Codigo de Falla

Codigo de Falla

Uploaded by

Marco Yarasca RomeroCopyright:

Available Formats

Codigo de Falla

Codigo de Falla

Uploaded by

Marco Yarasca RomeroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Codigo de Falla

Codigo de Falla

Uploaded by

Marco Yarasca RomeroCopyright:

Available Formats

DI−117

DIAGNOSTICS − ENGINE

DIDYB−01

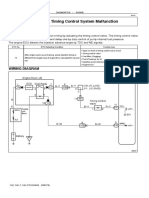

DTC P1670/32 Injection Pump System Malfunction

CIRCUIT DESCRIPTION

The correction system correct variations between each injection pump.

DTC No. DTC Detection Condition Trouble Area

S Injection pump correction unit circuit

P1670/32 Open or short in injection pump correction unit circuit S Injection pump correction unit

S Engine ECU

WIRING DIAGRAM

Engine ECU

I9

Injection Pump 5V

(Shielded)

26

LG DATA

DATA E16

1

5V

33

L CLK

VDD/CLK E16 E1

4

BR

GND

2

BR

D E

BR

E

J4 BR

J/C

E

ED

A23873

1HD−FTV ENGINE SUP (RM1179E)

DI−118

DIAGNOSTICS − ENGINE

INSPECTION PROCEDURE

1 Check for open and short in harness and connector between DATA of engine

ECU and DATA of injection pump correction unit (See page IN−19).

NG Repair or replace harness or connector.

OK

2 Check for open and short in harness and connector between CLK of engine ECU

and VDD/CLK of injection pump correction unit (See page IN−19).

NG Repair or replace harness or connector.

OK

3 Check for open in harness in injection pump correction unit terminal GND and

body ground (See page IN−19).

NG Repair or replace harness or connector.

OK

1HD−FTV ENGINE SUP (RM1179E)

DI−119

DIAGNOSTICS − ENGINE

4 Check waveform between terminal DATA of engine ECU connector.

PREPARATION:

E1 (a) Remove the glove compartment door.

(b) Connect an oscilloscope between terminals DATA and E1

of the engine ECU.

(c) Turn the ignition switch ON.

CHECK:

Within 0.5 seconds after the ignition switch is turned ON, check

DATA

the waveform between terminals DATA and E1 of the engine

A23883 ECU.

OK:

20 msec./DIV. The correct waveforms are as shown.

OK Check and replace engine ECU

2 V/DIV. A23894

NG

5 Check waveform between terminal CLK of engine ECU connector.

PREPARATION:

E1 (a) Remove the glove compartment door.

(b) Turn the ignition switch ON.

(c) Connect an oscilloscope between terminals CLK and E1

of the engine ECU.

CHECK:

Within 0.5 seconds after the ignition switch is turned ON, check

CLK the waveform between terminals CLK and E1 of the engine

A23883 ECU.

OK:

20 msec./DIV. The correct waveforms are as shown.

OK Go to step 7.

2 V/DIV. A23895

1HD−FTV ENGINE SUP (RM1179E)

DI−120

DIAGNOSTICS − ENGINE

NG

6 Check waveform between terminal CLK of engine ECU connector.

PREPARATION:

E1 (a) Remove the glove compartment door.

(b) Disconnect the injection pump correction unit connector.

(c) Turn the ignition switch ON.

(d) Connect an oscilloscope between terminals CLK and E1

of the engine ECU.

CHECK:

CLK Within 0.5 seconds after the ignition switch is turned ON, check

A23883 the waveform between terminals CLK and E1 of the engine

ECU.

20 msec./DIV. OK:

The correct waveforms are as shown.

NG Check and replace engine ECU.

2 V/DIV. A23895

OK

Check and replace injection pump (See Pub No. RM617E, page FU−113).

1HD−FTV ENGINE SUP (RM1179E)

DI−121

DIAGNOSTICS − ENGINE

7 Check voltage between DATA of wire harness and body ground.

Wire harness side PREPARATION:

Injection pump correction connector (a) Disconnect the injection pump correction unit connector.

DATA (b) Turn the ignition switch ON.

CHECK:

Measure the voltage between terminal DATA of the injection

pump correction unit connector and body ground.

OK:

Voltage: 4.5 to 5.5V

A23902

NG Check and replace engine ECU.

OK

Check and replace injection pump (See Pub No. RM617E, page FU−113).

1HD−FTV ENGINE SUP (RM1179E)

You might also like

- Teaching English Pronunciation For A Global World-WALKER - ARCHERDocument13 pagesTeaching English Pronunciation For A Global World-WALKER - ARCHERMarina MeloNo ratings yet

- SM VOLVO L90C WHEEL LOADER Service Repair ManualDocument16 pagesSM VOLVO L90C WHEEL LOADER Service Repair ManualMarco Yarasca Romero100% (2)

- Mazda 121 PCM 2000-2002Document8 pagesMazda 121 PCM 2000-2002Patricio ValenciaNo ratings yet

- Ewd 3C eDocument1 pageEwd 3C eallaucaamor50% (2)

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry DarmawanNo ratings yet

- Diagrama ABS Toyota HiluxDocument2 pagesDiagrama ABS Toyota HiluxMário Oliveira100% (1)

- DTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenDocument4 pagesDTC P0045/34 Turbo/Super Charger Boost Control Solenoid Circuit / OpenhenryantonioNo ratings yet

- ECT HiluxDocument6 pagesECT HiluxPhạm DuyNo ratings yet

- Ec ZD30 TD27 Nissan PatrolDocument1 pageEc ZD30 TD27 Nissan Patrolpalaboy88850% (2)

- Windows PDFDocument43 pagesWindows PDFCatalin BuleandraNo ratings yet

- Pin Data Sportage Wagon 2001Document4 pagesPin Data Sportage Wagon 2001Marcelo MendozaNo ratings yet

- DTC 0707 P7 F/Inj Timg FB DTC 0707 P7 F/Inj Timg FB DescriptionDocument6 pagesDTC 0707 P7 F/Inj Timg FB DTC 0707 P7 F/Inj Timg FB Descriptionbrandon alexi barrueto cancinoNo ratings yet

- SE655Document1 pageSE655indra rukmanaNo ratings yet

- For Preparation Description: Click HereDocument1 pageFor Preparation Description: Click HereOneysi Reyes UlloaNo ratings yet

- Blitz FATT DC InstallationDocument4 pagesBlitz FATT DC InstallationDave_BNo ratings yet

- Toyota 2AZ-FSEDocument4 pagesToyota 2AZ-FSEТимNo ratings yet

- DTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionDocument3 pagesDTC C1511/11 Torque Sensor 1 Malfunction DTC C1512/11 Torque Sensor 2 Malfunction DTC C1513/11 Torque Sensor Deviation Excessive Torque Sensor Power Supply Voltage Malfunc-TionSajjad Khaliq100% (1)

- DTC 97 EDU Circuit MalfunctionDocument5 pagesDTC 97 EDU Circuit Malfunctionkavidush123No ratings yet

- Harness & Wiring Diagram: To IndexDocument58 pagesHarness & Wiring Diagram: To Indexhidraulic100% (2)

- Lubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Document2 pagesLubrication System 1. General: Engine - 2Tr-Fe Engine EG-16Maxi SardiNo ratings yet

- Power Source: 78 HIACE (EWD622E)Document4 pagesPower Source: 78 HIACE (EWD622E)Egoro KapitoNo ratings yet

- BYD G3-Owner's Manual20110610-EN PDFDocument160 pagesBYD G3-Owner's Manual20110610-EN PDFamer100% (2)

- 41 Hilux (Cont. Next Page) : Power Source Abs (W/ VSC), TRC and VSCDocument4 pages41 Hilux (Cont. Next Page) : Power Source Abs (W/ VSC), TRC and VSCนายอัครชัย ทองเนียมNo ratings yet

- Transfer Control UnitDocument6 pagesTransfer Control UnitAlex HernandezNo ratings yet

- 4271 2GDocument24 pages4271 2GAlexandre Dantas HenriqueNo ratings yet

- Manual Vivant TacumaDocument76 pagesManual Vivant TacumaLuis Alberto Martinez Tinoco100% (1)

- 4M4 Gr13E PDFDocument36 pages4M4 Gr13E PDFcristian garciaNo ratings yet

- Fuse in XpandercrossDocument16 pagesFuse in XpandercrossMUHAMMAD IKHWANUDINNo ratings yet

- VSC Warning LightDocument3 pagesVSC Warning Lightbob loblawNo ratings yet

- 27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)Document8 pages27 Hilux (Cont. Next Page) : Engine Control (1GD-FTV)autocomtrucksNo ratings yet

- P0B3BDocument2 pagesP0B3BWah YudiNo ratings yet

- Ipdm E/R (Intelligent Power Distribution Module Engine Room)Document1 pageIpdm E/R (Intelligent Power Distribution Module Engine Room)Marc AmoresNo ratings yet

- P02ee00 - P02ef00 - P02F000 - P02F100 - P060694 - P062D00Document5 pagesP02ee00 - P02ef00 - P02F000 - P02F100 - P060694 - P062D00Yannick de WalqueNo ratings yet

- COROLLA 2009 AIRE ACONDICIonadoDocument10 pagesCOROLLA 2009 AIRE ACONDICIonadoJeison Jose Anthonio castro SagastumeNo ratings yet

- Accent Engine Control SystemDocument35 pagesAccent Engine Control Systemflash_24014910No ratings yet

- DTC B1135/24 Harf Connection in Airbag Sensor Assy ConnectorDocument2 pagesDTC B1135/24 Harf Connection in Airbag Sensor Assy ConnectorPhang KumwingNo ratings yet

- Pinout-Schematic DiagramsDocument14 pagesPinout-Schematic DiagramsIvan RdzNo ratings yet

- Yaris 2006+ Remote Start Wiring GuideDocument8 pagesYaris 2006+ Remote Start Wiring GuideOleg Mikhalitsyn100% (1)

- ABS (TMMMS Made), Brake Assist (TMMMS Made)Document12 pagesABS (TMMMS Made), Brake Assist (TMMMS Made)Albert BriceñoNo ratings yet

- CHEVROLETDocument1 pageCHEVROLETnicamarcosNo ratings yet

- Fuses Location - Land Cruiser 100 (1998-2007)Document4 pagesFuses Location - Land Cruiser 100 (1998-2007)30535jNo ratings yet

- SD313 24 Engine Control System (D4BH: 4D56 TCI 2.5L) (4) : F5 10A F13 10A F20 10ADocument1 pageSD313 24 Engine Control System (D4BH: 4D56 TCI 2.5L) (4) : F5 10A F13 10A F20 10AhaiderNo ratings yet

- SD313 1 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T) (1) ECM Terminal InformationDocument1 pageSD313 1 MFI Control System (G4HE/G4HG: EPSILON 1.0L/1.1L M/T) (1) ECM Terminal InformationHuy Trần QuốcNo ratings yet

- Control Unit: Engine-EcuDocument3 pagesControl Unit: Engine-EcuDwi Rizky Febriyanto IpepNo ratings yet

- EWD ActyonC0104004 PDFDocument6 pagesEWD ActyonC0104004 PDFAnderson BombistaNo ratings yet

- Injectors EcuDocument5 pagesInjectors Ecudane05100% (1)

- 2015 Nissan 370Z 3.7L Eng VIN A TouringDocument69 pages2015 Nissan 370Z 3.7L Eng VIN A TouringData TécnicaNo ratings yet

- Toyota Hilux - Lista Codigos de FallaDocument10 pagesToyota Hilux - Lista Codigos de Fallagustavoguti27100% (1)

- Engine Control System 1. General: Engine - 2Tr-Fe Engine EG-31Document32 pagesEngine Control System 1. General: Engine - 2Tr-Fe Engine EG-31Maxi Sardi100% (1)

- Electrical Components Location: A: EngineDocument13 pagesElectrical Components Location: A: EnginemiguelNo ratings yet

- Newrexton Ewd Cewd05009Document6 pagesNewrexton Ewd Cewd05009nicamarcosNo ratings yet

- Wiring Diagram: Engine Control SystemDocument21 pagesWiring Diagram: Engine Control SystemLionel Martin Sucasara100% (3)

- Citroen ZX ECM1Document2 pagesCitroen ZX ECM1jairpg21100% (1)

- General Data EDC17: Designation Technical Data / CommentsDocument9 pagesGeneral Data EDC17: Designation Technical Data / CommentsKrzysztof BrękNo ratings yet

- 50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Document4 pages50 Hilux (Cont. Next Page) : Power Source Combination Meter (From Jun. 2011 Production)Ichsan KurniawanNo ratings yet

- Pinout Nissan Ecr33 Rb25detDocument1 pagePinout Nissan Ecr33 Rb25detElmer AlanesNo ratings yet

- Nissan Almera n16 2001 Electronic Repair Manual 160Document1 pageNissan Almera n16 2001 Electronic Repair Manual 160netifig352No ratings yet

- ECM PINOUT Chevrolet-Sail PDFDocument2 pagesECM PINOUT Chevrolet-Sail PDFJhonatan Jibaja RamírezNo ratings yet

- Technical Data Vito 115 CDIDocument3 pagesTechnical Data Vito 115 CDImarkoNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- DTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionDocument2 pagesDTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionsundarNo ratings yet

- DTC P1600 ECM BATT Malfunction: Circuit DescriptionDocument2 pagesDTC P1600 ECM BATT Malfunction: Circuit DescriptionDesron SamuelNo ratings yet

- TOYOTA RAV4 Dashboard Warning LightsDocument1 pageTOYOTA RAV4 Dashboard Warning LightsMarco Yarasca RomeroNo ratings yet

- Ecs 1KD BDocument13 pagesEcs 1KD BMarco Yarasca RomeroNo ratings yet

- ChargingDocument3 pagesChargingMarco Yarasca RomeroNo ratings yet

- CS 2TRDocument3 pagesCS 2TRMarco Yarasca RomeroNo ratings yet

- 2003 D 2.0 RF-TCI Engine Control System (ETC)Document1 page2003 D 2.0 RF-TCI Engine Control System (ETC)Marco Yarasca RomeroNo ratings yet

- Parking Brake System Location Index: Ac5uuw00008105Document24 pagesParking Brake System Location Index: Ac5uuw00008105Marco Yarasca RomeroNo ratings yet

- Cruise Control System: SectionDocument135 pagesCruise Control System: SectionMarco Yarasca RomeroNo ratings yet

- Power Supply, Ground & Circuit Elements: SectionDocument144 pagesPower Supply, Ground & Circuit Elements: SectionMarco Yarasca RomeroNo ratings yet

- Exterior Lighting System: SectionDocument334 pagesExterior Lighting System: SectionMarco Yarasca RomeroNo ratings yet

- Access Start Authorization: 27-4, Battery, Disconnecting and ReconnectingDocument25 pagesAccess Start Authorization: 27-4, Battery, Disconnecting and ReconnectingMarco Yarasca RomeroNo ratings yet

- Access Start Authorization: 27-4, Battery, Disconnecting and ReconnectingDocument25 pagesAccess Start Authorization: 27-4, Battery, Disconnecting and ReconnectingMarco Yarasca RomeroNo ratings yet

- Assignment 2 Questions (UGPG) PDFDocument5 pagesAssignment 2 Questions (UGPG) PDFHenryNo ratings yet

- Maxell Usbt1-200 User ManualDocument120 pagesMaxell Usbt1-200 User ManualRoberto Carlos Torres ChiritoNo ratings yet

- Little Child Jesus Christian Academy Cabiao, Nueva Ecija, IncDocument4 pagesLittle Child Jesus Christian Academy Cabiao, Nueva Ecija, IncEuniceNo ratings yet

- Ch12. Tuples Notes With Question AnswersDocument22 pagesCh12. Tuples Notes With Question Answersgeetjn2007No ratings yet

- Application of Laser in Periodontics PDFDocument3 pagesApplication of Laser in Periodontics PDFRamona MateiNo ratings yet

- Lesson 1.4 Domain and Range of Functions PDFDocument36 pagesLesson 1.4 Domain and Range of Functions PDFhi mynameNo ratings yet

- Audit Committee and Timeliness of Financial ReportsDocument13 pagesAudit Committee and Timeliness of Financial ReportsAlexander Decker100% (1)

- Pattern Recognition Letters: Julien Lesouple, Cédric Baudoin, Marc Spigai, Jean-Yves TourneretDocument11 pagesPattern Recognition Letters: Julien Lesouple, Cédric Baudoin, Marc Spigai, Jean-Yves TourneretSergio AlumendaNo ratings yet

- Instruction Manual - Advance Series 480 Vacuum RegulatorDocument24 pagesInstruction Manual - Advance Series 480 Vacuum RegulatorĐình Sơn HoàngNo ratings yet

- Group 10 Ge 6 ReportDocument41 pagesGroup 10 Ge 6 ReportJonabel G. MontalboNo ratings yet

- Lesson PlanDocument7 pagesLesson PlanWing Jintalan BuenNo ratings yet

- Troll Warhammer ChartsDocument2 pagesTroll Warhammer ChartstristanludlowNo ratings yet

- Vehicle - Terrain SystemsDocument80 pagesVehicle - Terrain Systemsmohamed magdyNo ratings yet

- Lesson 4 - Part 2 - PersonDocument11 pagesLesson 4 - Part 2 - PersonyeuuutaekokNo ratings yet

- Lecture 2b - The Radar EquationDocument13 pagesLecture 2b - The Radar EquationSatishNo ratings yet

- Dapi PDFDocument2 pagesDapi PDFBrandon samuel Mendoza osegueraNo ratings yet

- SS 409M Wear Resistant SteelDocument10 pagesSS 409M Wear Resistant SteelUmesh chandra PancholiNo ratings yet

- Pki C Ei120s 100 DV1Document2 pagesPki C Ei120s 100 DV1Khánh NguyễnNo ratings yet

- HEC-RAS - 6.0 2DModelingUsersManual (Unlocked by WWW - Freemypdf.com)Document283 pagesHEC-RAS - 6.0 2DModelingUsersManual (Unlocked by WWW - Freemypdf.com)Isabela BalanNo ratings yet

- Pu Guard Bitumen BasedDocument3 pagesPu Guard Bitumen BasedSantosh Kumar PatnaikNo ratings yet

- Monsters of Murka v1.31Document111 pagesMonsters of Murka v1.31paxtone91No ratings yet

- 2 Day Website FormatDocument18 pages2 Day Website FormatPanacorp ResearchNo ratings yet

- Rubriks For ScrapbookDocument1 pageRubriks For ScrapbookJessa Baloro100% (1)

- Lecture 11 Propositional Logic Part 3 Natural DeductionDocument40 pagesLecture 11 Propositional Logic Part 3 Natural DeductionmminseolNo ratings yet

- CHUDD 2023 OPCR GuidesDocument14 pagesCHUDD 2023 OPCR GuidesWendel AbejoNo ratings yet

- Ca MDS BHCDocument30 pagesCa MDS BHCUlma HudinNo ratings yet

- 1 Evaluation Examination - GE Board October 2021Document2 pages1 Evaluation Examination - GE Board October 2021ARNOLD MORANNo ratings yet

- Sensors For Small Forces: ForceDocument5 pagesSensors For Small Forces: ForcePALANI MNo ratings yet

- SAP CRM 7.0 - ActionsDocument54 pagesSAP CRM 7.0 - ActionsNestor de Valais100% (1)