Kokam EV Pack Brochure V 1.9-Compressed PDF

Kokam EV Pack Brochure V 1.9-Compressed PDF

Uploaded by

SenaMecánicaElectrónicaCopyright:

Available Formats

Kokam EV Pack Brochure V 1.9-Compressed PDF

Kokam EV Pack Brochure V 1.9-Compressed PDF

Uploaded by

SenaMecánicaElectrónicaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Kokam EV Pack Brochure V 1.9-Compressed PDF

Kokam EV Pack Brochure V 1.9-Compressed PDF

Uploaded by

SenaMecánicaElectrónicaCopyright:

Available Formats

Xpand Battery Solution

For Transportation Application

Xpand Modular Pack

Electrifying Transport For High Performance E-Mobility

Xpand Battery System is designed for use in commercial truck,

Customizable Design

bus, tram, and heavy duty transportation. The system can be

integrated in parallel and in series to create very high energy and

high voltage systems. Furthermore, the “Variable Bulkhead”

design allows to customize the packs’ electrical and cooling

interfaces without having to retool the entire systems.

Single Unit Scalable Modular Design

Features

· Variable bulkhead design · Advanced ultrasonic welding of cell tabs to busbars

Superior Lithium Ion Battery · Advanced liquid cooling system · Durable and safe under the toughest conditions

· High power performance · New BMS, BDU and MCU · Available with high energy or high power cells

· Safe and wide range of operating temperature

· A function to prevent spreading a fire out · All external connections at front panel

Compact and High Reliability Battery Packs of the pack in case of internal fire · Low and stable impedance

· Efficient direct liquid cooling

· Ease of installation

· Customizable solution

· IP67 Compliant (with connectors mated)

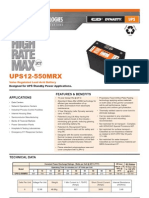

State-of-the-Art Battery Management Systems XMP 76P XMP 111E

· ISO-26262 compatible RTOS Cell Configuration 43HP - 2P24S 63UHE - 2P24S

· Highly configurable for any chemistry Discharge Energy (kWh) 7.6kWh (Rated @ C/2) 11.1kWh (Rated @ C/10)

· 12V and 24V compatible Specific Energy (Wh/kg) ≥99 ≥144

· Designed for system voltages up to 1,000V

Capacity (Ah) 86 (Rated @ C/2) 126 (Rated @ C/10)

Complete System Design and Component Selection Voltage (Nominal; V) 88.8 88.3

Mass (kg) 76.8 77.0

· Battery disconnect unit, System controller, Master controller

· Controls up to 300 cells in series; 24 strings in parallel Dimensions (L x W x H) 753 x 303 x 282 (mm)

Certification ISO 12405, ISO 20653, ISO 16750, GMW 16390,

Extensive R&D, Engineering, and Test & Validation Resources UNDOT 38.3, ECE R100 8E, IEC 62281, J2929, UN 38.3

Fully Automated Production Line

Xpand EV Battery System From Manufacturing Cells to Pack Assembly

Certified & Guaranteed

Advantages

· Easy to customize high voltage, low voltage and cooling interfaces to each application

· All connections at front panel; rear access not needed for installation

· Designed for use in very large strings and pack combinations

(Up to 1,000V per string, and up to 24 strings in parallel)

· Allows upgrades to connector styles, fuses, VTBs without tooling entire pack

· Robust, highly serviceable BDU with integrated SCU; standalone MCU

· Available with or without internal fuse (tested both ways for safety)

· Highly robust tab-to-busbar joint survives the harshest vibration & shock environments while maintaining

ultra-low DCIR

· Direct cooling to cell face; 50-75% less mass than competing technology; maximizes volumetric efficiency

· Enhanced cell separator eliminates the need for thermal barriers

EV Battery Pack Validation

Test Conditions Reference

Ingress Protection Mated: IP67, IPXXD, Unmated IPXXB ISO 20653

Mechanical Shock (XMP76P) 50G, 6ms, 3 axis, 10 each

ISO 12405

Mechanical Shock (XMP111E) 20.7G, 11ms, 3 axis, 10 each

Vibration Random, 3 Axis, 21 hr/axis ISO 12405

Composite Heat & Humidity RH 93%, 25°- 65°C, 28 day ISO 16750

Thermal Shock 85°C to-40°C within 30 min ISO 12405

UNDOT UN T1, T2, T3, T4, T5 UN 38.3

Housing Load Knee 150kN/m²; Foot 356kN/m² GMW16390

External Fuel Fire 130 sec over fuel fire ECE R100 8E

Drop Test 1.2m onto cement on corner IEC 62281

Unbalanced Overcharge 1 cell @ 200% forced overcharge

Forced Internal Coolant Leak Rotate and hold around each axis

External Short Circuit, Fused 5mΩ, 100 mΩ J2929, UN 38.3

External Short Circuit, Unfused 5mΩ J2929

Xpand EV Battery System-based Safety

Under Voltage Over Voltage

Certified & Guaranteed Cell (43Ah HP & 63Ah UHE)

Critical Threshold

Over

Block Operation Temperature

Reduced Performance

Reduced Performance

Reduced Performance

Temperature

Normal

Function

Reduced Performance

Blocked Charge Under

Blocked Operation Temperature

The cell incorporates ceramic coated separator and builds upon proven NMC

Open Circuit Voltage V chemistry. The tests cells, modules and systems were tested in its own test labs

Critical Threshold

Blocked Operation Blocked Operation or in certified regional test agency labs. Development and test of battery systems

(FETs or Contactors open) Critical Threshold are done according to the following standards :

Integrated, multiple layers of protection : Passive and active safety Obtained Additional Test & Certifications

UN transport test ST/SG/AC.10/11/Rev.6

Passive safety per many industry standards : Crush UN 38.3 T6, QC/T 743, GBT**, SAE J2464**

· ECE R100, R17; FMVSS; ISO 6469; UNDOT 38.3 Ellicert / INERIS Safety Tests Nail penetration SAE J2464, QC/T 743, GBT**

(French Automotive Consortium), ISO 12405-2 / EN 60068-2 / ISO 20653 / ISO 11452-2 Thermal stability SAE J2464

Analysis of hazardous substances during USABC (SAND2005‐3123)**

cell opening without thermal runaway

Active safety follows methods defined in ISO 26262 and IEC 61508 :

· Develop, execute, and maintain, safety plan through the entire product lifecycle Analysis of hazardous substances during USABC (SAND2005‐3123)**

cell opening with thermal runaway

· Strategies, activities, and procedures for achieving product safety

· Utilize tools, methods, and procedures from relevant industry standards, regulations, FTIR analysis of escaping gases in free space USABC (SAND2005‐3123)**

and best known practices of industry ** testing performed on similar chemistry cells having non ceramic coated separator

- DISCLAIMERS OF WARRANTIES

ALL MATERIALS AND SERVICES ON THIS DOCUMENT ARE PROVIDED “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, OR THE WARRANTY OF NON-INFRINGEMENT. THIS DOCUMENT COULD INCLUDE TECHNICAL

OR OTHER MISTAKES, INACCURACIES OR TYPOGRAPHICAL ERRORS. KOKAM ASSUMES NO RESPONSIBILITY FOR ERRORS OR OMISSIONS IN THE INFORMATION, DOCUMENTS,

SOFTWARE, MATERIALS AND/OR SERVICES WHICH ARE REFERENCED BY OR LINKED TO THIS DOCUMENT. KOKAM DOES NOT GRANT ANY EXPRESS OR IMPLIED RIGHT TO ANY PERSON

www.kokam.com

OR BUSINESS ENTITY UNDER ANY PATENTS, COPYRIGHTS, TRADEMARKS, OR TRADE SECRET INFORMATION WITH RESPECT TO THE MATERIALS AND SERVICES. NO PORTION OF THE battery@kokam.com

INFORMATION OR DOCUMENTS MAY BE REPRODUCED IN ANY FORM OR BY ANY MEANS WITHOUT THE PRIOR WRITTEN CONSENT OF KOKAM. IN NO EVENT SHALL KOKAM BE LIABLE

TO ANY PERSON OR BUSINESS ENTITY FOR ANY SPECIAL, PUNITIVE, INCIDENTAL, INDIRECT OR CONSEQUENTIAL DAMAGES BASED ON ANY USE OF THIS DOCUMENT.

You might also like

- Tesla Mega Pack DatasheetDocument2 pagesTesla Mega Pack DatasheetWinie Oseña100% (4)

- Bt50 Electr.Document32 pagesBt50 Electr.SenaMecánicaElectrónicaNo ratings yet

- C4 Picasso Engine Fusebox PDFDocument7 pagesC4 Picasso Engine Fusebox PDFSenaMecánicaElectrónica100% (1)

- iSitePower Outdoor Series-MTS9302A-HD10A2 (01074962) Datasheet 03 - (2...Document3 pagesiSitePower Outdoor Series-MTS9302A-HD10A2 (01074962) Datasheet 03 - (2...Maulanahsn MaulanaNo ratings yet

- Networking Assignment1 Fontsheet 1Document43 pagesNetworking Assignment1 Fontsheet 1Dương Bùi Thái100% (1)

- Ford C-Max 1.6l 2011 Timing BeltDocument11 pagesFord C-Max 1.6l 2011 Timing BeltSenaMecánicaElectrónica100% (1)

- HINO Dutro Fault Codes List PDFDocument4 pagesHINO Dutro Fault Codes List PDFSenaMecánicaElectrónica57% (7)

- iSitePower Outdoor Series-MTS9302A DatasheetDocument3 pagesiSitePower Outdoor Series-MTS9302A DatasheetMarco100% (1)

- Kokam Battery Solution: Transportation ApplicationDocument4 pagesKokam Battery Solution: Transportation Applicationtripathi prashantNo ratings yet

- MEGATRON 1.6MW X 3MWh BESS Datasheet 2024 Symtech Solar R 1Document11 pagesMEGATRON 1.6MW X 3MWh BESS Datasheet 2024 Symtech Solar R 1yyyNo ratings yet

- DS20200117 Conext MPPT 60 150Document2 pagesDS20200117 Conext MPPT 60 150Electroventica ElectroventicaNo ratings yet

- Conext™ MPPT 60 150 Solar Charge Controller: MPPT Multi-Stage Charging, Better Battery LifeDocument2 pagesConext™ MPPT 60 150 Solar Charge Controller: MPPT Multi-Stage Charging, Better Battery LifeIdham HawariNo ratings yet

- Xantrex Regulador MPPT 60A 150VDocument2 pagesXantrex Regulador MPPT 60A 150Vglopet569977No ratings yet

- Schneider Conext XW 60 150 MPPT Charge Controller Specs 2782042285Document2 pagesSchneider Conext XW 60 150 MPPT Charge Controller Specs 2782042285xray123zzzNo ratings yet

- Datasheet General Heavy Duty ESS EnglishDocument2 pagesDatasheet General Heavy Duty ESS EnglishDavid Alexander CeronNo ratings yet

- Document - IQ7XDocument2 pagesDocument - IQ7Xstanislav.vasyutaNo ratings yet

- Document - IQ7HSDocument2 pagesDocument - IQ7HSstanislav.vasyutaNo ratings yet

- 100kW MEGATRON - Battery Energy Storage Systems Datasheet - 2022 - Symte...Document13 pages100kW MEGATRON - Battery Energy Storage Systems Datasheet - 2022 - Symte...Sanjayan MaratNo ratings yet

- ZXDUPA-WR12 KZ OEC Up To 24kW Outdoor DC Power System Product DescriptionDocument7 pagesZXDUPA-WR12 KZ OEC Up To 24kW Outdoor DC Power System Product Descriptionhany.farag.farid.shenoudaNo ratings yet

- ARK 2.5L&H-A1 Introduction-EUDocument20 pagesARK 2.5L&H-A1 Introduction-EUJohnny Alberto GaleanoNo ratings yet

- Kokam Battery: 48V SolutionDocument2 pagesKokam Battery: 48V SolutionLucian A MUșaNo ratings yet

- HT72-18X (540-560) - Double GlassDocument2 pagesHT72-18X (540-560) - Double GlassGreenyoungcnNo ratings yet

- XESS ONE REV Specification REV 004Document2 pagesXESS ONE REV Specification REV 004torrespierredanielNo ratings yet

- OmniCube-A215 DatasheetDocument2 pagesOmniCube-A215 Datasheetvenkat86ramNo ratings yet

- 4907 Seanergy+battery+system SDP2#1Document2 pages4907 Seanergy+battery+system SDP2#1VENKATNo ratings yet

- Iq7x DS en UsDocument2 pagesIq7x DS en UsalbertusngNo ratings yet

- Data Sheet CD Ups12 220mrxDocument2 pagesData Sheet CD Ups12 220mrxJoe JoeNo ratings yet

- Seg C&i Bess 2307Document2 pagesSeg C&i Bess 2307Alexander MorrisonNo ratings yet

- 207kWh Onoffgrid Integrated SolutionDocument2 pages207kWh Onoffgrid Integrated SolutionyyyNo ratings yet

- MPPT 100 600 and MPPT 80 600 DatasheetDocument2 pagesMPPT 100 600 and MPPT 80 600 DatasheethaitoecheNo ratings yet

- Whats New in Orion2Document3 pagesWhats New in Orion2Ricardo Emanuel TavaresNo ratings yet

- AIO-30 Hybrid Power Station SpecificatiDocument4 pagesAIO-30 Hybrid Power Station Specificatiwindsorfood2756No ratings yet

- HITE EUROPE Full Range (2024.10.01)Document6 pagesHITE EUROPE Full Range (2024.10.01)inscriptionNo ratings yet

- Datasheet Deye SE G5.1 Pro B V2.1Document3 pagesDatasheet Deye SE G5.1 Pro B V2.1SINES FranceNo ratings yet

- Datasheet Deye LV 3u BatteryDocument3 pagesDatasheet Deye LV 3u BatteryDaniel LozanoNo ratings yet

- Datasheet A LV 3U Battery SE G5.1 Pro B V2.1Document3 pagesDatasheet A LV 3U Battery SE G5.1 Pro B V2.1Zaw Myo HtetNo ratings yet

- DS 20230511 ST2236UX Datasheet V16 ENDocument2 pagesDS 20230511 ST2236UX Datasheet V16 ENMazhr HamzaNo ratings yet

- Tesla Megapack DatasheetDocument3 pagesTesla Megapack DatasheetMukesh RajasekarNo ratings yet

- Caterpillar XQ1250G Containerized Gas Generator SetDocument6 pagesCaterpillar XQ1250G Containerized Gas Generator SetMacAllister MachineryNo ratings yet

- BP48100 SpecDocument4 pagesBP48100 SpecP&P IngenieriaNo ratings yet

- 5G Power Outdoor Series-MTS9304A-HX10A1 (01075308-002) Datasheet 2019101...Document3 pages5G Power Outdoor Series-MTS9304A-HX10A1 (01075308-002) Datasheet 2019101...elesoporte100% (1)

- DB Storage 10S en GrauDocument2 pagesDB Storage 10S en GraufabriziotissotNo ratings yet

- Brochure Borri B9000FXS EN OMG60098revD 03-18Document4 pagesBrochure Borri B9000FXS EN OMG60098revD 03-18Bender ArgentinaNo ratings yet

- Eaton DC Power SolutionsDocument2 pagesEaton DC Power SolutionsJose TomassettiNo ratings yet

- AEG Protect 8 33 End UPSDocument6 pagesAEG Protect 8 33 End UPSomarNo ratings yet

- Iq 7a Microinverter DatasheetDocument2 pagesIq 7a Microinverter DatasheetEe Qing KhooNo ratings yet

- IQ Battery 10T DS EN US 10 19 2021Document2 pagesIQ Battery 10T DS EN US 10 19 2021Karim BouissNo ratings yet

- Netsure 7100 Netsure 8100 Data Sheet EnglishDocument2 pagesNetsure 7100 Netsure 8100 Data Sheet EnglishTarek El-DeghedyNo ratings yet

- 0.25-0.5P CS-Datasheet-SolBank Energy Storage v1.52 UKDocument2 pages0.25-0.5P CS-Datasheet-SolBank Energy Storage v1.52 UKMichel RodriguesNo ratings yet

- Technical Docs Solar Project EIWCDocument12 pagesTechnical Docs Solar Project EIWCChayan SethNo ratings yet

- Datasheet Flatpack2 Cabinetized 32kW PDFDocument2 pagesDatasheet Flatpack2 Cabinetized 32kW PDFفيصل باديNo ratings yet

- ESM 120wDocument2 pagesESM 120wMulcue ProfeNo ratings yet

- C&D Ups12Document2 pagesC&D Ups12thien71cdd06No ratings yet

- Smartli SeriesDocument7 pagesSmartli Seriessyed razaNo ratings yet

- Datasheet ISitePower Outdoor Series MTS9304A HX10A1 5308 002Document3 pagesDatasheet ISitePower Outdoor Series MTS9304A HX10A1 5308 002Henrry Mijahuanca Villalobos0% (1)

- Micro Tec en - BDDocument1 pageMicro Tec en - BDpiotreNo ratings yet

- CPS4024+ (24 V Cabinet Power System)Document7 pagesCPS4024+ (24 V Cabinet Power System)Anonymous ipfuheXZaNo ratings yet

- Celdas Metal Clad SchneriderDocument6 pagesCeldas Metal Clad Schneriderfventura.orionNo ratings yet

- AC 200kWh Air-Cooling Battery MpackDocument2 pagesAC 200kWh Air-Cooling Battery MpackyyyNo ratings yet

- CD Ups12 150mrxDocument2 pagesCD Ups12 150mrxstuardobsaquicNo ratings yet

- Microinverter: Leading The Industry inDocument2 pagesMicroinverter: Leading The Industry inCristian MenesesNo ratings yet

- Aquaboy 2KW Solar SystemDocument3 pagesAquaboy 2KW Solar SystemMelissa RadoveckiNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- A Case Study for a Single-Phase Inverter Photovoltaic System of a Three-Bedroom Apartment Located in Alexandria, Egypt: building industry, #0From EverandA Case Study for a Single-Phase Inverter Photovoltaic System of a Three-Bedroom Apartment Located in Alexandria, Egypt: building industry, #0No ratings yet

- CamScanner 01-20-2023 18.16Document1 pageCamScanner 01-20-2023 18.16SenaMecánicaElectrónicaNo ratings yet

- Adjustable Pedal: SectionDocument13 pagesAdjustable Pedal: SectionSenaMecánicaElectrónicaNo ratings yet

- MuranoDocument6 pagesMuranoSenaMecánicaElectrónicaNo ratings yet

- Automatic Drive Positioner: SectionDocument167 pagesAutomatic Drive Positioner: SectionSenaMecánicaElectrónicaNo ratings yet

- Extract Files. 2. Run Carsoftware - Exe and Install It. 3. Enjoy If You Need It, Install Dotnetfx35SDocument1 pageExtract Files. 2. Run Carsoftware - Exe and Install It. 3. Enjoy If You Need It, Install Dotnetfx35SSenaMecánicaElectrónicaNo ratings yet

- Accelerator Control System: SectionDocument6 pagesAccelerator Control System: SectionSenaMecánicaElectrónicaNo ratings yet

- SSP - 463 The Amarok 2010 PDFDocument56 pagesSSP - 463 The Amarok 2010 PDFSenaMecánicaElectrónicaNo ratings yet

- Ford Kuga 2.5L 2008 Timing BeltDocument5 pagesFord Kuga 2.5L 2008 Timing BeltSenaMecánicaElectrónica100% (1)

- P0713Document6 pagesP0713SenaMecánicaElectrónicaNo ratings yet

- Kokam EV Pack Brochure V 1.9-Compressed PDFDocument4 pagesKokam EV Pack Brochure V 1.9-Compressed PDFSenaMecánicaElectrónicaNo ratings yet

- Linha Pesada Minas Soluções 2017.1Document129 pagesLinha Pesada Minas Soluções 2017.1SenaMecánicaElectrónicaNo ratings yet

- 5 SpohDocument4 pages5 SpohSenaMecánicaElectrónicaNo ratings yet

- A 46Document1 pageA 46SenaMecánicaElectrónicaNo ratings yet

- Toyota Batter 1Document6 pagesToyota Batter 1SenaMecánicaElectrónicaNo ratings yet

- 6L80EDocument8 pages6L80ESenaMecánicaElectrónica100% (1)

- Toyota Enteri 1Document3 pagesToyota Enteri 1SenaMecánicaElectrónica100% (1)

- 1GD 2GDDocument4 pages1GD 2GDSenaMecánicaElectrónicaNo ratings yet

- 06 Lateral Dynamics Y AxisDocument92 pages06 Lateral Dynamics Y AxisSenaMecánicaElectrónica100% (2)

- Isc Isl Cm2150Document19 pagesIsc Isl Cm2150SenaMecánicaElectrónicaNo ratings yet

- Art & Culture of Andhra Pradesh - Paintings of Andhra PradeshDocument10 pagesArt & Culture of Andhra Pradesh - Paintings of Andhra PradeshSrinivasNo ratings yet

- Bullet GraphDocument13 pagesBullet GraphRahul JainNo ratings yet

- Intelligent Transport Systems-A Case StudyDocument13 pagesIntelligent Transport Systems-A Case Studyani29archiNo ratings yet

- Elk-4 800 1HZC208015 202111 enDocument16 pagesElk-4 800 1HZC208015 202111 ensameershukur17No ratings yet

- Page 1 of 106: Date Developed: May 2021 Document No. Issued byDocument36 pagesPage 1 of 106: Date Developed: May 2021 Document No. Issued byJenny Samoranos100% (1)

- Logical Reasoning TestsDocument7 pagesLogical Reasoning Testsls-checkinNo ratings yet

- Asthma Training Module 2013Document204 pagesAsthma Training Module 2013Carlo AlvaradoNo ratings yet

- Principles of Crop ProductionDocument6 pagesPrinciples of Crop ProductionJanice VaflorNo ratings yet

- Crouse Hinds MTL Barracuda WorkstationsDocument4 pagesCrouse Hinds MTL Barracuda Workstationszhang012mike0727No ratings yet

- MEC2404 Frictional Flow in Pipe Lab RepoDocument10 pagesMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- Advantages and Disadvantages of Technology in Our Life: Presented:By Group2Document13 pagesAdvantages and Disadvantages of Technology in Our Life: Presented:By Group2Daryn CorpusNo ratings yet

- Multi-Purpose Plants For API Production: Facilities and EquipmentDocument5 pagesMulti-Purpose Plants For API Production: Facilities and EquipmentYanti SusilawatiNo ratings yet

- Wolverine Reading OrderDocument2 pagesWolverine Reading OrderTomasHamNo ratings yet

- SurveyDocument2 pagesSurveyhelloNo ratings yet

- Fertilizer and Soil Amendments HandbookDocument63 pagesFertilizer and Soil Amendments HandbookJitendra PankajNo ratings yet

- Dimensional FormulaDocument4 pagesDimensional FormulaSurajguptarocksNo ratings yet

- English Grade 3a Part 2Document129 pagesEnglish Grade 3a Part 2wahid bcsNo ratings yet

- Evolution Healing Centre - Lived Experiences of Stroke For Bermuda 2022Document22 pagesEvolution Healing Centre - Lived Experiences of Stroke For Bermuda 2022BernewsAdminNo ratings yet

- Huntik DuplicatesDocument17 pagesHuntik Duplicatesmiguel.zamezaNo ratings yet

- Individual Evaluation Sheet IesDocument4 pagesIndividual Evaluation Sheet IesJonalis Mait MandrialNo ratings yet

- Pedalpower ppg2 3 1Document7 pagesPedalpower ppg2 3 1ramsinghNo ratings yet

- Abhijit Dhar - CV1Document2 pagesAbhijit Dhar - CV1Abhijit PhoenixNo ratings yet

- NSE Ikeja January 2017 News LetterDocument7 pagesNSE Ikeja January 2017 News LetterbbllngNo ratings yet

- Helen of Troy Lesson PlanDocument2 pagesHelen of Troy Lesson PlanJF Mamjjasond SupanNo ratings yet

- 03 - Science, Technology and Nation-BuildingDocument17 pages03 - Science, Technology and Nation-BuildingeclarexeNo ratings yet

- Honda GX160 Owner's ManualDocument60 pagesHonda GX160 Owner's ManualLakshman NethaNo ratings yet

- Tos - Solo Taxonomy Eapp Q2Document2 pagesTos - Solo Taxonomy Eapp Q2roxannemarie.vidamoNo ratings yet

- Industrial RevolutionDocument24 pagesIndustrial RevolutionHafsah SiddiquaNo ratings yet

- Observation Task 6Document5 pagesObservation Task 6api-335617097No ratings yet