Fuel System: Section

Fuel System: Section

Uploaded by

skpppCopyright:

Available Formats

Fuel System: Section

Fuel System: Section

Uploaded by

skpppOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fuel System: Section

Fuel System: Section

Uploaded by

skpppCopyright:

Available Formats

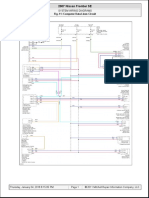

ENGINE

SECTION

FUEL SYSTEM

FL FL

E

CONTENTS

SERVICE INFORMATION ............................ 2 Removal and Installation .......................................... 4 F

Disassembly and Assembly ...................................... 8

PRECAUTIONS ................................................... 2

Precaution for Battery Service .................................. 2 FUEL TANK ...................................................... 10

G

Removal and Installation .........................................10

FUEL SYSTEM .................................................... 3

Checking Fuel Line ................................................... 3 SERVICE DATA AND SPECIFICATIONS

General Precaution ................................................... 3 (SDS) ................................................................. 12 H

Standard and Limit ..................................................12

FUEL LEVEL SENSOR UNIT, FUEL FILTER Tightening Torque ...................................................12

AND FUEL PUMP ASSEMBLY .......................... 4 I

Revision: 2009 February FL-1 2008 350Z

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Battery Service INFOID:0000000001646077

Before disconnecting the battery, lower both the driver and passenger windows. This will prevent any interfer-

ence between the window edge and the vehicle when the door is opened/closed. During normal operation, the

window slightly raises and lowers automatically to prevent any window to vehicle interference. The automatic

window function will not work with the battery disconnected.

Revision: 2009 February FL-2 2008 350Z

FUEL SYSTEM

< SERVICE INFORMATION >

FUEL SYSTEM

A

Checking Fuel Line INFOID:0000000001646078

Inspect fuel lines, fuel filler cap and fuel tank for improper attach- FL

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

C

SMA803A E

General Precaution INFOID:0000000001646079

WARNING: F

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

• Be sure to work in a well ventilated area and furnish workshop with a CO2 fire extinguisher. G

• Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

• Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

CAUTION: H

• Use gasoline required by the regulations for octane number. Refer to GI-4, "Precaution for Fuel

(Unleaded Premium Gasoline Required)".

• Before removing fuel line parts, perform the following procedures: I

- Release fuel pressure from the fuel lines. Refer to EC-78, "Fuel Pressure Check".

- Disconnect negative battery terminal.

• Always replace O-rings and clamps with new ones.

• Never kink or twist tubes when they are being installed. J

• Never tighten hose clamps excessively to avoid damaging hoses.

• After connecting fuel tube quick connectors, check quick con-

nectors are secure. K

Ensure that connector and resin tube do not contact any adja-

cent parts.

• After installing tubes, make sure there is no fuel leakage at

L

connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch

“ON” (with engine stopped). Then check for fuel leaks at con-

nections. M

- Start engine and rev it up and check for fuel leaks at connec-

tions.

• Use only a genuine NISSAN fuel filler cap as a replacement. If N

an incorrect fuel filler cap is used, the “MIL” may come on.

• For servicing “Evaporative Emission System” parts, refer to

EC-31.

O

SBIA0504E

Revision: 2009 February FL-3 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Removal and Installation INFOID:0000000001646080

PBIC1061E

Main fuel level sensor unit, fuel filter -

1. Retainer 2. 3. O-ring

and fuel pump assembly

4. Sub fuel level sensor unit

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-3, "General Pre-

caution".

1. Check fuel level on fuel gauge. If fuel gauge indicates more than

the level as shown in the figure (full or almost full), drain fuel

from fuel tank until gauge indicates level as shown in the figure

or below.

NOTE:

Because fuel will be spilled when removing main and sub fuel

level sensor units for the top of the fuel is above the main and

sub fuel level sensor units installation surface.

• As a guide, fuel level becomes the position as shown in the

figure or below when approximately 20 (5-1/4 US gal, 4-3/8

Imp gal) of fuel are drained from fuel tank. PBIC1139E

• In a case that fuel pump does not operate, perform the follow-

ing procedure.

a. Insert hose of less than 25 mm (0.98 in) in diameter into fuel filler tube through fuel filler opening to draw

fuel from fuel filler tube.

b. Disconnect fuel filler hose from fuel filler tube. Refer to FL-10.

c. Insert hose into fuel tank through fuel filler hose to draw fuel from fuel tank.

2. Release the fuel pressure from the fuel lines. Refer to EC-78, "Fuel Pressure Check".

3. Open fuel filler lid.

4. Open filler cap and release the pressure inside fuel tank.

5. Remove woofer or rear floor box mat and rear floor box. Refer to AV-44, "Removal and Installation of

Woofer and Woofer Amp (BOSE System)" or EI-36.

Revision: 2009 February FL-4 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

6. Remove inspection hole cover for main and sub fuel level sen-

sor units by turning clips clockwise by 90 degrees. A

FL

PBIC1062E

D

7. Disconnect harness connector and quick connector.

G

PBIC1063E

Disconnect quick connector as follows: H

• Hold the sides of connector, push in tabs and pull out fuel feed

tube.

• If quick connector sticks to tube of fuel level sensor unit, push

and pull quick connector several times until it start to move. I

Then disconnect quick connector by pulling.

K

SFE562A

CAUTION: L

Revision: 2009 February FL-5 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

• Quick connector can be disconnected when the tabs are

completely depressed. Never twist it more than neces-

sary.

• Never use any tools to disconnect quick connector.

• Keep resin tube away from heat. Be especially careful

when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Never bend or twist resin tube during installation and

disconnection.

• Never remove the remaining retainer on hard tube (or

equivalent) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or equivalent) is replaced,

also replace retainer with new one.

• Replace same color retainer as before replacing.

Retainer color: White

SBIA0504E

• To keep the connecting portion clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags or something similar.

PBIC0163E

8. Remove main fuel level sensor unit, fuel filter and fuel pump assembly, and sub fuel level sensor unit as

follows.

CAUTION:

• Never bend float arm during removal.

• Avoid polluting the inside by residue fuel. Draw out with avoiding inclination by supporting with

a cloth.

• Avoid impacts such as falling when handling components.

a. Removal of main fuel level sensor unit, fuel filter and fuel pump

assembly:

i. Remove retainer.

ii. Raise main fuel level sensor unit, fuel filter and fuel pump

assembly, and using snap ring pliers, remove fuel hose connec-

tor.

CAUTION:

Be careful not to damage fuel hose connector by expanding

them excessively.

b. Removal of sub fuel level sensor unit:

PBIC1578E

i. Remove retainer.

ii. Raise and release sub fuel level sensor unit to remove.

INSTALLATION

Note the following, and install in the reverse order of removal.

Revision: 2009 February FL-6 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

Main and Sub Fuel Level Sensor Unit

• When installing fuel hose connector insert them fully until a click A

sound of full stopper engagement is heard.

FL

PBIC1064E D

• Face main and sub fuel level sensor units as shown in the figure,

and install them with the knock pin on back aligned with pin hole on E

fuel tank.

PBIC1065E

H

• Install retainer so that its notch becomes parallel with the notch on

fuel tank.

I

K

PBIC1066E

L

• Tighten retainer mounting bolts evenly.

Quick Connector

Connect quick connector of fuel feed hose as follows: M

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard. N

3. After connecting, check that the connection is secure by following method.

• Visually confirm that the two tabs are connected to the connector.

• Pull the tube and the connector to check they are securely

connected. O

PBIC1653E

Revision: 2009 February FL-7 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

Inspection Hole Cover

1. Install inspection hole cover with direction mark (arrow) facing front of vehicle.

2. Lock clips by turning counter-clockwise.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leaks by applying fuel pres-

sure to fuel piping.

2. Start engine and rev it up and check there are no fuel leaks at the fuel system connections.

Disassembly and Assembly INFOID:0000000001646081

PBIC1081E

1. Fuel level sensor unit 2. Fuel filter and fuel pump assembly

CAUTION:

Sub fuel level sensor unit cannot be disassembled and should be replaced as a unit.

DISASSEMBLY

Remove fuel level sensor unit as follows.

1. Disconnect harness connector.

• Hold connector by fingers and pull it out, because there is no

stopper release tab.

PBIC1078E

2. Using suitable tool, pull up tabs points as shown in the figure

(two points) to release the lock.

CAUTION:

Be careful not to damage it.

PBIC1654E

Revision: 2009 February FL-8 2008 350Z

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

< SERVICE INFORMATION >

3. After fixing tabs are disengaged, slide fuel level sensor unit out

in direction shown by the arrow. A

CAUTION:

Never disassemble fuel filter and fuel pump assembly.

FL

PBIC1080E

D

ASSEMBLY

1. Check for damage of fuel level sensor unit installation position on the side of fuel filter and fuel pump

assembly.

E

2. Slide fuel level sensor unit until it aligns to installation groove, then insert it until it stops.

• Insert until you hear a “click” sound and actually feel the engagement.

• After inserting, apply force in reverse direction (removal direction) to ensure it cannot be pulled out.

F

3. Connect harness connector.

• Securely insert harness connector until it stops.

Revision: 2009 February FL-9 2008 350Z

FUEL TANK

< SERVICE INFORMATION >

FUEL TANK

Removal and Installation INFOID:0000000001646082

JPBIA1192GB

1. Grommet 2. Fuel filler cap 3. Clip

4. Fuel filler tube protector 5. Fuel tank mounting band 6. Fuel tank protector

7. Fuel tank 8. Vent tube 9. Vent hose

10. EVAP hose 11. Vent hose 12. Fuel filler hose

13. Fuel filler tube

• Refer to GI-8, "Component" for symbol marks in the figure.

REMOVAL

WARNING:

Be sure to read “General Precautions” before working on the fuel system. Refer to FL-3, "General Pre-

caution".

• Drain fuel from fuel tank if necessary. Refer to FL-4, "Removal and Installation".

• Perform work on level place.

1. Perform steps 2 to 7 of “REMOVAL” in “ FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP

ASSEMBLY” on main and sub fuel level sensor units. Refer to FL-4, "Removal and Installation".

2. Remove tunnel stay. Refer to RSU-5.

3. Remove exhaust front tube, center muffler and main muffler. Refer to EX-3.

4. Remove propeller shaft. Refer to PR-5.

CAUTION:

Never impact or damage propeller shaft tube.

5. Remove parking rear brake cables. Refer to PB-4.

6. Remove rear suspension assembly. Refer to RSU-5.

Revision: 2009 February FL-10 2008 350Z

FUEL TANK

< SERVICE INFORMATION >

7. Remove fuel tank protector.

8. Disconnect fuel filler hose, vent hose and EVAP hoses at fuel A

tank side.

FL

PBIC1674E

D

9. Remove fuel tank mounting band bolts while supporting fuel

tank. E

PBIC0878E

H

10. Supporting with hands, descend transmission jack carefully, and remove fuel tank.

CAUTION:

• Check that all connection points have been disconnected.

• Confirm there is no interference with vehicle. I

11. Remove fuel filler tube, if necessary.

INSTALLATION J

Note the following, and install in the reverse order of removal.

• Surely clamp fuel hoses and insert hose to the length below.

K

Fuel filler hose : 35 mm (1.38 in)

The other hoses : 25 mm (0.98 in)

• Be sure hose clamp is not placed on swelled area of fuel tube. L

• Tighten fuel hose clamp so that the distance between its lugs becomes to the following.

Fuel tank side : 8 - 12 mm (0.31 - 0.47 in) M

Fuel filler tube side : 5.7 - 9.7 mm (0.224 - 0.382 in)

• To connect quick connector, refer to FL-4, "Removal and Installation".

N

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), and check connections for leakage by applying fuel pres-

O

sure to fuel piping.

2. Start engine and rev it up and check there are no fuel leaks at the fuel system connections.

P

Revision: 2009 February FL-11 2008 350Z

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit INFOID:0000000001646083

Fuel tank capacity Approx. 76 (20 US gal, 16-3/4 Imp gal)

Fuel recommendation Refer to GI-4

Tightening Torque INFOID:0000000001646084

Unit : N·m (kg-m, ft-lb)

N·m (kg-m, in-lb)*

Main fuel level sensor unit, fuel filter and fuel pump assembly 2.0 - 2.5 (0.20 - 0.26, 18 - 22)*

Sub fuel level sensor unit 2.0 - 2.5 (0.20 - 0.26, 18 - 22)*

Fuel tank mounting band 37.0 - 49.0 (3.8 - 5.0, 27 - 36)

Fuel filler tube 10.9 - 14.7 (1.1 - 1.5, 8 - 11)

Fuel tank protector 10.9 - 14.7 (1.1 - 1.5, 8 - 11)

Revision: 2009 February FL-12 2008 350Z

You might also like

- Diagrama Sistema de Datos Nissan Frontier SE 2007 PDFDocument1 pageDiagrama Sistema de Datos Nissan Frontier SE 2007 PDFskppp100% (4)

- Caterpillar d8k Parts BookDocument20 pagesCaterpillar d8k Parts BookHassie100% (68)

- Selenium Test CaseDocument5 pagesSelenium Test Caseseeraj4urajNo ratings yet

- Nissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDocument13 pagesNissan Sentra 2009 Service Manual Nissan Sentra 2009 Service ManualFUEL SYSTEM PDFDavid BNo ratings yet

- Individual Task: Ayman I. Mohadali BSMT - 1Document5 pagesIndividual Task: Ayman I. Mohadali BSMT - 1Sheima Ainie JuripaeNo ratings yet

- FL PDFDocument8 pagesFL PDFAnonymous 64HDY7IiN0No ratings yet

- FL PDFDocument8 pagesFL PDFROSILENE PASSOSNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: Sectionmacau apNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionHarol CastilloNo ratings yet

- FL PDFDocument10 pagesFL PDFAldo ApazzaNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionJamar OliverNo ratings yet

- 2008 Nissan Versa 22Document14 pages2008 Nissan Versa 22Daryl TimothyNo ratings yet

- Fuel System: SectionDocument14 pagesFuel System: SectionAbu MaryamNo ratings yet

- Fuel SystemDocument14 pagesFuel Systemshortbus22No ratings yet

- flDocument14 pagesflbubbajones406No ratings yet

- Fuel System: SectionDocument14 pagesFuel System: Sectionfearimus1No ratings yet

- FL PDFDocument15 pagesFL PDFCarlos Tito AmésquitaNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: SectionYB MOTOR Nissan - Datsun SpecialistNo ratings yet

- Fuel System: SectionDocument17 pagesFuel System: SectionederengNo ratings yet

- 2007 Nissan Quest 43998Document14 pages2007 Nissan Quest 43998israelNo ratings yet

- 2002-Nissan-Altima-Fuel SystemDocument10 pages2002-Nissan-Altima-Fuel SystemSergio Robles CastroNo ratings yet

- Fuel System: SectionDocument8 pagesFuel System: SectionKatya FirsenkoNo ratings yet

- Fuel System: SectionDocument12 pagesFuel System: Sectiondavid94navarroNo ratings yet

- Ex PDFDocument6 pagesEx PDFOscar VillaseñorNo ratings yet

- 2007 Nissan Xterra 16Document18 pages2007 Nissan Xterra 16Roma Roma100% (1)

- Fuel System Service Manual On A 2008 Infiniti G37sDocument15 pagesFuel System Service Manual On A 2008 Infiniti G37sAdel HomsiNo ratings yet

- Sistema de Combustible Nissan 370 Z 2009Document15 pagesSistema de Combustible Nissan 370 Z 2009Hendrick CepedaNo ratings yet

- Acc VERSA 2011Document4 pagesAcc VERSA 2011Melvin MenjivarNo ratings yet

- 2008 Nissan Titan 27Document19 pages2008 Nissan Titan 27Rob MorelNo ratings yet

- Accelerator Control System: SectionDocument5 pagesAccelerator Control System: SectionEduardo ColinNo ratings yet

- Engine Lubrication System: SectionDocument12 pagesEngine Lubrication System: SectionAung Mh100% (1)

- Accelerator Control SystemDocument4 pagesAccelerator Control SystemPaolo MadambaNo ratings yet

- Acc PDFDocument5 pagesAcc PDFAlex HernandezNo ratings yet

- Accelerator Control System: SectionDocument5 pagesAccelerator Control System: SectionjonathanNo ratings yet

- Acc PDFDocument4 pagesAcc PDFHanselPerezAguirreNo ratings yet

- Fuel System: SectionDocument18 pagesFuel System: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionrickjmzbtchNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: SectionSmith Jara CunyaNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: Sectionภาคภูมิ ถ้ำทิมทองNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: Sectionjoeldqcgh29No ratings yet

- FFD 220930 003943Document33 pagesFFD 220930 003943Andres RodriguezNo ratings yet

- Accelerator Control System: SectionDocument4 pagesAccelerator Control System: Sectionibnu malkanNo ratings yet

- Accelerator Control SystemDocument3 pagesAccelerator Control SystemNapiNo ratings yet

- Ex PDFDocument6 pagesEx PDFCarlos Tito AmésquitaNo ratings yet

- Titan ExDocument6 pagesTitan ExjasleenNo ratings yet

- Manual de Taller de Nissan Frontier 2008Document11 pagesManual de Taller de Nissan Frontier 2008ruben7mojica100% (1)

- MT - Manual TransaxleDocument14 pagesMT - Manual TransaxleBRILLIANCE AUTO LIFENo ratings yet

- Acc PDFDocument5 pagesAcc PDFstaff055No ratings yet

- Fuel System: SectionDocument16 pagesFuel System: SectioncesarNo ratings yet

- Rear Final Drive: SectionDocument31 pagesRear Final Drive: SectionAnonymous 64HDY7IiN0No ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionRavishka SilvaNo ratings yet

- Accelarator Control SystemDocument4 pagesAccelarator Control Systempietruszka1No ratings yet

- Road Wheels & Tires: SectionDocument8 pagesRoad Wheels & Tires: SectionsdfsdNo ratings yet

- Accelerator Control System: SectionDocument3 pagesAccelerator Control System: SectionRolfy Jampol AyzanoaNo ratings yet

- Acc PDFDocument5 pagesAcc PDFAlexAnder CortezNo ratings yet

- Instrument Panel: SectionDocument14 pagesInstrument Panel: SectionOscar Villaseñor100% (1)

- Engine Mechanical: SectionDocument23 pagesEngine Mechanical: Sectionguta wondemu mamoNo ratings yet

- Accelerator Control System: SectionDocument5 pagesAccelerator Control System: Sectionwilder0l0pezNo ratings yet

- Exhaust System: SectionDocument7 pagesExhaust System: SectionZona Educación Especial ZacapaoaxtlaNo ratings yet

- Parking Brake System: SectionDocument7 pagesParking Brake System: SectionEduardo ColinNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Manual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFDocument148 pagesManual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFskpppNo ratings yet

- Front Axle: SectionDocument7 pagesFront Axle: SectionskpppNo ratings yet

- Sintermetal Manual DIESEL 2015 DigitalDocument120 pagesSintermetal Manual DIESEL 2015 DigitalBrian OrtegaNo ratings yet

- 11.sistema de Frenos AntibloqueoDocument93 pages11.sistema de Frenos AntibloqueoskpppNo ratings yet

- Driver Information System: SectionDocument87 pagesDriver Information System: SectionskpppNo ratings yet

- Exterior & Interior: SectionDocument47 pagesExterior & Interior: SectionskpppNo ratings yet

- Engine Cooling System: SectionDocument29 pagesEngine Cooling System: SectionskpppNo ratings yet

- Exhaust System: SectionDocument5 pagesExhaust System: SectionskpppNo ratings yet

- Auto Cruise Control System: SectionDocument2 pagesAuto Cruise Control System: SectionskpppNo ratings yet

- Engine Control System: SectionDocument665 pagesEngine Control System: SectionskpppNo ratings yet

- Engine Mechanical: SectionDocument145 pagesEngine Mechanical: SectionskpppNo ratings yet

- Brake Control System: SectionDocument126 pagesBrake Control System: SectionskpppNo ratings yet

- Audio Visual, Navigation & Telephone Sys-TEM: SectionDocument103 pagesAudio Visual, Navigation & Telephone Sys-TEM: SectionskpppNo ratings yet

- Automatic Air Conditioner: SectionDocument125 pagesAutomatic Air Conditioner: SectionskpppNo ratings yet

- Section: SERVICE INFORMATION ...........................Document72 pagesSection: SERVICE INFORMATION ...........................skpppNo ratings yet

- Frenos NissanDocument152 pagesFrenos NissanskpppNo ratings yet

- Body, Lock & Security System: SectionDocument226 pagesBody, Lock & Security System: SectionskpppNo ratings yet

- Brake System: SectionDocument55 pagesBrake System: SectionskpppNo ratings yet

- Engine Cooling System: SectionDocument32 pagesEngine Cooling System: SectionskpppNo ratings yet

- Transmision NissanDocument295 pagesTransmision NissanskpppNo ratings yet

- Engine Control System: SectionDocument665 pagesEngine Control System: SectionskpppNo ratings yet

- Driver Information System: SectionDocument98 pagesDriver Information System: SectionskpppNo ratings yet

- BR PDFDocument52 pagesBR PDFskpppNo ratings yet

- Engine Mechanical: SectionDocument184 pagesEngine Mechanical: SectionskpppNo ratings yet

- AAcondicionadoDocument148 pagesAAcondicionadoskpppNo ratings yet

- Body Control System: SectionDocument18 pagesBody Control System: SectionskpppNo ratings yet

- Guidelines For Authors Submitting Papers To THE NEW JOURNAL - A Template To FollowDocument6 pagesGuidelines For Authors Submitting Papers To THE NEW JOURNAL - A Template To FollowrodolfoNo ratings yet

- Ods LayoutDocument30 pagesOds Layoutfa_cooperNo ratings yet

- PROPOSED ENHANCEMENT REVIEW As Edited by Sir MikeDocument3 pagesPROPOSED ENHANCEMENT REVIEW As Edited by Sir MikeMichael BongalontaNo ratings yet

- Title /course Code Principles of AccountingDocument6 pagesTitle /course Code Principles of AccountingM Noaman AkbarNo ratings yet

- DRIMPDocument2 pagesDRIMPmohd isham shahril bin ismailNo ratings yet

- Effect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorDocument17 pagesEffect of Fuel Temperature On Mixing Characteristics of A Kerosene Jet Injected Into A Cavity-Based Supersonic CombustorCristianNo ratings yet

- Investment Function - AcceleratorDocument14 pagesInvestment Function - AcceleratorSmita KadianNo ratings yet

- Doctrine: The Lawyer's Oath Is NOT A Mere Ceremony or Formality For Practicing Law. Every Lawyer ShouldDocument1 pageDoctrine: The Lawyer's Oath Is NOT A Mere Ceremony or Formality For Practicing Law. Every Lawyer ShoulddadcansancioNo ratings yet

- Solutions To Homework Assignment #4, Math 253Document6 pagesSolutions To Homework Assignment #4, Math 253QwaAlmanlawiNo ratings yet

- RNC PAT ChecklistDocument41 pagesRNC PAT ChecklistSudipta DasNo ratings yet

- Global Business EnvironmentDocument77 pagesGlobal Business EnvironmentNiña Mae DiazNo ratings yet

- Systematic Reviews The Good, The Bad, and The Ugly - Yuan and Hunt (2009)Document7 pagesSystematic Reviews The Good, The Bad, and The Ugly - Yuan and Hunt (2009)felipeNo ratings yet

- PICE - Call For PapersDocument1 pagePICE - Call For PapersTina RosalesNo ratings yet

- 1 - 4. FT66 - YstDocument2 pages1 - 4. FT66 - Ystdeni rudinyNo ratings yet

- ProjectsDocument10 pagesProjectsm sherNo ratings yet

- Tieng Anh 11 Friends Global - Unit 5 - Test 1Document7 pagesTieng Anh 11 Friends Global - Unit 5 - Test 1quyenb2307590No ratings yet

- Criteria For Evaluation For Outstanding TeacherDocument4 pagesCriteria For Evaluation For Outstanding TeacherSonny Matias100% (2)

- Oracle Application Express (APEX) 5.0 Installation: SetupDocument23 pagesOracle Application Express (APEX) 5.0 Installation: Setupa3scribdNo ratings yet

- Sarrah - Written StatementDocument4 pagesSarrah - Written StatementSarrah SingapurwalaNo ratings yet

- Advance SpreadsheetDocument20 pagesAdvance SpreadsheetAnna RowenaNo ratings yet

- How To Quote AutoVu 3rd Generation Hardware - Sharp 3 and SharpXS - IMKFXDDocument17 pagesHow To Quote AutoVu 3rd Generation Hardware - Sharp 3 and SharpXS - IMKFXDMarcosNo ratings yet

- BTC School BookletDocument12 pagesBTC School BookletKunjan AmbreNo ratings yet

- IGCSE - ICT - Paper 1 Theory - Paper 11Document11 pagesIGCSE - ICT - Paper 1 Theory - Paper 11Tacha MoldovaNo ratings yet

- DCOM Dry CargoDocument352 pagesDCOM Dry CargoVasiMacovei100% (2)

- SK500LC Dash 10 CatalogDocument20 pagesSK500LC Dash 10 CatalogPHÁT NGUYỄN THẾNo ratings yet

- Cameron Granville 3 Asset Management, Inc. v. ChuaDocument7 pagesCameron Granville 3 Asset Management, Inc. v. ChuaClement del RosarioNo ratings yet

- MACF - Memory Address Content Forgery (Eric A. Schulman)Document11 pagesMACF - Memory Address Content Forgery (Eric A. Schulman)Eric A. SchulmanNo ratings yet