Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Uploaded by

Snigdha SarkarCopyright:

Available Formats

Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Uploaded by

Snigdha SarkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Unit - 2 BITUMEN AND TAR: Origin, Preparation, Properties and Chemical Constitution of Bituminous Road

Uploaded by

Snigdha SarkarCopyright:

Available Formats

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

UNIT - 2

BITUMEN AND TAR: Origin, preparation, properties and chemical constitution of bituminous road

binders; requirements. [4 Hours]

****************************************************************************

Introduction

Bituminous binders used in pavement construction works include both bitumen and tar. Both

bitumen and tar have similar appearance, black in colour though they have different characteristics.

Origin

Naturally occurring deposits of bitumen are formed from the remains of ancient, microscopic algae and

other once-living things. When these organisms died, their remains were deposited in the mud on the

bottom of the ocean or lake where they lived. Under the heat and pressure of burial deep in the earth,

the remains were transformed into materials such as bitumen, kerogen, or petroleum. Deposits at the La

Brea Tar Pitsare an example. There are structural similarities between bitumens and the organic matter

in carbonaceous meteorites. However, detailed studies have shown these materials to be distinct.

Asphalt or bitumen can sometimes be confused with "tar", which is a similar black, thermoplastic

material produced by the destructive distillation of coal. During the early and mid20th century when

town gas was produced, tar was a readily available product and extensively used as the binder for road

aggregates. The addition of tar to macadam roads led to the word tarmac, which is now used in

common parlance to refer to road-making materials. However, since the 1970s, when natural gas

succeeded town gas, asphalt (bitumen) has completely overtaken the use of tar in these applications.

BITUMEN is a petroleum product obtained by the distillation of petroleum crude.

TAR is a thermoplastic material obtained from the destructive distillation.

The grade of bitumen used for pavement construction work of roads and airfields are called paving

grades and used for water proofing of structures and industrial floors etc. are called industrial grades.

The paving bitumen available in India is classified into two categories

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 1

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

1) Paving bitumen from Assam petroleum denoted as A-type and designated as grades A35, A

90.etc.

2) Paving bitumen from other sources denoted as S-type and designated as grades S35, S90 etc.

The viscosity of bitumen is reduced some times by a volatile diluents this material is called Cutback.

The bitumen is suspended in a finely divided condition in an aqueous medium and stabilized with an

emulsifier; the material is known as Emulsion.

Difference between Bitumen and Tar

Sl. No. Bitumen Tar

Bitumen is found in black to brown in

1 Tar is usually found in brown colour

colour

Bitumen is obtained from fractional Tar is obtained by destructive distillation

2

distillation of crude oil of coal or wood

Bitumen is soluble in carbon disulphide

3 Tar is soluble in toluene

and carbon tetra chloride

Molecular weight range for road Molecular weight range for road tar is 150

4

bitumen is 400 to 5000 to 3000

Bitumen consists of large amount of Tar consist of large amount of oily matter

5

aromatic hydrocarbon with lower molecular weight

Bitumen show resistance to coating

Tar coats more easily and retain it better in

6 road aggregate and also does not retain

presence of water

in presence of water

7 Free carbon content is less Free carbon content is more

It shows more resistance to weathering It shows less resistance to weathering

8

action action

9 Less temperature susceptibility More temperature susceptibility

Bitumen

The source of road bitumen is either formed from petroleum or by natural processes as a result

of geological forces.

Different forms of bitumen

Cutback bitumen

Normal practice is to heat Bitumen to reduce its viscosity. In some situations preference is given to

use liquid binders such as cutback bitumen. In cutback bitumen Suitable solvent is used to lower the

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 2

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

viscosity of the bitumen. From the environmental point of view also cutback bitumen is preferred.

The solvent from the bituminous material will evaporate and the bitumen will bind the aggregate.

Cutback bitumen is used for cold weather Bituminous road construction and Maintenance. The

distillates used For preparation of cutback bitumen are naphtha, kerosene, diesel, oil and furnace oil.

There are different types of cutback bitumen Like rapid curing(RC),medium curing(MC), And slow

curing(SC).RC is recommended for Surface dressing and patchwork. MC is recommended For

premix With less quantity of fine aggregates.SC is used For premix with appreciable quantity of

fine aggregates.

Bitumen Emulsion

Bitumen emulsion is a liquid product in which bitumen is suspended in a finely divided condition in

an aqueous medium and stabilized by suitable material. Normally cationic type emulsions are used

in India. The bitumen content in the emulsion is around 60% and the remaining is water. When the

emulsion is applied on the road it breaks down resulting in release of water and the mix starts to set.

The time of setting depends upon the grade of bitumen. The viscosity of bituminous emulsions can

be measured as per IS:8887-1995.Threetypes of bituminous emulsions are available, which are

Rapid setting(RS),Medium setting (MS),And Slow setting (SC).Bitumen Emulsions are ideal

binders for hill road construction. Where Heating of bitumen or aggregates are difficult. Rapid

Setting emulsions are used for surface dressing work. Medium Setting emulsions are preferred for

premix jobs and patch repairs work. Slow setting Emulsions are preferred in rainy season.

Bituminous primers

In bituminous primer the distillate is absorbed by the road surface on which it is spread. The

absorption there for depends on the porosity of the surface. Bitumen primers are use full on the

stabilized surfaces and water bound macadam base courses. Bituminous primers are generally

prepared on road sites by mixing penetration bitumen with petroleum distillate.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 3

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

Modified Bitumen

Certain additives or blend of additives called as bitumen modifiers can improve properties of

Bitumen and bituminous mixes. Bitumen treated with these modifiers is known as modified

bitumen. Polymer modified bitumen(PMB)/crumb rubber modified Bitumen (CRMB) should be

used only in wearing course depending upon the requirements of extreme climatic variations. The

detailed specifications for modified bitumen have been issued by IRC: SP: 53-1999. It must be noted

that the performance of PMB and CRMB is dependent on strict Control on Temperature during

construction.

The advantages of using modified bitumen are as follows:

1. Lower susceptibility to daily and seasonal temperature variations

2. Higher resistance to deformation at high pavement temperature

3. Better age resistance properties

4. Higher fatigue life for mixes

5. Better adhesion between aggregates and binder

6. Prevention of cracking and reflective cracking.

Types

1) Rock Asphalt

a) It consists of limestone, sand stone naturally impregnated with bitumen.

b) The mineral matter will be about 90% and bitumen content of 10%.

2) Lake Asphalt

a) Mineral matter will be finely divided and dispersed through the bitumen

b) The whole mass is capable of flow

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 4

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

c) Type of lake asphalt used in road making in United Kingdom is Trinidad lake asphalt.

d) It is used in flexible road construction and also in rolled asphalt wearing courses.

Preparation of Road Bitumen from Petroleum

The refining of petroleum is most complex procedure producing a tremendous range of products

from the simplest hydrocarbon gas methane to the hardest bitumen with constituents of

molecular weight of the order of several thousands.

The preparation of different forms of bitumen for road purposes from petroleum is illustrated in

the above figure.

PREPARATION OF ROAD BITUMEN

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 5

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

a) Distillation of Petroleum

Bitumen is produced from selected crude oils by a process of concentration by distillation.

The distillate is obtained in the desired boiling point ranges by condensation in a fractionating

column.

It is first to heat the crude oil to a temperature lower than 350°C under atmospheric pressure

to drive off light fractions such as gasoline, kerosene and gas oil.

Further heating above 400°C is necessary to drive off heavier oils.

Refining of the topped crude is carried out by use of reduced pressures and steam injection in

the fractionating column.

The incoming crude is pumped through a continuous pipe-still similar to that used in tar-

distillation plants, where it is raised to desired temperature (between 200 and 400° C)

It is then injected into a fractionating column where at the reduced pressure volatile

components flash into vapours.

The vapours are condensed into fractions of decreasing boiling point by condensation at

points at higher levels in the fractionating column.

A flow diagram representing the distillation of topped oil in a modern refinery is given in

figure below:

BITUMEN PRODUCTION

b) Air-Rectification of Refinery Bitumen

Bitumen produced by straight steam-refining from crude oils may be deficient in the

components of high molecular weight which are insoluble in heptanes, asphaltenes fractions.

It is common practice to increase the asphaltene content by oxidation of the hot straight-run

bitumen by a current of air blown through it.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 6

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

These are bitumen of high softening point produced by an oxidation by air-blowing at high

temperatures.

The oxidation is more extensive and the blown bitumens have rubbery qualities required for

certain industrial purposes and not used as binders for road aggregates.

Chemical Constitution of Bitumen

Bitumen although formed from distillation process causes some changes which is closely

related in chemical nature to its primary source i.e., the crude petroleum oil.

Bitumen is completely soluble in carbon-di-sulphide but most of them divide the bitumen

soluble in carbon-di-sulphide into 3 fractions:

a) Carbenes: fraction insoluble in carbon tetrachloride.

b) Asphaltenes: fraction insoluble in light aliphatic hydrocarbon solvent such as petroleum

ether.

c) Maltenes: fraction soluble in light aliphatic hydrocarbon solvent

The molecular weight of asphaltene fraction is estimated between 1800 and 1,40,000 and

maltenes have molecular weight between 370 and 710.

The hydrocarbons in petroleum are of four basic forms:

a) Saturated aliphatic groups or paraffins

b) Naphthenic groups or cycloparaffins

c) Aromatic ring compounds

d) Aliphatic groups with olefin double bonds

Aliphatic group normally does not present in road bitumen. The approximate proportions of

the other three groups in the molten groups can be obtained from modified Waterman

analysis.

Many properties of bitumen, particularly the non-Newtonian flow properties suggest that

bitumen is a colloidal system. The colloidal nature of bitumen is due to the presence of

asphaltenes in association with high molecular weight material from the maltenes fraction,

form a disperse phase. This complex is normally referred as ‘micellar phase’.

On the basis of flow properties, bitumen can be divided into two types, ‘sol’ type, in which

there is little interaction between micelles or a ‘gel’ type in which interaction of micelles are

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 7

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

great enough to cause a loose structure formation. Most of the distilled road bitumens are sol

type, blowing leads to gel type structures.

Requirements of Bitumen

The desirable properties of bitumen depend on the mix type and construction.

a) Mixing: type of materials used, construction method, temperature during mixing, etc.

b) Attainment of desired stability of the mix

c) To maintain the stability under adverse weather conditions

d) To maintain sufficient flexibility and thus avoid cracking of bituminous surface and

e) To have sufficient adhesion with the aggregates in the mix in presence of water

Desirable Properties of Bitumen

1) Viscosity

The viscosity of the bitumen at the time of mixing and compaction should be adequate. This

is achieved by heating the bitumen and aggregate prior to mixing or by use of cutbacks or

emulsions of suitable grade.

2) Temperature Susceptibility

The bituminous material should not be highly temperature susceptible. During the hottest

weather of the region the bituminous mix should not become too soft or unstable. During cold

weather the mix should not become too hard and brittle, causing cracking. The material

should be durable.

3) Adhesion Property

In presence of water the bitumen should not strip off from the aggregate. There has to be

adequate affinity and adhesion between the bitumen and aggregate used in the mix.

Tests on bitumen

There are a number of tests to assess the properties of bituminous materials. The following

tests are usually conducted to evaluate different properties of bituminous materials.

1. Penetration test

2. Softening point test

3. Ductility test

4. Viscosity test

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 8

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

5. Specific gravity test

6. Heat stability test

a. Flash point test

b. Fire point test

c. Loss on heating test

7. Solubility test

8. Thin film oven test

9. Float test

10. Water content test

1. Penetration test:

An indirect method of measuring viscosity is the measure of penetration of a standard needle

under standard conditions of load, time & temperature. The test measures the hardness or

softness of bitumen in terms of penetration expressed in mm/10th of std needle.

Temperature= 250C [test to be performed after sample is kept for 1hr in H2O bath at this

temperature]

Load on needle = 100 g

Time in which penetration is recorded = 5 s

The penetration is measured by a graduated dial.

Bitumen is softens to a poring consistency a depth more than 15mm in the container is

poured. The expected penetration sample is cooled in 60 min in air and 60 min in water

before testing. The standard needle is positioned to get a penetration value for 5sec and is

noted.

The penetration value obtained is represented in 80-100 or 80/100 grade bitumen at standard

consistence and it range from 20-225mm.

In cold region bitumen with High penetration value is used.

In warm region low penetration value is used ex. 30/40 grade.

The factors which affect the Penetration test is test temperature, needle size and weight and

period of cooling.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 9

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

1. Softening point:

The softening point is the temperature at which the substance attains a particular degree of

softening under specified condition of test. A viscosity material like bitumen or tar doesn’t

have a well defined softening point. However a std test determines the temperature at which a

std ball will pass through a disc of bitumen contained in ring. The test is known as ring & ball

test.

A brass ring of internal dia 17.5 mm at top and 15.9 mm at bottom and of depth 6.4mm.The

steel ball of 9.5mm dia and 2.5g. Support distance is 25mm between the bottom of the ring

and top surface of the bottom plate of support is provided. Glass container of 85mm dia and

120mm depth is used. The bitumen is heated to poring consistency and poured into ring and

cooled for half an hour before testing. A brass ring containing the bitumen sample is

suspended in H2O or glycerin at given temperature a steel ball is placed on the disc of

bitumen. The liquid medium is then heated at a rate of 50C increase per minute. Metal plate

placed at a specified bituminous material touches the bottom at the softening point. With

increase in temperature bitumen melts and come down with the weight of ball at particular

temperature it touches the bottom plate that point temperature is noted.

The softening point is range between 35 to 750C.

The liquid water is used for bitumen having softening point less than 800C and Glycerine is

for softening point more than 800C.

Higher softening point indicates lower temp. susceptibility and in warm climet.

The factors which affect the softening points are quality and type of liquid used, weight of

ball, distance between bottom of the ring and bottom base plate and rate of temperature.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 10

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

2. Ductility test:

In flexible pavement construction it is important that the binders form ductile thin film

around the aggregate. This serves as a satisfactory binder in improving the physical

interlocking of the aggregate bitumen mixes. Under traffic loads the bitumen layer is

subjected to repeated deformation and recoveries. The binder material which does not possess

sufficient ductility would crack and thus provide pervious pavement surface. The test is

believed to measure the adhesive property of bitumen and its ability to stretch. The ductility

of a binder is an indication of its elasticity & ability to deform under load & return to original

condition upon removal of the load. A material which doesn’t possess adequate ductility

would crack under a load.

This is unsatisfactory since water can penetrate into the surfacing through there cracks. The

property is determined by measuring the distance that a std briquette of bitumen, necked to a

cross section of 1 sq-cm will stretch without breaking when elongated at a rate of 5 cm/min at

270C. The ductility values should be a minimum of 50 as per IS.

The briquette mould is filled with bitumen and cool for 30 min in air and 30 min in water

before testing. Then it is fixed to expanding machine assembly which stretches the bitumen at

a rate of 5cm/min and expands till to break and the point is noted by scale.

The factors which affect the ductility is pouring and test temperature, dimension of briquette

mould, rate of pulling and period of cooling.

3. Viscosity Test:

Viscosity is the property of a fluid that determines the resistance offered by the fluid to a

shearing force under laminar flow conditions, it is thus the opposite of fluidity.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 11

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

The determination of viscosity is generally done by efflux viscometers. They work on

common principles, though they differ in detail. The liquid under test is poured to a specified

level into a container surround by water or oil bath providing temperature control at the base

of the container is a small orifice with a simple valve control on opening valve, the time in

seconds is recorded for a stated quantity of liquid to discharge into a measuring liquid below.

The different type of viscosity testing operator is there they are Efflux viscometer, Standard

tar viscometer (10mm dia orifice and 50ml fluid to discharge), Saybolt furol viscometer

(3mm dia orifice and 60ml fluid to discharge).

The bitumen is placed in to a standard tar viscometer or efflux viscometer and its temperature

is raised to test temperature specified (35, 40, 45, 55& 600C). When the temperature reaches

respective test temperature orifice valve is open time elapse is noted to collect the bitumen of

50ml. The time required to collect a bottom container of 50ml is five indirectly the viscosity

of bitumen. Then is specified in VG 10, VG20, VG 30 and VG 40.

4. Specific gravity test:

In most applications bitumen is weighed, but finally in use with aggregate the bitumen

content is converted on volume basis. Hence determine of specific gravity value is required

for conversion of weight to volume. Specific gravity of a binder doesn’t influence its

behavior but all the same, its value is needed for mix design.

Specific gravity of bitumen varies from 0.97 to 1.02.

Specific gravity of tar varies from 1.16 to 1.28.

There are two methods to test the specific gravity of bitumen

a. Pycnometer method

b. Balance method

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 12

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

Generally balance method is used in that a cup of 50ml capacity is used and it is oiled before

using. The bitumen is poured in to cup and cooled and its weight e is noted and weight of cup

with bitumen when immersed in distilled water is weighed f. Specific gravity of bitumen is

the ratio of e to the difference between (e and f).

It is used to convert the weight in to volume. Determines Purity of bitumen if the impurity

present in the bitumen by showing high value of specific gravity.

5. Heat stability test:

When a bituminous binder is heated continuously it starts emitting volatile vapors above a

certain temperature and these volatile vapors can momentarily catch fire in form of flash and

continued heating get fired.

a. Flash point:

The flash point of bitumen is that temperature at which it gives off vapors, which ignites in

the pressure of a flame, but don’t continue to burn. The flame point is an induction of critical

temperature at & above which suitable precautions should be taken to eliminate fire hazards.

The ISI test describes the Penske-Martin method. The method involves a cup into which the

bitumen is filled. The bitumen sample is then heated at a rate of 5-60C/min stirring the

material continuously.

The test flame is applied at intervals. The flash point is taken at the temperature read on the

thermometer when flame causes a bright flash in the interior of cup in a closed system & at

the surface of material in open system. It is 2200c.

b. Fire point test:

If heating is continued beyond the flash point, the vapors ignite in the pressure of a flame &

continue to burn indicating the fire point temperature. There is no standard method to

determine the spontaneous ignition temperature, which can only broadly indicate.

c. Loss on heating test:

The effect of heat on a bituminous binder is the loss of volatile constituents. This loss causes

the binder to harden. Thus one method of testing the desirable property of a binder is to find

out the loss on heating. This is achieved by an accelerated heating test a 50gm sample is

weight is taken and maintained at a temperature of 1600c for 5hours. Then it expressed as

a percentage of loss in original weight is determined.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 13

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

6. Solubility test:

It has already been indicated that all bitumen are substantially soluble in CS 2. This is one of

the points that define bitumen. Hence any impurity in bitumen in the form of inert minerals,

carbon, salts etc. could be quantitatively analyzed by dissolving the samples of bitumen in

any of the two solvents.

A sample of 2g of bitumen is dissolved in 100ml of solvent and filtered in soluble material is

washed, dried and weighed then it is expressed in percent of original sample. The Indian

specifications require 99% solubility.

7. Thin film oven test:

In this test, a sample of bitumen is subjected to hardening conditions as would be expected

during hot mixing operations. A 50ml sample of bitumen is placed in a flat bottomed sample

pan 140mm inside diameter & 10mm deep, the weighed sample & container are placed in a

shelf which rotates at 5 to 6 rpm for 5 hrs in a ventilated oven maintained at 1630C. The loss

in weight of the sample is expressed as % of the original weight. This method is then used for

identify short term aging or hardening of bitumen.

Tar

Tar is the viscous liquid obtained when natural organic materials such as wood and coal

carbonized or destructively distilled in the absence of air. Based on the materials from which

tar is derived, it is referred to as wood tar or coal tar. It is more widely used for road work

because it is superior.

There are five grades of roads tar: RT-1, RT-2, RT-3, RT-4 and RT-5, based on their viscosity

and other properties.

RT-1 has the lowest viscosity and is used for surface painting under exceptionally cold weather

as this has very low viscosity.

RT-2 is recommended for standard surface painting under normal Indian climatic conditions.

RT-3 may be used for surface painting, renewal coats and premixing chips for top course and

light carpets.

RT-4 is generally used for premixing tar macadam in base course.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 14

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

RT-5 is adopted for grouting purposes, which has highest viscosity among the road tars.

The various tests carried out on road tars are:

a) Specific gravity test

b) Viscosity test on standard tar viscometer

c) Equiviscous temperature (EVT)

d) Softening point

e) Softening point of residue

f) Float test

g) Water content

h) Phenols, percent by volume

i) Naphthalene, percent by weight

j) Matter insoluble in toluene, percent by

weight

k) Distillation fraction on distillation upto

200°C, 200°C to 270°C and 270°C to

330°C

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 15

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

The properties and requirements for five grades of road tars based on the above test results are

given by the ISI are given in below table.

Road Tar Grades

Sl. No. Property RT-2 RT-3 RT-4 RT-5

RT-1

Viscosity by standard tar

viscometer (10 mm)

1

(a) at temperature, °C 35 40 45 55 -

(b) viscosity range, seconds 33-55 30-55 35-60 40-60 -

Equiviscous temperature

2 32-36 37-41 43-46 53-57 63-67

(EVT) range, °C

3 Softening point, °C - - - - 45-50

Specific gravity range at

4 1.16-1.26 1.16-1.26 1.18-1.28 1.18-1.28 1.18-1.28

27°C

Softening point of residue,

5 48 50 52 54 56

°C Max.

Water content, percent by

6 0.5 0.5 0.5 0.5 0.5

weight, Max.

Phenols, percent by volume,

7 2 2 2 2 1

Max.

Naphthalene, percent by

8 4 3.5 3 2.5 2

weight, Max.

Matter insoluble in toluene,

9 22 22 24 24 24

percent by weight, Max.

Distillation fractions, percent

by weight (g per 100 g)

distilling:

(a) upto 200°C, Max. 0.5 0.5 0.5 0.5 0.5

10

(b) from 200° to 270°C 5-12 2-9 1-6 0.5-4 0-4

(c) from 270° to 300°C 4-10 4-8 3-6 2-7 1-5

Total distillation (b+c), Max. 16 14 12 10 7

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 16

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

Preparation of Tar

There are three stages in the production of road tar:

1) Carbonization of coal to produce crude tar

2) Refining or distillation of crude tar

3) Blending of distillation residue with distillate oil fractions to give the desired road tar.

a) High-Temperature Carbonization of Coal

The carbonization or destructive distillation of coal consists essentially of heating a thin

layer of coal enclosed in a chamber of refractory brick-work for several hours at temperature

about 1000° C. Majority there are two major methods for carbonization, they are:

a) Carbonization in Coke-ovens

b) Carbonization in gas-works retorts

Carbonization in Coke-Ovens

A batch of about 16 tons of coal is loaded into a coke-oven.

Coke oven consists of large thin box lined with brick, 40 feet long, 14 feet high and 1 ½ feet

wide.

The charge of coal is heated for 18 hours at a temperature of 1200° C.

Each ton of coal yields 8 gallons of crude tar.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 17

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

b) Distillation of Crude Tar

The crude tar obtained by the condensation of the vapours emitted from coal in the course of

carbonization is subjected to distillation process.

The distillation or refining of tar is carried out by tar distillers.

The process consists, first heating the crude tar to remove water and some light oils (Benzole),

then heating further and condensing the heavier vapour in a fractionating column.

The operation is carried out in two stages:

In the first stage, the tar passes through the tubes in the cooler part of the furnace at a

temperature of 140°C.

It is then passed to a dehydration chamber where the pressure is released and water and light oil

is released.

The remaining tar is then passed to the second stage of the pipe-still at a temperature of 300°C.

From pipe-still, tar passes to a chamber at a lower pressure where vaporization takes place.

The vapours are condensed in a fractionating column which forms fractions of different boiling

point ranges.

The residue which is not distilled is base-tar or pitch.

In order of increasing boiling points they may be classified as light oil, carbolic oil, naphthalene

oil, wash oil, anthracene oil.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 18

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

c) Blending of Tar-Distillation Fractions to Produce Road Tar

It is evident from the above that a tar of a suitable viscosity for use on the roads could be left as

residue simply by stopping the distillation at the appropriate point.

Road tar 1 and 2, on the basis of viscosity, having viscosities of 10 to 40 and 40 to 125 seconds

at Standard Tar Viscosity (STV) at 30°C.

Type-A having high softening point is used for surface dressings and base courses. Type-B is

used for wearing courses and carpets.

PREPARATION OF ROAD TAR

Type A = Base tar + Naphthalene oil

Type B = Base tar + Wash oil + Anthracene oil

Chemical Constitution of Tar

It is estimated that there are over 10,000 compounds in tar. Out of this 300 have been

separated. The distillate oils consist largely of aromatic hydrocarbons, with one or more methyl

groups attached to the nucleus, with smaller quantities of aromatic hydroxy compounds,

paraffinic hydrocarbons and heterocyclic compounds with oxygen, nitrogen or sulphur in the

ring.

Dickinson developed a method called ‘solvent fractionation’ which uses n-hexane,

benzene and pyridine as solvents to give five fractions. He divided up in this way tars produced

from vertical-retort, horizontal-retort and coke-oven crudes and by measurement of mean

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 19

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

molecular weights. Typical structures for the solvent fractions haven been suggested by

spectroscopic examination on the basis of molecular weight and C/H ratio.

The differences in chemical structure between tars from different carbonization processes are

reflected in different in their properties. Tars produced by carbonization in coke-ovens or

horizontal retorts have more purely aromatic hydrocarbons compared to vertical retorts. Thus,

where as in coke-oven tar distillate oils over 90 percent may consist of aromatic hydrocardon of

benzene, naphthalene, anthracene and phenanthrene series, similar oils from vertical retort tars

contain up to 25% of phenolic material and the same amount of paraffins, this is because

temperature reached in coke-ovens and horizontal retorts will be higher than continuous vertical

retorts and the vapours evolved during carbonization are in contact with hot coke for a longer

period.

Vertical-retort tars are often referred as low-aromatic tars while coke-oven and horizontal-retort

tars as high-aromatic tars. In general, the high-aromatic class is distinguished by wider

molecular weight range, higher specific gravity, higher pitch content and low phenolic content.

1. What are the differences between bitumen and tar? How is asphalt produced?

2. What are the tests conducted on bitumen? Mention the importance of each.

3. Enumerate the properties of Bitumen and Tar

4. Write a note on Bitumen and Tar. Explain the chemical constituents of bituminous road

binders.

5. Explain the physical requirements of aggregates and bitumen.

6. What are the tests conducted on bitumen? Mention the importance of each.

7. Briefly explain the preparation of bitumen with neat figure.

8. Describe penetration test to be carried out on bitumen with standard values recommended for

construction.

9. Mention the various tests conducted on Bitumen. Explain any three tests with neat sketches.

10.Differentiate between Bitumen and Tar. How is asphalt produces?

11.What are the important requirements of test to be carried out on bitumen for road work

?explain important aspects or IS standard of each.

12.Explain briefly the procedure adopted in the laboratory along with neat sketch and limitations

to be considered as per IS/IRC standards for bitumen.

13.Explain in brief the preparation of bitumen with a flow chart.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 20

PAVEMENT MATERIALS AND CONSTRUCTION 10CV763

14.Explain the desirable properties of bitumen.

15.Describe the softening point test and thin film oven test and their significance.

Vinod.B.R, Asst.Professor Department of Civil Engg,BMSIT&M, Bangalore Page 21

You might also like

- Pavement Deterioration and Its CausesDocument7 pagesPavement Deterioration and Its Causesخيرالله موسى نوافNo ratings yet

- Construction of Roads Part1Document18 pagesConstruction of Roads Part1anonymousNo ratings yet

- 3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementDocument56 pages3.1 DCC30103 - Chapter 3.1 Construction of Flexible PavementFATIN NABILA100% (1)

- Highway MaintenanceDocument13 pagesHighway MaintenancePia CajayonNo ratings yet

- Tunneling in Soft StrataDocument8 pagesTunneling in Soft StrataPooja RautNo ratings yet

- CE2255 UwDocument116 pagesCE2255 UwPremKumarNo ratings yet

- CE3026 Traffic Engineering and Management Lecture Notes 1Document95 pagesCE3026 Traffic Engineering and Management Lecture Notes 1NAAC CivilNo ratings yet

- Tag On Car MethodDocument5 pagesTag On Car Methodnarendra khatiwadaNo ratings yet

- HIGHWAY ENGINEERING (2marks) PDFDocument10 pagesHIGHWAY ENGINEERING (2marks) PDFGanesh Padmanaban100% (2)

- Special Concretes and Concreting Methods PDFDocument26 pagesSpecial Concretes and Concreting Methods PDFSathish Selva100% (1)

- Highway Maintenance 2003Document80 pagesHighway Maintenance 2003Pranesh Gr100% (1)

- Presentation On RoadDocument23 pagesPresentation On RoadKapil Pant0% (1)

- Civil-Vii-Pavement Materials and Construction (10CV763) - SolutionDocument36 pagesCivil-Vii-Pavement Materials and Construction (10CV763) - SolutionLokesh KNo ratings yet

- Report On RoadsDocument12 pagesReport On RoadsHidayat UllahNo ratings yet

- Highway Engineering Course Outline (CoTM) - 3rd YrDocument2 pagesHighway Engineering Course Outline (CoTM) - 3rd YrTarmok Hirpo100% (1)

- Pavement Materials CharacterisationDocument15 pagesPavement Materials CharacterisationKellesia WilliamsNo ratings yet

- Transportation EngineeringDocument301 pagesTransportation EngineeringKapil Kushwah100% (1)

- Bituminous MaterialsDocument53 pagesBituminous MaterialsRoopen FearkyNo ratings yet

- BCE 3107 Transportation Engineering PDFDocument118 pagesBCE 3107 Transportation Engineering PDFmoradNo ratings yet

- 01-Transportation Engg - Prof. AamirDocument69 pages01-Transportation Engg - Prof. AamirChandan KumarNo ratings yet

- Rigid Versus Flexible Pavement DesignDocument3 pagesRigid Versus Flexible Pavement DesignAlbertJnBaptisteNo ratings yet

- Contour MAP: GROUP 8 (Pasilbas, Yongco, Hepgano, Cajes, Frondozo)Document22 pagesContour MAP: GROUP 8 (Pasilbas, Yongco, Hepgano, Cajes, Frondozo)Virgilio Velasco IIINo ratings yet

- Survey-1 Lab ManualDocument41 pagesSurvey-1 Lab ManualBalajiValmiki100% (1)

- Lecture 1 - Traffic Engineering PDFDocument61 pagesLecture 1 - Traffic Engineering PDFGajendra JoshiNo ratings yet

- Module 1 (Ce 361 - Advanced Concrete Technology)Document43 pagesModule 1 (Ce 361 - Advanced Concrete Technology)Rahul patilNo ratings yet

- Transportation Engineering-Ii: Flexible Pavement DesignDocument59 pagesTransportation Engineering-Ii: Flexible Pavement DesignUsman HaiderNo ratings yet

- Drag LinesDocument4 pagesDrag LinesShafiek IsmailNo ratings yet

- Questions On Seasoning of Timber 46pts: Assessment 1Document4 pagesQuestions On Seasoning of Timber 46pts: Assessment 1renan100% (2)

- Belete Highway II-1Document674 pagesBelete Highway II-1Nathan KebedeNo ratings yet

- Highway and Pavement ConstructionDocument35 pagesHighway and Pavement ConstructionCherylNo ratings yet

- Environmental Engineering Notes PDFDocument61 pagesEnvironmental Engineering Notes PDFDhanjit HazarikaNo ratings yet

- 5.pavement MaterialsDocument84 pages5.pavement MaterialssmaajNo ratings yet

- Difference Between Flexible & Rigid PavementsDocument2 pagesDifference Between Flexible & Rigid PavementsLo0oVve100% (2)

- Exploring Brts For Accident Reduction A ReviewDocument3 pagesExploring Brts For Accident Reduction A ReviewRahul kumar100% (1)

- SPECIFICATIONS Final PPT - MVDocument13 pagesSPECIFICATIONS Final PPT - MVAbid mullaNo ratings yet

- Presentation On LintelsDocument2 pagesPresentation On LintelsAbdulrahman SalemNo ratings yet

- Chapter 6: Road and Highway Economics and FinanceDocument49 pagesChapter 6: Road and Highway Economics and FinanceYosiNo ratings yet

- Analysis, Specification and Estimate On Road WorksDocument71 pagesAnalysis, Specification and Estimate On Road WorksAnonymous BACdUNvPZ280% (5)

- TunnelingDocument44 pagesTunnelingShawn ChenNo ratings yet

- Utp Module 01 PPT NotesDocument102 pagesUtp Module 01 PPT NotesYogeshNo ratings yet

- 2020.highwaye NotesDocument110 pages2020.highwaye NotesEmmanuel AfedzieNo ratings yet

- Road Classification DesignDocument39 pagesRoad Classification DesignAmirul ZolkhairiNo ratings yet

- Estimating and Costing Question PaperDocument4 pagesEstimating and Costing Question PaperIrfan KhanNo ratings yet

- Report On Black Spot AnalysisDocument45 pagesReport On Black Spot AnalysisJitu Meena100% (2)

- Setting Out WorksDocument21 pagesSetting Out WorksZawani Abu Rais100% (1)

- Road Development and Highway Network PlanningDocument76 pagesRoad Development and Highway Network PlanningNitin VermaNo ratings yet

- Highway AlignmentDocument14 pagesHighway AlignmentSai Ashrith Moturi100% (1)

- Chain SurveyingDocument16 pagesChain Surveyingajith100% (1)

- Concrete Technology NotesDocument36 pagesConcrete Technology Notesshalu R FNo ratings yet

- Construction of Flexible PavementDocument5 pagesConstruction of Flexible PavementSaad IrfanNo ratings yet

- BMCP - Lectute Notes PDFDocument84 pagesBMCP - Lectute Notes PDFManiko ManikoNo ratings yet

- Ce 223 Notes 2010.2011Document128 pagesCe 223 Notes 2010.2011Athiyo MartinNo ratings yet

- Concrete Technology Unit 4Document30 pagesConcrete Technology Unit 4sainathNo ratings yet

- Various Methods of Setting Out Simple Circular CurveDocument9 pagesVarious Methods of Setting Out Simple Circular CurveGireEsh Badoni100% (1)

- Chapter 5, Soil Engineering For Highway DesignDocument57 pagesChapter 5, Soil Engineering For Highway DesignIsmail Hrichi100% (1)

- Rotary IntersectionDocument24 pagesRotary IntersectionPark Leo0% (1)

- Highway EngineeringDocument105 pagesHighway EngineeringAnkit kumarNo ratings yet

- 20CE52IDocument30 pages20CE52Ishastry_vishNo ratings yet

- Bituminous MaterialsDocument6 pagesBituminous MaterialsImmanuel LangatNo ratings yet

- Mass SpectrometryDocument49 pagesMass SpectrometryV CNo ratings yet

- Applied Chemistry q1 Module 3Document5 pagesApplied Chemistry q1 Module 3MockyNo ratings yet

- Production of Ethylene GlycolDocument15 pagesProduction of Ethylene Glycolindahazhr100% (6)

- Effect of Naringenin On Alcl3 Induced Alzheimir Disease in Drosophila FlyDocument27 pagesEffect of Naringenin On Alcl3 Induced Alzheimir Disease in Drosophila FlyPeter AiyedeNo ratings yet

- Chemsheets GCSE 1237 Condensation Polymers ANS Mn74Document4 pagesChemsheets GCSE 1237 Condensation Polymers ANS Mn74lolNo ratings yet

- Purwanchal Vidyamandir SESSION: 2021-2022 Class: Ix Subject: BiologyDocument8 pagesPurwanchal Vidyamandir SESSION: 2021-2022 Class: Ix Subject: BiologyKartavya Jhunjhunwala 9ANo ratings yet

- Processing and Storage Effects On Orange Juice Aroma: A ReviewDocument13 pagesProcessing and Storage Effects On Orange Juice Aroma: A ReviewSwetha RameshNo ratings yet

- Protecting Reagent TCIDocument12 pagesProtecting Reagent TCItech PSNo ratings yet

- Levinthal's ParadoxDocument3 pagesLevinthal's Paradoxperception888No ratings yet

- Hybrid Molecules The Privileged Scaffolds For VariousDocument37 pagesHybrid Molecules The Privileged Scaffolds For VariousAntônio Neto MachadoNo ratings yet

- Siew Hoong Shuit, Keat Teong Lee, Azlina Harun Kamaruddin, Suzana YusupDocument4 pagesSiew Hoong Shuit, Keat Teong Lee, Azlina Harun Kamaruddin, Suzana YusupAsri GaniNo ratings yet

- Classification of Bacteria On The Basis of Mode of NutritionDocument8 pagesClassification of Bacteria On The Basis of Mode of Nutritionbukhari syedNo ratings yet

- Polymerase Chain ReactionDocument12 pagesPolymerase Chain ReactionSaswat MohapatraNo ratings yet

- Harga ObatDocument4 pagesHarga ObatNovena AzaNo ratings yet

- Catalog AmwayDocument35 pagesCatalog Amwaypradeep mathurNo ratings yet

- Antiperspirants & DeodorantsDocument18 pagesAntiperspirants & DeodorantsGULSHAN MADHUR100% (1)

- Egg Yolk OilDocument35 pagesEgg Yolk OilAbu ZakiNo ratings yet

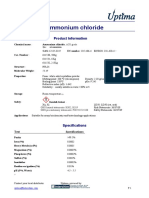

- Ammonium Chloride: Product InformationDocument2 pagesAmmonium Chloride: Product InformationusamaNo ratings yet

- Biofuels: Certified Reference StandardsDocument4 pagesBiofuels: Certified Reference StandardsAlexSNo ratings yet

- Kjeldahl Knowledge Base Guide enDocument76 pagesKjeldahl Knowledge Base Guide enGiang Lê HươngNo ratings yet

- BLP Synthetic and Metal Mesh SlingsDocument12 pagesBLP Synthetic and Metal Mesh SlingsMohamed FathyNo ratings yet

- MSAT II and Benzene ManagementDocument2 pagesMSAT II and Benzene ManagementWong Yee Sun100% (1)

- StereochemistryDocument10 pagesStereochemistryAditya RaghavanNo ratings yet

- Industrial Waste SurweyDocument34 pagesIndustrial Waste SurweyOmaya TariqNo ratings yet

- Butyl TitanateDocument22 pagesButyl TitanatesidneidecarvalhoNo ratings yet

- The Fundamental Problems Regarding The Relative Hydrogen (RH) Score in Biochemistry by Gârban - ZenoDocument8 pagesThe Fundamental Problems Regarding The Relative Hydrogen (RH) Score in Biochemistry by Gârban - ZenoScutul_CrestinNo ratings yet

- Alcohols, Phenols, and Ethers Shobhit NirwanDocument9 pagesAlcohols, Phenols, and Ethers Shobhit NirwanMithil Mohanraj100% (1)

- 18CEO306T MSWM Unit4Document71 pages18CEO306T MSWM Unit4Sabarigirivasan LNo ratings yet

- Chemical Composition Acacia NiloticaDocument7 pagesChemical Composition Acacia NiloticaOscar ArangoNo ratings yet

- Yr 10 Revision PosterDocument3 pagesYr 10 Revision Posternesrine boufadenNo ratings yet