RC Stair Slabs

RC Stair Slabs

Uploaded by

Assad Mohammed AliCopyright:

Available Formats

RC Stair Slabs

RC Stair Slabs

Uploaded by

Assad Mohammed AliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

RC Stair Slabs

RC Stair Slabs

Uploaded by

Assad Mohammed AliCopyright:

Available Formats

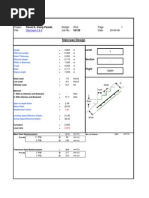

DT126/3 Third Year Civil Technician Diploma- Reinforced Concrete Design

RC Stair Slabs

Types:

There are two types of stair flights, classified on the direction of span:

1. Transverse: The steps may be supported on both sides, or may be cantilevered

from an adjacent wall, for example.

2. Longitudinal: The stair flight spans onto landings or beams at either end of the

stair flight.

Design of Transverse Stairs:

Design of these sections are based on the average effective depth of the section. These

flights may cantilever from a wall or span from a wall to a stringer beam, for example.

Design of Longitudinal Stairs:

The design of these stairs is more complicated. The additional factors to consider are:

1. Geometry:

Given the rise, going and the number of steps, the span and overall height rise can

be determined:

Span = (No. Steps – 1) × going Height = No. Steps × rise

Slope Length = √(Span2 + Height2)

SPAN

8

7

6

5

HEIGHT

GOING 4

2

RISE 1

WAIST

EFFECTIVE

1 SPAN

When the flight is built monolithically into members spanning at right angles to

its span, the effective span is given by:

la = 0.5(lb1 + lb2)

where la = clear horizontal distance between supporting members

lb1 = Breadth of supporting member at end 1 but ≤ 1.8 m

lb2 = Breadth of supporting member at end 2 but ≤ 1.8 m

Lecturer: Colin Caprani

DT126/3 Third Year Civil Technician Diploma- Reinforced Concrete Design

Otherwise the effective span should be taken as the distance between the

centrelines of support, or the clear distance between support faces plus the

effective depth, whichever is less.

If a flight is built into a wall (which is running in the same direction as the span)

by at least 110 mm, 150 mm can be taken off the loaded width of the stair flight.

The thickness of the waist is taken as the slab thickness.

2. Loading:

The dead load is based on the slope length of the stair flight. The average

thickness of the stair slab is used to calculate the dead load:

h = 0.5 × rise × going / √(rise2 + going2) + waist + finishes

Finishes are included as they are generally assumed to have a density equal to that

of concrete.

The live load is based on the plan area of the stairs and is to be taken as the same

to the floor which the stairs give access, but ≥ 3 kN/m2 and ≤ 5 kN/m2.

If two stair flights, at right angles, share a landing, the landing loads may be

assumed to be divided equally between the spans. As part of the landing may be

considered as part of the stair flight, the loading on the landing must be taken into

account in the shear check.

3. Design:

Flights with significant end restraint, such as those that are continuous with their

supporting slabs or beams may be designed for mid-span design moment of

wl2/10 and hogging moment at the supports of the same value. Where there is not

sufficient end restraint the stair slab is to be designed for wl2/8.

The maximum shear should be ascertained from a simply-supported model of the

stair slab. Shear should not be critical in a stair flight.

When the stair flight (on plan) occupies at least 60% of the effective span, the

permissible span/d ratio may be increased by 15%.

Lecturer: Colin Caprani

DT126/3 Third Year Civil Technician Diploma- Reinforced Concrete Design

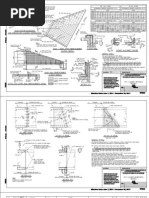

CRANKED BARS

FOR CONTINUITY

LANDING U-BAR

WITH LANDING

MAIN STEEL

4. Detailing:

The reinforcement arrangement in stair flights follows a standard pattern.

Deviation from this is not recommended unless a specific need arises.

Longitudinal steel is the main reinforcement and in the transverse direction the

minimum percentage of steel is provided as “distribution steel” to help prevent

cracking.

Strength requirements are not always critical for stair slabs. It is therefore

essential that the other limit states are checked:

a. Deflection

b. Cracking

c. Min % As

Lecturer: Colin Caprani

You might also like

- Cost Estimator's Reference ManualDocument742 pagesCost Estimator's Reference ManualAssad Mohammed Ali86% (14)

- Design of Raft FoundationDocument4 pagesDesign of Raft FoundationAmer GonzalesNo ratings yet

- Steel Design Calculation For Bridge False WorksDocument10 pagesSteel Design Calculation For Bridge False Worksnelvar2005No ratings yet

- Load Combination For Steel Design Per BS en 1990 EditionDocument6 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru DeenNo ratings yet

- Concrete Mix Design StepsDocument11 pagesConcrete Mix Design StepsMuhammad Mahamudul Hasan94% (17)

- Hazard AnalysisDocument39 pagesHazard AnalysisRaveena JainNo ratings yet

- Piles Table of Contents - Chapter 23Document46 pagesPiles Table of Contents - Chapter 23HumayunKabir100% (1)

- Masonry Wall Footing DesignDocument18 pagesMasonry Wall Footing DesignAnonymous 0JQGC2No ratings yet

- SSE Retaining - Wall - ACI Sheet v1.02Document1 pageSSE Retaining - Wall - ACI Sheet v1.02SES DESIGN100% (1)

- FENCEDocument7 pagesFENCEARUN RAWATNo ratings yet

- Design of Retaining Wall Type1 As Per ACI-318-95Document3 pagesDesign of Retaining Wall Type1 As Per ACI-318-95DIRACLTDANo ratings yet

- Beam On Elastic Foundation-Finite ElementDocument29 pagesBeam On Elastic Foundation-Finite ElementfaridhassaniNo ratings yet

- Effective Length of Stepped ColumnDocument1 pageEffective Length of Stepped ColumnSunil PulikkalNo ratings yet

- Example 2 Isolated FootingDocument34 pagesExample 2 Isolated FootingDemse ZelelewNo ratings yet

- Pad Footing ExampleDocument6 pagesPad Footing ExampleYoussef AliNo ratings yet

- Concrete Diaphragm In-Plane Shear Design Based On ACI 318-19Document1 pageConcrete Diaphragm In-Plane Shear Design Based On ACI 318-19Niky OrtegaNo ratings yet

- From Vice President: MessageDocument36 pagesFrom Vice President: MessageThaung Myint OoNo ratings yet

- 1 Selection of Retaining Walls E (Clause 3.1) S: WallDocument3 pages1 Selection of Retaining Walls E (Clause 3.1) S: Wallashwani kumar100% (1)

- Design PDFDocument260 pagesDesign PDFPrf El-SakhawyNo ratings yet

- Members With Combined Bending and Axial ForceDocument32 pagesMembers With Combined Bending and Axial ForceJohn RomanusNo ratings yet

- Chap 7 Foundation DesignDocument36 pagesChap 7 Foundation DesignZulhasri WahapNo ratings yet

- Pad Foundation DesignDocument4 pagesPad Foundation Designg4goharNo ratings yet

- Slab-On-Grade Reinforcing DesignDocument9 pagesSlab-On-Grade Reinforcing DesignAdam GreenlawNo ratings yet

- SMHB Sdn. BHD.: Jurutera PerundingDocument8 pagesSMHB Sdn. BHD.: Jurutera PerundingWangTF100% (1)

- P 1515 - Design and Contstruction of Anchored and Strutted Sheet Pile Walls Iin Soft Clay PDFDocument36 pagesP 1515 - Design and Contstruction of Anchored and Strutted Sheet Pile Walls Iin Soft Clay PDFmilepnNo ratings yet

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Document15 pagesDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- Slab DesignDocument38 pagesSlab Designmathewsujith31No ratings yet

- 2.pile - Cap.design ColumnsDocument9 pages2.pile - Cap.design Columnstaha abu el hanaNo ratings yet

- 6 Eccecntric FootingDocument21 pages6 Eccecntric FootingDeep ZaveriNo ratings yet

- Polefdn - Pole Foundation Analysis ProgramDocument10 pagesPolefdn - Pole Foundation Analysis ProgramANGEL .No ratings yet

- LECTURE2 Shear ConnectionDocument36 pagesLECTURE2 Shear ConnectionMahmoud A SalamaNo ratings yet

- 6.2.pile Length CalculationDocument26 pages6.2.pile Length CalculationCucarot Carot100% (1)

- PILES CARRYING CAPACITY ANALYSIS SoftwareDocument7 pagesPILES CARRYING CAPACITY ANALYSIS SoftwareJhon Anaya VerdeNo ratings yet

- BoxDocument8 pagesBoxJack Danielz LubisNo ratings yet

- Staircase DesignDocument1 pageStaircase DesignJennifer PearsonNo ratings yet

- Bi-Axial Bending (Design of Footing)Document21 pagesBi-Axial Bending (Design of Footing)JonasIrvinGallegoNo ratings yet

- Learn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareDocument108 pagesLearn Raft-RC Raft Foundation Analysis Design and Drawing SoftwareRahul Kumar100% (2)

- Base Plate Design As Per AiscDocument3 pagesBase Plate Design As Per AiscAamir SuhailNo ratings yet

- Flat Slab Direct Design MethodDocument20 pagesFlat Slab Direct Design Methodsidiq7No ratings yet

- Design of Biaxial ColumnDocument5 pagesDesign of Biaxial ColumndineshNo ratings yet

- Pole FDNDocument24 pagesPole FDNyoussefNo ratings yet

- Composite Steel DesignDocument33 pagesComposite Steel DesignALABIADESINA100% (1)

- POLEFDNDocument10 pagesPOLEFDNcoolkaisyNo ratings yet

- WallDocument44 pagesWallUmesh ChamaraNo ratings yet

- One Way Continuous SlabDocument5 pagesOne Way Continuous SlabBia MughalNo ratings yet

- As Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjaDocument32 pagesAs Per RCC Design (B.C. Punmia) Page 184 Example 7.6 Design of Cantilever ChajjajaffnaNo ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- PCA TIME SAVING DESIGN AIDS - ColumnsDocument9 pagesPCA TIME SAVING DESIGN AIDS - ColumnsvNo ratings yet

- Seismic Load Calc: Equivalent Lateral Force Analysis: InputDocument5 pagesSeismic Load Calc: Equivalent Lateral Force Analysis: InputMohammed Saleem Syed KhaderNo ratings yet

- Compined FootingDocument12 pagesCompined FootingNguyen Duc Hoa100% (1)

- Timber Roof Beam 1Document4 pagesTimber Roof Beam 1John Smith100% (1)

- Combined Footing Design PDFDocument2 pagesCombined Footing Design PDFRenee100% (1)

- 7 Mat Foundation - FullDocument34 pages7 Mat Foundation - FullRJ JordanNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Design of A Multistorey BuildingDocument30 pagesDesign of A Multistorey BuildingArpan SidhuNo ratings yet

- MyNotes CombinedFooting Rev1Document7 pagesMyNotes CombinedFooting Rev1engrnoreendelacruzNo ratings yet

- CIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaDocument22 pagesCIV5304: Design of Structural Elements III: Engr DR Nuruddeen Muhammad MusaNuruddeen Muhammad100% (1)

- Analysis & Design of Structure - Ii Sessional Course No:-3106 Credit:-1.50Document39 pagesAnalysis & Design of Structure - Ii Sessional Course No:-3106 Credit:-1.50Jahorul IslamNo ratings yet

- Chapter 4 TrussesDocument68 pagesChapter 4 TrussesaisyahNo ratings yet

- Unit8 PDFDocument14 pagesUnit8 PDFVictor OmotoriogunNo ratings yet

- Effective Span Length: 139 Concrete Deck SlabsDocument5 pagesEffective Span Length: 139 Concrete Deck SlabsJohn Royer Araúz Fuentes100% (1)

- How To Calculate Lap Length in Column Beam and Slab - Lapping ZoneDocument10 pagesHow To Calculate Lap Length in Column Beam and Slab - Lapping ZoneQamar JamilNo ratings yet

- Concrete Formwork DesignDocument17 pagesConcrete Formwork DesignRsjBugtongNo ratings yet

- 6 Differential LevelDocument27 pages6 Differential LevelAssad Mohammed AliNo ratings yet

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- Text Book List 2006 - 2007: University of Bristol Department of Civil EngineeringDocument9 pagesText Book List 2006 - 2007: University of Bristol Department of Civil EngineeringAssad Mohammed AliNo ratings yet

- Flat Slab DesignDocument2 pagesFlat Slab DesignKim ChanthanNo ratings yet

- Kayyali, Abdelhamid ResumeDocument3 pagesKayyali, Abdelhamid ResumeAbdülhamit KayyaliNo ratings yet

- PG Diploma in Piping Design and Autocad Training CourseDocument4 pagesPG Diploma in Piping Design and Autocad Training CourseWin Linn100% (1)

- Mech Placement Details PDFDocument22 pagesMech Placement Details PDFJayanth KumarNo ratings yet

- Manpower Resource Mobilization-Demobilization ScheduleDocument84 pagesManpower Resource Mobilization-Demobilization ScheduleJavierNo ratings yet

- Design Intelligence Rankings 2015Document168 pagesDesign Intelligence Rankings 2015mscygnusNo ratings yet

- The Role of Statistics in EngineeringDocument42 pagesThe Role of Statistics in EngineeringMohammed Abushammala50% (2)

- Asheesh ResumeDocument3 pagesAsheesh ResumeChandan Swami100% (1)

- Basf Masterrheobuild 1000 TdsDocument3 pagesBasf Masterrheobuild 1000 TdsDevendraNo ratings yet

- CVDocument3 pagesCVsenthil rajaNo ratings yet

- Adobe Scan 04 Dec 2023Document1 pageAdobe Scan 04 Dec 20232OO11AO231 Srinija PodishettyNo ratings yet

- Box CulvertDocument8 pagesBox CulvertPradeep S Gowda100% (3)

- Engineering EconomicsDocument28 pagesEngineering EconomicsTeeni AbeysekaraNo ratings yet

- B.E. (With Credits) - Regular - CBCS (Electronics and Telecommunication Engineering) - F.E. C-Scheme - Sem I (1T01831) Examination: December 2020Document2 pagesB.E. (With Credits) - Regular - CBCS (Electronics and Telecommunication Engineering) - F.E. C-Scheme - Sem I (1T01831) Examination: December 2020Arman SinghNo ratings yet

- Industrial AutomationDocument33 pagesIndustrial Automationbhuvanesh85No ratings yet

- Concrete and Masonry SafetyDocument57 pagesConcrete and Masonry SafetyZabNo ratings yet

- Bhushan Patil - CVDocument2 pagesBhushan Patil - CVSuyog PatilNo ratings yet

- Beam DesignDocument6 pagesBeam DesignRenz PagcaliwaganNo ratings yet

- Quality Engineer Production Control Manager in Houston TX Resume Cynthia SheplerDocument3 pagesQuality Engineer Production Control Manager in Houston TX Resume Cynthia SheplerCynthiaSheplerNo ratings yet

- Strength of Concrete PDFDocument19 pagesStrength of Concrete PDFwdewdwNo ratings yet

- Questionnaires With Answers On The Automotive Engine Fundamentals: Bangladesh PerspectiveDocument29 pagesQuestionnaires With Answers On The Automotive Engine Fundamentals: Bangladesh PerspectiveAlireza HassaniNo ratings yet

- Ee0301 Electrical and Electronics Measurements PDFDocument8 pagesEe0301 Electrical and Electronics Measurements PDFakash mishraNo ratings yet

- IS2018 Architecture Design of NPP Systems Through Viewpoints Analysis v1.8Document16 pagesIS2018 Architecture Design of NPP Systems Through Viewpoints Analysis v1.8islam1825022No ratings yet

- Invitation LetterDocument2 pagesInvitation LetterPushpa Mohan RajNo ratings yet

- Finite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Document6 pagesFinite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Aswaja313No ratings yet

- Master Thesis Examples Computer ScienceDocument4 pagesMaster Thesis Examples Computer Sciencecynthiawilsonarlington100% (2)

- Horizons-Rapidwall Brochure 2018Document16 pagesHorizons-Rapidwall Brochure 2018ridminjNo ratings yet

- 1 s2.0 S0950061822028689 MainDocument16 pages1 s2.0 S0950061822028689 Main陈湘恒No ratings yet

- Civil EngineeringDocument2 pagesCivil EngineeringMohammed QaddourahNo ratings yet

- Civil Soil CementDocument18 pagesCivil Soil CementAnonymous rwyhPFvNo ratings yet