STDB 2 B

STDB 2 B

Uploaded by

garpheetCopyright:

Available Formats

STDB 2 B

STDB 2 B

Uploaded by

garpheetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

STDB 2 B

STDB 2 B

Uploaded by

garpheetCopyright:

Available Formats

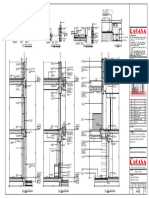

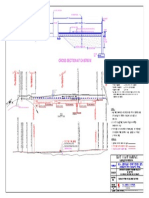

60'-6" USUAL 10" 17'-0" 17'-0" 10" GENERAL NOTES (CONTINUED FROM SHEET 1 OF 2)

3 •" EXPANSION JOINT

JRCP 21. CONSTRUCT ANCHOR LUGS, EXPANSION JOINTS, AND SLEEPER

NO.5 @ 6"LONGITUDINAL STEEL

SLABS AS DETAILED IN SECTION A-A. THESE WILL BE PAID

CONSTRUCTION JOINT OR FOR IN ACCORDANCE WITH ITEM, "CONCRETE PAVEMENT

ARMOR JOINT (SEE BRIDGE TERMINALS."

ƒ " EXPANSION JOINT

END TIE BARS

END CURB RETURN

EXPANSION JOINTS DETAILS)

22. REINFORCING STEEL FOR TERMINAL ANCHOR SYSTEMS MAY

BE GRADE 40 OR GRADE 60.

@ CURB RETURNS

6

A 1

A 23. PLACE CONCRETE FOR ANCHOR LUGS AS SOON AS POSSIBLE

ANCHOR LUGS NO.4 @ 18"TRANSVERSE STEEL AFTER COMPLETING EXCAVATION,TO PRESERVE THE INHERENT

NOTE:

OFFSET TO FREEWAY SOIL CHARACTERISTICS. EXCAVATING FOR AND PLACING

LEAVE ISLAND AREA OPEN

CONCRETE FOR ANCHOR SYSTEM MAY BE IN PREFORMED SECTIONS

(SEE PLAN SHEETS) UNLESS OTHERWISE SHOWN

20' CORRESPONDING TO THE WIDTH OF PAVING PLACEMENT.

SAWED JOINTS

IN THE PLANS. BRIDGE

APPROACH SLAB

TYPICAL LAYOUT 24. APPLY A STEEL TROWEL FINISH TO SLEEPER SLABS AND

X (TERMINAL ANCHORAGE AT BRIDGES) AND COAT WITH AN ASPHALT BOND BREAKER.

MA X

4" MA

2" 25. THE DETAILS FOR ANCHORS, LUGS, EXPANSION JOINTS,

1 ‚" D x 22" EPOXY COATED

AND SLEEPER SLABS ARE NOT APPLICABLE UNLESS SHOWN

DOWEL BARS @ 12" SPA.

ELSEWHERE IN THE PLANS.

1" ASPHALT ETHYLENE VINYL ACETATE

CONSTRUCTION JOINT

BOND BREAKER JOINT SEAL PLACED UNDER 26. APPROACH SLAB WILL BE PAID FOR IN ACCORDANCE WITH THE

SEE NOTE A COMPRESSION (EPOXY BONDED ITEM "CONCRETE STRUCTURES."

CONSTRUCTION JOINT (ROUGHEN THE CONSTRUCTION JOINT TO CONCRETE)

BY BROOMING WITH A STIFF BROOM TRANSVERSE TO THE

COAT THIS HALF OF DOWEL BAR WITH 27. WITHIN 5 MINUTES OF SAWING, COMPLETELY REMOVE THE

C

L OF PAVEMENT AND CLEAN THE ROUGHENED SURFACE BITUMINOUS MASTIC TO PREVENT BOND. RESULTING SLURRY FROM THE JOINT BY FLUSHING WITH HIGH

SURFACE OF LAITANCE AND LOOSE MATERIAL PRIOR TO

11" PRESSURE WATER. THEN ALLOW THE JOINT TO DRY FOR A

PLACING CONCRETE PAVEMENT.) 3 •" ROADWAY BRIDGE

MINIMUM OF 48 HOURS BEFORE SANDBLASTING THE JOINT.

„ "

BARS "A"(SPACED AT • PLASTIC DOWEL CAP

END CURB RETURN (4" MIN. LENGTH)

THE SPACING OF THE #4@18" T

(5'R USUAL 28. DO NOT SHEAR CUT DOWEL BARS.

LONITUDINAL STEEL) NO.5 @ 6"

I

*

S

FACE OF CURB

"T"

L

29. SIZE ADDITIONAL SHEAR BARS AS LONGITUDIAL

A

N

D

BARS AND SPACE THEM MIDWAY BETWEEN ALTERNATE

LONGITUDINAL BARS ALONG THE TRANSVERSE CONSTRUCTION

6" JOINT FORMED AT THE LEAVE-OUT.

6" LIME TREATED 6" (TYP) 2'-0"

NO.5x2'-9"@12"C-C

3'-0"

SUBGRADE

TIE BARS POLYETHYLENE

SLEEPER SLAB NO.5x(SLAB WIDTH-4")

FOAM(6 LB. 30. IF THE CONCRETE DESIGN REQUIRES GREATER THAN 5.5 SACKS

@10" SPACING

DENSITY) OF CEMENTITIOUS MATERIAL PER CUBIC YARD, WRITTEN

3'-0" NORMAL FACE OF ABUTMENT APPROVAL BY THE AREA ENGINEER WILL BE REQUIRED. ENSURE

TO JOINT BACKWALL CONCRETE PAVEMENT MIXES PLACED FROM APRIL 1 TO OCTOBER

2'-0" 31 CONTAIN A MINIMUM OF 25 PERCENT BY WEIGHT OF CLASS

6-NO.4 X (SLAB WIDTH-4") EXPANSION JOINT JUNCTION WITH BRIDGE "F" FLY ASH.

TYPICAL ANCHOR LUG

6" B B SECTION A-A 31. IN LOCATIONS WHERE THE PLANS CALL FOR FAST TRACK

MEET EXISTING CONC. PAVM'T

CONCRETE PAVEMENT IN LIEU OF JRCP (LAID ON COMPACTED OR

ƒ" EXPANSION JOINT STABILIZED SUBGRADE), USE DETAILS IN THIS STANDARD IN

SAWED JOINT TO MATCH CONJUNCTION WITH THE APPROPRIATE FAST TRACK CONCRETE

EXIST JRCP PROP JRCP

LONGITUDINAL SPECIFICATION. IF THE JRCP IS LAID UPON A BASE STRUCTURE,

CONSTRUCTION JOINT ADD 3" TO THE FAST TRACK PAVEMENT THICKNESS TO COMPENSATE

BREAK BACK THE EXISTING FOR THE BASE.

C MAJOR STREET OF CITY STREET SAWED JOINT SEALED CONCRETE AND EXPOSE THE EXISTING

WITH CLASS 4, 5, OR 7 REINFORCING STEEL TO PROVIDE

SEALING MATERIAL

CONSTRUCTION JOINT

FOR A 33 TIMES BAR DIAMETER LAP.

FRONTAGE STREET

TIE BARS

6"

MAX

7"

T

EXIST JRCP PROP JRCP

NO.4 BARS

SAWED JOINT SEALED WITH CLASS 4,

EXISTING BASE @ 12" BASE AND 10"10"

5, OR 7 JOINT SEALING MATERIAL

TREATED

SUBGRADE 1 „"x22" EPOXY COATED DOWEL BAR @ 12"C-C

SECTION B-B ** T/2 +1 •"

COAT THIS HALF WITH BITUMINOUS MASTIC

MIN

8"

(FOR PROPOSED PAVEMENT DEPTHS OF 7" MAX)

T

TIE BARS

BASE AND

REPLACE ANY BENT LONGITUDNIAL REINFORCING. IF THERE IS NOT SUFFICIENT TREATED

DRILL HOLE TO PROVIDE PLASTIC DOWEL CAP TO FIT

EXPOSED REINFORCING TO PROVIDE A MINIMUM OF A 33 TIMES BAR DIAMETER LAP, DOWEL (2" MIN LENGTH) SUBGRADE

SNUG FIT. PLACE USING

ƒ " EXPANSION JOINT

REMOVE THE EXISTING PAVEMENT AND SUFFICIENTLY EXPOSE THE EXISTING REINFORCING MEET EXISTING SUBGRADE

EPOXY GROUT.

TO PROVIDE A 33 TIMES BAR DIAMETER LAP. REPLACE ANY SHEAR BARS THAT ARE

* SEE NOTE A DISTURBED, BY DRILLING AND GROUTING AS REQUIRED BY NOTE #29. PERFORM THIS SECTION B-B

@ CURB RETURNS

SEE NOTE A

CORRECTIVE ACTION AT NO EXPENSE TO THE DEPARTMENT. (FOR PROPOSED PAVEMENT DEPTHS OF 8" MIN)

BEGIN TIE BARS

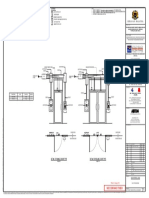

NOTE A:

* SEE SHEET 1 OF 2 FOR …"

ƒ"

STEEL PLACEMENT FOR THE

*IN AREAS OF CURB RETURNS RESPECTIVE LANE WIDTHS.

CLASS 4, 5, OR 7 JOINT

‚ "

CLASS 4, 5, OR 7 JOINT

‚ "

OR OTHER IRREGULAR AREAS, EDGE OF CONC. SEALING MATERIAL

SEALING MATERIAL

PLACE A REINFORCEMENT

ARRANGEMENT WHICH WILL BE BLOCK OUT

1 ƒ "

END CURB RETURN LONGITUDINAL

PLACEMENT LENGTH VARIES

MIN

APPROXIMATELY EQUAL BY STEEL

(25' R USUAL 1 ‚"

**

Texas Department of Transportation

… "

WEIGHT TO THE MAIN SLAB OR

‚ "

FACE OF CURB) TIE BARS @ 20"

AS DIRECTED. Houston District

T/4

FIBER BOARD

TYPICAL 6" MIN

12" MAX

2' USUAL •" D EXPANSION

1'-6" 1'-6"

1'-9"MIN

6

POLYETHYLENE

JOINT FILLER

JOINTED REINFORCED

NOTE: " FOAM BACKER,

3 CONCRETE PAVEMENT

2'-9"

PLACE TRANSVERSE SAWED SAW JOINT ROD

+ T/2

"

JOINTS WHERE DIRECTED. 1" D POLYETHYLENE

ˆ" MINIMUM WIDTH FOAM BACKER ROD DETAILS

OPTIONAL SAW CUT

EXPANSION JOINT DESIGN

1'-6" SAWED JOINT EXPANSION JOINTS (FOR PAVEMENT THICKNESS 10 INCHES OR LESS)

BARS A (NO.4 BARS) ** IF SILICEOUS RIVER GRAVEL IS JRCP SHEET 2 OF 2

#5 BARS x3'-0" USED AS THE COARSE AGGREGATE,

FILE: STDB-2.dgn DN: CK: DW: CK:

CONCRETE SLAB THIS DEPTH IS T/3.

TRANSVERSE STEEL

C TxDOT MAR.2004 DIST FED REG PROJECT NO. SHEET

DETAIL OF BLOCKOUT REVISIONS

INTERSECTION OF MAJOR STREET WITH FRONTAGE STREET *OMIT TIE BARS

JOINT SEALING DETAILS 5/05 2004 SPECS

HOU 6

@ INLET BLOCK-OUT 7/2010 ADDED NOTE

COUNTY CONTROL SECT JOB HIGHWAY

TYPICAL REINFORCING PLAN 9/2013 ADDED NOTE

You might also like

- MAGNUM 225, 250, 280, 310 SERIES TRACTORS Euro Electrical Schematic 87389709Document4 pagesMAGNUM 225, 250, 280, 310 SERIES TRACTORS Euro Electrical Schematic 87389709Fábio CostaNo ratings yet

- Huesker Incomat Filterpoint Mattress Data Aug. 2010Document2 pagesHuesker Incomat Filterpoint Mattress Data Aug. 2010garpheetNo ratings yet

- Jis A 5335 1987 Pretensioned Spun Concrete Piles PDFDocument12 pagesJis A 5335 1987 Pretensioned Spun Concrete Piles PDFgarpheetNo ratings yet

- Department of Defence Handbook-Mooring DesignDocument264 pagesDepartment of Defence Handbook-Mooring DesigngarpheetNo ratings yet

- New Approved Builders For Publishing - 2019 PDFDocument6 pagesNew Approved Builders For Publishing - 2019 PDFVincent Oswyn100% (1)

- SPE-22350-PA - Integrated Reservoir Management PDFDocument8 pagesSPE-22350-PA - Integrated Reservoir Management PDFPedroNo ratings yet

- Water Supply DetailsDocument1 pageWater Supply DetailsUsha CastagneNo ratings yet

- Foundation Plan ScheduleDocument1 pageFoundation Plan Schedulerm.trinidadfNo ratings yet

- General Drawing Exchanger N°2Document1 pageGeneral Drawing Exchanger N°2calinvasco190670No ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignKevinNo ratings yet

- Clean-Out Detail Air Chamber Detail: General NotesDocument1 pageClean-Out Detail Air Chamber Detail: General NotesJem CapistranoNo ratings yet

- Mulimbayan Residence - PL (For Construction)Document7 pagesMulimbayan Residence - PL (For Construction)Jhanchris CortezNo ratings yet

- PML3 Sys Dep00 XX DR V 49011 - R0Document1 pagePML3 Sys Dep00 XX DR V 49011 - R0prabhash vermaNo ratings yet

- BD SuperstructureDocument18 pagesBD SuperstructureAshutoshAparajNo ratings yet

- Lac 569 A 400 Wall Sections A 402Document1 pageLac 569 A 400 Wall Sections A 402Anjum BasraNo ratings yet

- Alta Prima Conv S-2Document1 pageAlta Prima Conv S-2Ronnel John CruzNo ratings yet

- Cabana StructuralDocument1 pageCabana StructuralAlsean Soriano DetubioNo ratings yet

- General Layout: Lokasi: Dermaga Jetty Ct-3 BpksDocument1 pageGeneral Layout: Lokasi: Dermaga Jetty Ct-3 BpksJhonDoeDoeNo ratings yet

- Phep-Power House - PH-200 - Shop DWGSDocument4 pagesPhep-Power House - PH-200 - Shop DWGStrivikramraoNo ratings yet

- 20220208 ENTRANCE GATEPLAN 01Document1 page20220208 ENTRANCE GATEPLAN 01rkgargassociates45No ratings yet

- TYPEPLANGAD - 2x6x5RUB - V1-ModelDocument1 pageTYPEPLANGAD - 2x6x5RUB - V1-ModelP Rajender ReddyNo ratings yet

- Jaipur Furniture Layout 3rd FloorDocument1 pageJaipur Furniture Layout 3rd Floorkunal SharmaNo ratings yet

- 04-R.C.C DETAIL IN R.I.B-ModelDocument1 page04-R.C.C DETAIL IN R.I.B-ModelManvendra Singh RaghuwanshiNo ratings yet

- Section BB Blow Up Detail 1 (Louvers Panel) : SCALE 1:100 SCALE 1:50Document1 pageSection BB Blow Up Detail 1 (Louvers Panel) : SCALE 1:100 SCALE 1:50Fawwaz RotiNo ratings yet

- Confidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116Document1 pageConfidential Client Not For Construction: 1301 Burlington Street SUITE 100 P 816.361.1177 N Kansas City, Mo 64116mirza.adeelNo ratings yet

- Compound 2: Inset: Drainage OutfallDocument1 pageCompound 2: Inset: Drainage Outfall김대환No ratings yet

- General Arrangement ISO TC-ModelDocument1 pageGeneral Arrangement ISO TC-ModelFikri Barry AlfianNo ratings yet

- Ee PlanDocument1 pageEe PlanPaul MendozaNo ratings yet

- research on indian village cultureDocument1 pageresearch on indian village culturesuryat4512No ratings yet

- Hydraulic Calculation Rev-B After UpdationDocument100 pagesHydraulic Calculation Rev-B After UpdationkarthiNo ratings yet

- California: Engineering Services Division ofDocument1 pageCalifornia: Engineering Services Division ofProfessor PuppiesNo ratings yet

- Bbstds 43Document1 pageBbstds 43KY PengNo ratings yet

- Rly. Platform DrawingDocument1 pageRly. Platform DrawingAtul Kumar MishraNo ratings yet

- Rekod Full Penyelengaraan Bay Gtaw Atc 2Document1 pageRekod Full Penyelengaraan Bay Gtaw Atc 2Nurliyana SamsudinNo ratings yet

- Schedule of ColumnDocument1 pageSchedule of ColumnJaybert DumaranNo ratings yet

- Cross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Document1 pageCross Section at Ch.8700 M: EXST. RAIL LEVEL 163.669Atul Kumar MishraNo ratings yet

- 2.438M Wide Passage: Schedule of Opening Schedule of RCC Columns & Footings Schedule of RCC Slab Schedule of R.C.C BeamDocument1 page2.438M Wide Passage: Schedule of Opening Schedule of RCC Columns & Footings Schedule of RCC Slab Schedule of R.C.C BeamAvik DasNo ratings yet

- Power Distribution Diagram PDFDocument1 pagePower Distribution Diagram PDFPrasanna GothaneNo ratings yet

- USUGAN Package 2 Gen - DrawingDocument1 pageUSUGAN Package 2 Gen - DrawingabigailNo ratings yet

- MC-PH01-P04-06A09-SPL-DWG-SWP-520002-A - 50m POOL DETAILS - SHEET 1Document1 pageMC-PH01-P04-06A09-SPL-DWG-SWP-520002-A - 50m POOL DETAILS - SHEET 1danger1wolfNo ratings yet

- San Clemente ST 07 PDFDocument1 pageSan Clemente ST 07 PDFMel Frederick MadriagaNo ratings yet

- S 1 PDFDocument1 pageS 1 PDFfrancis sebastian lagamayoNo ratings yet

- XLP Pre L15 WL15P51Document2 pagesXLP Pre L15 WL15P51Aria NickbakhtNo ratings yet

- 11.2 - Box Culvert Condition SurveyDocument2 pages11.2 - Box Culvert Condition SurveyEskinderNo ratings yet

- WTERJET TRENCH-ModelDocument1 pageWTERJET TRENCH-Modelagrawalmr3No ratings yet

- HVAC Designs BookDocument9 pagesHVAC Designs BookAfsal KalpathyNo ratings yet

- Nasunggan 11Document1 pageNasunggan 11kifobe9283No ratings yet

- Roof Framing-Roof FramingDocument1 pageRoof Framing-Roof FramingSantiago VallejoNo ratings yet

- A320 PainelDocument1 pageA320 PainelClaudio FamadasNo ratings yet

- 01 PMCDocument1 page01 PMCsrishtiNo ratings yet

- Plumbing Plan 1Document1 pagePlumbing Plan 1Dialyn San Jose MangcoyNo ratings yet

- Frame Connection To Steel Substrate Through Buck D: Roof Plan UpperDocument1 pageFrame Connection To Steel Substrate Through Buck D: Roof Plan UpperArturo Antolin Chávez ApeñaNo ratings yet

- 2-101-8 Heater Burner Piping ArrangementsDocument1 page2-101-8 Heater Burner Piping ArrangementsJavier JimenezNo ratings yet

- Elevation Detail 4Document1 pageElevation Detail 4Kresta Ellece LomabaoNo ratings yet

- Rehabilitation and Expansion of Puntales Feeder Port: 10mmø Bars at 250Mm O.C.B.W. Serrated StepDocument1 pageRehabilitation and Expansion of Puntales Feeder Port: 10mmø Bars at 250Mm O.C.B.W. Serrated Stepalezandro del rossiNo ratings yet

- MRT M&E Drawing3Document1 pageMRT M&E Drawing3qinxuekunNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NoteschrisNo ratings yet

- Alta Merra Conv S-2Document1 pageAlta Merra Conv S-2Ronnel John CruzNo ratings yet

- PCC221 Recovery BoilerDocument4 pagesPCC221 Recovery BoilerHEMANT RAMJINo ratings yet

- Spread Footing Schedule: Bucks County Justice CenterDocument19 pagesSpread Footing Schedule: Bucks County Justice CenterBandula PrasadNo ratings yet

- A1 Final Abt P7Document1 pageA1 Final Abt P7Jomari KaiserNo ratings yet

- Pump Station Standard Details 2023Document11 pagesPump Station Standard Details 2023Trường Thịnh PhanNo ratings yet

- MTD Statement - GT Concrete Mattresses (302 401-Ms-0912)Document2 pagesMTD Statement - GT Concrete Mattresses (302 401-Ms-0912)garpheetNo ratings yet

- W1 - EN - Anchor Selector Chart 2019 05 24Document1 pageW1 - EN - Anchor Selector Chart 2019 05 24garpheetNo ratings yet

- Base Hinged Masts Technical Data PDFDocument1 pageBase Hinged Masts Technical Data PDFgarpheetNo ratings yet

- Tensar Erosion Control PDFDocument12 pagesTensar Erosion Control PDFgarpheetNo ratings yet

- Ship Particular Ratu Zulaikha Update 28 April 2015Document2 pagesShip Particular Ratu Zulaikha Update 28 April 2015garpheet0% (1)

- Ship Particular-OB Oceanbay 23315 Update 18 Oktober 2016Document2 pagesShip Particular-OB Oceanbay 23315 Update 18 Oktober 2016garpheetNo ratings yet

- ACEFormer™ Product Brochure PDFDocument2 pagesACEFormer™ Product Brochure PDFgarpheetNo ratings yet

- Cim 16500 21aDocument320 pagesCim 16500 21agarpheetNo ratings yet

- MTD Statement - GT Concrete Mattresses (302 401-Ms-0912)Document2 pagesMTD Statement - GT Concrete Mattresses (302 401-Ms-0912)garpheetNo ratings yet

- Bar Reinforcement Welded Wire Fabric: Concrete Pavement Jointed ReinforcedDocument1 pageBar Reinforcement Welded Wire Fabric: Concrete Pavement Jointed ReinforcedgarpheetNo ratings yet

- 05 Grating Info Interstate Grating Heavy DutyDocument2 pages05 Grating Info Interstate Grating Heavy DutygarpheetNo ratings yet

- Waterfront Inspection Guidelines ManualDocument126 pagesWaterfront Inspection Guidelines Manualgarpheet100% (2)

- Jis G 3532 2011 PDFDocument26 pagesJis G 3532 2011 PDFgarpheet100% (1)

- 2022 SKO Awards RecognitionDocument5 pages2022 SKO Awards RecognitionMarcio AlmeidaNo ratings yet

- Chittoor TestResultsDocument13 pagesChittoor TestResultsPlacementMitsNo ratings yet

- BarChip Fibres Replace Steel in Chilean HousingDocument2 pagesBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoNo ratings yet

- Pande Artha L Ade Fitriyanti L Joshua Gama Wastara - PPT Case Study Tropis Non Tropis PDFDocument18 pagesPande Artha L Ade Fitriyanti L Joshua Gama Wastara - PPT Case Study Tropis Non Tropis PDFAdhe Fitriyanti ArifinNo ratings yet

- Application of Geophysical Methods in CiDocument12 pagesApplication of Geophysical Methods in CiyaredNo ratings yet

- 2015 MB Wa Winning Homes AwardsDocument220 pages2015 MB Wa Winning Homes AwardsSandu TatianaNo ratings yet

- Comflor Composite Floor Deck Brochure UKDocument68 pagesComflor Composite Floor Deck Brochure UKSuciu Bogdan AlexandruNo ratings yet

- CASA 802 Norwich UniversityDocument21 pagesCASA 802 Norwich UniversityNicoleNo ratings yet

- Analysis of The November 2017 ExamDocument5 pagesAnalysis of The November 2017 Examtapera_mangeziNo ratings yet

- ABB OHB BrochureDocument20 pagesABB OHB BrochureErwin WiraNo ratings yet

- Engineering Mechanics Statics and Dynamics Irving H Shames PDFDocument2 pagesEngineering Mechanics Statics and Dynamics Irving H Shames PDFNeci CardenoNo ratings yet

- Specification For Fabricated PVC Fittings For Potable Water SuppliesDocument5 pagesSpecification For Fabricated PVC Fittings For Potable Water SuppliesgavallapalliNo ratings yet

- 3SEM07Document18 pages3SEM07nikaro1989No ratings yet

- Wind Load HotelDocument45 pagesWind Load HoteljohnNo ratings yet

- 5 3 pg1Document1 page5 3 pg1api-233065480No ratings yet

- Bubble Deck Slab DesignDocument9 pagesBubble Deck Slab Designnihar100% (1)

- Artificial Intelligence Robotics MCQ: Ads byDocument68 pagesArtificial Intelligence Robotics MCQ: Ads bySam SamNo ratings yet

- CV of Asif SiddiquiDocument2 pagesCV of Asif SiddiquiRubayetNo ratings yet

- Peek Datasheet Curbell PDFDocument1 pagePeek Datasheet Curbell PDFseeralan_1986No ratings yet

- Sem-VIII Course Exit SurveyDocument6 pagesSem-VIII Course Exit SurveyMayur ShrivastavaNo ratings yet

- HFGHG DDGF Js FGJSD GJDocument12 pagesHFGHG DDGF Js FGJSD GJChloe JemimahNo ratings yet

- Computer Aided Design and Manufacturing: Instruction To CandidatesDocument2 pagesComputer Aided Design and Manufacturing: Instruction To CandidatesAnjaiah MadarapuNo ratings yet

- Amol Resume 362Document2 pagesAmol Resume 362rautamol2019No ratings yet

- Schneider Electric India System Integrators Anand Ahuja: Aadhaarshila@dataone - inDocument5 pagesSchneider Electric India System Integrators Anand Ahuja: Aadhaarshila@dataone - inGopi Ganapathy0% (1)

- PG PHD Admission Jul 2023Document5 pagesPG PHD Admission Jul 2023apce.28No ratings yet

- ASTM D7264 - Teste de Flexão em CompósitosDocument2 pagesASTM D7264 - Teste de Flexão em CompósitosLuizNo ratings yet

- Traa, J.W.A. - RUP vs. MSF - A Comparative StudyDocument140 pagesTraa, J.W.A. - RUP vs. MSF - A Comparative Studyapi-3776312100% (1)

- English For Chemical EngineerDocument94 pagesEnglish For Chemical EngineerKresna Thufail ANo ratings yet