CPT Series Control Transformers: Six Easy Steps

CPT Series Control Transformers: Six Easy Steps

Uploaded by

Mahfudz FauziCopyright:

Available Formats

CPT Series Control Transformers: Six Easy Steps

CPT Series Control Transformers: Six Easy Steps

Uploaded by

Mahfudz FauziOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

CPT Series Control Transformers: Six Easy Steps

CPT Series Control Transformers: Six Easy Steps

Uploaded by

Mahfudz FauziCopyright:

Available Formats

CPT Series Control Transformers

(Inrush VA data should be obtained from the device

manufacturers.)

The inrush load power factor is difficult to determine without

50 VA detailed vector analysis of all the control components. In the

to absence of such information, we recommend that a 40% power

500 VA factor be utilized.

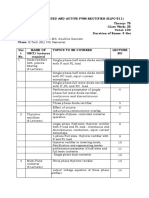

Six easy steps

Once the three circuit variables have been determined, follow

these steps to select the proper transformer.

1. Determine your primary (supply) and secondary (output) voltage

requirements, as well as the required frequency (i.e. 60 Hz).

2. Calculate the total sealed VA of your circuit.

3. Calculate the inrush VA by adding the inrush VA of all components

being energized together. Remember to add the sealed VA of all

components that do not have inrush VA (lamps, timers, etc.), as they

do present a load to the transformer during maximum inrush. If the

inrush for your components is unknown, assume a 40% inrush

power factor.

480 VAC Primary 4. Calculate the total inrush VA using one of two methods:

120 VAC Secondary 5. If the nominal supply voltage does not fluctuate more than 5%, then

Get years of reliable service from a or

quality transformer at a practical price

CPT transformers for

industrial applications reference the 90% secondary voltage column in the Regulation Data

Table for the correct VA rating.

The CPT series of control transformers is specifically designed for If the supply voltage varies up to 10%, the 95% secondary voltage

high inrush applications requiring reliable output voltage stability. column should be used to size the transformer.

Designed to meet industrial applications where electromagnetic 6. Using the regulation data table below, select the appropriate VA

devices such as relays, solenoids, etc. are used, the CPT series rated transformer:

transformers maximize inrush capability and output voltage A. With a continuous VA rating that is equal to or greater than the

regulation when electromagnetic devices are initially energized. value in Step 3.

B. With a maximum inrush VA equal to or greater than the value

Quality construction obtained in Step 5.

improves performance

The CPT series of control transformers uses Mylar, Nomex and Note: See fuse section in this catalog for over-current protection chart for

transformers.

other high-quality insulating materials. Insulation is used to elec-

trically insulate turn to turn windings, layer to layer windings,

primary to secondary windings and ground.

All CPT transformers are vacuum impregnated with VT polyester Transformer Regulation Data Table

resin and oven-cured, which seals the surface and eliminates mois-

Continuous Inrush VA @ 40% Power Factor

ture. Filling the entire unit provides a strong mechanical bond and VA

offers protection from the environment. Part Number Transformer 85% Secondary 90% Secondary 95% Secondary

Control transformer selection

Nameplate Voltage Voltage Voltage

CPT115-50-F 50 270 210 160

To select the proper transformer, you must first determine three CPT115-75-F 75 435 365 255

characteristics of the load circuit. They are total steady-state CPT115-100-F 100 655 520 370

(sealed) VA, total inrush VA, and inrush load power factor.

CPT115-150-F 150 1300 1010 700

Total steady-sstate “sealed” VA is the total amount of VA that the

CPT115-200-F 200 1975 1500 1020

transformer must supply to the load circuit for an extended length

of time. Calculate by adding the total steady-state VA of all devices CPT115-250-F 250 2680 2030 1340

in your control circuit. (The operating VA data for the devices CPT115-300-F 300 2970 2270 1510

should be available from the manufacturers.) CPT115-500-F 500 6300 5035 3305

The inrush VA is the amount of VA that the transformer must supply Note: It is recommended that a control transformer be sized at a 40% power factor.

for all components in the control circuit that are energized Some components in a circuit, such as electromagnetic devices, typically operate at

together. Consideration for the start-up sequence may be required. that level due to their inherently lower power factor. Selecting a transformer at 40%

power factor will more than adequately size the unit for all the various loads in the

circuit.

26–96 Power Products 1 - 80 0 - 633 - 0405

CPT Series Control Transformers Specifications PLC

Overview

Features: DL05/06

PLC

• UL/CSA/CE approved

• 50/60 Hz DL105

PLC

• Primary: 240/480, 230/460, 220/440 VAC FUSES NOT INCLUDED (See Edison fuse section for HCTR fuses)

• Secondary: 120, 115, 110 VAC DL205

• Copper coils, epoxy encapsulated PLC

• FK-3 fuse block: (note 5)

DL305

Primary: 2 x type CC rejection fuses PLC

Secondary: One midget fuse

• Compatible with all CPTSG2, CPTSG3 and CPTSG4 DL405

PLC

finger-safe terminal covers (see price list)

• Universal mounting base Field I/O

Software

(note 5) C-more

HMIs

Other HMI

(note 5) AC Drives

Motors

Steppers/

Servos

Motor

Controls

Proximity

Sensors

Photo

Sensors

Limit

Switches

Encoders

Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

CPT Series Control Transformer Specifications

TB’s &

Part Number Price Volt/Amp Output Primary

Voltage Secondary Shipping Dimensions (inches) Wiring

Rating Current (50/60Hz) Voltage Weight (lbs.) A B C D E F G H Power

CPT115-50-F <---> 50 0.43A 3.60 3.41 3.75 4.07 2.50 NA 2.50 3.00 2.75

Enclosures

CPT115-75-F <---> 75 0.65A 4.35 3.31 4.00 4.07 2.44 NA 2.50 3.00 2.75

CPT115-100-F <---> 100 0.87A 5.15 3.50 4.50 4.07 2.63 NA 2.50 3.00 2.75 Appendix

CPT115-150-F <---> 150 1.30A 240/480, 6.15 3.75 4.22 4.70 2.75 3.13 3.75 4.25 3.32

230/460, 120, 115, 110

Part Index

CPT115-200-F <---> 200 1.74A 220/440, 7.75 3.75 4.22 4.70 2.75 3.13 3.75 4.25 3.32

CPT115-250-F <---> 250 2.17A 9.50 4.00 4.80 5.33 3.00 3.13 3.75 4.50 3.83

CPT115-300-F <---> 300 2.61A 10.75 4.00 4.80 5.33 3.00 3.13 3.75 4.50 3.83

CPT115-500-F <---> 500 4.35A 14.75 5.00 5.25 5.45 4.00 3.75 4.37 5.25 4.45

w w w. a u to m at i o n d i re c t . c o m / p owe ra n d a c c es s o r i es Power Products 26–97

CPT Series Transformers Terminal Covers

Finger-safe terminal covers

These one-piece molded terminal covers are a quick and

easy way to provide safety and protection in the workplace.

They protect operators from potential shock hazards and

guard against accidental contact with the fuses.

Features

• Strong, yet flexible, clear Lexan polyester material

will not break or chip.

• See-through material allows view of the fuse

and/or terminal connections.

• One size fits all; purchase all three for complete

protection.

Terminal Covers

Part Number Pcs/Pkg Price Description.

CPTSG2 4 <---> Safety puller fuse cover for primary fuse

CPTSG3 2 <---> Domed terminal cover for secondary fuse

CPTSG2 Flat terminal cover, for unfused primary and/or

CPTSG3 CPTSG4 2 <--->

unfused secondary terminals

CPTSG4

Test Lead Terminal Terminal

Access Hole Cover CPTSG4 Cover CPTSG4

Domed

Terminal Test Lead

Mounting Cover CPTSG3 Access Hole

Mounting

Hole Hole

PT PT

Transformer Transformer

Mounting Mounting

Protrusion Protrusion

Secondary

Fuse Clips

26–98 Power Products 1 - 80 0 - 633 - 0405

Recommendations for Overcurrent

Protection - UL and CSA (North American)

Standards

UL and CSA (North American) Standards

North American standards, including UL 508, National Electric Code 450, and the Canadian Electrical Code, Part 1, require

overcurrent protection on all control circuit transformers. There are two options for overcurrent protection:

Option 1 (Primary only Protection)

Provide an overcurrent device in the primary circuit rated to the current of the transformer. The overcurrent limits are as follows:

Primary 9 Amps or more: no more than 125% of rated current

Primary 2 to 9 Amps: no more than 167% of rated current

Primary less than 2 Amps: no more than 300% of rated current for power circuits

no more than 500% of rated current for control circuits

Note: This method is considered less desirable, as start-up inrush to the transformer can frequently surpass the current rating of the device and result in

nuisance interruptions.

Option 2 (Primary and Secondary Protection)

The second option is to install overcurrent devices in both the primary and secondary circuits of the transformer. In this option,

the secondary device must be rated no more than 125% of rated current of the transformer and the primary no more than

250%. CEC permits 300% overcurrent on the primary for this option.

In both options listed, it is recommended that time delay fuses be considered to avoid unnecessary interruptions.

PRIMARY (UL and CSA) HCTR Current Limiting Class CC Fuses

AMP Pcs/Pkg

To assist in the selection of fuses, the following chart recommends Part Number Rating Weight Price

the maximum primary fuse rating in amperes. The first number

HCTR-25 0.25 10/1 0.2 lb <--->

shown is the maximum overcurrent protection when the primary

current is less than 2 amps and the overcurrent protection device HCTR-5 0.5 10/1 0.2 lb <--->

is rated for 300%. The second number (shown in brackets) is HCTR-75 0.75 10/1 0.2 lb <--->

recommended when the primary is less than 2 amps and the over- HCTR1 1 10/1 0.2 lb <--->

current device is to be rated at 500% of rated current. Where only HCTR1-25 1.25 10/1 0.2 lb <--->

one number is indicated, the primary is 2 amps or more and one

HCTR1-5 1.5 10/1 0.2 lb <--->

rating of overcurrent protection is shown as optimal. Choose the

next higher fuse rating if these numbers do not correspond with HCTR2 2 10/1 0.2 lb <--->

standard fuse selections. HCTR2-5 2.5 10/1 0.2 lb <--->

HCTR3 3 10/1 0.2 lb <--->

HCTR3-5 3.5 10/1 0.2 lb <--->

Primary CPT115 VA RATING

Voltage HCTR4 4 10/1 0.2 lb <--->

50 75 100 150 200 250 300 500

HCTR5 5 10/1 0.2 lb <--->

6/10 1 1-1/4 2 2-1/2 3-2/10 4 4

220 HCTR6 6 10/1 0.2 lb <--->

(1-1/8) (1-6/10) (2-1/4) (3-2/10) (4-1/2) (5-6/10) (6-1/4)

HCTR7-5 7.5 10/1 0.2 lb <--->

6/10 8/10 1-1/4 1-8/10 2-1/2 3-2/10 3-1/2 4

230 HCTR8 8 10/1 0.2 lb <--->

(1) (1-6/10) (2) (3-2/10) (4) (5) (6-1/4)

HCTR10 10 10/1 0.2 lb <--->

6/10 8/10 1-1/4 1-8/10 2-1/4 3 3-1/2 3-1/2

240 HCTR15 15 10/1 0.2 lb <--->

(1) (1-1/2) (2) (3) (4) (5) (6-1/4)

HCTR20 20 10/1 0.2 lb <--->

3/10 1/2 6/10 1 1-1/4 1-6/10 2 2-1/4

440 HCTR25 25 10/1 0.2 lb <--->

(1/2) (8/10) (1-1/8) (1-6/10) (2-1/4) (2-8/10) (3-2/10) (5-6/10)

HCTR30 30 10/1 0.2 lb <--->

3/10 4/10 6/10 8/10 1-1/4 1-6/10 1-8/10 3-2/10

460

(1/2) (8/10) (1) (1-6/10) (2) (2-1/2) (3-2/10) (5) Note: See catalog page 26-65 for characteristic curves.

3/10 4/10 6/10 8/10 1-1/4 1-1/2 1-8/10 3

480

(1/2) (3/4) (1) (1-1/2) (2) (2-1/2) (3) (5)

2 Power Products 1 - 80 0 - 633 - 0405

Recommendations for Overcurrent PLC

Overview

Protection - UL and CSA (North American) DL05/06

PLC

Standards, continued DL105

PLC

DL205

PLC

SECONDARY MEN General Purpose Midget Class Fuses

DL305

PLC

The overcurrent protection listed below, in amperes, is 125% of Part AMP DL405

the rated current of the transformer. Choose the next higher fuse Number Rating Pcs/Pkg Weight Price PLC

rating if these numbers do not correspond with standard fuse MEN-5 0.5 10/1 0.2 lb <--->

selections. Field I/O

MEN-6 0.6 10/1 0.2 lb <--->

MEN1 1 10/1 0.2 lb <---> Software

MEN1-4 1.4 10/1 0.2 lb <--->

Secondary CPT115 VA RATING C-more

MEN1-5 1.5 10/1 0.2 lb <---> HMIs

Voltage 50 75 100 150 200 250 300 500

MEN2 2 10/1 0.2 lb <---> Other HMI

110 3/4 1-1/8 1-1/2 2-1/4 3 3-1/2 4-1/2 7-1/2

115 6/10 1 1-4/10 2 2-8/10 3 4 7

MEN2-5 2.5 10/1 0.2 lb <--->

MEN3 3 10/1 0.2 lb <---> AC Drives

120 6/10 1 1-1/4 2 2-1/2 3-2/10 4 6-1/4

MEN3-5 3.5 10/1 0.2 lb <--->

Motors

MEN4 4 10/1 0.2 lb <--->

MEN5 5 10/1 0.2 lb <--->

Steppers/

MEN6 6 10/1 0.2 lb <---> Servos

MEN7 7 10/1 0.2 lb <---> Motor

Controls

MEN8 8 10/1 0.2 lb <--->

MEN10 10 10/1 0.2 lb <---> Proximity

Sensors

MEN12 12 10/1 0.2 lb <--->

Photo

MEN15 15 10/1 0.2 lb <---> Sensors

MEN20 20 10/1 0.2 lb <---> Limit

Switches

MEN25 25 10/1 0.2 lb <--->

MEN30 30 10/1 0.2 lb <---> Encoders

Note: See catalog page 26-70 for characteristic curves. Pushbuttons/

Lights

Process

Relays/

Timers

Comm.

TB’s &

Wiring

Power

Enclosures

REFERENCES:

UL 508, 32.7 Appendix

UL 845, 11.16 and 11.17

Part Index

NEC 430-72 (c) exception #2

NEC 450-3 (b) 1 and 2

CEEC Part 1, 26-256

w w w. a u to m at i o n d i re c t . c o m / p owe ra n d a c c es s o r i es Power Products 3

You might also like

- Especificaciones Tecnicas AVR Stamford SA465Document4 pagesEspecificaciones Tecnicas AVR Stamford SA465MH..2023No ratings yet

- ECM Motors PDFDocument4 pagesECM Motors PDFNdia2007No ratings yet

- Pages From T 500VA 240-480 Primary120-240VAC4.17 - 2.08A SecondaryDocument1 pagePages From T 500VA 240-480 Primary120-240VAC4.17 - 2.08A SecondaryAnonymous EP0GKhfNo ratings yet

- EVC600C User Manual (English)Document6 pagesEVC600C User Manual (English)dhany reza100% (1)

- AVR 380 ManualDocument14 pagesAVR 380 Manualkazishah100% (1)

- Sx440, STAMFORD ManualDocument4 pagesSx440, STAMFORD ManualSarawut PipeNo ratings yet

- Current Transformers, Voltage Transformers and Instrument Transformers - IndiaDocument10 pagesCurrent Transformers, Voltage Transformers and Instrument Transformers - IndiaVijay PitchaiahNo ratings yet

- As480 Avr Newage StamfordDocument6 pagesAs480 Avr Newage Stamfordabuzer1981No ratings yet

- Avr Newage mx321 PDFDocument4 pagesAvr Newage mx321 PDFLiya MahagamaNo ratings yet

- Transformer Basics Chapter 4Document4 pagesTransformer Basics Chapter 4Fahad AlamNo ratings yet

- AVR AS440 Data SheetDocument4 pagesAVR AS440 Data SheetMazhar Hussain100% (2)

- Type FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersDocument12 pagesType FEC Epoxy Encapsulated, Copper-Wound Industrial Control TransformersTOLENTINONo ratings yet

- TFW & TFDW Series AC Synchronous Generator.: Instructions For Safe Operation and MaintenanceDocument9 pagesTFW & TFDW Series AC Synchronous Generator.: Instructions For Safe Operation and MaintenanceMark ManzanasNo ratings yet

- Dongan Industrial Control PDFDocument39 pagesDongan Industrial Control PDFElmar Syvill UcatNo ratings yet

- Ea15a Manual en PDFDocument6 pagesEa15a Manual en PDFTimmyJuriNo ratings yet

- Mx341 Avr Newage StamfordDocument4 pagesMx341 Avr Newage Stamfordabuzer1981No ratings yet

- Remote Control Interface: General Description Technical SpecificationDocument6 pagesRemote Control Interface: General Description Technical SpecificationKenNaNo ratings yet

- 700 Series AC Dielectric Test SetsDocument7 pages700 Series AC Dielectric Test SetsKhoilnNo ratings yet

- Avr PM300Document6 pagesAvr PM300menale libayeNo ratings yet

- TD - As480 Avr - 04.08 - 02 - GBDocument6 pagesTD - As480 Avr - 04.08 - 02 - GBmo7amedengNo ratings yet

- PACT Analog: Current TransformersDocument28 pagesPACT Analog: Current TransformersMiguel Bartolo CruzNo ratings yet

- IVG - FivestarDocument8 pagesIVG - FivestarAno035No ratings yet

- UCDI274K 311 1P TD EN - Rev - ADocument10 pagesUCDI274K 311 1P TD EN - Rev - AMuntasir MunirNo ratings yet

- PWC Charging System (1630 ACE HO) (GTX, RXP, RXT Series - WAKE PRO) - Shop Manual smr2016-031 - enDocument9 pagesPWC Charging System (1630 ACE HO) (GTX, RXP, RXT Series - WAKE PRO) - Shop Manual smr2016-031 - enboredinjacksonvilleNo ratings yet

- Micron TransformersDocument7 pagesMicron TransformersJedha YantiNo ratings yet

- UENR87840001Document14 pagesUENR87840001Brian RomanoNo ratings yet

- Sa465 Automatic Voltage Regulator (Avr)Document4 pagesSa465 Automatic Voltage Regulator (Avr)KenNaNo ratings yet

- Generator TroubleshootingDocument22 pagesGenerator TroubleshootingMichael Cabrera Rabino100% (2)

- R448 Leroy Somer Manual enDocument4 pagesR448 Leroy Somer Manual enJohn GarnetNo ratings yet

- Abb RelayDocument6 pagesAbb RelayTAHIR HUSAINNo ratings yet

- Uninterruptible Power Supply Units (Ups) Scope of WorksDocument6 pagesUninterruptible Power Supply Units (Ups) Scope of WorksKapila NayananandaNo ratings yet

- Over Voltage RelayDocument6 pagesOver Voltage Relayee306087No ratings yet

- SS440 InstructionsDocument4 pagesSS440 Instructionsgurunathan14No ratings yet

- Substation CommissioningDocument83 pagesSubstation Commissioningdidi sudiNo ratings yet

- Avr MX321Document3 pagesAvr MX321Ahmad ArpaniNo ratings yet

- Manual Stamford Avr MX342 PDFDocument4 pagesManual Stamford Avr MX342 PDFSeVictor Rudas CajaNo ratings yet

- Automatic Voltage RegulatorDocument5 pagesAutomatic Voltage Regulatorvirendkumar50% (2)

- HCI4F 311 1P TD EN - Rev - A PDFDocument9 pagesHCI4F 311 1P TD EN - Rev - A PDFRenzo zuñiga ahonNo ratings yet

- Inbound 4714998840874424268Document64 pagesInbound 4714998840874424268Dimitrios KoustasNo ratings yet

- A Guide On Load Flow Analysis Using ETAPDocument20 pagesA Guide On Load Flow Analysis Using ETAPMalik EltayiebNo ratings yet

- Sizing The Control Transformer For A PanelDocument16 pagesSizing The Control Transformer For A PanelKishore KrishnaNo ratings yet

- Ma325 Automatic Voltage Regulator Avr Bdsar ComDocument4 pagesMa325 Automatic Voltage Regulator Avr Bdsar ComAngel MartinezNo ratings yet

- Testing of Potential Transformers PDFDocument6 pagesTesting of Potential Transformers PDFMuhammad asif100% (1)

- UCI224CDocument9 pagesUCI224CChristian Rivera FloverNo ratings yet

- Electrical Power Systems Quality Lecture 2Document43 pagesElectrical Power Systems Quality Lecture 2Carlnagum 123456789No ratings yet

- Manual HPMV DNDocument42 pagesManual HPMV DNHudson CostaNo ratings yet

- Note To Spec. Writer: This System Must Be Only Installed On Bushings That HaveDocument6 pagesNote To Spec. Writer: This System Must Be Only Installed On Bushings That HaveRisdian Tetap OutsiderNo ratings yet

- Ses-12 TDPSDocument31 pagesSes-12 TDPSbaljeetjatNo ratings yet

- Especificaciones Tecnicas AVR Stamford SX440Document4 pagesEspecificaciones Tecnicas AVR Stamford SX440MH..2023No ratings yet

- TL Veichi AC60Document43 pagesTL Veichi AC60Dương Quốc Thái100% (1)

- A Guide On Load Flow Analysis Using ETAPDocument19 pagesA Guide On Load Flow Analysis Using ETAPReza Maulana MirazaNo ratings yet

- HCI534C/544C - Winding 311 Single Phase: Technical Data SheetDocument9 pagesHCI534C/544C - Winding 311 Single Phase: Technical Data SheetAhmed El-FayoumyNo ratings yet

- Rockwell Automation Test ProcedureDocument4 pagesRockwell Automation Test ProceduremaricruolivarNo ratings yet

- UCI224F 311 1P TD EN - Rev - ADocument9 pagesUCI224F 311 1P TD EN - Rev - AAndresNo ratings yet

- Falt & AlarmDocument26 pagesFalt & Alarmpartha majiNo ratings yet

- WT-3A Operation Manual (English)Document8 pagesWT-3A Operation Manual (English)Наталья100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Fide Rating InaDocument3 pagesFide Rating InaMahfudz FauziNo ratings yet

- ZEECO Product and IndustriesDocument3 pagesZEECO Product and IndustriesMahfudz FauziNo ratings yet

- D-Direct-Coupled Volute Pumps PDFDocument73 pagesD-Direct-Coupled Volute Pumps PDFMahfudz FauziNo ratings yet

- Krueger Exhaaust FanDocument4 pagesKrueger Exhaaust FanMahfudz FauziNo ratings yet

- ATEX V IECEx Comparison PDFDocument1 pageATEX V IECEx Comparison PDFMahfudz FauziNo ratings yet

- Etap Validation Cases and Comparison Results: Load FlowDocument68 pagesEtap Validation Cases and Comparison Results: Load FlowMahfudz FauziNo ratings yet

- Droop Setting in TurbineDocument2 pagesDroop Setting in TurbinepurnaNo ratings yet

- ACS 600 4 Quadrant DriveDocument4 pagesACS 600 4 Quadrant DriveRadu BabauNo ratings yet

- PLH190FT (12V190AH) : PLH Series-Long Standby LifeDocument2 pagesPLH190FT (12V190AH) : PLH Series-Long Standby LifeAlayn1807No ratings yet

- Indian Power SectorDocument38 pagesIndian Power SectorAbhay Singh ChandelNo ratings yet

- Ug 5th LCPWMDocument2 pagesUg 5th LCPWMBabbu DograNo ratings yet

- TLE-TE 9 - Q2 - Mod1 - ICT CSSDocument18 pagesTLE-TE 9 - Q2 - Mod1 - ICT CSSKirsten SethNo ratings yet

- Acon (Screw Terminal) WR SeriesDocument4 pagesAcon (Screw Terminal) WR SeriesfiilckyzkurvenyNo ratings yet

- IEEE STD C37.42-2016 TRANG 1.24Document2 pagesIEEE STD C37.42-2016 TRANG 1.24HopNo ratings yet

- Power Quality 438-IIDocument55 pagesPower Quality 438-IIyuscahyopNo ratings yet

- Electronics 09 01959 v2Document14 pagesElectronics 09 01959 v2Reda DjatouNo ratings yet

- HIMOINSA TransferSwitch Brochure En-20160519Document9 pagesHIMOINSA TransferSwitch Brochure En-20160519jorgeNo ratings yet

- Harmony Vertical Axis Wind Turbine: (ICCIP-2019) Available On: Elsevier-SSRNDocument7 pagesHarmony Vertical Axis Wind Turbine: (ICCIP-2019) Available On: Elsevier-SSRNirappa karaganviNo ratings yet

- 2.12.1 HOJA DE DATOS Vigirex RH10P, RH21P, RH99P - TDS15 PDFDocument9 pages2.12.1 HOJA DE DATOS Vigirex RH10P, RH21P, RH99P - TDS15 PDFabarr2009100% (1)

- 23 Energy ProductionDocument18 pages23 Energy ProductionnikoaNo ratings yet

- Distribution Business Unit Cummins Field Service Report Pal EngineersDocument1 pageDistribution Business Unit Cummins Field Service Report Pal EngineersPrabhu VijayakumaranNo ratings yet

- Sustainability 12 03944 v2Document30 pagesSustainability 12 03944 v2Rafaela MartinsNo ratings yet

- Analysis of Dynamic Behaviour of Electric Power Systems WithDocument4 pagesAnalysis of Dynamic Behaviour of Electric Power Systems WithayalmalikiNo ratings yet

- Load Flow Analysis and Short CircuitDocument16 pagesLoad Flow Analysis and Short CircuitAkram Hossen100% (1)

- 5G Power Outdoor Series-MTS9304A-HX10A1 (01075308-002) DatasheetDocument3 pages5G Power Outdoor Series-MTS9304A-HX10A1 (01075308-002) Datasheetlaabidi salemNo ratings yet

- Bataan Nuclear Power PlantDocument15 pagesBataan Nuclear Power Plantlesly AnneNo ratings yet

- List Spare Part Electrical & Part Autosortir: NO Spesifikasi Type Brand QTY Req Unit RemarkDocument7 pagesList Spare Part Electrical & Part Autosortir: NO Spesifikasi Type Brand QTY Req Unit RemarkSubistia IrwanNo ratings yet

- Negative Sequence & Zero Sequence Reactance PDFDocument6 pagesNegative Sequence & Zero Sequence Reactance PDFviksoniNo ratings yet

- Power CapacitorDocument88 pagesPower CapacitorShamim Ahsan ParvezNo ratings yet

- Specification For MV Switchboards / Motor Control CentresDocument33 pagesSpecification For MV Switchboards / Motor Control CentresDanish MohammedNo ratings yet

- Solar Power Bank With Wireless ChargingDocument4 pagesSolar Power Bank With Wireless ChargingEditor IJTSRDNo ratings yet

- Lesson PlanDocument4 pagesLesson PlanAyyar KandasamyNo ratings yet

- Cooperat Ve, NC,: ElectricDocument4 pagesCooperat Ve, NC,: Electricdick headNo ratings yet

- Question Bank On OHE As CorrectDocument6 pagesQuestion Bank On OHE As CorrectNagi Reddy ChintakuntaNo ratings yet

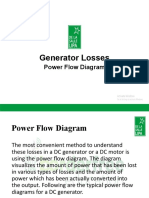

- Generator Losses: Power Flow DiagramDocument10 pagesGenerator Losses: Power Flow DiagramTrisha SARMIENTONo ratings yet