Mechanical Troubleshooting: Testing & Adjusting

Mechanical Troubleshooting: Testing & Adjusting

Uploaded by

DavidCopyright:

Available Formats

Mechanical Troubleshooting: Testing & Adjusting

Mechanical Troubleshooting: Testing & Adjusting

Uploaded by

DavidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Mechanical Troubleshooting: Testing & Adjusting

Mechanical Troubleshooting: Testing & Adjusting

Uploaded by

DavidCopyright:

Available Formats

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Welcome: j210jed

Product: TRACK-TYPE TRACTOR

Model: D8R TRACK-TYPE TRACTOR 9EM

Configuration: D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE)

POWERED BY 3406C Engine

Testing and Adjusting

3406C ENGINE FOR CATERPILLAR BUILT MACHINES

Media Number -SENR1028-02 Publication Date -01/02/2006 Date Updated -05/08/2013

SENR10280002

Testing & Adjusting

Mechanical Troubleshooting

Troubleshooting can be difficult. The Troubleshooting Index gives a list of possible problems. To make a

repair to a problem, make reference to the cause and correction on the pages that follow.

This list of problems, causes, and corrections will only give an indication of where a possible problem can

be, and what repairs are needed. Normally, more or other repair work is needed beyond the

recommendations in the list.

Remember that a problem is not normally caused only by one part, but by the relation of one part with other

parts. This list is only a guide and cannot give all possible problems and corrections. The serviceman must

find the problem and its source, then make the necessary repairs.

1. Engine Crankshaft Will Not Turn When Start Switch Is On.

2. Engine Will Not Start.

3. Engine Misfires Or Runs Rough.

4. Stall At Low RPM.

5. Sudden Changes In Engine RPM.

6. Not Enough Power.

7. Too Much Vibration.

8. Loud Combustion Noise.

9. Valve Train Noise (Clicking).

10. Oil In Cooling System.

11. Mechanical Noise (Knock) In Engine.

12. Fuel Consumption Too High.

13. Loud Valve Train Noise.

14. Too Much Valve Lash.

15. Valve Rotocoil Or Spring Lock Is Free.

16. Oil At The Exhaust.

17. Little Or No Valve Lash.

18. Engine Has Early Wear.

19. Coolant In Lubrication Oil.

20. Too Much Black Or Gray Smoke.

1 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

21. Too Much White Or Blue Smoke.

22. Engine Has Low Oil Pressure.

23. Engine Uses Too Much Lubrication Oil.

24. Engine Coolant Is Too Hot.

25. Exhaust Temperature Is Too High.

26. Starting Motor Does Not Turn.

27. Alternator Gives No Charge.

28. Alternator Charge Rate Is Low Or Not Regular.

29. Alternator Charge Is Too High.

30. Alternator Has Noise.

31. Rack Solenoid Does Not Stop Engine.

Troubleshooting Problems

Problem 1: Engine Crankshaft Will Not Turn When Start Switch Is On

Probable Cause:

1. Battery Has Low Output

Make Reference to Problem 26.

2. Wires Or Switches Have Defect

Make Reference to Problem 26.

3. Starting Motor Solenoid Has A Defect

Make Reference to Problem 26.

4. Starting Motor Has A Defect

Make Reference to Problem 26.

5. Inside Problem Prevents Engine Crankshaft From Turning

If the crankshaft can not be turned after the driven equipment is disconnected, remove the fuel

injection nozzles and check for fluid in the cylinders when the crankshaft is turned. If fluid in the

cylinders is not the problem, the engine must be disassembled to check for other inside problems.

Some of these inside problems are bearing seizure, piston seizure, or wrong pistons installed in the

engine.

Problem 2: Engine Will Not Start

Probable Cause:

1. Starting Motor Turns Too Slow

Make reference to Problem 27.

2. Dirty Fuel Filter

Install new fuel filter.

3. Dirty Or Broken Fuel Lines

2 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Clean or install new fuel lines as necessary.

4. Fuel Transfer Pump

At starting rpm, the minimum fuel pressure for fuel transfer pump must be 20 kPa (3 psi). If fuel

pressure is less than 20 kPa (3 psi), change the fuel filter element. Look for air in the fuel system. If

fuel pressure is still low, install a new fuel transfer pump.

5. No Fuel To Cylinders

Put fuel in fuel tank. "Prime" (remove the air and/or poor quality fuel) the fuel system.

6. Poor Quality Fuel

Remove the fuel from the fuel tank. Install a new fuel filter element. Put a good grade of clean fuel in

the fuel tank. See Diesel Fuels and Your Engine, SEBD0717.

7. Wrong Fuel Injection Timing

Make adjustment to timing.

8. Shutoff Solenoid Will Not Move To Extended Position

The solenoid must get electricity to stop the engine. Operate the control for the shutoff solenoid and

see if the solenoid makes a noise (clicking sound). If this sound can be heard and the engine will not

start, remove the solenoid. Now see if the engine will start. If the engine starts, the shutoff solenoid

either needs an adjustment or it is defective and replacement of the solenoid is necessary.

Problem 3: Engine Misfires Or Runs Rough

Probable Cause:

1. Fuel Pressure Is Low

Make sure there is fuel in the fuel tank. Look for leaks or defective bends in the fuel line between fuel

tank and fuel transfer pump. Look for air in the fuel system. Check fuel pressure.

If fuel pressure is lower than 170 kPa (25 psi) install a new filter element. The outlet pressure of the

fuel transfer pump at full load must be 240 kPa (35 psi). If fuel pressure is still low, install a new fuel

transfer pump.

2. Air In Fuel System

Find the air leak in the fuel system and correct it. If air is in the fuel system, it will probably get in on

the suction side of fuel transfer pump.

3. Leak Or Break In Fuel Line Between Fuel Injection Pump And Fuel Injection Nozzle

Install a new fuel line.

4. Wrong Valve Lash.

Make adjustment according to the Subject, Valve Lash Setting.

5. Defect In Fuel Injection Nozzle(s) Or Fuel Injection Pump(s)

3 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Run engine at rpm that misfires the most and runs the roughest. Then loosen a fuel line nut on the fuel

injection nozzle for each cylinder, one at a time. Find the cylinder where a loosened fuel line nut does

not change the way the engine runs. Test the fuel injection pump and fuel injection nozzle for that

cylinder. Install new parts where needed.

6. Wrong Fuel Injection Timing

Make adjustment to timing.

7. Bent Or Broken Push Rod

Replacement of push rod is necessary.

8. Fuel Has "Cloud Point" Higher Than Atmospheric Temperature ("Cloud Point"=Temperature

Which Makes Wax Form In Fuel).

Drain the fuel tank, lines, and fuel injection pump housing. Change the fuel filter. Fill the tank with

fuel which has the correct "cloud point" and remove the air from the system with the priming pump.

Problem 4: Stall At Low RPM

Probable Cause:

1. Fuel Pressure Is Low

Make sure there is fuel in the fuel tank. Look for leaks or defective bends in the fuel line between fuel

tank and fuel transfer pump. Look for air in the fuel system. Check fuel pressure.

If fuel pressure is lower than 170 kPa (25 psi) install a new filter element. The outlet pressure of the

fuel transfer pump at full load must be 240 kPa (35 psi). If fuel pressure is still low, install a new fuel

transfer pump.

2. Idle RPM Too Low

Make adjustment to governor so idle rpm is the same as given in the TMI (Technical Marketing

Information) or Fuel Setting And Related Information Fiche.

3. Defect In Fuel Injection Nozzle(s)

Install a new fuel injection nozzle.

4. Engine Accessories

Check engine accessories for damage and correct adjustment. If necessary, disconnect the accessories

and test the engine.

5. Defect In Fuel Injection Pump(s)

Install new parts if needed.

Problem 5: Sudden Changes In Engine Speed (rpm)

Probable Cause:

1. Failure Of Governor Or Fuel Injection Pump

4 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Look for damaged or broken springs, linkage or other parts. Remove the governor. Check for free

travel of fuel rack. Be sure fuel injection pumps are installed correctly. Check for correct governor

spring. Install new parts for those that have damage or defects.

Problem 6: Not Enough Power

Probable Cause:

1. Poor Quality Fuel

Remove the fuel from the fuel tank. Install a new fuel filter element. Put a good grade of clean fuel in

the fuel tank.

2. Fuel Pressure Is Low

Make sure there is fuel in the fuel tank. Look for leaks or defective bends in the fuel line between fuel

tank and fuel transfer pump. Look for air in the fuel system. Check fuel pressure.

If fuel pressure is lower than 170 kPa (25 psi) install a new filter element. The outlet pressure of the

fuel transfer pump at full load must be 240 kPa (35 psi). If fuel pressure is still low, install a new fuel

transfer pump.

3. Leaks In Air Inlet System

Check the pressure in the air inlet manifold. Look for restrictions in the air cleaner.

4. Governor Linkage

Make adjustment to get full travel of linkage. Install new parts for those that have damage or defects.

5. Wrong Valve Lash

Make adjustment according to the Subject, Valve Lash Setting.

6. Defect In Fuel Injection Nozzle(s) Or Fuel Injection Pumps

Run engine at rpm that misfires the most or runs the roughest. Then loosen a fuel line nut on the fuel

injection pump for each cylinder, one at a time. Find the cylinder where a loosened fuel line nut does

not change the way the engine runs. Test the fuel injection pump and fuel injection nozzle for that

cylinder. Install new parts where needed.

7. Wrong Fuel Injection Timing

Make adjustment to timing.

8. Rack Setting Too Low

Make reference to the TMI (Technical Marketing Information) or Fuel Setting And Related

Information Fiche.

9. Defect In Aftercooler

Check temperature of inlet and outlet water supply. Remove any external or internal restrictions.

10. Fuel Ratio Control

5 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Control either needs an adjustment or it is damaged and a new control is needed.

11. Turbocharger Has Carbon Deposits Or Other Causes Of Friction

Make inspection and repair of turbocharger as necessary.

Problem 7: Too Much Vibration

Probable Cause:

1. Loose Bolt Or Nut For Pulley Or Damper

Tighten bolt or nut.

2. Pulley Or Damper Has A Defect

Install a new pulley or damper.

3. Engine Supports Are Loose, Worn, Or Have A Defect

Tighten all bolts that hold engine supports. Install new components if necessary.

4. Engine Misfires Or Runs Rough

Make Reference to Problem 3.

Problem 8: Loud Combustion Noise (Sound)

Probable Cause:

1. Poor Quality Fuel

Remove the fuel from the fuel tank. Install a new fuel filter element. Put a good grade of clean fuel in

the fuel tank. See Diesel Fuels and Your Engine, SEBD0717.

2. Defect In Fuel Injection Nozzle(s)

Install new fuel injection nozzle(s).

3. Defect In Fuel Injection Pump(s)

Install new fuel injection pump(s).

4. Wrong Fuel Injection Timing

Make adjustment to timing.

Problem 9: Valve Train Noise (Clicking)

Probable Cause:

1. Damage To Valve Spring(s), Locks Or Broken Or Worn Valve Lifter

Install new parts where necessary. Broken locks can cause the valve to get into the cylinder. This will

cause much damage.

2. Not Enough Lubrication

6 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Check lubrication in valve compartment. There must be a strong flow of oil at engine high rpm, but

only a small flow of oil at low rpm. Oil passages must be clean, especially those that send oil to the

cylinder head.

3. Too Much Valve Lash

Make adjustment according to the Subject, Valve Lash Setting

4. Damage In Bridge For Valves

Make a replacement of the bridge and make an adjustment as necessary.

Problem 10: Oil In Cooling System

Probable Cause:

1. Defect In Core Of Engine Oil Cooler

Install a new engine oil cooler.

2. Failure Of Cylinder Head Gasket Or Water Seals

Install a new head gasket and new water seals in spacer plate.

Problem 11: Mechanical Noise (Knock) In Engine

Probable Cause:

1. Failure Of Bearing For Connecting Rod

Inspect the bearing for the connecting rod and the bearing surface (journal) on the crankshaft. Install

new parts where necessary.

2. Damaged Timing Gears

Install new parts where necessary.

3. Damaged Crankshaft

Make replacement of the crankshaft.

4. Defect In Attachment

Repair or install new components.

Problem 12: Fuel Consumption Too High

Probable Cause:

1. Fuel System Leaks

Tighten or make replacement of parts at points of leakage.

2. Fuel And Combustion Noise (Knock)

Make Reference to Problem 3 and Problem 6.

7 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

3. Wrong Fuel Injection Timing

Make adjustment to timing.

Problem 13: Loud Valve Train Noise

Probable Cause:

1. Damage To Valve Spring(s)

Make replacement of parts with damage.

2. Damage To Camshaft

Make replacement of parts with damage. Clean engine thoroughly. If replacement of camshaft is

made, new valve lifters are also necessary.

3. Damage To Valve Lifter

Clean engine thoroughly. Make replacement of the damaged valve lifters. Inspect camshaft lobes for

damage. Look for valves that do not move freely. Make an adjustment to valve lash according to the

Subject, Valve Lash Setting.

4. Damage In Bridge For Valves

Make replacement of the bridge and make an adjustment as necessary.

Problem 14: Too Much Valve Lash

Probable Cause:

1. Not Enough Lubrication

Check lubrication in valve compartment. There must be a strong flow of oil at engine high rpm, but

only a small flow at low rpm. Oil passages must be clean, especially those that send oil to the cylinder

head.

2. Rocker Arm Worn At Face That Makes Contact With Bridge

If there is too much wear, install new parts or rocker arms. make adjustment of valve lash according

to the Subject, Valve Lash Setting.

3. End Of Valve Stem Worn

If there is too much wear, install new valves. Make adjustment to valve lash according to the Subject,

Valve Lash Setting.

4. Bridge For Valves Worn

Make an adjustment or replacement as necessary.

5. Worn Push Rods

If there is too much wear, install new push rods. Make adjustment of valve lash according to the

Subject, Valve Lash Setting.

6. Broken Or Worn Valve Lifters

8 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Install new valve lifters. Check camshaft for wear. Check for free movement of valves or bent valve

stem. Clean engine thoroughly. Make adjustment of valve lash according to the Subject, Valve Lash

Setting.

7. Worn Cams On Camshaft

Install a new camshaft. Install new valve lifters. Check for free movement of valves or bent valve

stems. Make adjustment of valve lash according to the Subject, Valve Lash Setting.

Problem 15: Valve Rotocoil Or Spring Lock Is Free

Probable Cause:

1. Broken Locks

Broken locks can cause the valve to get into the cylinder. This will cause much damage.

2. Broken Valve Spring(s)

Install new valve spring(s).

3. Broken Valve

Replace valve and other damaged parts.

Problem 16: Oil At The Exhaust

Probable Cause:

1. Too Much Oil In the Valve Compartment

Look at both ends of the rocker arm shaft. Be sure a plug is in each end of the shaft.

2. Worn Valve Guides

Reconditioning of the cylinder head is needed.

3. Worn Piston Rings

Inspect and install new parts as needed.

Problem 17: Little Or No Valve Lash

Probable Cause:

1. Worn Valve Seat Or Face Of Valve

Reconditioning of cylinder head is needed. Make adjustment of valve lash according to the Subject,

Valve Lash Setting.

Problem 18: Engine Has Early Wear

Probable Cause:

1. Dirt In Lubrication Oil

Remove dirty lubrication oil. Install a new engine oil filter element. Put clean oil in the engine.

9 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

2. Air Inlet Leaks

Inspect all gaskets and connections. Make repairs if leaks are found.

3. Fuel Leakage Into Lubrication Oil

This will cause high fuel consumption and low engine oil pressure. Make repairs if leaks are found.

Install new parts where needed.

Problem 19: Coolant In Lubrication Oil

Probable Cause:

1. Failure Of Engine Oil Cooler Core

Install a new engine oil cooler. Drain crankcase and refill with clean lubricant. Install new engine oil

filter element.

2. Failure Of Cylinder Head Gasket Or Water Seals

Install a new cylinder head gasket and new water seals in the spacer plate. Tighten the bolts that hold

the cylinder head according to the Specifications.

3. Crack Or Defect In Cylinder Head

Install a new cylinder head.

4. Crack Or Defect In Cylinder Block

Install a new cylinder block.

5. Damaged Seals For Cylinder Liners

Make replacement of the seals.

Problem 20: Too Much Black Or Gray Smoke

Probable Cause:

1. Not Enough Air For Combustion

Check air cleaner for restrictions.

2. Defective Fuel Injection Nozzle(s)

Install new fuel injection nozzle(s).

3. Wrong Fuel Injection Timing

Make adjustment of timing.

4. Defect In Fuel Ratio Control

Make adjustment to or install new control.

Problem 21: Too Much White Or Blue Smoke

10 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Probable Cause:

1. Too Much Lubrication Oil In Engine

Remove extra oil. Find where extra oil comes from. Put correct amount of oil in engine.

2. Engine Misfires Or Runs Rough

Make reference to Problem 3.

3. Wrong Fuel Injection Timing

Make adjustment to timing.

4. Worn Valve Guides

Reconditioning of cylinder head is needed.

5. Worn Piston Rings

Install new parts as necessary.

6. Failure Of Turbocharger Oil Seal

Check inlet manifold for oil and make repair to turbocharger if necessary.

Problem 22: Engine Has Low Oil Pressure

Probable Cause:

1. Dirty Engine Oil Filter Or Engine Oil Cooler

Install new engine oil filter. Clean or install new engine oil cooler. Remove dirty oil from engine. Put

clean oil in engine.

2. Diesel Fuel In Lubrication Oil

Find the place where diesel fuel gets into the lubrication oil. Make repairs as needed. Remove the

lubrication oil that has diesel fuel in it. Install a new engine oil filter element. Put clean oil in the

engine.

3. Too Much Clearance Between Rocker Arm Shaft And Rocker Arms

Check lubrication in valve compartment. Install new parts as necessary.

4. Engine Oil Pump Suction Pipe Has A Defect

Replacement of pipe is needed.

5. Pressure Regulating Valve Does Not Close

Clean valve and housing. Install new parts as necessary.

6. Engine Oil Pump is Worn Or Has A Defect

Repair or make replacement of necessary parts.

11 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

7. Too Much Clearance Between Crankshaft And Crankshaft Bearings

Check the engine oil filter to correct operation. Install new parts as necessary.

8. Defect In Oil Pressure Indicator

Install new indicator.

9. Too Much Bearing Clearance For Idler Gear

Inspect bearings and make replacement as necessary.

Problem 23: Engine Uses Too Much Lubrication Oil

Probable Cause:

1. Too Much Lubrication Oil In Engine

Remove extra oil. Find where extra oil comes from. Put correct amount of oil in engine.

2. Oil Leaks

Find all oil leaks. Make repairs as needed.

3. Oil Temperatures Is Too High

Check operation of engine oil cooler. Install new parts if necessary. Clean the core of the engine oil

cooler.

4. Too Much Oil In The Valve Compartment

Look at both ends of the rocker arm shaft. Be sure a plug is in each end of the shaft.

5. Worn Valve Guides

Reconditioning of the cylinder head is needed.

6. Worn Piston Rings And Cylinder Liners

Inspect and install new parts as needed. Reconditioning of the cylinder block can be necessary.

7. Failure Of Seal Rings In Turbocharger

Check inlet manifold for oil and make repair to turbocharger if necessary.

Problem 24: Engine Coolant Is Too Hot

Probable Cause:

1. Restriction To Flow Of Coolant Through Radiator Core Tubes Or Heat Exchanger

Clean and flush radiator or heat exchanger.

2. Restriction To Air Flow Through Radiator

Remove all restrictions of air flow.

12 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

3. Low Fan Speed

Check for worn or loose fan belt.

4. Not Enough Coolant In System

Add coolant to cooling system.

5. Pressure Cap Has A Defect

Check operation of pressure cap. Install a new pressure cap if necessary.

6. Combustion Gases In Coolant

Find out where gases get into the cooling system. Make repairs as needed.

7. Water Temperature Regulator (Thermostat) Or Temperature Indicator Has A Defect

Check water temperature regulator for correct operation. Check temperature indicator operation.

Install new parts as necessary.

8. Water Pump Has A Defect

Make repairs or replacement of the water pump as necessary. Put correct tension on drive belt for

water pump.

9. Too Much Load On The System

Make a reduction to the load.

10. Wrong Fuel Injection Timing

Make adjustment to timing.

Problem 25: Exhaust Temperature Is Too High

Probable Cause:

1. Air Inlet Or Exhaust System Has A Restriction

Remove restriction.

2. Wrong Fuel Injection Timing

Make an adjustment to the timing.

Problem 26: Starting Motor Does Not Turn

Probable Cause:

1. Battery Has Low Output

Check condition of battery. Charge battery or make replacement as necessary.

2. Wires Or Switch Has Defect

Make repairs or replacement as necessary.

13 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

3. Starting Motor Solenoid Has A Defect

Install a new solenoid.

4. Starting Motor Has A Defect

Make repair or replacement of starting motor.

Problem 27:. Alternator Gives No Charge

Probable Cause:

1. Loose Drive Belt For Alternator

Make an adjustment to put the correct tension on the drive belt.

2. Charging Or Ground Return Circuit Or Battery Connections Have A Defect

Inspect all cables and connections. Clean and tighten all connections. Make replacement of parts with

defect.

3. Brushes Have A Defect

Install new brushes.

4. Rotor (Field Coil) Has A Defect

Install a new rotor.

Problem 28: Alternator Charge Rate Is Low Or Not Regular

Probable Cause:

1. Loose Drive Belt For Alternator

Make an adjustment to put the correct tension on the drive belt.

2. Charging Or Ground Return Circuit Or Battery Connections Have A Defect

Inspect all cables and connections. Clean and tighten all connections. Make replacement of parts with

defects.

3. Alternator Regulator Has A Defect

Install a new alternator regulator.

4. Alternator Brushes Have A Defect

Install new brushes.

5. Rectifier Diodes Have A Defect

Make replacement of rectifier diode that has a defect.

6. Rotor (Field Coil) Has A Defect

Install a new rotor.

14 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Problem 29: Alternator Charge Is Too High

Probable Cause:

1. Alternator Or Alternator Regulator Has Loose Connections

Tighten all connections to alternator or alternator regulator.

2. Alternator Regulator Has A Defect

Install a new alternator regulator.

Problem 30: Alternator Has Noise

Probable Cause:

1. Drive Belt For Alternator Is Worn Or Has A Defect

Install a new drive belt for the alternator.

2. Loose Alternator Drive Pulley

Check groove in pulley for key that holds pulley in place. If groove is worn, install a new pulley.

Tighten pulley nut according to Specifications.

3. Drive Belt And Drive Pulley For Alternator Are Not In Alignment

Make an adjustment to put drive belt and drive pulley in correct alignment.

4. Worn Alternator Bearings

Install new bearings in the alternator.

5. Rotor Shaft Is Bent

Make replacement of the rotor shaft.

6. Rectifiers In The Alternator Are Shorted

Make replacement of the diode assembly.

Problem 31: Rack Solenoid Does Not Stop Engine

Probable Cause:

1. Electrical Connections Are Not Correct

Correct electrical connections and wiring.

2. Adjustment for Plunger Shaft Is Not Correct

Make an adjustment to the plunger shaft.

3. Wrong Plunger In Solenoid

Install the correct plunger in the solenoid.

15 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

4. Not Enough Plunger Travel

Make an adjustment to the plunger shaft or make replacement of the solenoid if necessary.

5. Defect In Solenoid Wiring

Make replacement of the solenoid.

Fuel System

Either too much fuel or not enough fuel for combustion can be the cause of a problem in the fuel system.

Many times work is done on the fuel system when the problem is really with some other part of the engine.

The source of the problem is difficult to find, especially when smoke comes from the exhaust. Smoke that

comes from the exhaust can be caused by a defective fuel injector, but it can also be caused by one or more

of the reasons that follow:

a. Not enough air for good combustion.

b. An overload at high altitude.

c. Oil leakage into combustion chamber.

d. Not enough compression.

e. Fuel injection timing incorrect.

Fuel System Inspection

A problem with the components that send fuel to the engine can cause low fuel pressure. This can decrease

engine performance.

1. Check the fuel level in the fuel tank. Look at the cap for the fuel tank to make sure the vent is not filled

with dirt.

2. Check the fuel lines for fuel leakage. Be sure the fuel supply line does not have a restriction or a defective

bend. Verify that the fuel return line has not collapsed in the sections subject to heat.

3. Install a new fuel filter. Clean the primary fuel filter.

4. To remove air from the fuel system, use the procedure that follows:

a. Use the priming pump to remove air from the low pressure side of the fuel system.

b. Loosen one-half turn the fuel injection line nuts at each adapter in the valve cover base. Move throttle

lever to Low Idle position. Use the starting motor to turn the engine until fuel without air flows from the

loose connections. Tighten the nuts.

NOTE: Because of the check assemblies in the fuel injection pump outlets the priming pump will not give

enough pressure to remove air from the fuel injection lines.

5. Inspect the fuel bypass valve to see that there is no restriction to good operation.

Fuel Transfer Pump

With the engine operating at full load speed, the fuel transfer pump moves fuel through the secondary filter

and the fuel injection pump housing at approximately 240 kPa (35 psi).

16 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

To check the fuel transfer pump pressure, disconnect the fuel line (from the filter) at the fuel injection pump

housing inlet. Install a tee at the inlet and connect the fuel line to the tee. Connect a pressure indicator to the

tee and start the engine.

Minimum fuel pressures must be 70 kPa (10 psi) at low idle and 170 kPa (25 psi) at full load speed (and

engine under full load).

If the fuel pressure is not above the minimum specifications, stop the engine. Make a replacement of the

primary and secondary fuel filters and check to make sure the fuel lines and hoses are not plugged or

damaged.

Start the engine and again check the fuel pressure. If the fuel pressure is not above the minimum

specification, a repair or replacement of the fuel transfer pump is needed.

Checking Engine Cylinders Separately

An easy check can be made to find the cylinder that runs rough (misfires) and causes black smoke to come

out of the exhaust pipe.

Run the engine at the speed that is the roughest. Loosen the fuel line nut at a fuel injection pump. This will

stop the flow of fuel to that cylinder. Do this for each cylinder until a loosened fuel line is found that makes

no difference in engine performance. Be sure to tighten each fuel line nut after the test, before the next fuel

line nut is loosened. Check each cylinder by this method. When a cylinder is found where the loosened fuel

line nut does not make a difference in engine performance, test the fuel injection pump and fuel injection

nozzle for that cylinder.

Temperature of an exhaust manifold port, when the engine runs at low idle speed, can also be an indication

of the condition of a fuel injection nozzle. Low temperature at an exhaust manifold port is an indication of

no fuel to the cylinder. This can possibly be an indication of an fuel injection nozzle with a defect. Extra

high temperature at an exhaust manifold port can be an indication of too much fuel to the cylinder, also

caused by an fuel injection nozzle with a defect.

The most common defects found with the fuel injection nozzle are:

1. Carbon on tip of the fuel injection nozzle or in the fuel injection nozzle orifice.

2. Steel wire brushing of fuel injection tip.

3. Orifice wear.

4. Dirty fuel injection nozzle screen.

Testing Fuel Injection Nozzles

Testing of the fuel injection nozzles must be done off the engine. Perform the following tests using the

5P4150 Nozzle Testing Group to determine if nozzle performance is acceptable:

Valve Opening Pressure Test

Flush The Nozzle

Tip Leakage Test

Orifice Restriction Test

Bleed Screw Leakage Test

17 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Refer to Special Instruction SEHS7292, for operation of the 5P4150 Nozzle Testing Group.

Fuel Injection Lines

Fuel Injections Lines With Support Bracket

(1) A vertical line through the number one fuel injection pump.

The nuts that hold a fuel injection line to a fuel injection pump must be tightened to the correct torque. If the

nut is loose, fuel will leak from the connection. If the nut is tightened too tight, the inside diameter of the

line will become smaller and cause a restriction to the flow of fuel in the line. Use a torque wrench and a

5P0144 Fuel Line Socket to tighten the fuel injection line nuts to 42 ± 7 N·m (31 ± 5 lb ft).

Be sure the fuel injection line clamps are installed in the correct

location. Incorrectly installed clamps may allow the fuel injection lines

to vibrate and become damaged. The damaged lines may leak and cause

a fire.

18 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

NOTE: Align brackets in position to fuel lines such that when the fasteners are tightened no strain will be

added to the fuel lines while tightening fasteners.

Checking The Plunger And Lifter Of An Fuel Injection Pump

NOTE: There are no different size spacers available to adjust the timing dimension of the fuel injection

pumps. If the pump plunger or the lifter is worn, they must be replaced. Because there is no adjustment to

the timing dimension possible, there is No Off Engine Lifter Setting Procedure.

When there is too much wear on the fuel injection pump plunger, the lifter may also be worn and there will

not be good contact between the two parts. To stop fast wear on the end of a new plunger, install new lifters

in the place of the lifters that have wear.

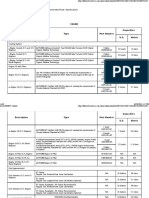

Wear Between Lifter And Plunger

Figure A illustrates the contact surfaces of a new pump plunger and new lifter. In Figure B the pump plunger and lifter have worn

considerably. Figure C shows how the flat end of a new plunger makes poor contact with a worn lifter, resulting in rapid wear to both

parts.

A fuel injection pump can have a good fuel flow coming from it but not be a good pump because of slow

timing that is caused by wear on the bottom end of the plunger. When making a test on a pump that has been

used for a long time, use a micrometer and measure the length of the plunger. If the length of the plunger is

shorter than the minimum length (worn) dimension given in the chart install a new pump.

Look for wear at the top part of the plunger. Check the operation of the plunger according to the instructions

for the Fuel Injection Test Bench.

Removal And Installation Of Fuel Injection Pumps

19 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

This procedure can be done with the fuel injection pump housing on or off the engine.

Before the 6V7050 Compressor Group is used for the first time, or if the group has been disassembled,

make the following adjustment:

1. An fuel injection pump that is to be used for this adjustment (or one that is to be removed or installed)

must have another fuel injection pump installed next to it. The second fuel injection pump serves as the

compressor mounting stud. If there are not two fuel injection pumps next to each other, install two fuel

injection pumps without the lifter springs. See Installation Of Fuel Injection Pumps for the correct

alignment of the pump at assembly.

Adjustment of 6V7050 Compressor Group

(A) 6V7015 Clamp.

(B) Bracket assembly.

(C) 4B2046 Nut.

(D) 8T0937 Nut.

(E) 2N3476 Screw.

2. Put bracket assembly (B) over one of the pump bonnets.

3. Put the clamp ram on the center of the other fuel injection pump bonnet with 2N3476 Screw (E) in

contact with the fuel line seat.

NOTE: The 6V7015 Clamp (A) should not be locked down.

4. Install and tighten 8T0937 Nut (D).

5. Adjust screw in or out until the top of bracket assembly (B) just starts to move when the clamp ram is

locked down.

6. Tighten 4B2046 Nut (C) to hold 2N3476 Screw (E) in position.

Removal Of Fuel Injection Pumps

20 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

NOTICE

Before any parts are removed from the fuel injection pump housing,

thoroughly clean all dirt from the housing. Dirt that gets inside the

pump housing will cause much damage.

NOTE: The fuel rack must be in the zero (center) position before the fuel injection pumps can be removed

or installed. Follow Steps 1 through 5.

Fuel Injection Pump Housing

(1) Plug (rack centering pin).

(2) Cover (rack position indicator).

1. Remove plug (1) and cover (2) from the fuel injection pump housing.

Fuel Rack Against Timing Pin in the Zero Position

(3) 6V4186 Timing Pin.

2. Install the 6V4186 Timing Pin (3) in the top of the fuel injection pump housing. Make sure 6V4186

Timing Pin (3) engages in the slot of the fuel rack as shown.

Holding Fuel Rack in Zero Position

(3) 6V4186 Timing Pin.

(4) 8T9198 Bracket Assembly.

(5) 1U5426 Compressor Assembly.

21 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

3. Install 8T9198 Bracket Assembly (4) on the fuel injection pump housing. Make sure the lever of the

bracket assembly is engaged in the slot of the fuel rack.

4. Install the 1U5426 Compressor Assembly (5) all the way into the 8T9198 Bracket Assembly (4) to

compress the spring.

5. Tighten the collet on 6V4186 Bracket Assembly (4) to hold 1U5426 Compressor Assembly (5). Spring

force now holds the fuel rack against 6V4186 Timing Pin (3) in the zero position.

Fuel Injection Pump Housing

(3) 6V4186 Timing Pin.

(6) 8T5287 Wrench.

(7) 6V7050 Compressor Group.

(8) Retainer bushing.

6. Remove the fuel injection line from the pump to be removed and also the fuel injection lines on each side

of the pump to be removed.

There is spring force on the fuel injection pump plunger and barrel

assembly. Removal of retainer bushing (8) without the 6V7050

Compressor Group correctly installed can cause bodily injury.

7. Use 8T5287 Wrench (6) to loosen retainer bushing (8) one quarter turn. Do not remove the bushing at this

time.

8. Install 6V7050 Compressor Group (7) on the pump housing over 8T5287 Wrench (6). Lower the screw in

the compressor ram to the fuel line seat before the nut is tightened to hold the compressor group in position.

This centers the compressor group.

Fuel Injection Pump Housing

(3) 6V4186 Timing Pin.

(6) 8T5287 Wrench.

(7) 6V7050 Compressor Group.

(8) Retainer bushing.

22 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

9. Use 8T5287 Wrench (6) to loosen retainer bushing (8) until it is out of the threads. Slowly raise the

compressor tool handle to release the spring force.

Fuel Injection Pump Housing

(9) 8S2244 Extractor.

10. Remove the 6V7050 Compressor Group and the 8T5287 Wrench. Install 8S2244 Extractor (9) on the

fuel injection pump threads. Carefully pull the pump straight up and out of the pump housing bore. Remove

the spacer from the pump housing bore.

Be careful when an fuel injection pump is disassembled. Do not damage the surface on the plunger. The

plunger and barrel are made as a set. Do not put the plunger of one pump in the barrel of another pump. If

one part is worn, install a complete new pump assembly. Be careful when the plunger is put into the bore of

the barrel. When fuel injection pumps are removed from the fuel injection pump housing, keep the parts

together so they can be installed in the same location in the housing.

Installation Of Fuel Injection Pump

NOTICE

The fuel rack Must Be In The Center Position before the correct

installation of an fuel injection pump is possible.

1. Put the fuel rack in the center position. See Removal of Fuel Injection Pumps for this procedure.

Fuel Injection Pump Installation

(1) 8S2244 Extractor.

(2) Pump barrel.

(3) Gear segment.

2. Put 8S2244 Extractor (1) on the threads of the fuel injection pump.

3. Make sure the lifter for the pump to be installed is at the bottom of its travel (cam lobe is at its lowest

point).

23 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

4. Put the groove in pump barrel (2) in alignment with the slot (groove) in gear segment (3).

5. Be sure the spacer is in position in the pump housing bore.

Fuel Injection Pump Housing (Top View)

(4) Pin.

(5) Dowel.

6. Carefully install the pump straight down into the pump housing bore.

NOTE: The slot (groove) in gear segment (3) must be in alignment with pin (4) in the side of the lifter and

the groove in pump barrel (2) must be in alignment with dowel (5) in the housing bore.

Fuel Injection Pump Housing

(6) 6V4186 Timing Pin.

(7) 8T5287 Wrench.

(8) 6V7050 Compressor Group.

(9) Retainer bushing.

7. Remove the 8S2244 Extractor. Put the O-ring seal, retainer bushing (9) and 8T5287 Wrench (7) in

position on the top of the fuel injection pump. Install 6V7050 Compressor Group (8).

8. Slowly move the handle of the 6V7050 Compressor Group down to push the fuel injection pump into the

bore.

NOTICE

The handle of the 6V7050 Compressor Group must move smoothly

down to the lock position. Do not force the handle if it stops. If the

handle does not move smoothly down to the lock position, raise the

handle, remove the 6V7050 Compressor Group, and repeat Steps 3

through 8.

9. Put the O-ring seal in position in the pump housing bore. Use the 8T5287 Wrench to install the retainer

bushing.

24 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

10. Remove the 6V7050 Compressor Group. Tighten the retainer bushing to 270 ± 13 N·m (200 ± 10 lb ft).

NOTICE

The bushing must be tightened to the correct torque. Damage to the

housing will be the result if the bushing is too tight. If the bushing is

not tight enough, the pump will have leakage.

11. Install the fuel injection lines to the pump and tighten to 42 ± 7 N·m (31 ± 5 lb ft). See Fuel Injection

lines in this section for more information.

Be sure the fuel injection line clamps are installed in the correct

locations. Incorrectly installed clamps may allow the fuel injection lines

to vibrate and become damaged. The damaged lines may leak and cause

a fire.

The following steps can be used to insure correct installation and operation of any number of individual

replacement pumps on most machine engines.

12. Remove or activate the shutoff solenoid if it is installed in the rack actuator housing.

NOTE: The manual shutoff override lever can be used to move the shutoff solenoid out of the way so the

fuel rack can be moved.

NOTE: To check the installation of a replacement pump, it is necessary to have full rack travel in both

directions. The actual zero location of the timing pin and rack are not used to check the installation of

replacement pumps.

Check Fuel Rack Travel

(6) 6V4186 Timing Pin.

(10) 8T9198 Bracket Assembly.

13. Remove the compressor and 8T9198 Bracket Assembly (10) from the fuel injection pump housing.

25 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Illustration 1. Correct installation in full load position.

14. Raise the timing pin and move the rack to the full load position. Use finger pressure to be sure the rack

is at full rack travel (beyond full load position).

15. If the fuel injection pump installation is correct, when the timing pin is lowered it will be on the rack as

shown in Illustration 1.

Illustration 2. Incorrect installation, full load position restricted by less than full rack travel.

16. If the fuel injection pump installation is not correct, the timing pin position will be approximately 1.91

mm (.075 in) toward the slot for each tooth position out of alignment (see Illustration 2). This will reduce

fuel rack travel, even though it may not affect the rack setting, because of additional rack travel at static

conditions.

26 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Illustration 3. Correct installation at no load (fuel off) position.

17. Raise the timing pin and move the rack to the no load (fuel off) position.

18. If the fuel injection pump installation is correct, when the timing pin is lowered it will be in the timing

slot, less than 1.91 mm (.075 in) from the rear face of the slot as shown in Illustration 3.

Illustration 4. Incorrect installation, fuel shutoff position restricted by less than full rack travel.

19. If the fuel injection pump installation is not correct, the timing pin position will be more than 1.91 mm

(.075 in) from the rear face of the timing slot in the rack (see Illustration 4).

20. When all fuel injection replacement pumps are installed correctly remove 6V4186 Timing Pin (6) from

the fuel injection pump housing and install the plug.

21. Install the gasket and cover over the fuel rack on the side of the fuel injection pump housing.

NOTICE

27 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

If one or more of the fuel injection pumps have been installed wrong, it

is possible for the engine to run out of control when started. When any

of the fuel injection pumps have been removed and installed with the

fuel injection pump housing on the engine, take the precautions (steps)

that follow to stop the engine if it starts to overspeed (run out of

control).

Turbocharger Air Inlet Opening

a. Remove the air cleaner pipe from the turbocharger leaving the air inlet open as shown.

b. Set the governor control at low idle. No pressure applied to the accelerator pedal (up).

Stopping The Engine

c. Start the engine, and if engine starts to overspeed (run out of control), put a steel plate over the air inlet as

shown to stop the engine.

Be careful when plate is put against air inlet opening. Due to excessive

suction, the plate can be pulled quickly against air inlet opening. To

avoid crushed fingers, do not put fingers between plate and air inlet

opening.

Finding Top Center Compression Position For No. 1 Piston

28 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

No. 1 piston at top center (TC) on the compression stroke is the starting point of all timing procedures.

NOTE: On some engines there are two threaded holes in the flywheel. These holes are in alignment with

the holes with plugs in the left and right front of the flywheel housing. The two holes in the flywheel are at a

different distance from the center of the flywheel so the timing bolt cannot be put in the wrong hole.

Locating Top Center (Left Side of Engine)

(1) Timing bolt.

(2) Location (timing bolt).

(3) Storage location.

Locating Top Center (Right Side of Engine)

(4) Location (timing bolt).

1. The timing bolt (1) is kept in storage location (3) and can be installed in either the left side of the engine

at location (2) or in the right side of the engine at location (4). Remove bolts and cover from flywheel

housing. Remove the plug from the timing hole in the flywheel housing.

Using 9S9082 Engine Turning Tool

(1) Timing bolt.

(5) 9S9082 Engine Turning Tool.

2. Put timing bolt (1) [long bolt that holds cover on the flywheel housing] through the timing hole in the

flywheel housing. Use the 9S9082 Engine Turning Tool and 1/2 inch drive ratchet wrench to turn the engine

flywheel in the direction of normal engine rotation until the timing bolt engages with the threaded hole in

the flywheel.

NOTE: If the flywheel must be turned opposite normal engine rotation approximately 45 degrees. Then

turn the flywheel in the direction of normal rotation until the timing bolt engages with the threaded hole.

The reason for this procedure is to make sure the play is removed from the gears when the No. 1 piston is

29 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

put on top center.

3. Remove the front valve cover from the engine.

Checking No. 1 Inlet And Exhaust Valves

4. The inlet and exhaust valves for the No. 1 cylinder are closed if No. 1 piston is on the compression stroke

and the rocker arms can be moved by hand. If the rocker arms can not be moved and the valves are slightly

open the flywheel must be turned again. Remove the timing bolt and turn the flywheel in the direction of

normal engine rotation 360 degrees until the timing bolt can be installed. The No. 1 piston is now in the top

center compression position.

Checking Engine Timing With 8T5300 Timing Indicator Group

And 8T5301 Diesel Timing Adapter Group

8T5300 Timing Indicator Group

(1) 8T5250 Engine Timing Indicator.

(2) 5P7366 Cable Assembly.

(3) 6V2197 Magnetic Transducer.

(4) 5P7362 Cable.

(5) 6V2199 and 6V3093 Transducer Adapters.

(6) 8K4644 Fuse.

The 8T5300 Timing Indicator Group must be used with the 8T5301 Diesel Timing Adapter Group.

30 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

8T5301 Diesel Timing Adapter Group

(7) 5P7437 Adapter.

(8) 6V2198 Cable.

(9) 5P7436 Adapter.

(10) 6V7910 Transducer.

(11) 5P7435 Adapter.

(12) 6V3016 Washer.

A high pressure fuel line must be disconnected. To avoid personal injury

or fire from fuel spray, the engine must be stopped before the fuel line is

disconnected.

When checking the dynamic timing on an engine without a mechanical advance, Caterpillar recommends

that the service personnel calculate and graph the dynamic timing on a worksheet like SEHS8140. These

worksheets are available in pads of 50 sheets, order one SEHS8140. See Special Instruction SEHS8580, for

information required to calculate the timing curve.

After the timing values are calculated and plotted, the dynamic timing should be checked with the 8T5300

Engine Timing Indicator Group. To do this, the service personnel must operate the engine from 1000 rpm

(base rpm) to high idle and from high idle to 1000 rpm (base rpm). Unstable readings are often obtained

below 1000 rpm. They must record the dynamic timing at each 100 rpm and at the specified speeds during

both acceleration and deceleration. Then they should plot the results on the worksheet.

Inspection of the plotted value will show if the timing is within specifications. See Special Instruction

SEHS8580 for information required to calculate the timing.

1. See the Engine Information Plate for the performance specification number and make reference to the

TMI (Technical Marketing Information) or Fuel Setting And Related Information Fiche for the correct

timing specifications to use.

2. Make reference to Operation Instructions inside the lid of the 8T5300 Timing Indicator (1) or Special

Instruction SEHS8580 for complete instructions and calibration.

The engine must be stopped before the timing indicator group is

installed. A high pressure fuel line must be disconnected and a probe

must be installed against the flywheel.

31 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Transducer In Position (Typical Example)

(10) Injection transducer.

(13) Fuel injection line (for No. 6 cylinder).

3. Loosen all fuel line clamps that hold No. 1 fuel injection line, and disconnect fuel injection line (13) for

the No. 1 cylinder at the fuel injection pump. Slide the nut up and out of the way. Put 5P7436 Adapter (9) in

its place and turn adapter (9) onto the fuel pump bonnet until the top of the bonnet threads are

approximately even with the bottom of the "window" in the adapter.

4. Put the 5P7435 Tee Adapter (11) on the injection transducer (10), and put the end of the 5P7435 Tee

Adapter (11) in the "window" of the 5P7436 Adapter (9).

5. Put fuel injection line (13) on top of 5P7435 Tee Adapter (11). Install 5P7437 Adapter (7), and tighten to

42 N·m (31 lb ft).

6. Remove the plug from the flywheel housing. Install transducer adapter (5) into the hole the plug was

removed from. Tighten only a small amount.

Transducer In Position

(3) Magnetic transducer.

(5) Transducer adapter.

7. Push magnetic transducer (3) into the pipe adapter (5) until it makes contact with the flywheel. Pull it

back out 1.5 mm (.06 in) and lightly tighten the knurled locknut.

8. Connect the cables from the transducers to Engine Timing Indicator (1). Calibrate and make adjustments.

For calibration procedure, make reference to Special Instruction SEHS8580.

9. Start the engine, and let it reach operating temperature. Then run the engine at approximately one-half

throttle for eight to ten minutes before measuring timing.

10. Run the engine at the speeds required, and record the timing indicator readings. If the engine timing is

not correct, make reference to Checking Engine Timing By Timing Pin Method for static adjustment of the

fuel injection pump drive. If the timing advance is not correct, do the steps that follow to make an

adjustment.

32 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Typical Illustration Front Of Engine

(14) Access cover (for governor and fuel pump drive group).

11. Stop the engine and remove access cover (14).

Typical Illustration Automatic Timing Advance Unit

(15) Locknut.

(16) Screw.

(17) Screw.

(18) Setscrew [located inside of screw (17)].

12. If the adjustments are being made because of an engine horsepower rating change of for replacement of

parts, start with an initial setting as follows:

a. Adjustment screw (16) must extend out from the retainer approximately 27.9 mm (1.10 in).

b. Setscrew (18) must be below the end of screw (17) approximately 17.78 mm (.700 in) on an

engine with 11 degrees timing advance and 19.05 mm (.750 in) on an engine with 10 degree

timing advance.

13. To adjust the speed where the fuel injection timing starts to advance, loosen locknut (15) and turn screw

(16). Turn screw (16) clockwise to increase the speed where the timing advance starts. Tighten locknut (15)

to a torque of 70 ± 15 N·m (50 ± 11 lb ft).

(19) 6V2106 Tool Group.

NOTE: If the speed where timing advance starts is adjusted, the speed where the automatic timing advance

should also be adjusted.

14. To adjust the speed where the fuel injection automatic timing advance stops, loosen locknut (15) and

turn setscrew (18) clockwise to decrease the stop speed. Tighten locknut (15) to a torque of 2.25 ± 0.25 N·m

33 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

(20 ± 2 lb in). 6V2106 Tool Group (19) [part of 6V6070 Governor Adjusting Tool Group] can be used to

make this adjustment.

15. After each adjustment, install access cover (14) and recheck the automatic timing advance with the

8T5300 Timing Indicator Group.

16. If the automatic timing advance unit cannot be adjusted to operate within the correct range, or the

operation of the unit is not smooth, repair or replace the automatic timing advance unit (governor and fuel

pump drive group).

Checking Engine Timing By Timing Pin Method

Mechanical Timing Advanced Units

1. Put No. 1 piston at top center on the compression stroke. Make reference to Finding Top Center

Compression Position For No. 1 Piston. Remove the timing bolt from the flywheel and use 9S9082 Engine

Turning Tool to rotate the crankshaft clockwise 45 degrees as seen from the flywheel end of the engine.

Fuel Injection Pump

(1) Plug (timing pin hole).

2. Remove plug (1) from the fuel injection pump housing.

Timing Pin Installed

(2) 6V4186 Timing Pin.

3. Install 6V4186 Timing Pin (2) in the fuel injection pump housing as shown. Slowly rotate the crankshaft

counterclockwise (as seen from the flywheel end of the engine) until 6V4186 Timing Pin (2) goes into the

slot in the fuel pump camshaft.

34 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

4. Put the timing bolt in the timing hole in the flywheel housing. Rotate the crankshaft counterclockwise (as

seen from the flywheel end of the engine) until the fuel pump camshaft is tight against 6V4186 Timing Pin

(2). This removes gear clearance from the drive train. If the bolt can be installed in the timing hole in the

flywheel, the timing of the fuel injection is correct.

Front Of Engine

(3) Access cover (for governor and fuel pump drive group).

5. If the timing bolt does not go into the timing hole in the flywheel, the timing is not correct. Do the steps

that follow to adjust the fuel injection pump timing.

a. Remove access cover (3).

Governor And Fuel Pump Drive Group

(3) Access cover.

(4) Bolts.

b. Loosen eight bolts (4). With 6V4186 Timing Pin (2) installed and the timing bolt removed,

turn the flywheel clockwise (opposite the direction of engine rotation) a minimum of 45

degrees. The reason for this step is to remove play from the timing gears when the engine is put

on top center (TC).

c. Tighten two bolts (4) 180 degrees apart, evenly to a torque of 3 N·m (27 lb in). This puts a

slight clamping force on the gear for the next step.

d. Turn the flywheel slowly in the direction of engine rotation until the timing bolt can be

35 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

installed in the flywheel. The number one piston is now at top center (TC).

NOTE: The crankshaft can be turned from the front of the engine by using a wrench on the

vibration damper bolts, if necessary.

e. Tighten eight bolts (4) to a torque of 55 ± 10 N·m (40 ± 7 lb ft). Remove the timing bolt from

the flywheel and 6V4186 Timing Pin (2) from the fuel injection pump housing.

6. Turn the flywheel clockwise (opposite the direction of normal engine rotation) a minimum of 45 degrees.

Now, turn the flywheel in the direction of engine rotation until 6V4186 Timing Pin (2) drops into slot of

pump camshaft. Now turn the flywheel more, in the direction of normal engine rotation, until all gear

clearance is removed from the drive train. Check to see that the timing bolt will go into the flywheel.

7. If the timing is not correct, do the procedure of Steps 5b through 5e again.

8. If the timing is correct, remove the timing bolt from the flywheel and timing pin from the fuel injection

pump housing. Install access cover (3) and plug (1).

Automatic Timing Advance Units

1. Put No. 1 piston at top center on the compression stroke. Make reference to Finding Top Center

Compression Position For No. 1 Piston. Remove the timing bolt from the flywheel and use 9S9082 Engine

Turning Tool to rotate the crankshaft clockwise 45 degrees as seen from the flywheel end of the engine.

NOTE: The crankshaft can be turned from the front of the engine by using a wrench on the vibration

damper bolts, if necessary.

Front Of Engine (Typical Examine)

(1) Access cover [for automatic timing advance (governor and fuel pump drive group)].

2. Remove timing advance access cover (1).

36 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Automatic Timing Advance Unit

(2) Retainer.

(3) Nuts.

(4) Bolts.

3. Loosen nuts (3) and remove retainer (2) and the flyweight spring from the timing advance unit. Make

sure that the flyweight spring does not fall out and get lost.

NOTE: Do not loosen the locknuts and adjustment screws in the end of retainer (2). If the adjustment

screws are moved from their original settings, the dynamic engine timing must be set by using the 8T5300

Timing Indicator Group after the static timing pin procedure is completed.

4. Loosen bolts (4) that hold the timing advance unit together.

5. Tighten bolts (4) to a torque of 1.8 ± 0.3 N·m (16 ± 3 lb in). This puts a slight clamping force on the fuel

pump drive gear to hold it in position. Also, the fuel pump camshaft can be turned or held in position

separate from the engine crankshaft. The drive gear is allowed to slip.

Fuel Injection Pump

(5) Plug (timing pin hole).

6. Remove plug (5) from the fuel injection pump housing.

Timing Pin Installed

(6) 6V4186 Timing Pin.

7. With No. 1 piston 45 degrees before Top Center, slowly rotate the crankshaft counterclockwise (as seen

from the flywheel end of the engine) until 6V4186 Timing Pin (6) goes into the slot in the fuel pump

camshaft and the timing bolt can be installed in the timing hole in the flywheel.

37 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Install Holding Tool

(3) Nut.

(7) 1U8271 Holding Tool.

8. Install the 1U8271 Holding Tool (7) and push the timing advance unit piston back as follows:

a. Turn the knurled nuts on the holding tool out until each stud is 6.4 mm (.25 in) below the

surface of the nut.

b. Put 1U8271 Holding Tool (7) in position on the cap screws that hold retainer (2). Install and

tighten nuts (3) finger tight. Make sure that the four tangs on the loose inner ring of the holder

tool are positioned at the corners of the four flyweights and flyweights are free to move.

c. Tighten the four large knurled nuts evenly by hand until a positive stop is felt. No external

component contact can be seen. The positive stop is the timing advance piston making contact

at the bottom of its travel. This step makes sure that the timing advance unit is in its most

retarded timing position.

Tighten Drive Bolts And Remove Tooling

(4) Bolts.

9. Tighten the four bolts (4) to a torque of 55 ± 7 N·m (41 ± 5 lb ft).

10. Remove holding tool from the automatic timing advance unit.

11. Remove the timing pin bolt from the flywheel and 6V4186 Timing Pin (6) from the fuel injection pump

housing.

12. Install the flyweight spring and retainer (2) on the timing advance unit. Make sure the spring is in its

correct position and tighten the four nuts to hold the retainer in position.

13. Install access cover (1) on the timing gear housing and plug (5) in the fuel injection pump housing.

14. If necessary, check the dynamic timing of the engine with the 8T5300 and 8T5301 Tool Groups. Make

reference to Special Instructions SEHS8580, for the correct installation and operation of the tool groups.

Also, see Checking Engine Timing With 8T5300 Timing Indicator Group And 8T5301 Diesel Timing

Adapter Group for the procedure to check the dynamic timing of the engine.

Fuel Setting Procedure

38 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

6V6070 Governor Adjusting Tool Group

NOTE: If the 8T1000 Electronic Position Indicator Group is used, make reference to Special Instruction

SEHS8623 for information on the use of the tool group.

The fuel setting procedure can be used with the fuel injection pump and governor on or off the engine.

Fuel Injection Pump And Governor

(1) Cover (rack position indicator).

(2) Plug (rack centering pin).

1. Remove plug (2) and cover (1) from the fuel injection pump housing.

Indicator And Centering Pin Installed

(3) 6V4186 Timing Pin.

(4) 6V6109 Bracket Assembly.

(5) 2A0762 Bolt (1/4-20 NC X .625 in).

(6) 8H9178 Ground Body Bolt (1/4-20 NC X 1.00 in).

(7) 5P4814 Collet.

(8) 6V6106 Dial Indicator.

39 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

NOTE: If the 8T1000 Position Indicator Group is used instead of the dial indicator, use Step 3 for the

installation of the probe.

2. Install the rack position indicator as follows:

a. Install the 5P4814 Collet (7) on the 6V6109 Bracket Assembly (4).

Slot In Fuel Injection Pump Rack

(9) Slot.

b. Position the indicator arm in approximately the middle of its travel to make sure that it will engage

in slot (9) in the rack. Put 6V6109 Bracket Assembly (4) in position on the fuel injection pump

housing.

c. Install 8H9178 Ground Body Bolt (6) first. Then install 2A0762 Bolt (5).

d. Be sure the indicator arm moves freely.

e. Put 6V6106 Dial Indicator (8) in position in 5P4814 Collet (7).

f. Put the 9S8903 Contact Point on the 6V2030 Extension and install on 6V6106 Dial Indicator (8).

NOTE: The 9S8903 Contact Point will not go through the collet and must be assembled after the

indicator stem has passed through the collet.

g. Tighten 5P4814 Collet (7) just enough to hold the dial indicator.

3. Install the rack position probe as follows:

a. Install the 5P4814 Collet (7) on the 6V6109 Bracket Assembly (4).

b. Position the indicator arm in approximately the middle of its travel to make sure that it will engage

in slot (9) in the rack. Put 6V6109 Bracket Assembly (4) in position on the fuel injection pump

housing.

c. Install 8H9178 Ground Body Bolt (6) first. Then install 2A0762 Bolt (5).

d. Be sure the indicator arm moves freely.

e. Put probe (A) in position in 5P4814 Collet (7).

f. Put the 9S8903 Contact Point on the 6V2030 Extension and install on probe (A).

NOTE: The 9S8903 Contact Point will not go through the collet and must be assembled after the

indicator stem has passed through the collet.

g. Adjust probe (A) in 5P4814 Collet (7) so that the shaft can be moved through the entire

measurement range without reaching the end of the shaft travel. Tighten the collet.

40 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Probe And Centering Pin Installed

(3) 6V4186 Timing Pin.

(4) 6V6109 Bracket Assembly.

(5) 2A0762 Bolt (1/4-20 NC X .625 in).

(6) 8H9178 Ground Body Bolt. (1/4-20 NC X 1.00 in).

(7) 5P4814 Collet.

(A) 8T1002 Probe.

Position Fuel Injection Pump Rack

(10) 6V6151 Adapter.

(11) 6V7942 Hook

4. Remove the shutoff solenoid, if equipped, or cover and install the 6V6151 Adapter (10).

5. Move the governor control lever to the "LOW IDLE" position (rotate governor shaft counterclockwise).

6. Install the 6V4186 Timing Pin (3) in the top of the fuel injection pump housing. Push the timing pin in

until contact with the fuel rack is made.

7. Use 6V7942 Hook (11) through 6V6151 Adapter (10) to push the sleeve and rack to the "SHUTOFF"

position. Make sure 6V4186 Timing Pin (3) engages in slot (9).

Push Rack To Shutoff

(11) 6V7942 Hook.

(12) Servo valve.

8. Move the governor control lever to the "FULL LOAD" position (rotate governor shaft clockwise) and

fasten it in this position.

41 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Pull Rack Against Timing Pin

(11) 6V7942 Hook.

(12) Servo valve.

9. Use the 6V7942 Hook (11) to pull the sleeve and rack [through servo valve (12)] against the timing pin.

Fuel Rack Against Timing Pin

10. Adjust the 6V6106 Dial Indicator (8) in the collet to zero and tighten the collet. Make sure all needles of

the indicator are on zero.

NOTE: If the Electronic Position Indicator Group is used, press the ZERO switch on the front panel. This

sets the display to zero.

11. Remove the 6V4186 Timing Pin (3), 6V7942 Hook (11) and release the governor control lever.

6V7941 Compressor Assembly

(13) Rod.

12. Turn rod (13) in the 6V7941 Compressor Assembly until the knob is approximately 25.4 mm (1.00 in)

away from the compressor body.

NOTE: The 6V7941 Compressor Assembly is used to compress the overfueling spring through the linkage.

The overfueling spring must be compressed to get an accurate fuel setting measurement.

42 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Install The 6V7941 Compressor Assembly

(10) 6V6151 Adapter.

(14) 6V7941 Compressor Assembly.

13. Install 6V7941 Compressor Assembly (14) in 6V6151 Adapter (10) as shown.

Static Fuel Setting

(13) Rod (part of 6V7941 Compressor Assembly).

(15) 8T0500 Circuit Tester.

(16) Insulated terminal.

14. Fasten the clip end of the 8T0500 Circuit Tester (15) to insulated terminal (16), and put the other end to

a good electrical ground.

NOTE: If the Electronic Position Indicator Group is used, the built-in continuity tester can be used instead

of 8T0500 Circuit Tester (15). Use the built-in tester only for static readings.

15. Hold the governor control lever in the "FULL LOAD" position (rotate governor shaft clockwise).

16. Turn rod (13) of compressor assembly in (clockwise) until the light in 8T0500 Circuit Tester (15) goes

off and the dial indicator hands move an additional 2 mm in the negative (-) direction after the light goes out

(2 complete revolutions of the large needle on the dial indicator).

NOTICE

DO NOT turn the rod any further in if the rod begins to tighten.

Damage to the governor can occur if the rod is turned in further.

NOTE: The static fuel setting (Step 18) and the static full torque setting (Step 19) must be within ± .25 mm

of the setting on the Engine Information Plate. If the setting is within ± .25 mm an adjustment is not

necessary. If the Engine Information Plate is gone or the Full Torque Setting is not on the Engine

Information Plate, see TMI (Technical Marketing Information) or Fuel Setting And Related Information

Fiche for the correct settings.

43 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Adjustment Of Governor

(17) Adjustment screw cover.

17. Remove adjustment screw cover (17) from the rear of the governor housing.

18. Slowly turn rod (13) out (counterclockwise) until the circuit tester light just comes on. This is the static

fuel setting. See the Engine Information Plate or the TMI (Technical Marketing Information) or Fuel Setting

And Related Information Fiche for the correct static fuel setting.

NOTE: When the rod is turned out, there can be a small initial movement of the dial indicator hands, then,

they will stop moving while the rod is turned out for approximately another 11/2 turns. Now the indicator

hands will begin to move again and will follow the turning of the rod until the setting is reached. It is

important that the rod be turned slowly so that the rack can follow the governor components.

NOTE: If rod (13) is turned out too fast, a wrong measurement can be read on the dial indicator as the light

comes on. Repeat Steps 16 and 18 to make sure the correct measurement is taken.

19. Continue to turn the rod out until the indicator hand stops moving. Then turn the rod out two additional

turns. Push in on the rack stop collar to make sure it is in the correct position. The new reading on the

indicator is the full torque static setting.

Example:

Static Fuel Setting = 2.18 mm

Full Torque = 3.18 mm

This means the torque rise setting is 1.00 mm. An addition of the fuel setting and the torque rise setting is

not necessary.

20. See the Engine Information Plate or the TMI (Technical Marketing Information) for the correct static

full torque setting.

21. Determine how much the settings will have to be changed (see examples). Use the chart that follows to

determine how far the adjusting screws must be turned.

44 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Since "desired setting" is higher than "actual reading," turn adjusting screw out (counterclockwise)

approximately 1/4 turn. Recheck the new setting and readjust if necessary.

Since "desired setting" is lower than "actual reading," turn the adjusting screw in (clockwise) approximately

1 1/8 turns. Recheck the new setting and readjust if necessary.

45 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

Negative numbers work differently than positive numbers. If one number (-1.25) has a large digital value

than another one (-1.05), the first number (-1.25) is actually less than the other one. Therefore, in this

example the "desired setting" is lower than the "actual reading". Turn the adjusting screw in (clockwise)

approximately 1/4 turn. Recheck the new setting and readjust if necessary.

The "desired setting" is higher than the "actual reading". Turn the adjusting screw out (counterclockwise)

approximately 11/8 turns. Recheck the new setting and readjust if necessary.

The "desired setting" is lower than the "actual reading". Turn the adjusting screw in approximately 2 7/8

turns.

The "desired setting" is higher than the "actual reading". Turn the adjusting screw out approximately 2 7/8

turns.

Adjustment Of Fuel Setting

46 of 102 3/21/18, 4:25 PM

D8R TRACK-TYPE TRACTOR 9EM00001-UP (MACHINE) POW... https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?retu...

(18) Fuel setting screw.

(19) 6V2106 Rack Adjustment Tool Group.

Adjustment Of Full Torque Setting

(19) 6V2106 Rack Adjustment Tool Group.

(20) Torque rise setting screw.

NOTE: If you are working from the side of the engine and cannot see the adjusting screws, use the outer

edge of the opening in the governor housing to guide the 6V2106 Tool Group onto the fuel setting screw.

Use the inner edge of the opening to guide the 6V2106 Tool Group onto the full torque setting adjustment

screw.

22. If both settings are to be increased, turn torque rise adjustment screw (20) out (counterclockwise) the