50kVA 400Hz Converter Heli A Model 4070

50kVA 400Hz Converter Heli A Model 4070

Uploaded by

Mazhar SafdarCopyright:

Available Formats

50kVA 400Hz Converter Heli A Model 4070

50kVA 400Hz Converter Heli A Model 4070

Uploaded by

Mazhar SafdarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

50kVA 400Hz Converter Heli A Model 4070

50kVA 400Hz Converter Heli A Model 4070

Uploaded by

Mazhar SafdarCopyright:

Available Formats

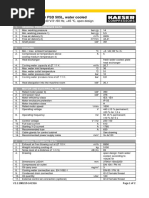

Technical

Description

50kVA/400Hz

Issue A

Converter

Technical Description

50kVA Converter

3x440V/60Hz >> 3x200V+N/400Hz

Date: 16-Jun -2016 Page 1 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

Table of contents

1 INTRODUCTION .......................................................................................................................................................... 3

2 DESCRIPTION OF CONVERTERS .................................................................................................................................. 3

2.1 GENERAL ................................................................................................................................................................ 3

2.2 EMI SUPPRESSOR .................................................................................................................................................... 3

2.3 POWER STAGE & FILTER ............................................................................................................................................ 5

2.4 FREQUENCY GENERATION .......................................................................................................................................... 5

2.5 CONTROL ELECTRONIC .............................................................................................................................................. 7

2.5.1 Frequency Generation & reference voltage generation. ............................................................................. 8

2.5.2 PWM generation ......................................................................................................................................... 8

2.5.3 Output voltage control and output current control .................................................................................... 8

2.5.4 Fault detection ............................................................................................................................................ 9

3 MECHANICAL ARRANGEMENT ................................................................................................................................. 10

4 TECHNICAL DATA ...................................................................................................................................................... 11

4.1 INPUT VOLTAGE ..................................................................................................................................................... 11

4.2 OUTPUT VOLTAGE 400HZ ....................................................................................................................................... 11

4.3 GENERAL .............................................................................................................................................................. 11

4.4 DESIGN ................................................................................................................................................................ 11

4.5 LOCAL CONTROL & MONITORING ............................................................................................................................. 12

4.6 COOLING REQUIREMENTS ........................................................................................................................................ 12

4.7 ANTI CONDENSATION HEATING ................................................................................................................................. 12

4.8 RELIABILITY ........................................................................................................................................................... 13

Date: 16-Jun-2016 Page 2 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

1 INTRODUCTION

EUROATLAS introduces hereby state-of-the-art static power conversion equipment designed

under the measures of the latest available technology and providing typically environmental

features as shock resistance, wide operating temperature range, humidity and low structure

borne noise. Furthermore EMI measures are provided in order to operate the equipment together

with sensitive equipment.

The proposed static power conversion equipment fulfils the main requirements stated in

customers specification. There are several performance data which are even better than required.

2 DESCRIPTION OF CONVERTERS

2.1 General

(see block diagram next page)

Basically the converter is designed to convert an ac voltage of 440V/60Hz into a high quality 3ph

sine voltage with 200Vac and a frequency of 400Hz. The output power is to be used for helicopter

supply.

The technology is based on pulse width modulation (PWM) technique and uses a 3ph IGBT

(insulated gate bipolar transistor) power stage. The output voltage control is designed for single

phase regulation providing excellent line voltage regulation even at 100% unbalanced load.

State-of-the-art control electronic is integrated utilising programmable logic devices and micro

controllers and featuring on-board fault detection.

Overload and short circuit situations are managed by accordant derating of the power stage.

The input stage is formed by a galvanic separated transformer providing a delta and a star voltage

on secondary side to build a 12 pulse rectifier for generating the DC link voltage.

The output is designed with a transformer in star connection used for providing the neutral phase.

2.2 EMI Suppressor

The EMI suppression circuitry is used to fulfil the limits of the MIL-STD-461. Measures are provided

to reduce differential mode and common mode interferences on input and output leads.

Date: 16-Jun-2016 Page 3 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

Block Diagram

Date: 16-Jun-2016 Page 4 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

2.3 Power Stage & Filter

The power stage consists of three transistorized half-bridges with IGBT-technology (IGBT =

Insulated Gate Bipolar Transistor), a gate drive circuit and an output low-pass filter. Each half-

bridge is built of two power IGBTs (upper and lower).

The power transistors are driven by galvanically insulated gate drives. The transmission of PWM-

driver signals from the control circuit to the power stages are isolated by optical couplers. The

actual output power sine wave is obtained from the output power PWM signal using a second

order LC low-pass reducing the harmonics and forming the fundamental wave.

2.4 Frequency Generation

The technology is based on the pulse width modulation (PWM) technique (see Functional Block

diagram : PWM-Signal Generation). The centre of the control system is a crystal controlled digital

frequency generation providing

the sine wave references,

the minimum power transistor dead time

the necessary chopper signals to generate a multi pulse PWM sine wave.

Date: 16-Jun-2016 Page 5 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

PWM Power Generation

Date: 16-Jun-2016 Page 6 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

2.5 Control Electronic

The control electronic is designed to adopt all electronic functions that are required to build a

complete converter system except power stage and power driver. Following functions are

provided:

frequency generation

PWM generation

3 phase voltage sense with active rectifier and averager

3 phase output voltage regulation

common output current regulation

over current detection

short circuit detection

soft start circuit

output voltage reference circuit

power stage fault management

drive circuits for start contactor,

input contactor and output contactors

converter on/off logic

fault logic

generation of all monitoring signals

generation of signals for external use

start/stop management

input voltage supervision

dc link voltage supervision

aux supplies for 15V, 5V and 24V

Date: 16-Jun-2016 Page 7 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

2.5.1 Frequency Generation & reference voltage generation.

The master clock frequency of the system is about 10MHz. This frequency is divided into several

sub frequencies required for the individual applications inside the PLD.

The PWM signal required for the inverter power stage is build by a sine / triangle comparison. The

frequency of the triangle is equal to the switching frequency of the power stages and is generated

by an analogue triangle generator on this board. The sine wave frequency is equivalent to the

output sine wave of the inverter. There are three sine reference voltages generated digitally.

2.5.2 PWM generation

The three phase sine reference outputs are compared with a bipolar triangle.

Each comparator PWM signal is splitted to an upper and a lower power transistor drive signal

taking into consideration the power transistor dead time.

2.5.3 Output voltage control and output current control

The control electronic provides single phase output voltage control and is equipped with three

pathes each build of

an averager

an active rectifier

an active low pass filter

and a PI voltage controller

The voltage control is of type average amplitude control providing excellent static output voltage

control and a sufficient dynamic control. Due to single phase control the output voltage tolerance

is very low even at unbalanced loads of 100%. During start-up the output voltage rises with a

linear slope during approximately 160 ms. The output voltages can be adjusted by a

potentiometer.

The output voltage of the PI voltage controller sets the amplitude of sine reference by using a

multiplying D/A converter.

Turning down a service potentiometer will interrupt the voltage control loop and allows a

manually output voltage adjustment without control loop influence for service purpose.

The output current control is a common circuit for all three phases and allows current limiting and

constant current mode during short circuit conditions. The current sense simply consists of three

current transformers with full wave rectifiers and shunts.

Date: 16-Jun-2016 Page 8 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

The current sense signals are amplified and merged to a common signal as actual value of output

current. Several comparator circuits are provided to check the output current value for short

circuit conditions and for over load.

The introduction of a short circuit sequence is derived from an over current signal of the power

stage that indicates the maximum allowable current for the power transistors. Generally the short

circuit sequence is starting with a shut down of the power stages by switching them to high

impedance. The temporary shut down signal (10ms-20ms) prepares the voltage controller and the

current controller for a soft start. After the shut down signal is released the current controller sets

the constant current mode. When the short circuit is cleared the unit returns to the voltage mode

automatically. Constant current mode and over load are limited in time. After a certain time has

passed the inverter switches off to failure mode.

2.5.4 Fault detection

The control electronic provides a fault detection and fault analysing circuit. The fault logic is build

by a priority logic giving the most important failures the highest priority.

The priority logic consists of a register representing a binary fault number. All occurrences of

failures initiate a fault latch where the fault number is displayed on a 7-segment display located on

the control board. A summing fault will be displayed on the monitoring panel.

Following parameters are supervised (as a minimum)

input voltage supervision for upper and lower limit*)

input charge voltage detection for existence of a minimum voltage *)

output voltage supervision for upper limit *)

24V aux voltage supervision for lower limit *)

fan supervision **)

internal air temperature for upper limit **)

power stage temperature for upper limit *)

over load supervision for upper limit and time **) *)

*) Immediately converter switch off when fault occurs.

**) Warning only

Generally all converter switch-off by fault have to be cleared by pressing the stop push button on

the monitoring panel.

Date: 16-Jun-2016 Page 9 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

3 MECHANICAL ARRANGEMENT

The converter is housed in a steel frame cabinet containing fixed mounted units like transformers

and slide-in drawers for power electronics. All assemblies are accessible from the front by opening

the front door.

The cooling of the converters is achieved by fans. The air inlet is distributed on the front panel of

the converter. The air exhaust is located on the rear side of the cabinet.

Assemblies made of AlMg3. Cable entry from the bottom side. General construction according to

BV 3100.

Cabinet shown without shock mounts.

Weight (complete cabinet) 720kg ± 5% (without shock mounts)

Dimensions cabinet W=810mm H=1612 D=610mm (without shock mounts)

Service space in front 850mm

Cable inlet from bottom side

Date: 16-Jun-2016 Page 10 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

4 TECHNICAL DATA

4.1 Input Voltage

Voltage 440V, 3ph according to STANAG 1008 e8

Frequency 60Hz ±5%

Current, nominal approx. 75A at 440V and nominal load

Current, inrush less than nominal input current.

Power factor > 0.9

4.2 Output Voltage 400Hz

General MIL-STD 704 F

Power 50kVA , power factor 1.0…0.8ind

Voltage 3ph 200V/115V adjustable by 5%

Static tolerance < 1 % at any static and balanced load

Volt. unbalance < 5% at 100% unbalanced load

Volt. transient < 5% @ load step 50-100-50%, < 16% @ load step 0-100-0%, rec.20ms

Ampl. modulation 2 %

Distortion (THD) 3.0 %

Overload capacity 150% for 2min., 120% for 10min.

Short circuit current 200% of nom. current for 10 seconds

Frequency 400Hz with < ±0.1 % tolerance, crystal controlled

Efficiency >90%

4.3 General

Shock acc. to BV 0430/1.89

Vibration acc. to BV 0440/10.90

RFI / EMI acc. to MIL-STD 461F, CE102, RE102

Acoustic noise 65 db(A)20uPa in 1m distance

Insulation resistance Power leads > 10MΩ, signal leads > 100MΩ

Operating temperature 0°C…..45°C

Humidity nominal 85%, max 100% for 1h non condensing

Protection IP 43

Isolation acc. to VDE 0110, Part 1

Roll and Pitch arbitrary

4.4 Design

General design GL Germanischer Lloyd Electrical Installation GL III-1-3a, 15.12.2003

Date: 16-Jun-2016 Page 11 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

4.5 Local Control & Monitoring

Controls Local Extern

hard wired

Start and stop push buttons for converter X -

Start and stop push buttons for 400Hz output - X

Lamp test push button X -

Monitoring Local Extern

hard wired

Standby indication X -

On line indication 400Hz X X

Input voltage present lamp X -

Elapsed time counter X -

Output voltage, output current, output frequency and X -

output power by combined LCD meter

Warnings / Faults Local Extern

hard wired

Overload X -

High temperature X X

Fan failure X -

Internal fault X X

4.6 Cooling requirements

Following air flow rates have to be considered:

Equipment Condition Power losses Cooling requirement

One 400Hz converter Full load (50 kVA) 5500 W 1000 m³/h

Depending on the utilisation of the converter a sufficient air exchange (inlet / outlet) at the

cabinet location has to be provided.

4.7 Anti condensation heating

Power 100W

Voltage 440V/60Hz

Date: 16-Jun-2016 Page 12 of 13

Technical

Description

50kVA/400Hz

Issue A

Converter

4.8 Reliability

MTBF: EUROATLAS garantuees a system level Mean Time

Between Failure (MTBF) of 18.000 hrs, based upon the

following assumptions:

1) Normal operating conditions: Ambient Temperature = 25 C

Effective cooling

System output load = nominal value

2) Failure Rate Calculations based MIL-HDBK-217F + Notice Feb.’95

upon: Parts Stress Method

Environment “Naval Sheltered” (Ns) at 25C

CECC 00 801 document for CECC component data

NPRD-91 document for non-electronic parts data

3) Reliability / MTBF modeling and MIL-STD-756B

prediction based upon: Mission reliability model

Mission operating hours << Basic operating hours

System parts subject to planned maintenance not

taken into account, assuming these parts are

maintained as recommended by EUROATLAS.

MTTR: EUROATLAS garantuees a system level Mean Time To

Repair of less than 1 hr. based upon the following

assumptions:

1) Calculation and prediction based upon: MIL-HDBK-472, Procedure V, Method A.

Intermediate Level Repair by “Remove & Replace”-

Method

2) Repair times of Line Replacable Units, using system fault detection & location < 20 Min.

3) Customer maintenance personnel participated in training course by EUROATLAS

4) Maintenance tasks and Fault-finding tasks are carried out according technical manual

instructions.

Date: 16-Jun-2016 Page 13 of 13

You might also like

- Download Complete Hypertension: A Companion to Braunwald's Heart Disease 3rd Edition George L. Bakris - eBook PDF PDF for All ChaptersDocument41 pagesDownload Complete Hypertension: A Companion to Braunwald's Heart Disease 3rd Edition George L. Bakris - eBook PDF PDF for All Chaptersgernangeten100% (2)

- BOLMAN - AND - DEAL Test Bank by Barbara McKeonDocument84 pagesBOLMAN - AND - DEAL Test Bank by Barbara McKeonitwasawesome100% (2)

- JetPower III 400 HZ GPU Ground MountedDocument2 pagesJetPower III 400 HZ GPU Ground MountedloadrpkNo ratings yet

- Product Snapshot: Hybrid Energy Storage InverterDocument2 pagesProduct Snapshot: Hybrid Energy Storage InverterAlmoudamer0% (1)

- Leaflet ESI 48 120V 1000VA enDocument2 pagesLeaflet ESI 48 120V 1000VA enJoseric21100% (1)

- ApojejDocument8 pagesApojejKhashane Willy MohaleNo ratings yet

- 400Hz ConverterDocument2 pages400Hz ConverterIlham WaskitoNo ratings yet

- Rele Sobretension DPC01DM48Document6 pagesRele Sobretension DPC01DM48LeonardoNo ratings yet

- SFC 8000 Combo LitDocument2 pagesSFC 8000 Combo Litrizcst9759No ratings yet

- Design and Performance Analysis of 400Hz Static Frequency ConverterDocument3 pagesDesign and Performance Analysis of 400Hz Static Frequency ConverterEditor IJTSRDNo ratings yet

- 10KWDocument4 pages10KWD C Sirdes SirdesNo ratings yet

- 281 ITW GSE Hobart 140 180 GPU PDFDocument2 pages281 ITW GSE Hobart 140 180 GPU PDFDario GuerraNo ratings yet

- Voltage To Frequency Converter Folosind Ci 555 TimerDocument11 pagesVoltage To Frequency Converter Folosind Ci 555 TimerAl ZanoagaNo ratings yet

- Flex Core - PC5 Watt TransducersDocument4 pagesFlex Core - PC5 Watt TransducersYuri Moura100% (1)

- PDS1-400K: FeaturesDocument2 pagesPDS1-400K: FeaturesMario BaezNo ratings yet

- Om MTX X702Document36 pagesOm MTX X702Nicolae EnacheNo ratings yet

- A Technology Review On Matrix Converter: K.V.Kandasamy, Sarat Kumar Sahoo, S.Prabhakar KarthikeyanDocument3 pagesA Technology Review On Matrix Converter: K.V.Kandasamy, Sarat Kumar Sahoo, S.Prabhakar KarthikeyanDineshKanawatNo ratings yet

- 400Hz ConverterDocument2 pages400Hz ConverterThanhha Nguyen100% (2)

- Molded Case Circuit Breakers: Unusual Operating ConditionsDocument2 pagesMolded Case Circuit Breakers: Unusual Operating ConditionsThor LundeNo ratings yet

- CompactgpuDocument2 pagesCompactgpuMekougou OndoaNo ratings yet

- VEIKONG VFD500-PV Solar Pumping Inverter UserDocument44 pagesVEIKONG VFD500-PV Solar Pumping Inverter UserSina11No ratings yet

- DPX-15503 - Cummins 66 KVADocument7 pagesDPX-15503 - Cummins 66 KVAEdwin GallegosNo ratings yet

- Vehicle Mounted Ground Power Unit 90 KVA For DMP AirDocument2 pagesVehicle Mounted Ground Power Unit 90 KVA For DMP AirWilliam Jaldin CorralesNo ratings yet

- Agec 260a Cummins 90kvaDocument2 pagesAgec 260a Cummins 90kvaAntonio ArrotoNo ratings yet

- GPU - SinePower PDFDocument4 pagesGPU - SinePower PDFrocaoNo ratings yet

- INVERTER OFF GRID SOLAR INVERTER (INPOWERS) 1800 MPK-SeriesDocument1 pageINVERTER OFF GRID SOLAR INVERTER (INPOWERS) 1800 MPK-SeriesMajid abdulNo ratings yet

- Datasheet 2Document10 pagesDatasheet 2miguel angel jaramilloNo ratings yet

- 765 01 00 PW6000 S3 User ManualDocument68 pages765 01 00 PW6000 S3 User ManualWaheed MidoNo ratings yet

- 400Hz Ground Power Unit: FeaturesDocument3 pages400Hz Ground Power Unit: Featurestuyen vuNo ratings yet

- Ups NX300 PDFDocument112 pagesUps NX300 PDFnamNo ratings yet

- MT+ CX 1-3K Service Manual - Revised 51Document51 pagesMT+ CX 1-3K Service Manual - Revised 51ajayhedau02No ratings yet

- AC Power Supply SystemDocument5 pagesAC Power Supply SystemMuhammedNayeemNo ratings yet

- Smartonline Singlephase 10kvaDocument74 pagesSmartonline Singlephase 10kvaMagdiel Omar Zavala GutierrezNo ratings yet

- Basler BE3-27T ManualDocument2 pagesBasler BE3-27T ManualstuartsjgNo ratings yet

- Tai Lieu Bien Tan TMEICDocument30 pagesTai Lieu Bien Tan TMEICSỹ PhúNo ratings yet

- User Manual Product Description Rectifier DPR 2000B/ 2900B Energe SeriesDocument14 pagesUser Manual Product Description Rectifier DPR 2000B/ 2900B Energe Seriesmoumen BoughraraNo ratings yet

- Top209 PDFDocument17 pagesTop209 PDFguiodanielNo ratings yet

- Enertainer Info For PGBDocument2 pagesEnertainer Info For PGBMohd Lutfi MahaliNo ratings yet

- 0-Trihal 3150kva-24kvDocument4 pages0-Trihal 3150kva-24kvRonald MalaveNo ratings yet

- Bo Bien Doi Tan So - Huong Dan Su Dung 140444 030kVA 3X200V - ManualDocument39 pagesBo Bien Doi Tan So - Huong Dan Su Dung 140444 030kVA 3X200V - ManualVăn Xuân Nguyễn0% (1)

- DLT-100 Serie UPS User ManualDocument25 pagesDLT-100 Serie UPS User Manuala.elwahabNo ratings yet

- Single Phase Single Stage Bidirectional Isolated Zvs Acdc With PFCDocument8 pagesSingle Phase Single Stage Bidirectional Isolated Zvs Acdc With PFCSamyak ParakhNo ratings yet

- 3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFDocument6 pages3512 1275 kVA Prime Low BSFC - EMCP4 - EU PDFAashish MoyalNo ratings yet

- Sukho SPD List May 2019Document104 pagesSukho SPD List May 2019Inder SinghNo ratings yet

- Fabricantes PSU 2the MaxDocument51 pagesFabricantes PSU 2the Maxhoaxnet100% (1)

- 250X SMPS With Power MosfetDocument13 pages250X SMPS With Power MosfetAislan Souza0% (1)

- RC7017-datasheet-V3 6 5Document48 pagesRC7017-datasheet-V3 6 5tuananh1965No ratings yet

- Catalogo RWGDocument8 pagesCatalogo RWGFolpoNo ratings yet

- Voltronic Inverter Setup SOP PDFDocument6 pagesVoltronic Inverter Setup SOP PDFtongaiNo ratings yet

- Easy UPS 3M Cert of OriginDocument1 pageEasy UPS 3M Cert of OriginAsad NizamNo ratings yet

- Manual ABBDocument234 pagesManual ABBSesFasabiSaavedraNo ratings yet

- Maintenance: Battery Test Cleaning Storage Battery Maintenance and Disposal/ Recycling of BatteriesDocument2 pagesMaintenance: Battery Test Cleaning Storage Battery Maintenance and Disposal/ Recycling of BatteriesAnas MemonNo ratings yet

- S Bms ManualDocument44 pagesS Bms ManualnathanaelorNo ratings yet

- 9700 ManualDocument64 pages9700 ManualGilberto OlveraNo ratings yet

- MGE Galaxy 6000: "High Availability, High Performance"Document8 pagesMGE Galaxy 6000: "High Availability, High Performance"cristiNo ratings yet

- Air Circuit Breakers SEA - CA - 2014-01-07 150dpi PDFDocument38 pagesAir Circuit Breakers SEA - CA - 2014-01-07 150dpi PDFDhairyasheel PatilNo ratings yet

- PVH-L2550E Commissioning Procedure Rev3 (EN) PDFDocument33 pagesPVH-L2550E Commissioning Procedure Rev3 (EN) PDFNguyễn Trung Hiếu100% (1)

- Z Source InverterDocument16 pagesZ Source InverterpradeepagrahariNo ratings yet

- Dale Power Solutions LTD: DC Thyristor Systems Datasheet Erskine Single Phase Input DCV RangeDocument4 pagesDale Power Solutions LTD: DC Thyristor Systems Datasheet Erskine Single Phase Input DCV RangeYousefNo ratings yet

- #3 MV1000 Micro Technology Presentation - Sept 2018 VSADocument46 pages#3 MV1000 Micro Technology Presentation - Sept 2018 VSAadolfoNo ratings yet

- TH8056 012Document26 pagesTH8056 012Uldemar TapiaNo ratings yet

- Snva 465 ADocument13 pagesSnva 465 Aeneas.baroneNo ratings yet

- NC2.1 3000 0608 011Document1 pageNC2.1 3000 0608 011Mazhar SafdarNo ratings yet

- Marine Compressor FSD 505L, Water Cooled, 2605 M H, 14 Bar (G), 440 V 3...Document2 pagesMarine Compressor FSD 505L, Water Cooled, 2605 M H, 14 Bar (G), 440 V 3...Mazhar SafdarNo ratings yet

- Kaeser Marine CompressorsDocument24 pagesKaeser Marine CompressorsMazhar SafdarNo ratings yet

- A FSD Marine en - 17 108861Document2 pagesA FSD Marine en - 17 108861Mazhar SafdarNo ratings yet

- Loading Basic and PU SW - MCU8 - eDocument27 pagesLoading Basic and PU SW - MCU8 - eMazhar SafdarNo ratings yet

- JW Fishers Mfg. Inc.: 2021 Order Blank - Price ListDocument6 pagesJW Fishers Mfg. Inc.: 2021 Order Blank - Price ListMazhar SafdarNo ratings yet

- Mtu Middle East-Fresh Oil - Omd 113-Shrj 1250-01Document1 pageMtu Middle East-Fresh Oil - Omd 113-Shrj 1250-01Mazhar SafdarNo ratings yet

- Macedonian Studies Journal, Vol 1 Issue 2, 2014Document168 pagesMacedonian Studies Journal, Vol 1 Issue 2, 2014Makedonas Akritas100% (1)

- Action Research Report Scogin 1Document9 pagesAction Research Report Scogin 1api-439194759No ratings yet

- SCA BIM Standards ManualDocument184 pagesSCA BIM Standards Manualgsirin100% (1)

- What Is Nano?: Science, Technology, Society and NanoworldDocument9 pagesWhat Is Nano?: Science, Technology, Society and NanoworldKae CeeNo ratings yet

- Lycothrissa: Engraulis Encrasicholina Coilia CoiliaDocument23 pagesLycothrissa: Engraulis Encrasicholina Coilia CoiliaYusrina AfrohNo ratings yet

- Los Angeles: Luka Arapovic 3.eDocument19 pagesLos Angeles: Luka Arapovic 3.eLuka ArapovićNo ratings yet

- (RESUME) Meena StanikzaiDocument5 pages(RESUME) Meena Stanikzaiabhay.rajauriya1No ratings yet

- Part Catalog Mf5709Document595 pagesPart Catalog Mf5709Dedy setiawan100% (1)

- Sheave Design - TimcoDocument10 pagesSheave Design - TimcotungNo ratings yet

- Sylvius Leopold Weiss (1687-1750) : Compiled byDocument60 pagesSylvius Leopold Weiss (1687-1750) : Compiled byPeerawitMmeekAunruanNo ratings yet

- SECOND QUARTER EXAM - Attempt Review PEDocument16 pagesSECOND QUARTER EXAM - Attempt Review PEneiljohn geraldez100% (1)

- LTSP Practice GuideDocument14 pagesLTSP Practice GuidePaul Webster100% (4)

- The Kantian Sublime and The Revelation of FreedomDocument274 pagesThe Kantian Sublime and The Revelation of Freedomjoseph_goethe100% (1)

- Den DR OlogyDocument436 pagesDen DR OlogyCBSE UGC NET EXAMNo ratings yet

- Test Clasa A9aDocument2 pagesTest Clasa A9aAdriana BrebenelNo ratings yet

- Noise in Communication SystemsDocument35 pagesNoise in Communication SystemsGoitom HaileNo ratings yet

- FOUNDATION 3 - Day 21Document6 pagesFOUNDATION 3 - Day 21mainguyenngocdiemNo ratings yet

- SOAL PAS B. INGGRIS SMA IT KLS X SEM Ganjil 2021-2022Document7 pagesSOAL PAS B. INGGRIS SMA IT KLS X SEM Ganjil 2021-2022Rahmat Randi Al BangkawyNo ratings yet

- Buamah RashidDocument75 pagesBuamah RashidSamuelVamsiNo ratings yet

- A Big Tuck Shop Project Feasibility Report: Prepared By: Ansa Nazir AhmedDocument10 pagesA Big Tuck Shop Project Feasibility Report: Prepared By: Ansa Nazir AhmedAnsa AhmedNo ratings yet

- HNDA 2205 PM Tools and Programming Assignment 1Document3 pagesHNDA 2205 PM Tools and Programming Assignment 1Cyber ShopNo ratings yet

- Craftsman 98023 40V 12V Lithium-Ion Cordless ChainsawDocument6 pagesCraftsman 98023 40V 12V Lithium-Ion Cordless ChainsawJoe ZhaoNo ratings yet

- G7881 Fault CodDocument16 pagesG7881 Fault CodMai Doan Nhu ThuanNo ratings yet

- Manual Apollo FireDocument156 pagesManual Apollo FireAgnaldo JuniorNo ratings yet

- 李怀印:《现代中国的形成》Document351 pages李怀印:《现代中国的形成》Biaolin Wang100% (2)

- Signature Assign DraftDocument9 pagesSignature Assign Draftapi-589324815No ratings yet

- Pat Big Xi 2021Document8 pagesPat Big Xi 2021Claudia Yosephine TantonoNo ratings yet

- IndianOceanSecurityTaskforceWeb PDFDocument132 pagesIndianOceanSecurityTaskforceWeb PDFvishakha chaudharyNo ratings yet