VAUTID ASW 145 Engl 041016

VAUTID ASW 145 Engl 041016

Uploaded by

maiquelernCopyright:

Available Formats

VAUTID ASW 145 Engl 041016

VAUTID ASW 145 Engl 041016

Uploaded by

maiquelernOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

VAUTID ASW 145 Engl 041016

VAUTID ASW 145 Engl 041016

Uploaded by

maiquelernCopyright:

Available Formats

VAUTID 145

Tubular wire and welding rod

Hardfacing material for highest abrasion and high temperatures

VAUTID Material characteristics

FOTO

Specification Tubular wire electrode DIN EN 14700 T Fe16 gtz

Welding rod DIN EN 14700 E Fe16 gtz

Material type High-carbon-high-chromium-molybdenum alloy on iron base with tungsten, vanadium and niobium special

Alloy components carbides

C – Cr – Mo – Nb – V – W – Fe

Weld deposit characteristics VAUTID 145 produces a wear-resistant, primary carbide-containing weld deposit with high hardness at high

temperatures. The application temperatures should not exceed 750° C. The weld deposit exhibits cracks,

cannot be machined and has limited shock resistance

Weld deposit properties Hardness (acc. DIN 32525-4): 60-65 HRC*

Recommended applications Recommended particularly for the hardfacing of parts subjected to strong abrasion and average shock

stress as well as high temperatures, e.g. fan components, furnace top bell facing, hot dust ducts, screens or

sinter crushers

Standard sizes Tubular wire: Diameter 1,6 / 2,0 / 2,4 / 2,8 / 3,2 mm

Packing: Mandrels 15 kg, Reels 25 kg, Drums 250 kg

Welding rods: Diameter 3,25 / 4,0 / 5,0 / 6,0 mm

Packing: 5 kg packages

* subject to common industrial fluctuations

Welding instructions for tubular wires: Welding instructions for welding rods:

VAUTID 145 tubular wire is welded without inert gas on the +pole (a.c. VAUTID 145 welding rods can be welded with d.c. on the +pole but also

possible). Weave technique is usual. Preheating of base material and with a.c. The amount of layers should be limited to 2. It is not necessary

VAUTID 18/8/6 – buffer layers are to be recommended on hard weldable, to re-dry the electrodes prior to welding.

massive components. The amount of layers should be limited to 2. VAUTID 145 welding rods are high-performance electrodes with a

deposition rate of 220%.

Diameter Current (A) Voltage (V) Stick out Diameter Current (A)

(mm) (mm) (mm)

1,6 150 – 270 24 – 27 20 – 40 3,25 100 – 120

2,0 180 – 300 25 – 28 25 – 40 4,0 120 – 160

2,4 230 – 350 26 – 29 25 – 50 5,0 170 – 210

2,8 260 – 420 27 – 29 30 – 55 6,0 210 – 250

3,2 290 – 470 28 – 30 30 – 55

This data sheet corresponds to the present state of production (October 2016) and can be

Welding positions (EN ISO 6947): PA, PB changed anytime.

VAUTID GROUP Phone: + 49 711 / 44 04-0 E-Mail: vautid@vautid.de

Brunnwiesenstr. 5 Fax: + 49 711 / 44 20 39 Web: www.vautid.com

73760 Ostfildern

You might also like

- GED Maths Ready TestDocument6 pagesGED Maths Ready Testtds67057No ratings yet

- AZ IIW Catalogue App EnglischDocument1 pageAZ IIW Catalogue App EnglischXxNo ratings yet

- RT Film ReviewDocument1 pageRT Film Reviewpriti kumariNo ratings yet

- Sample Financial Reports For Livelihood AssociationDocument7 pagesSample Financial Reports For Livelihood AssociationOslec AtenallNo ratings yet

- Inspections and Audits For Boilers and Pressure VesselsDocument2 pagesInspections and Audits For Boilers and Pressure VesselsNDTInstructorNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- Beam ProfileDocument11 pagesBeam Profilevirat viratNo ratings yet

- 6082 t6 Aluminium Round BarDocument12 pages6082 t6 Aluminium Round Barben norwoodNo ratings yet

- 6082 T6 Aluminum Plate SuppliersDocument9 pages6082 T6 Aluminum Plate Supplierssanghvi overseas incNo ratings yet

- Uw 28-Welding ProcedureDocument13 pagesUw 28-Welding ProcedureDenny AgusNo ratings yet

- Eddy Current and Non Contacting TransducerDocument10 pagesEddy Current and Non Contacting TransducerRam Krishna SinghNo ratings yet

- A Study On Low Magnetic PermeabilityDocument28 pagesA Study On Low Magnetic PermeabilitymishikhanNo ratings yet

- Hot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaDocument4 pagesHot Rolled Products, Cold Rolled Products, Galvanised Products From Flats, Tata Steel, IndiaraajmrkNo ratings yet

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza Prada100% (1)

- RST 37Document8 pagesRST 3725091972No ratings yet

- Welding Forum - Heat Input CalculationDocument11 pagesWelding Forum - Heat Input CalculationMatthew BallardNo ratings yet

- NDT (RT) TTSchedule Page 80 HrsDocument1 pageNDT (RT) TTSchedule Page 80 HrsdashNo ratings yet

- Training - Air Arc GougingDocument21 pagesTraining - Air Arc GougingmukeshayoorNo ratings yet

- WedgesDocument4 pagesWedgesBrandon EricksonNo ratings yet

- TABLE 4 Nut Proof Load Values, KN: OTE OTEDocument1 pageTABLE 4 Nut Proof Load Values, KN: OTE OTEanishNo ratings yet

- Surveyof Underwater NDTTechnologiesfor Offshore AssetsDocument11 pagesSurveyof Underwater NDTTechnologiesfor Offshore AssetsPranoy MukherjeeNo ratings yet

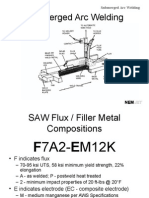

- Submerged Arc WeldingDocument4 pagesSubmerged Arc WeldingshifaNo ratings yet

- Is 2062Document2 pagesIs 2062niketpatel3121No ratings yet

- Ultrasonic TestingDocument86 pagesUltrasonic TestingKoblandy OrazaevNo ratings yet

- Introduction To NDT BasicDocument27 pagesIntroduction To NDT BasicAngela WalkerNo ratings yet

- Table T276Document1 pageTable T276Anbarasan PerumalNo ratings yet

- WeldingDocument14 pagesWeldingrockmanmaxNo ratings yet

- Welding R1Document49 pagesWelding R1proxywarNo ratings yet

- Duplex IQI 67 - 113Document2 pagesDuplex IQI 67 - 113Esin DenizNo ratings yet

- Weld Australia TGN-SW04 - Welding Safety - Audit Checklist FinalDocument14 pagesWeld Australia TGN-SW04 - Welding Safety - Audit Checklist Finalpaullavall1968No ratings yet

- Ruukki Hot Rolled Steels Ultrasonic Testing 2011 PDFDocument5 pagesRuukki Hot Rolled Steels Ultrasonic Testing 2011 PDFpvdang8453No ratings yet

- Modes of Heat Transfer PresentationDocument12 pagesModes of Heat Transfer PresentationYashvir SinghNo ratings yet

- Partial List of ISO SpecificationsDocument4 pagesPartial List of ISO Specificationsskynyrd75No ratings yet

- Identification of Weld DiscountinuitiesDocument42 pagesIdentification of Weld DiscountinuitiesAhmed shabanNo ratings yet

- Company Profil CV - Citra Harapan Jaya All CustomerDocument6 pagesCompany Profil CV - Citra Harapan Jaya All Customersutrisno00100% (1)

- FBW Manual-Jan 2012-Revised and Corrected CS2Document68 pagesFBW Manual-Jan 2012-Revised and Corrected CS2Dinesh CandassamyNo ratings yet

- PCN General RulesDocument25 pagesPCN General RulesSangeeth Kavil PNo ratings yet

- Pocketbook On Ultrasonic Testing of Rail (Need-Based)Document25 pagesPocketbook On Ultrasonic Testing of Rail (Need-Based)ME TECHNOLOGYNo ratings yet

- NDT of Rail Welds During The Construction of The Rapid Transportation System in KaohsiungDocument7 pagesNDT of Rail Welds During The Construction of The Rapid Transportation System in KaohsiungBenzhar TubieraNo ratings yet

- Ultrasonidos Manual PDFDocument78 pagesUltrasonidos Manual PDFJose Luis Gonzalez Perez100% (1)

- Creeping Wave ProbesDocument1 pageCreeping Wave ProbesFrank Pinedo LopezNo ratings yet

- Calibration For Anisotropic Effects On Shear Wave Velocity For Improvements of Weld Inspections in TMCP SteelsDocument16 pagesCalibration For Anisotropic Effects On Shear Wave Velocity For Improvements of Weld Inspections in TMCP SteelsHermann LeonardoNo ratings yet

- Iwe Mig Welding MachineDocument2 pagesIwe Mig Welding Machinem ramakrishna reddyNo ratings yet

- Liquid or Dye Penetrant InspectionDocument43 pagesLiquid or Dye Penetrant InspectionTrinadh Venkata Kumar NillaNo ratings yet

- Duplex IQI To en 462Document1 pageDuplex IQI To en 462Jhordy Moises Pinedo CàrdenasNo ratings yet

- Strengthening MechanismsDocument19 pagesStrengthening MechanismsAnas Anwar ArainNo ratings yet

- Comparison ASTM A 3388 & ISO 11496Document1 pageComparison ASTM A 3388 & ISO 11496Rahul MoottolikandyNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8Document9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8muraliNo ratings yet

- Rtfi Notes 3Document23 pagesRtfi Notes 3Ajith PayyanurNo ratings yet

- Impact Hardness TestDocument7 pagesImpact Hardness TestAse Sharew100% (1)

- WeldingDocument21 pagesWeldingprabhatkumar_6657012No ratings yet

- Visual TestingDocument1 pageVisual TestingAnonymous GE8mQqxNo ratings yet

- IQI SelectionDocument1 pageIQI SelectionnavitaNo ratings yet

- ATTAR Phased Array Visualisation ToolDocument3 pagesATTAR Phased Array Visualisation ToolGOUTHAM RATHINAMNo ratings yet

- Optimization of Submerged Arc WeldingDocument4 pagesOptimization of Submerged Arc WeldingricardoNo ratings yet

- Ultrasonic Guided Waves For NDE OF Welded Structures: An Overview byDocument44 pagesUltrasonic Guided Waves For NDE OF Welded Structures: An Overview byMejazMallick100% (1)

- VAUTID ASW 143 Engl 041016Document1 pageVAUTID ASW 143 Engl 041016rusf123No ratings yet

- Vautid 100, Engl 041016Document1 pageVautid 100, Engl 041016Maria TzagarakiNo ratings yet

- Vautid100 EnglDocument1 pageVautid100 EnglRamona CrangasNo ratings yet

- Hardface StaincarbwDocument1 pageHardface StaincarbwMarcos VieroNo ratings yet

- SidewallDocument6 pagesSidewallmaiquelernNo ratings yet

- TechPlasty - PE1000 - Polyethylene 1000 - 2020-06-02Document2 pagesTechPlasty - PE1000 - Polyethylene 1000 - 2020-06-02maiquelernNo ratings yet

- FM 400 8X4 Tipper With 29 Cu.M Coal BodyDocument4 pagesFM 400 8X4 Tipper With 29 Cu.M Coal BodymaiquelernNo ratings yet

- Bauer - Catalogo IE3-IE4 PMSMDocument476 pagesBauer - Catalogo IE3-IE4 PMSMmaiquelernNo ratings yet

- Lorbrand Idler Catalogue Reduced SizeDocument88 pagesLorbrand Idler Catalogue Reduced SizemaiquelernNo ratings yet

- Roller Chain Drive DesignDocument19 pagesRoller Chain Drive DesignmaiquelernNo ratings yet

- G 440 XT 8x4 Heavy Tipper: 23 CU.m ROCK BodyDocument2 pagesG 440 XT 8x4 Heavy Tipper: 23 CU.m ROCK BodymaiquelernNo ratings yet

- Premas: 6th Brazilian Cement Conference CBCDocument48 pagesPremas: 6th Brazilian Cement Conference CBCmaiquelernNo ratings yet

- MSHA's Guide To Equipment GuardingDocument40 pagesMSHA's Guide To Equipment GuardingmaiquelernNo ratings yet

- AND Accessories: Elevator BoltsDocument3 pagesAND Accessories: Elevator BoltsmaiquelernNo ratings yet

- Delft University of Technology Faculty Mechanical, Maritime and Materials EngineeringDocument51 pagesDelft University of Technology Faculty Mechanical, Maritime and Materials EngineeringmaiquelernNo ratings yet

- 176 EN Hardox 400 Roundbars V1 2020 SSABDocument4 pages176 EN Hardox 400 Roundbars V1 2020 SSABmaiquelernNo ratings yet

- Titan Horizontal Grinder Flyer v5Document2 pagesTitan Horizontal Grinder Flyer v5maiquelernNo ratings yet

- 3% 5Hylvwd'Lvwlqomr 5Hylvwd'LvwlqomrDocument24 pages3% 5Hylvwd'Lvwlqomr 5Hylvwd'LvwlqomrmaiquelernNo ratings yet

- Types of Log Debarkes - Guide To Advantages and Disadvantages - Veneer ServicesDocument11 pagesTypes of Log Debarkes - Guide To Advantages and Disadvantages - Veneer ServicesmaiquelernNo ratings yet

- PP Woodprocessing Chipstorage Powerscrew DataDocument2 pagesPP Woodprocessing Chipstorage Powerscrew DatamaiquelernNo ratings yet

- THIELE CATALOG Gabellaschen-Forged-Link-Chains ENDocument49 pagesTHIELE CATALOG Gabellaschen-Forged-Link-Chains ENmaiquelernNo ratings yet

- M3891Document44 pagesM3891maiquelernNo ratings yet

- 3.3 Pretreatment CHEM-C1150 Wood Chips PreparationDocument62 pages3.3 Pretreatment CHEM-C1150 Wood Chips PreparationmaiquelernNo ratings yet

- A Company Continually Evolving.: Introduzione Inglese 14-01-2003 11:04 Pagina 3Document115 pagesA Company Continually Evolving.: Introduzione Inglese 14-01-2003 11:04 Pagina 3maiquelernNo ratings yet

- Euclid Algorithm PDFDocument2 pagesEuclid Algorithm PDFJasonNo ratings yet

- FMDocument14 pagesFMJorge Gonzalez LopezNo ratings yet

- ATV12HU22M3: Product Data SheetDocument3 pagesATV12HU22M3: Product Data SheetOscar J Llanos MNo ratings yet

- PromotionLetter 202005A027561Document2 pagesPromotionLetter 202005A027561vicky sam ka keiNo ratings yet

- Breakdown For EWAN - Sep 2018 - W4Document11 pagesBreakdown For EWAN - Sep 2018 - W4SalmanNo ratings yet

- Eurocode ExampleDocument3 pagesEurocode ExamplevuhuythinhNo ratings yet

- 6-16-2020 DOJ-ATF Pistol Brace LetterDocument3 pages6-16-2020 DOJ-ATF Pistol Brace LetterDuncanNo ratings yet

- FBS115 PDFDocument2 pagesFBS115 PDFharmonoNo ratings yet

- Assignment 4 DT NB LR SolutionDocument5 pagesAssignment 4 DT NB LR SolutionYvette SuNo ratings yet

- Zaiger Motion To ContinueDocument2 pagesZaiger Motion To ContinueSusanBaskoNo ratings yet

- ThiesDeviceUtility ManualDocument24 pagesThiesDeviceUtility Manualcagil.greenpowermonitorNo ratings yet

- Aircraft Financing GiniesDocument21 pagesAircraft Financing GiniesvinaymathewNo ratings yet

- Technical Analysis: Presented by Anita Singhal 1Document41 pagesTechnical Analysis: Presented by Anita Singhal 1anita singhalNo ratings yet

- ADDITIONAL CASES FULL and DIGESTSDocument17 pagesADDITIONAL CASES FULL and DIGESTSjannagotgoodNo ratings yet

- B.A. MGT First YearDocument13 pagesB.A. MGT First YearA vyasNo ratings yet

- Comparison of Calculation Result of 3 BuDocument31 pagesComparison of Calculation Result of 3 BuCbdtxd PcbtrNo ratings yet

- Resume Jarvis 2019Document2 pagesResume Jarvis 2019api-457918051No ratings yet

- Oil BadamiDocument29 pagesOil Badamiatis100% (1)

- Survey Report - Pharmaceutical Marketing - Ethical and Responsible ConductDocument20 pagesSurvey Report - Pharmaceutical Marketing - Ethical and Responsible ConductBrand SynapseNo ratings yet

- Marketing Management Book - 1Document328 pagesMarketing Management Book - 1sameerkh2305No ratings yet

- Concession Contract HandbookDocument19 pagesConcession Contract HandbookDody AdiNo ratings yet

- Instructions For MMW ProjectsDocument2 pagesInstructions For MMW ProjectsChi De LeonNo ratings yet

- New Trinitas in A NutshellDocument29 pagesNew Trinitas in A Nutshellgorot1No ratings yet

- B FSRTC BLDG and C and S Works1517Document418 pagesB FSRTC BLDG and C and S Works1517Wan IkkhuwaeNo ratings yet

- DC Motor Speed Control Using Arduino in ProteusDocument5 pagesDC Motor Speed Control Using Arduino in ProteusRamshaNo ratings yet

- Project GSTDocument128 pagesProject GSTthilakNo ratings yet

- A Nairn Transport Company Luggage LabelDocument5 pagesA Nairn Transport Company Luggage LabelRoberto Ortega MicalizziNo ratings yet