD KANPUR Dehat, Uttar PradeshPrateek AgarwalNo ratings yet

- Autodesk Inventor ExerciseDocument1 pageAutodesk Inventor ExerciseHAVOC 48No ratings yet

- 2010 PBT e InternetDocument20 pages2010 PBT e InternetMohammed RiyazNo ratings yet

- User Manual: Original Instructions (En)Document195 pagesUser Manual: Original Instructions (En)Bryan VazNo ratings yet

- Currie Palletizer Product Line PDFDocument4 pagesCurrie Palletizer Product Line PDFtintucinbNo ratings yet

- BRPH Manual PDFDocument160 pagesBRPH Manual PDFRoland ArimadoNo ratings yet

- Mechanical Desktop 6Document376 pagesMechanical Desktop 6Armin HodžićNo ratings yet

- CREMICA FOODS INDUSTRIES LTD PUNJAB - Offer - 65ILSW35 +65ST35Document17 pagesCREMICA FOODS INDUSTRIES LTD PUNJAB - Offer - 65ILSW35 +65ST35Mahima GuptaNo ratings yet

- WP-5050F Carton Sealer English ManualDocument24 pagesWP-5050F Carton Sealer English Manualensi116No ratings yet

- Katalog-SA CA IQDocument16 pagesKatalog-SA CA IQVictor Godoy100% (1)

- Clearpack Proposal For The 200 BPM Complete Water PET Filling Line For Clean Water and Allied Products Pvt. LTD, Rajpura, PunjabDocument19 pagesClearpack Proposal For The 200 BPM Complete Water PET Filling Line For Clean Water and Allied Products Pvt. LTD, Rajpura, PunjabMahima GuptaNo ratings yet

- 13 2 1 Non Vibratory Part FeederDocument45 pages13 2 1 Non Vibratory Part Feederdavid mierNo ratings yet

- Automatic Capping PDFDocument6 pagesAutomatic Capping PDFBazinNo ratings yet

- Shell & Tube Heat Exchanger Inspection Report ExampleDocument4 pagesShell & Tube Heat Exchanger Inspection Report ExampleHari Krishna BodepudiNo ratings yet

- MNE 3046 Part 1Document68 pagesMNE 3046 Part 1ChunMan SitNo ratings yet

- NAV BHARAT FLOUR MILLS JAMMU - Offer - 85ILSW55 +85ST55Document17 pagesNAV BHARAT FLOUR MILLS JAMMU - Offer - 85ILSW55 +85ST55Mahima GuptaNo ratings yet

- HSD PDFDocument3 pagesHSD PDFDavid AguilarNo ratings yet

- THAI FOOD NEPAL - Offer - INVOSPEED S20Document12 pagesTHAI FOOD NEPAL - Offer - INVOSPEED S20Mahima GuptaNo ratings yet

- SZ180/SZ160/SZ100S Serises: Foshan Soontrue Zhuguan Intelligent Equipment Co.,LtdDocument12 pagesSZ180/SZ160/SZ100S Serises: Foshan Soontrue Zhuguan Intelligent Equipment Co.,Ltdzarkaa yamamaNo ratings yet

- Ipinium Meat Rounders Manual Maintenance PDFDocument38 pagesIpinium Meat Rounders Manual Maintenance PDFalvaroNo ratings yet

- Parker Rotary KnifeDocument14 pagesParker Rotary KnifeNaveen NagarNo ratings yet

- Edda 1500 Kanepe PaketlemeDocument25 pagesEdda 1500 Kanepe PaketlemeEMRE KAAN USTA100% (1)

- UR5 Service Manual enDocument238 pagesUR5 Service Manual enjesus trujilloNo ratings yet

- Aesus Manual AESFill AF1C Generic May 2014Document62 pagesAesus Manual AESFill AF1C Generic May 2014Randy ErazoNo ratings yet

- MONO Equipment Omega Pluse With Wirecut User ManualDocument92 pagesMONO Equipment Omega Pluse With Wirecut User ManualLuis HernanNo ratings yet

- The Design Development of Automated Programmable Orientation Tools For Vibratory Bowl Feeders PDFDocument166 pagesThe Design Development of Automated Programmable Orientation Tools For Vibratory Bowl Feeders PDFmayank0738No ratings yet

- Section 05 Mechanical Spare PartsDocument151 pagesSection 05 Mechanical Spare PartsAmelio RamosNo ratings yet

- Clearpack Proposal For The 200 BPM Water PET Filling Line For Bubbling River Pvt. LTD., Hapur, Uttar PradeshDocument8 pagesClearpack Proposal For The 200 BPM Water PET Filling Line For Bubbling River Pvt. LTD., Hapur, Uttar PradeshMahima GuptaNo ratings yet

- MMH1105Sorting CompaniesDocument4 pagesMMH1105Sorting CompaniessachinNo ratings yet

- SerialParallelRobotManipulatorsITO12 PDFDocument468 pagesSerialParallelRobotManipulatorsITO12 PDFGuilherme HenriqueNo ratings yet

- Fabrication of Hydraulic Pipe Bending Machine PDFDocument2 pagesFabrication of Hydraulic Pipe Bending Machine PDFAndrew100% (1)

- Mct10 and LCPDocument35 pagesMct10 and LCPMIGUEL PEÑA100% (2)

- Creality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.From EverandCreality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.Rating: 3 out of 5 stars3/5 (1)

- MicroPython Cookbook: Over 110 practical recipes for programming embedded systems and microcontrollers with PythonFrom EverandMicroPython Cookbook: Over 110 practical recipes for programming embedded systems and microcontrollers with PythonNo ratings yet

- Central Electricity Authority Fuel Management Division Monthly Report of Import of Coal MAY-2020Document2 pagesCentral Electricity Authority Fuel Management Division Monthly Report of Import of Coal MAY-2020g.subhadeep6890No ratings yet

- CoalInventory 2019 PDFDocument25 pagesCoalInventory 2019 PDFg.subhadeep6890No ratings yet

- Analysis: Liberalising The Mining Sector Recent DevelopmentsDocument3 pagesAnalysis: Liberalising The Mining Sector Recent Developmentsg.subhadeep6890No ratings yet

- BEST MYT Order - Final Order - Case 26 of 2013-28 08 2013Document308 pagesBEST MYT Order - Final Order - Case 26 of 2013-28 08 2013g.subhadeep6890No ratings yet

- Selecting The Proper Conveyor Belt: Single Pulley DriveDocument18 pagesSelecting The Proper Conveyor Belt: Single Pulley Drivettr_1983No ratings yet

- Conveyor Belt Maintenance Manual 2010Document46 pagesConveyor Belt Maintenance Manual 2010paul_lesberg100% (1)

- FCIA Is FC NVMe Ready For Prime Time FinalDocument35 pagesFCIA Is FC NVMe Ready For Prime Time FinalJames ZhangNo ratings yet

- Commissioning and Maintenance P22X/En Cm/B44 Micom P220/P225Document28 pagesCommissioning and Maintenance P22X/En Cm/B44 Micom P220/P225hendranafiat.aisNo ratings yet

- Odds of Getting A My Cloud Gen 1 V - S A Gen 2 - My Cloud - Personal Cloud Storage - My Cloud - WD CommunityDocument1 pageOdds of Getting A My Cloud Gen 1 V - S A Gen 2 - My Cloud - Personal Cloud Storage - My Cloud - WD CommunitySergio GarciaNo ratings yet

- Unit-4 TocDocument14 pagesUnit-4 TocAnonymous yGN2aqyMNo ratings yet

- F-r100 Industrial Router Technical Specification v1.0.0Document3 pagesF-r100 Industrial Router Technical Specification v1.0.0Xiamen Four-Faith Industrial Router supplierNo ratings yet

- Rust Concurrency CookbookDocument212 pagesRust Concurrency CookbookvenkatnethaNo ratings yet

- Blog ExamplesDocument8 pagesBlog ExamplesMin OshNo ratings yet

- The Future of NewspapersDocument94 pagesThe Future of NewspapersChrisEUKNo ratings yet

- Thyristor: o o o o o o o oDocument4 pagesThyristor: o o o o o o o oЕри БгNo ratings yet

- Inverse Laplace Transformation Ex 11 2 Umer Asghar MethodDocument34 pagesInverse Laplace Transformation Ex 11 2 Umer Asghar MethodSikandar Khan100% (1)

- Unv CameraDocument36 pagesUnv CameraSamer OthmanNo ratings yet

- Article Careers360 20240126124229Document11 pagesArticle Careers360 20240126124229Ankur SahaNo ratings yet

- LCD4Bit ModDocument5 pagesLCD4Bit ModCleison Armando Manrique Aguirre100% (1)

- CCNA CloudDocument100 pagesCCNA CloudFooz foozNo ratings yet

- CCTV Cabling Layout PDFDocument1 pageCCTV Cabling Layout PDFPamina GorospeNo ratings yet

- Fault FindingDocument12 pagesFault FindingdamirNo ratings yet

- Midterm (STS)Document2 pagesMidterm (STS)Jeacelyn SumalinogNo ratings yet

- Raghu PPQM CVDocument4 pagesRaghu PPQM CVraaghuNo ratings yet

- 0.2. 9.0 Release NotesDocument156 pages0.2. 9.0 Release NotesMichał GabryelskiNo ratings yet

- Applying Fast-Fourier Transform in MAGMAPDocument3 pagesApplying Fast-Fourier Transform in MAGMAPPratama AbimanyuNo ratings yet

- Assessments For Grades 10 To 12Document13 pagesAssessments For Grades 10 To 12ruqayyah7867No ratings yet

- UHFReader Demo Software User's Guidev1Document17 pagesUHFReader Demo Software User's Guidev1Carlo Grant YuNo ratings yet

- Srishti BrochureDocument2 pagesSrishti Brochureಕುಮಾರ ಗುಬ್ಬಿNo ratings yet

- CHP 7Document7 pagesCHP 7Zafar FarooqNo ratings yet

- DETECTOR DIACAM ASIC Service Manual (3544298 Rev04)Document142 pagesDETECTOR DIACAM ASIC Service Manual (3544298 Rev04)Leandro Pabon VillarrealNo ratings yet

- IC 555 ProjectsDocument14 pagesIC 555 ProjectsParth Lad100% (1)

- List of Oe - UpdatedDocument57 pagesList of Oe - UpdatedseethaNo ratings yet

- Mission of Dell CompanyDocument40 pagesMission of Dell Companyxyz skillNo ratings yet

- Portal Info StubDocument2 pagesPortal Info Stubindahsalsabila938No ratings yet