Gantrex Raillok w30 Data Sheet Imperial

Gantrex Raillok w30 Data Sheet Imperial

Uploaded by

Sergio HernandezCopyright:

Available Formats

Gantrex Raillok w30 Data Sheet Imperial

Gantrex Raillok w30 Data Sheet Imperial

Uploaded by

Sergio HernandezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Gantrex Raillok w30 Data Sheet Imperial

Gantrex Raillok w30 Data Sheet Imperial

Uploaded by

Sergio HernandezCopyright:

Available Formats

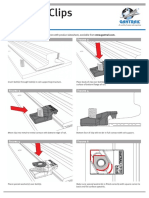

RailLok™ Series

WELDABLE CLIPS - W30

Adjustment range

Patented

New features :

• Double wedge with patented

self-contact design of

inclined bolt

• Bolts incorporate a

“Square Shank Base”

• Resistance to vertical forces

CLIPS C max Lateral Bolt torque Resistance to Resistance to Estimated

adjustment lateral forces vertical forces weight

Inches Inches lb-ft kips kips lb

W30/AN 1-1/2 3/4 405 67.4 6.7 6.15

W30/BN 1-7/8 3/4 405 67.4 6.7 6.28

W30/CN 1-1/16 3/4 405 67.4 6.7 6.55

N: nose height, not compressed, adapted to the rail type (see table on next page).

Notes on next page

Full designation

W30/AN • Clip Specification

or W30/BN • Clip Selection Table

or W30/CN Upper component and nose height (N)

according to rail type and foot size (F).

Components

• Components Materials

2x Sp M22 Cl8 GAL

• Installation and Welding Instructions

- Recommended weld throat size :

1 x W30/32N

1/4”; weld leg size being then 5/16”.

or 1 x W30/42N

or 1 x W30/49N - Any low hydrogen rod suitable for use with

structural steel may be used.

2 x SSB M22x49 8.8 GAL

1 x W30/29

www.gantrex.com GSUS-EN 2017-10 R3.0

In USA, contact GANTREX Inc. – 1-800-242-6873 – info.pittsburgh@gantrex.com

In Canada, contact GANTREX Canada Inc. – 1-800-884-5960 – info.ajax@gantrex.com

RailLok™ Series

WELDABLE CLIPS - W30

CLIP SPECIFICATION

The RailLok™ patented clips are specifically designed to facilitate correct mounting of crane rails :

• The patented design with inclined bolt ensures tight and full self-contact with the rail foot.

• Bolts with “Square Shank Base” allow the use of impact-wrenches.

• Easier installation because of the wider adjustment range.

• Compact design : fits narrow girders and soleplates, avoid interference with guide rollers.

Once installed, the clips are self-locking and self-tightening.

CLIP SELECTION TABLE

Mounting

F K H Weight

with pad without

Inches Inches Inches lb/yd

9/32” RailLok™ pad

A120 8.7 4.7 4.1 202 W30/BM W30/AJ

A150 8.7 5.9 5.9 303 W30/BM W30/AJ

104CR (MRS51) 5 2-1/2 5 104 W30/BM W30/AM

105CR (MRS52) 5-3/16 2-9/16 5-3/16 105 W30/AH W30/AM

135CR (MRS67) 5-3/16 3-7/16 5-3/4 135 W30/BM W30/AM

171CR (MRS85) 6 4.3 6 171 W30/BJ W30/AI

175CR (MRS87B) 6 4-1/4 6 175 W30/BM W30/AJ

MRS125 7.1 4.7 7.1 252 W30/CM W30/BM

MRS221 8.7 8.7 6.3 446 W30/BI W30/AH

Note : All dimensions are rounded off to serve as general guidelines only. Contact Gantrex for rail sizes not shown above and for help selecting rail pads.

COMPONENTS MATERIALS

The RailLok™ W30 is standard with a weldable forged steel lower component, a ductile cast iron upper component and vulcanize-bonded rubber nose. As

standard, the bolts and nuts are hot dip galvanized. The upper component can also be hot dip galvanized on request. Contact Gantrex for other options.

INSTALLATION AND SUGGESTED WELD INSTRUCTIONS

The lower component is welded on the support parallel to the axis of the rail and the upper component is fastened to it by means of two bolts and nuts.

The recommended torque is 405 lb-ft. Electrical and pneumatic torque wrenches are allowed as long as the minimum torque of 330 lb-ft is met and the

torque does not exceed 516 lb-ft.

It is recommended the torque is regularly controlled with a calibrated torque wrench.

For most applications, the recommended weld throat size is 1/4”; the weld leg size is then 5/16”. Use any low hydrogen rod suitable for use with

structural steel: ISO2560 type E 42 5 B 32 H5, E7018 or equivalent. For full instructions on weld size and electrodes, refer to the data sheet “Installation

and suggested weld instructions”.

Do not apply protective coating on the contact surface between upper and lower components unless accepted by Gantrex. Do not use solvents as they

may seriously damage the rubber nose.

We reserve the right to discontinue or change specifications or design at any time without prior notice and without incurring

any obligation whatsoever.

Disclaimer: for regional use only

www.gantrex.com GSUS-EN 2017-10 R3.0

In USA, contact GANTREX Inc. – 1-800-242-6873 – info.pittsburgh@gantrex.com

In Canada, contact GANTREX Canada Inc. – 1-800-884-5960 – info.ajax@gantrex.com

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Gantrex Raillok w20 Steel - LTDocument2 pagesGantrex Raillok w20 Steel - LTOkky PoerwantoNo ratings yet

- Gantrex Raillok w10 Data Sheet ImperialDocument2 pagesGantrex Raillok w10 Data Sheet Imperialjhon jairo arangoNo ratings yet

- Gantrex Raillok w15 Steel - LTDocument2 pagesGantrex Raillok w15 Steel - LTOkky PoerwantoNo ratings yet

- Fem 9 511Document2 pagesFem 9 511Emilio Jose Andia AbregiNo ratings yet

- Raillok w30 Data Sheet ImperialDocument2 pagesRaillok w30 Data Sheet Imperial30410929100% (1)

- GSUS EN CLIPS RailLok-Clip-BG20 2017-10 R3.0-1Document2 pagesGSUS EN CLIPS RailLok-Clip-BG20 2017-10 R3.0-1Jani BondNo ratings yet

- Gantrex Raillok Bg20 Data Sheet ImperialDocument2 pagesGantrex Raillok Bg20 Data Sheet Imperialjhon jairo arangoNo ratings yet

- GSUS EN CLIPS RailLok-Clip-BG10 2017-10 R2.0-1Document2 pagesGSUS EN CLIPS RailLok-Clip-BG10 2017-10 R2.0-1Jani BondNo ratings yet

- Lift-Off Restraints: No Welding - No Drilling - Just ClampingDocument20 pagesLift-Off Restraints: No Welding - No Drilling - Just ClampingRamzi Ben AhmedNo ratings yet

- Boltable Grooved Clips - B 20: Raillok™ SeriesDocument2 pagesBoltable Grooved Clips - B 20: Raillok™ SeriesNebojsa MomcilovicNo ratings yet

- Gantrex Raillok bg15 Data Sheet - ImperialDocument2 pagesGantrex Raillok bg15 Data Sheet - Imperialjhon jairo arangoNo ratings yet

- Bogaert - A - Transmission Roller Chains BTC 2016Document132 pagesBogaert - A - Transmission Roller Chains BTC 2016Paulo MarcelinoNo ratings yet

- Gantrex Raillok Bg10 Data Sheet MetricDocument2 pagesGantrex Raillok Bg10 Data Sheet MetricJD100% (1)

- Boltable Grooved Clips: Raillok™ SeriesDocument2 pagesBoltable Grooved Clips: Raillok™ SeriesmelanitisNo ratings yet

- GXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W25 Instal & Weld Instruc - 2018-02 - R1.1Emmanuel Hernandez100% (1)

- Acoples PIX PowerWare CatalogueDocument12 pagesAcoples PIX PowerWare CatalogueOscar Orellana CruzNo ratings yet

- Geared Machines March 2018Document31 pagesGeared Machines March 2018mahmoud abasNo ratings yet

- Wedge SoketDocument1 pageWedge SoketOscar Ortiz VazquezNo ratings yet

- ATI-X1-16-Rev DDocument2 pagesATI-X1-16-Rev DffpardoNo ratings yet

- Technical EC Sheet: T 6055 GB 1 June 05Document17 pagesTechnical EC Sheet: T 6055 GB 1 June 05Fayyaz NadeemNo ratings yet

- GXHQ - EN - STEEL SUPPORTS - Discontinuous Mounting On Concrete - 2018-02 - R6.0Document4 pagesGXHQ - EN - STEEL SUPPORTS - Discontinuous Mounting On Concrete - 2018-02 - R6.0Nilda ReyesNo ratings yet

- RailLok Clip BG15 - 2016-06 Rev0Document2 pagesRailLok Clip BG15 - 2016-06 Rev0Galbadrakh BaasandorjNo ratings yet

- Material HandlingDocument10 pagesMaterial HandlingEric BaretteNo ratings yet

- VSHORE Product GuideDocument6 pagesVSHORE Product GuideSal CarrivaleNo ratings yet

- Cord Reel Reel CraftDocument1 pageCord Reel Reel CraftsidrataNo ratings yet

- Bullivants - PWB Anchor 8 Materials HandlingpdfDocument60 pagesBullivants - PWB Anchor 8 Materials HandlingpdfJill McIntoshNo ratings yet

- Weldlok 15 Data SheetDocument2 pagesWeldlok 15 Data Sheetjhon jairo arangoNo ratings yet

- Gantrex Pad Mk6Document4 pagesGantrex Pad Mk6reza nasiriNo ratings yet

- Standard WireropesDocument6 pagesStandard Wireropesmohkal1260No ratings yet

- GXHQ - EN - CLIPS - RailLok Clip W10-W15&W17 Instal & Weld Instruc - 2018-02 - R2.1Document4 pagesGXHQ - EN - CLIPS - RailLok Clip W10-W15&W17 Instal & Weld Instruc - 2018-02 - R2.1Emmanuel HernandezNo ratings yet

- MAPAL VersaCut enDocument16 pagesMAPAL VersaCut enPlant Head PrasadNo ratings yet

- SCM 012-130 SaeDocument12 pagesSCM 012-130 SaekazdanoNo ratings yet

- GCF Gate ValveDocument7 pagesGCF Gate Valvemohamed KotpNo ratings yet

- Boltable Clips - B30: Clips B Max C Max Lateral Adjustment Bolt Torque (NM) Estimated WeightDocument2 pagesBoltable Clips - B30: Clips B Max C Max Lateral Adjustment Bolt Torque (NM) Estimated WeightAlex IgnatovNo ratings yet

- Drive System Bearings: June 1, 2018Document24 pagesDrive System Bearings: June 1, 2018Anonymous YggO6T6GzNo ratings yet

- Weldlok 43 Data SheetDocument2 pagesWeldlok 43 Data Sheetjhon jairo arangoNo ratings yet

- PumpWorks 610 PWD Brochure1Document6 pagesPumpWorks 610 PWD Brochure1Octa RioNo ratings yet

- RBC Roller CamfollowersDocument56 pagesRBC Roller CamfollowersЮра ПименовNo ratings yet

- Solutions For: Marine & OffshoreDocument28 pagesSolutions For: Marine & OffshoreBimo Cungkring IINo ratings yet

- CableDocument1 pageCableYenifer MoralesNo ratings yet

- RailokDocument2 pagesRailokOscar ChappilliquenNo ratings yet

- Model 621 LR B Data SheetDocument1 pageModel 621 LR B Data SheetMohammed GallowNo ratings yet

- Specification Equipment For StringingDocument36 pagesSpecification Equipment For StringingedwardoNo ratings yet

- cp1210 SpecsDocument2 pagescp1210 Specsyoucef alimNo ratings yet

- Engineered Conveyor Pulleys: Power Transmission ComponentsDocument2 pagesEngineered Conveyor Pulleys: Power Transmission ComponentsHà NguyễnNo ratings yet

- Shore "X" 11-Kip Shoring SystemDocument4 pagesShore "X" 11-Kip Shoring SystematiNo ratings yet

- Closed Swage Sockets National Swage ButtonsDocument1 pageClosed Swage Sockets National Swage ButtonshoiNo ratings yet

- HDCB 01 Uk PDFDocument4 pagesHDCB 01 Uk PDFhepcomotionNo ratings yet

- T Series CouplingsDocument4 pagesT Series CouplingsiradocajNo ratings yet

- Stabox Sam PDFDocument28 pagesStabox Sam PDFEdmond TakacsNo ratings yet

- Toyota BT Traigo 9FBMK20T-35T Chapter 12 (Mast) 02-03-2022 Service TrainingDocument27 pagesToyota BT Traigo 9FBMK20T-35T Chapter 12 (Mast) 02-03-2022 Service TrainingDennis SteinbuschNo ratings yet

- Strutfast Metal Framing - LRDocument8 pagesStrutfast Metal Framing - LRzimtonyNo ratings yet

- W36LB CompletoDocument8 pagesW36LB Completoeliot martinezNo ratings yet

- wedge anchoring clamps Σελίδα 48 και 49Document1 pagewedge anchoring clamps Σελίδα 48 και 49Konstantinos SynodinosNo ratings yet

- Ground Engaging Tools GETDocument160 pagesGround Engaging Tools GETmalik rashidov100% (1)

- Scrap HandlerDocument2 pagesScrap HandlerAlex KarimNo ratings yet

- Handloader's Digest: The World's Greatest Handloading BookFrom EverandHandloader's Digest: The World's Greatest Handloading BookRating: 2 out of 5 stars2/5 (1)

- Food Safety Training Titan Frozen FruitDocument44 pagesFood Safety Training Titan Frozen FruitSergio HernandezNo ratings yet

- Certificate of Analysis: LAB-004A-FRM-00Document1 pageCertificate of Analysis: LAB-004A-FRM-00Sergio HernandezNo ratings yet

- SDS PA 6 MonofilamentDocument2 pagesSDS PA 6 MonofilamentSergio HernandezNo ratings yet

- Hamilton Beach 1.1 Cu. Ft. 1000W Stainless Steel MicrowaveDocument16 pagesHamilton Beach 1.1 Cu. Ft. 1000W Stainless Steel MicrowaveSergio HernandezNo ratings yet

- Catalogo Carbones Helwig GDE-006Document17 pagesCatalogo Carbones Helwig GDE-006Sergio HernandezNo ratings yet

- Gantrail Fitting Instructions 3 Series DS 0814Document2 pagesGantrail Fitting Instructions 3 Series DS 0814Sergio HernandezNo ratings yet

- Gantrail Fitting Instructions 7 Series DS 1214Document2 pagesGantrail Fitting Instructions 7 Series DS 1214Sergio HernandezNo ratings yet

- Identificador Ejes MeritorDocument98 pagesIdentificador Ejes MeritorSergio Hernandez100% (1)

- Gantrail Fitting Instructions 6 Series DS 0915Document2 pagesGantrail Fitting Instructions 6 Series DS 0915Sergio HernandezNo ratings yet

- How To Use A Hydraulic Ironworker MachineDocument26 pagesHow To Use A Hydraulic Ironworker MachineSergio HernandezNo ratings yet

- Open Conductor Bar PDFDocument48 pagesOpen Conductor Bar PDFSergiSerranoNo ratings yet

- TKW Fasteners ProfileDocument37 pagesTKW Fasteners ProfileRishi GautamNo ratings yet

- Iron Ore PosterDocument2 pagesIron Ore PosterJawad HamzeNo ratings yet

- BS 00336 2010Document44 pagesBS 00336 2010HazimNo ratings yet

- Steel Standards: ASTM A500-01A ASTM A53 / A53M-01Document1 pageSteel Standards: ASTM A500-01A ASTM A53 / A53M-01Tieu KakaNo ratings yet

- Iron and SteelDocument65 pagesIron and SteelSunny PatilNo ratings yet

- Welding Defect in GTAWDocument19 pagesWelding Defect in GTAWMuhammad Ghiyats100% (1)

- A517a517m-17 1.04 PDFDocument4 pagesA517a517m-17 1.04 PDFlean guerreroNo ratings yet

- Welding AISI 4130Document5 pagesWelding AISI 4130Patrick DominguezNo ratings yet

- E6010Document3 pagesE6010Anonymous oUoJ4A8xNo ratings yet

- HVOF CoatingDocument3 pagesHVOF CoatingsumohiNo ratings yet

- 04 Welding SOPDocument3 pages04 Welding SOProhan khariwaleNo ratings yet

- Maintenance/upgrading of Hydraulic Piping System: Service Bulletin #41Document12 pagesMaintenance/upgrading of Hydraulic Piping System: Service Bulletin #41DmNo ratings yet

- Extraction of MetalsDocument2 pagesExtraction of Metalsdan964No ratings yet

- Thyssen Krupp SteelDocument14 pagesThyssen Krupp Steel^passwordNo ratings yet

- Dewatering and Calcination of Laterite OresDocument11 pagesDewatering and Calcination of Laterite OresDavid SanchezNo ratings yet

- Economic and Product Design Considerations in MachiningDocument29 pagesEconomic and Product Design Considerations in Machininghashir siddiquiNo ratings yet

- Ieema October 2023Document2 pagesIeema October 2023Rallison MarketingNo ratings yet

- Weekly Report Nivea 003Document3 pagesWeekly Report Nivea 003ade_wildan2No ratings yet

- Occurrence and Extraction of Metals: Module - 6Document15 pagesOccurrence and Extraction of Metals: Module - 6Manish kumarNo ratings yet

- Nabl Scope TC 7876Document79 pagesNabl Scope TC 7876Kothiyal MukeshNo ratings yet

- Government of Andhra Pradesh: RD STDocument2 pagesGovernment of Andhra Pradesh: RD STEngineer-in-ChiefIrrigation GajwelNo ratings yet

- Catalogo Closet3 RichelieuDocument2 pagesCatalogo Closet3 RichelieuDiego SánchezNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausNo ratings yet

- Nah & Kim (2011) - Establishment of Slip Coefficient For Slip Resistant Connection - KoreaDocument9 pagesNah & Kim (2011) - Establishment of Slip Coefficient For Slip Resistant Connection - KoreawackokidNo ratings yet

- Martensite and The Control of Retained AusteniteDocument6 pagesMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNo ratings yet

- A Study On Metal Extrusion Process: July 2018Document8 pagesA Study On Metal Extrusion Process: July 2018Nadia Mezghani0% (1)

- DoITPoMS - TLP Library Introduction To Deformation ProcessesDocument12 pagesDoITPoMS - TLP Library Introduction To Deformation ProcessesAbdulrahman AlnagarNo ratings yet

- 29g KSBDocument1 page29g KSBGut BeerliNo ratings yet

- Platzhalter Für Titel: Industrial Power BrushesDocument44 pagesPlatzhalter Für Titel: Industrial Power BrushesToniase Guimaraes BarrosNo ratings yet

- Case Study: Forensic Analysis of A Corroded Wireline Data Logging Cable Sample With A Brass Rope Socket ConeDocument3 pagesCase Study: Forensic Analysis of A Corroded Wireline Data Logging Cable Sample With A Brass Rope Socket ConefelipeNo ratings yet