The Design Temperature of Flare Systems

The Design Temperature of Flare Systems

Uploaded by

Qayyum KhanCopyright:

Available Formats

The Design Temperature of Flare Systems

The Design Temperature of Flare Systems

Uploaded by

Qayyum KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

The Design Temperature of Flare Systems

The Design Temperature of Flare Systems

Uploaded by

Qayyum KhanCopyright:

Available Formats

The design temperature of flare systems

A key objective when setting flare system design conditions is to maintain

the integrity of the system during fire relief

PAUL DAVID

Paul David Process Ltd

A

great deal has been writ- process engineer, faced with This can lead to the somewhat

ten about the minimum tables of relief case data, has to uncomfortable result that the

design temperature place a number in the box on PRV fire case operating temper-

of flare and blow-down sys- the line list that says ‘Design ature is higher than its design

tems because cold tempera- Temperature’. It is a number temperature.

tures can cause brittle failure or for which he or she will be held If during the fire the vessel

over-stressing of flare piping. accountable. PRV opens to relieve vapour,

Less has been written about set- The design temperature of the temperature of the fluid

ting the maximum design tem- process equipment is usually entering the flare system may

perature of flare system piping. the higher of: the maximum be much higher than the ves-

American Petroleum Institute normal operating temperature sel design temperature. Such

(API) Standard 521,1 which is plus a margin (typically of the a possibility gives rise to the

used throughout the indus- order of 25°C); or the highest question: should the design

try by process engineers, gives temperature expected during temperature of the flare system

only general guidance on how start-up, shutdown or upset. be higher than the design tem-

to approach the task of setting Upset conditions include the perature of the vessel it serves?

the (mechanical) design tem- operation of the pressure relief A fire on a hydrocarbon pro-

perature. The standard advises valve and for equipment con- cessing unit usually means

that the extremes of temper- taining a saturated liquid the that a loss of containment

ature of the fluids entering temperature is higher at relief has already occurred. When

the header should be consid- pressure than at normal pres- a vessel containing hydrocar-

ered, heat transfer analysis sure. The selection of relief bon is subject to heat input

may be performed, it is com- valve body and flange rat- from a major fire, further fail-

mon to exclude the fire case, ing are normally based on the ure (for instance at the vessel

and careful analysis is required. equipment design conditions. flanges) should not be unex-

There is considerable scope The fire contingency is not pected. Although this results

for interpretation by individ- normally considered when set- in an escalation of the fire, the

uals and companies of how ting the design temperature incident is still contained in the

this is to be implemented. The of the equipment or its associ- same plant area.

author’s experience is that com- ated pressure relief valve (PRV). If hot vapour relief to the

pany standards differ in their The fire relief temperature for flare system causes sufficient

approach and in the level of a heavy hydrocarbon mixture, stress at any point in the flare

detail they offer, sometimes with a wide boiling range, can header (by thermal expan-

giving rise to more questions be very much higher than the sion) then significant dam-

than answers. The refinery equipment design temperature. age can occur. This may cause

www.digitalrefining.com/article/1001352 PTQ Q1 2017 1

loss of containment at a loca- carbons will have very high tents since thermal cracking is

tion remote from the origi- calculated fire relief tempera- endothermic.

nal fire. The result would be a tures. The heavier the hydrocar- If the calculated fire relief

major escalation of the incident. bon and the higher the PRV set temperature is higher than

It is therefore not illogical that pressure, the higher will be the 350°C it should be treated with

parts of the flare system should relief temperature. If we take the extreme caution.

have a higher design temper- average boiling point as indica-

ature than that of the equip- tive of the temperature a vessel Vessels containing vapour

ment from which the fire relief might be expected to reach, then When vessels containing only

stream originates. However, the a distillate stream with an aver- gas or vapour are subject to

header piping in on-plot flare age boiling point of 300°C might fire heat input, very high ini-

systems is highly constrained be over 400°C at a relieving tial relieving temperatures can

(by many piping branches) and pressure of 5 barg. The design be calculated depending on

likely to be large in diameter. of the flare sub-header piping the ratio of normal operating

Setting an unreasonably high would be very challenging at to relieving pressure. In some

design temperature will result this sort of temperature. cases the calculated relief tem-

in major mechanical design Actually, the relieving tem- perature will be infeasibly high

problems. perature is unlikely to reach and failure of the vessel would

There is no industry wide 400°C and it is therefore have occurred before relief. In

practice for setting design tem- unlikely that the flare piping any case the mass relief rate is

perature based on fire case data. would ever reach this temper- likely to be low and the relief

This scenario requires careful ature. Hydrocarbons tend to relatively short lived. Failure

consideration to avoid either start cracking if the tempera- of the vessel is likely unless

an inadequate specification or ture exceeds a value of around the vessel is effectively cooled

an infeasible specification. API 350°C; if the liquid in a vessel by fire-water. In either case the

Standard 521 states that it is is boiling at 350°C it is likely relief will cease. For these rea-

common practice to exclude the that some cracking is occurring sons, relief from a vessel con-

fire relief scenario when spec- at the vessel walls. The lower taining vapour only is unlikely

ifying the design temperature molecular weight materials to heat up a significant por-

of the flare headers. It may be produced by cracking will tend tion of the flare piping and

a common practice but, in the to reduce the effective vapour is unlikely to determine the

author’s experience, it is cer- pressure of the liquid and make design temperature of the flare

tainly not ubiquitous. To con- it unlikely that the temperature system.

sider fire case for the majority will continue to rise in the way

of refinery PRVs but to ignore predicted from the feed stream What is the temperature

it when specifying the disposal boiling range. downstream of the pressure

system to which they discharge Depending on hydrocarbon relief valve?

might be considered question- type and molecular weight, it Overall, the flow through a

able. After all, a fire on an oil may well be that the hydrocar- relief valve is considered to be

refinery is a reasonably foresee- bon in the vessel will become approximately isenthalpic – the

able contingency. supercritical at the relieving nozzle flow is isentropic, but

The following sections pressure and will no longer this does not continue through-

assume that the fire case will boil. Prediction of what hap- out the valve. Therefore it is

not be ignored and consider pens inside the vessel is now usual to expect a temperature

some of the issues that will even more difficult since crack- drop across the relief valve due

therefore arise. ing will still occur (or increase to the pressure falling at con-

since the wall temperature is stant enthalpy. This is typi-

What is the fire case relieving likely to increase). The for- cally of the order of 1.5°C per

temperature? mation of light hydrocarbons bar drop across the PRV for a

Wetted wall vessels will tend to increase the crit- hydrocarbon stream.

Many refinery vessels contain- ical pressure of the mixture The flow velocity at the relief

ing wide boiling range hydro- and also cool the vessel con- valve outlet is almost always

2 PTQ Q1 2017 www.digitalrefining.com/article/1001352

higher than at the relief valve flow calculations for estimat- lower than at the PRV outlet

inlet. Rigorous flow simulators ing PRV back pressures from – heat transfer, limited by the

will indicate a further temper- the flare piping. While this is outside co-efficient, is slow. The

ature drop below the stagna- reasonable in that it results in a wall temperature in the first

tion temperature which would conservative back pressure esti- segment is also not much lower

be calculated by a process mate (for gases at above ambi- than the PRV vapour outlet

simulator at the valve outlet. ent temperature) isothermal temperature.

(Stagnation temperature is the flow calculations are not gen- As we move downstream

temperature that would occur erally suitable for estimating through the flare system, this

if the flow was brought to rest the flare temperature pro- process keeps repeating itself.

isentropically.) This additional file. Isothermal flow is equiv- The gas and wall tempera-

temperature drop will gener- alent to adiabatic flow with tures rise later (due to the

ally not amount to more than a the exponent in the equation larger upstream mass of metal

few degrees and should not be PVγ= constant set to a value of to be heated) and the steady-

accounted for in simple heat 1. For heavy hydrocarbons, the state temperature is lower (due

transfer calculations to estimate ideal gas value of γ is not much to the greater upstream heat

the wall temperature. Due to above 1, which is why the cal- transfer area). The rate of both

the velocity profile, the velocity culated temperature drop (in these effects is dependent on

of the fluid next to the wall is the absence of heat transfer) is the relief case and the system

zero and the fluid temperature usually small. geometry. However, on a typ-

at the wall would be nearer the While all these effects are ical process unit the time to

stagnation temperature than directionally ‘helpful’ for the steady state is still likely to be

the bulk flowing temperature flare system, their combined measured in minutes and the

for adiabatic flow.2 The flow effect is relatively small. steady-state temperature is

is not actually adiabatic, since When hot gases flow through likely to be well within 50°C of

heat transfer through the pipe a PRV into the flare system, the the PRV outlet temperature.

wall occurs, but the principle heat transfer from the gas to the Off-plot flare headers are

that the velocity related temper- cold pipe will initially result often of considerable length,

ature drop is not fully experi- in relatively rapid cooling of are designed with considerable

enced at the wall remains. the hot gas. The heat transfer flexibility, and have far fewer

As vapour flows through coefficient between the flow- connections. They are down-

pipe of constant diameter, its ing gas stream and metal is stream of the sub-header, often

pressure will fall and its veloc- likely to be limited by the foul- downstream of a large knock-

ity will increase – this results ing factor (refinery flare lines out drum, and the header itself

in a reduction in tempera- are typically heavily scaled). has considerable mass and rel-

ture. This effect may briefly Nevertheless the inside coeffi- atively large heat transfer area.

be reversed when a flow from cient will be well over an order All the considerations for the

a small pipe enters a larger of magnitude greater than the sub-header apply but, for the

header, causing the velocity to outside coefficient and this off-plot header as a whole, the

reduce. Any fall in tempera- results in the pipe wall heating rate of temperature rise will

ture due to velocity increase in quickly. Since the outside coef- be significantly slower and the

the flare system will normally ficient is very low, the steady- steady-state temperature will

be less than 10°C for heavy state pipe wall temperature is also be lower.

hydrocarbons at typical back quite close to the relief stream

pressures. Again, care should temperature. Near the PRV, What is the hazard?

be taken in accounting for this the steady-state temperature Process engineers are accus-

temperature drop – the fluid will be reached within minutes. tomed to think of the flanges as

temperature close to the wall Once the steady-state tempera- the weak points in piping sys-

would be higher than the bulk ture is reached in the pipe seg- tems and most of us are quite

temperature for adiabatic flow. ment just downstream of the capable of assessing their pres-

Note: API Standard 521 recom- PRV, the gas temperature into sure-temperature rating. For

mends the use of isothermal the next segment is not much flare sub-headers with multiple

www.digitalrefining.com/article/1001352 PTQ Q1 2017 3

branches, the thermal expan- However, 350°C would be a essary to be careful with this

sion of the header can cause very high design temperature approach – the fluid flow and

stresses for which the flange for the process unit flare sub- heat transfer in the flare system

pressure-temperature rating is header or downstream piping can be modelled with rigour

not directly relevant. It is the and refinery headers gener- but the process engineer should

temperature of the pipe wall ally have design temperatures question whether the model

(causing thermal growth) that lower than this. There are sev- of the process vessel, during

is important, not necessarily eral reasons for this, including the fire, is equally rigorous.

the temperature of the flanges. those that have been discussed The calculated fire case piping

Resultant over-stresses, which above: metal temperature is used by

might occur due to fire relief, • There will be some heat loss/ the stress engineer to ensure the

can be in the sub-header or one temperature drop as the vapour integrity of the flare system and

of the branches and can only be flows through the PRV and a suitable mechanical design

predicted by a full stress anal- flare piping temperature is back calculated.

ysis. This stress analysis will • If the relief valve opens inter- All short-term overstress allow-

reflect the fact that only part of mittently then flare piping ances in the relevant piping

the sub-header may be at high may not reach its equilibrium design code should be taken

temperature, depending on the temperature into account for the fire case.

location of the fire. Where the • The relief stream from For units where the fire

failure occurs is not necessar- the vessel in question may relief temperature is assessed

ily intuitive. It may well be that mix with other material at 350°C, a sub-header design

the failure is at a flange, but the as it enters the sub-header temperature in the range

flange that fails may not be one • It takes time for the vapour 250°C to 300°C may not be

that experiences the highest to heat the metal of the flare unexpected.

temperature. The stress may be sub-header. The off-plot flare system

caused by the growth of piping The heat-up time may also design temperature is found

elsewhere. allow the fire brigade to start by similar considerations and

Failure in the flare sys- cooling sprays on the area sur- methods to those applying to

tem during a localised fire is a rounding the fire. Although the sub-headers. Generally, the

highly undesirable event. The the flare header is unlikely to design temperature is lower

flare is an important safety be their priority, cooling of the than for the on-plot piping

system. As the fire scenario process equipment in the fire since there is more opportunity

unfolds, operators may vent area should reduce the relief for heat loss in the upstream

gas from numerous locations rate. piping.

into the flare. Failure will result There are two methods by It is not normally consid-

in highly flammable or toxic which the design temperature ered that the PRV tail-pipe or

gas venting to atmosphere at an of the flare sub-header is usu- flare headers will experience

unexpected location. ally set: fire engulfment. On-plot flare

1. Large companies sometimes sub-headers will normally be

Setting the flare system design have a ‘not to be exceeded’ at an elevation above the 7.6m

temperature value based on experience. This (25ft) normally considered for

The flare system does not usu- value is derived from many fire relief calculations1 and PRV

ally have a design temperature years of operating multiple pro- tail-pipes should be situated

lower than the flowing temper- cess units and is known to be above their respective head-

ature for non-fire contingencies. practical for design from the ers. Direct radiation is there-

Setting the design tempera- piping stress viewpoint. fore not normally taken into

ture of the PRV tail-pipe to a 2. The second method is based account when determining pip-

value of 300°C-350°C, based on on rigorous fluid flow with heat ing design temperatures. Where

the fire case, might not be con- transfer calculations to give an there are particular concerns,

sidered unreasonable for equip- expected metal temperature for it may be advisable to provide

ment containing heavy or wide the flare sub-header during the fire-proof insulation although

boiling hydrocarbon streams. worst case scenario. It is nec- this is unusual on flare piping.

4 PTQ Q1 2017 www.digitalrefining.com/article/1001352

The provision of any insulation, rity, particularly during upset ble for the flare piping stress

of course, affects the heat loss conditions. analysis.

calculations discussed above. The use of relieving temper-

atures, and hence flare design References

Conclusion temperatures, of higher than 1 American Petroleum Institute

It is important to know the around 350°C are unlikely to be Standard 521, Pressure relieving and

Depressuring systems. Sixth Edition, Jan

objective when setting flare warranted for typical refinery

2014.

system design conditions. For hydrocarbon streams. For other

2 Shackelford A, Temperature Effects

large hydrocarbon process- materials, the behaviour of the

for High-velocity Gas Flow, Chemical

ing plant, one key objective is material at elevated tempera- Engineering, Jan 2015.

to maintain the integrity of the tures needs to be reviewed.

flare system during fire relief. Design temperature of Paul David is Director and Process

The consequences of the fire downstream sub-headers and Engineer with Paul David Process,

providing process engineering and

may cause upsets or shutdowns headers is based on the max-

overpressure protection services. He

on other process units and imum expected metal tem-

holds a bachelor’s degree in chemical

the flare system is a key util- perature. This is often set by engineering from the University of Bath

ity under these conditions. A experience since the exact and has over 30 years’ experience in the

flare system failure may result behaviour of the relieving industrial gases, chemical and oil refining

in a large release of flamma- material when heated by fire industries. For more than 20 years he

ble material at an unexpected and the actual contingency is worked at a major UK oil refinery.

location. The author is aware not known until it happens. In

of an incident where a huge the absence of extensive, rele-

fireball was caused by a pro- vant experience, the large sim- LINKS

cess unit venting into a dam- ulation effort required should

aged flare system. Although in be tempered by good judge- More articles from the following

categories:

this case the damage was not ment. The data generated dur-

Combustion Systems and

caused by thermal expansion it ing the fire case study should Engineering

emphasised the importance of be documented and reviewed Emissions Reduction

maintaining flare system integ- with the engineer responsi-

www.digitalrefining.com/article/1001352 PTQ Q1 2017 5

You might also like

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersFrom EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersRating: 4.5 out of 5 stars4.5/5 (2)

- 2.heat-Exchangers From Ch6 - Mihir's HandbookDocument12 pages2.heat-Exchangers From Ch6 - Mihir's HandbookThế Quang LêNo ratings yet

- Realities of Heat Flux in Fired HeatersDocument5 pagesRealities of Heat Flux in Fired HeatersSushil SharmaNo ratings yet

- IFP Materials PDFDocument20 pagesIFP Materials PDFProcess EngineerNo ratings yet

- Cracked Gas CompressorDocument7 pagesCracked Gas CompressorfvaefaNo ratings yet

- Tower Pressure Control CH 5Document10 pagesTower Pressure Control CH 5Abhimanyu SharmaNo ratings yet

- A Design Adn Rating Method For Shell and Tube Heat ExchangerDocument8 pagesA Design Adn Rating Method For Shell and Tube Heat Exchangerhuynhthanhtamga1981100% (1)

- Divided Wall ColumnsDocument6 pagesDivided Wall ColumnsswaminathanNo ratings yet

- Hot Potassium Carbonate Process - OdtDocument2 pagesHot Potassium Carbonate Process - OdtMahmoud HendawyNo ratings yet

- Steam Jet EjectorDocument13 pagesSteam Jet EjectorNeesha VijayNo ratings yet

- Caustic Scrubber Designs For Refinery Gases ComplDocument28 pagesCaustic Scrubber Designs For Refinery Gases ComplTaniadi SuriaNo ratings yet

- Stepwise Simulation of Vacuum Transfer Line HydraulicsDocument6 pagesStepwise Simulation of Vacuum Transfer Line HydraulicsJose CantorNo ratings yet

- 6.vapour Power CyclesDocument18 pages6.vapour Power CyclesJayneel Gajjar100% (1)

- HRSG Understand The BasicsDocument14 pagesHRSG Understand The BasicsMazen Darwish100% (1)

- The Different Types of Reboiler Available For Demanding ApplicationsDocument8 pagesThe Different Types of Reboiler Available For Demanding ApplicationsForcus onNo ratings yet

- Troubleshooting A C3 Splitter Tower Part 1 EvaluationDocument6 pagesTroubleshooting A C3 Splitter Tower Part 1 EvaluationZangNo ratings yet

- Article - 1001191 Managing Fouling in Refinery PDFDocument13 pagesArticle - 1001191 Managing Fouling in Refinery PDFDavid Diaz PadillaNo ratings yet

- Quickly Design CO2 - Amine AbsorberDocument6 pagesQuickly Design CO2 - Amine AbsorbersnapshotspixNo ratings yet

- Study of Vapour Absorption System Using Waste Heat-F0283439Document6 pagesStudy of Vapour Absorption System Using Waste Heat-F0283439Anonymous NGXdt2BxNo ratings yet

- Homework 1Document9 pagesHomework 1AgithaNo ratings yet

- Intro To Steam Condensers For Steam Power Plants PDFDocument34 pagesIntro To Steam Condensers For Steam Power Plants PDFegamboa004100% (1)

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- Replacing A Corroded Column With Packing InternalsDocument4 pagesReplacing A Corroded Column With Packing InternalsPlutarco Chuquihuanga CórdovaNo ratings yet

- Xu Distillation How To Push A Tower To Its Maximum Capacity PDFDocument9 pagesXu Distillation How To Push A Tower To Its Maximum Capacity PDFRajendraNo ratings yet

- Steam: Fig. 10.1.1 A Typical Basic Steam CircuitDocument47 pagesSteam: Fig. 10.1.1 A Typical Basic Steam Circuitkris_2k3100% (1)

- Eliminating The Claus FurnaceDocument9 pagesEliminating The Claus Furnaceoujda1977No ratings yet

- Continuous Heat Stable Salts Removal From Amine SolutionsDocument12 pagesContinuous Heat Stable Salts Removal From Amine SolutionsGopi Kiran NNo ratings yet

- Guidelines For Ethylene Quench Tower Rev 17Document17 pagesGuidelines For Ethylene Quench Tower Rev 17totongop0% (1)

- Themodynamic Model Selection For CHEMCADDocument19 pagesThemodynamic Model Selection For CHEMCADratnakar patharkarNo ratings yet

- Types of Thermodynamic ProcessDocument8 pagesTypes of Thermodynamic ProcessSaranrajPachayappanNo ratings yet

- Trol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsDocument14 pagesTrol/restricted/course/fourth/course/mo Dule3-1.html: Module 3.1: Control of Distillation ColumnsRimeli RoychoudhuryNo ratings yet

- PTQ Q4 2004 - Foam Control in Crude Units PDFDocument8 pagesPTQ Q4 2004 - Foam Control in Crude Units PDFWong Yee SunNo ratings yet

- Selective Hydrogenation of Vinyl Acetylene To 1,3-Butadiene in Concentrated Vinyl Acetylene Mixed C4 by PdAl2O3 CatalystDocument1 pageSelective Hydrogenation of Vinyl Acetylene To 1,3-Butadiene in Concentrated Vinyl Acetylene Mixed C4 by PdAl2O3 CatalystPaisan InsornNo ratings yet

- Increase FCCU Processing CapacityDocument4 pagesIncrease FCCU Processing Capacitysaleh4060No ratings yet

- Sieve Tray Column: Design of HC Process Equipments PE 350Document14 pagesSieve Tray Column: Design of HC Process Equipments PE 350Shreya Sahajpal KaushalNo ratings yet

- Modern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumDocument10 pagesModern Spent-Caustic Wastewater Treatment Simulation by Aspen Plus in Electrolytic MediumarmanNo ratings yet

- Distillation DesignDocument30 pagesDistillation DesignAPURVA SUMAN 18CH10033100% (1)

- Vacuum Column DesignDocument6 pagesVacuum Column DesignAtul Choudhari100% (1)

- Sour Water Strippers Design and Operation PDFDocument6 pagesSour Water Strippers Design and Operation PDFJetul PatelNo ratings yet

- Heat Exchangers - Course Content: Section 7 - Troubleshooting ProblemsDocument14 pagesHeat Exchangers - Course Content: Section 7 - Troubleshooting ProblemsJorge Enciso AcuñaNo ratings yet

- Definition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsDocument2 pagesDefinition & Types of Reboilers - A. Thermosiphon - : Reboiler CircuitsWade ColemanNo ratings yet

- PRT Lecture - 16 17Document30 pagesPRT Lecture - 16 17HimaNo ratings yet

- Compact Heat Exchangers Part 3 Retrofit Heat Recovery Networks With Plate ExchangersDocument6 pagesCompact Heat Exchangers Part 3 Retrofit Heat Recovery Networks With Plate Exchangersthorem100% (1)

- 2004 Rev Vacuum EjectorDocument5 pages2004 Rev Vacuum EjectorIndranil HatuaNo ratings yet

- Heat Exchanger PerformanceDocument6 pagesHeat Exchanger Performanceramadoss_alwar7307No ratings yet

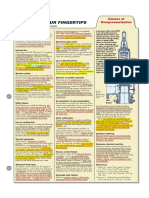

- Facts at Your Fingertips-200802-Pressure ReliefDocument1 pageFacts at Your Fingertips-200802-Pressure Reliefonizuka-t2263No ratings yet

- 11-Troubleshooting Oil FiringDocument19 pages11-Troubleshooting Oil FiringLuis Enrique Leyva OvalleNo ratings yet

- CO2 Capture ProjectDocument8 pagesCO2 Capture Projecthoang.le842002No ratings yet

- Chemical Cleaning and FoulingDocument4 pagesChemical Cleaning and FoulingoswaldoNo ratings yet

- Vacuum Unit Pressure Control PTQ Revamps 2006Document5 pagesVacuum Unit Pressure Control PTQ Revamps 2006majope1966No ratings yet

- Energy Efficiency Improvement in An Ethylene PlantDocument5 pagesEnergy Efficiency Improvement in An Ethylene Plantshubham bobdeNo ratings yet

- Consider A Practical Approach To Vacuum Unit RevampsDocument10 pagesConsider A Practical Approach To Vacuum Unit Revampsjokish100% (1)

- CDU Increase Distillate YieldDocument9 pagesCDU Increase Distillate Yieldrvkumar61No ratings yet

- AbsorptionDocument54 pagesAbsorptionBebo El MasryNo ratings yet

- Ammonia Synthesis and Molecular SieveDocument25 pagesAmmonia Synthesis and Molecular Sieveaehque04No ratings yet

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 pagesCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- AIChE-Condenser Performance Monitoring - 020340Document4 pagesAIChE-Condenser Performance Monitoring - 020340Leon SanchezNo ratings yet

- Multiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsFrom EverandMultiphase Catalytic Reactors: Theory, Design, Manufacturing, and ApplicationsNo ratings yet

- BN-DG-C01J Plant Layout - Storage Tanks: Home Services Software Library ContactDocument17 pagesBN-DG-C01J Plant Layout - Storage Tanks: Home Services Software Library ContactQayyum KhanNo ratings yet

- Al Huwaisah GGP Pipeline Project Hydraulic Report: RevisionDocument49 pagesAl Huwaisah GGP Pipeline Project Hydraulic Report: RevisionQayyum KhanNo ratings yet

- Flow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Document1 pageFlow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Qayyum KhanNo ratings yet

- Heat Tran BuriedDocument3 pagesHeat Tran BuriedQayyum KhanNo ratings yet

- PDO Discipline-Document Type Matrix: - Based On EPP Standard Document Types List Rev 15Document10 pagesPDO Discipline-Document Type Matrix: - Based On EPP Standard Document Types List Rev 15Qayyum KhanNo ratings yet

- ASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Document5 pagesASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Qayyum KhanNo ratings yet

- LFI Tool - PD-HX-REP-003 Rev.01Document26 pagesLFI Tool - PD-HX-REP-003 Rev.01Qayyum KhanNo ratings yet

- Fakhr-9 (A3)Document11 pagesFakhr-9 (A3)Qayyum KhanNo ratings yet

- Relief and Flare Sytem Design (Autosaved)Document51 pagesRelief and Flare Sytem Design (Autosaved)Qayyum KhanNo ratings yet

- On Hore and Off ShoreDocument7 pagesOn Hore and Off ShoreQayyum KhanNo ratings yet

- An Automated Fall Detection System Using AccelerometerDocument4 pagesAn Automated Fall Detection System Using AccelerometerQayyum KhanNo ratings yet

- Comparison of Pha Methods PDFDocument10 pagesComparison of Pha Methods PDFQayyum KhanNo ratings yet

- Automation SensorDocument2 pagesAutomation SensorQayyum KhanNo ratings yet

- An Automated Fall Detection System Using AccelerometerDocument4 pagesAn Automated Fall Detection System Using AccelerometerQayyum KhanNo ratings yet

- Heat Reclaim Chillers: Capturing Heat For Useful Energy SavingsDocument4 pagesHeat Reclaim Chillers: Capturing Heat For Useful Energy Savings185412No ratings yet

- Heat Insulation: Submitted byDocument31 pagesHeat Insulation: Submitted byamishaNo ratings yet

- Thermal 2 MarksDocument14 pagesThermal 2 MarksDhanush RajNo ratings yet

- Sample 11788Document16 pagesSample 11788chennishalu57No ratings yet

- Determination of Vapor PressureDocument5 pagesDetermination of Vapor PressureAbhinav AnandNo ratings yet

- IIT Bombay Department of Mechanical Engineering ME 209:thermodynamics (S2) Autumn 2020Document3 pagesIIT Bombay Department of Mechanical Engineering ME 209:thermodynamics (S2) Autumn 2020SumitNo ratings yet

- Triple Point ExperimentDocument2 pagesTriple Point ExperimentSana SyedNo ratings yet

- 2016 Lototskyy New Model of Phase Equilibria in Metal e HydrogenDocument23 pages2016 Lototskyy New Model of Phase Equilibria in Metal e Hydrogenlokothwayo1No ratings yet

- Heat and Material BalanceDocument27 pagesHeat and Material BalanceFatin ZulkifliNo ratings yet

- Chem Ch4 NIE Premium NOtesDocument19 pagesChem Ch4 NIE Premium NOtesAadil ShaikhNo ratings yet

- Course OutlineDocument2 pagesCourse OutlineHevi Angelo Rios TadenaNo ratings yet

- TOPIC 2 Part 2 DJJ20063 AKDocument27 pagesTOPIC 2 Part 2 DJJ20063 AKdhanheshNo ratings yet

- Flash Steam - TLV - A Steam Specialist Company (Worldwide)Document5 pagesFlash Steam - TLV - A Steam Specialist Company (Worldwide)kaustavNo ratings yet

- Test 1 AnswerDocument4 pagesTest 1 AnswerHilmyZulkifliNo ratings yet

- CFX MultiphaseDocument40 pagesCFX MultiphaseIvanripsNo ratings yet

- Flow of Hot Oil Over A Flat Plate:: External Forced ConvectionDocument8 pagesFlow of Hot Oil Over A Flat Plate:: External Forced Convectionvarshasdm1987100% (1)

- School of Mechanical Sciences: Heat Transfer (Me3L001)Document1 pageSchool of Mechanical Sciences: Heat Transfer (Me3L001)Arka PalNo ratings yet

- CH 10Document4 pagesCH 10Muizzudin AzaliNo ratings yet

- State of Matter School Chemistry Raj SirDocument36 pagesState of Matter School Chemistry Raj SirRavi DuttNo ratings yet

- Entropy Generation MinimisationDocument13 pagesEntropy Generation MinimisationKar AbhishekNo ratings yet

- Assignment Brief (FV2001)Document2 pagesAssignment Brief (FV2001)Nan fungNo ratings yet

- Technical SelectionDocument6 pagesTechnical SelectionAGUNG SURYO ADI NUGROHONo ratings yet

- Hap Free CoolingDocument2 pagesHap Free CoolingHnin PwintNo ratings yet

- Energy Recovery, Calculation MethodsDocument21 pagesEnergy Recovery, Calculation MethodsRanga VamshiNo ratings yet

- Water Consumption of Cooling Towers ASME Power 2015Document5 pagesWater Consumption of Cooling Towers ASME Power 2015Zaka ZaheeriNo ratings yet

- tg22 July 2009v2 PDFDocument8 pagestg22 July 2009v2 PDFShrikantKarwaNo ratings yet

- PHYS 1401 General Physics I Experiment 13 Latent Heat of FusionDocument4 pagesPHYS 1401 General Physics I Experiment 13 Latent Heat of FusionAlicia HaughtonNo ratings yet

- Air Heater Fix1Document9 pagesAir Heater Fix1Swar SwarraditNo ratings yet

- Apd CalculationDocument4 pagesApd CalculationRashel Hasan100% (1)

- CH3510 Expt2Document12 pagesCH3510 Expt2studytimeforjee2022No ratings yet