Professional Documents

Culture Documents

PCV Data Sheet PDF

PCV Data Sheet PDF

Uploaded by

veenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCV Data Sheet PDF

PCV Data Sheet PDF

Uploaded by

veenaCopyright:

Available Formats

INDEX

Sr No. Tag No. P&ID No. Page No. Remark Revision

1 10-PV-2007 14495-10-PR-PID-0001 3-5

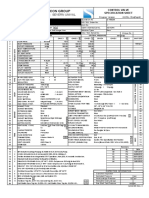

HINDUSTAN PETROLEUM CORPORATION LIMITED (HPCL)

VVSPL CAPACITY AUGMENTATION PROJECT

Project No: 403102-14495 SHEET

Datasheet No: 14495-10-IC-DAS-0001 2 OF 5

General Notes

Notes: NA - Not applicable, VTA - Vendor to Advise REV

1. Datasheet shall be read in conjunction with Instrument Design Basis 14495-00-IC-BOD-0001, Specification For Control Valves 14495-00-IC-SPC-0001 &

Piping Material Specification 14495-00-PE-SPC-0001.

2. 316SS tag plates stamped with Tag No. in 15mm characters shall be permanently attached using 316SS screws or wire.

3. External painting of Control valves shall be as per " Specification for External Painting and Protective Coating 14495-00-PE-SPC-0005" .

4. Valves shall be hydro tested at 1.5 times design pressure.

5. Each actuator unit shall include the motor, hydraulic pump, hydraulic manifold, accumulator, in-built safety system, pressure sensor indication of hydraulic oil

pressure along with position indicators, electrical & hydraulic controls, terminal box,level switch, level gauge, clogging indicator, filter etc. as a self-contained

unit. The actuator shall be sized to provide adequate thrust to ensure the complete intended travel of the valve under the extreme operating conditions.

6. For 600# rating valves(RF Flanges), gaskets shall be 4.5 mm Thk,Spiral Wound, SS 316+ Graphite with Soft Steel Centering Ring to ASME B16.20.

Whereas for 900# Rating valves (RTJ Flanges) gaskets shall be RTJ Type, Octagonal Ring Joint,Soft Iron To ASME B16.20 - 90 HB MAX.

7. Actuator shall be non intrusive type.

8. 100% Radiography shall be done. All test & Calibration certification shall be provided.

9. Stud, bolts shall have full length thread with two hexagonal nuts as per ASME B 18.2.1/18.2.2.

10. The valve, actuator and accessories shall be factory tested and delivered as a complete, pre-assembled package as specified in the specification and

datasheet.

11. Cable Gland shall be double compression type made of Ni plated brass.The same shall be dual certified.

12. Spare Cable entry shall be plugged suitably with dual certified plugs.

13. Vendor to recommend anti-cavitation/low noise dB trim based on the calculation.

14. Control Valve shall be sized as per ISA 75.01.01 & noise calculation as per IEC 60534-8-4

15. Direction of flow shall be clearly indicated/stamped or cast on the valve body.

16. Corrosion allowance shall be 1.5 mm

18. Actuator shall be sized with 150% of safety factor.

19. Stem packing material shall be braided graphite top and bottom rings. Die- formed flexible graphite intermediate rings with corrosion inhibitor.

20. Following features for actuators shall be provided additionally:

a. Feature for data records shall also be provided

b. A local backlit LCD display shall be provided on the actuator for indication of actuator's parameter and configuration

c. A separately sealed compartment containing segregated power and control terminals shall be provided. Earthing terminals shall be provided at the external

of Control Valve.

d. Actuator motor shall be provided with stall detection device to stop the motor, if motor operation is inhibited.

e. The terminal compartment shall be separated from the inner electrical components of the actuator by means of a watertight seal so that the actuator

electrical components are protected from the ingress of moisture and foreign materials when the terminal cover is removed during installation and

maintenance.

21. All valves shall have mechanical position indicator showing % opening.

22. For 900# Rating , valves with size upto 14" shall be designed as per BS 1873 whereas for valves with size greater than 14" shall be designed as per ASME

B16.34

23. For 600# Rating , valves with size upto 12" shall be designed as per BS 1873 whereas for valves with size greater than 12" shall be designed as per ASME

B16.34

HINDUSTAN PETROLEUM CORPORATION LIMITED (HPCL)

VVSPL CAPACITY AUGMENTATION PROJECT

Project No: 403102-14495 SHEET

Datasheet No: 14495-10-IC-DAS-0001 3 of 5

Data Sheet for Control Valves

Instrument type Tag No. Manufacturer Model No. REV

Valve 10-PV-2007 VTA VTA

Actuator VTA VTA

Position Transmitter VTA VTA

Positioner VTA VTA

1 Service Description Vizag Mainline Pump 10-PA-CF-104 Discharge Pressure Control

GENERAL

2 P&ID / Ref. Dwg. no. 14495-10-PR-PID-0001

3 Line Number 16"-P-10-2004-E1X

4 Pipe Line Size Upstream: 16" 900# Schedule: 100 Downstream: 16" 900# Schedule: 100

5 Hazardous Area Classification Zone 2, Group IIA/ IIB, T3

6 Flow Conditions Units Min. Normal Max.

7 Flow rate m3/h 580

8 Inlet pressure kg/cm2g 79

9 Outlet pressure kg/cm2g 78

10 Allowable Pressure drop (Note 1) kg/cm2 1

0

11 Inlet Temperature C 25

12 Calc. Flow Coeff. (Cv) VTA

13 Calc. Sound Level dB(A) VTA

PROCESS DATA

14 Fluid Name HSD (Note 1) 58 Specific Heat Ratio (Cp/Cv) N/A

15 Fluid State Liquid 59 Critical Press. kg/cm2g 53

0

16 Vapour Frac. N/A 60 Critical Temp. C

17 Opr. Specific Gravity 0.835 (Note 1) 61 Base Sp. Gravity

18 Liquid Density kg/m³ 835 (Note 1) 62 Base Pressure Kg/cm2g

0

19 Gas/Vapour density N/A 63 Base Temperature C

20 Opr. Mol. Weight N/A 64 Max. Shutoff Dp (Kg/cm²) 84 (HOLD 1)

Max. Allowable Sound Pressure Level

21 Opr. Viscosity (cSt) 3 (Note 1) 65 <85

dB(A)

22 Opr. Vapour Press. kg/cm2A 0.7 (Note 1 ) 65

23 Opr. Comp. Factor (Z) N/A 66

24 Design Temperature (Max./Min) 65 / Ambient 67

25 Design Pressure kg/cm2g 84 68

26 Body Type Globe 69 Actuator Type Electro Hydraulic Spring Return

27 Bonnet Type Standard (Bolted) 70 Drives 3 Phase Motor

28 Body Size 14"(VTA) 71 Spring Range VTA

VALVE BODY

29 Flange Rating/ Facing 900# / RTJ 72 Cable Entry (For Power) 3/4" NPT (1 No.) VTA

30 Flange Finish Smooth Finish 63 µinRA max. 73 Cable Entry (For Control) 1/2" NPT (2 No.) VTA

31 Flow Action To Close(VTA) 74 Power Supply 415VAC,3 Phase,4 Wire, 50Hz

32 Body/Bonnet Material ASTM A216 WCB 75 Fail Safe Action Fail Close

33 Stem Packing Material Refer General Note 19 76

ACTUATOR

34 Bolting Material ASTM A193 Gr. B7/A194 Gr.2H 77 Handwheel No

35 Direction of Flow Permenently Marked 78 Hydraulic Type / Capacity VTA

36 Trim Type Standard (VTA) 79 Mounting Position Top

37 Size VTA 80 Bench Set Range VTA

38 Characteristic Equal% 81 Oil Pressure Control Switch Yes (VTA)

39 Seat Leakage Class ANSI Class IV 82 Oil Temp. Control Switch Yes (VTA)

40 Plug Balance Balanced (VTA) 83 Contact type/ Rating SPDT/ 24VDC ,2A (VTA)

41 Rated Travel VTA 84 IP Rating/Electrical Certification IP 65 min. / EEx-'d'

TRIM

42 Plug Material Stellited 85 Actuator Material Carbon Steel /Anodized Aluminium

43 Seat Material Stellited(Renewable Type) 86 Local Indication Backlit LCD Required

44 Cage / Guide Material Stellited (VTA) 87 Manual Override Handpump

SMART Type HART Electro-

45 88

Stem / Shaft Material 13% Cr. Positioner Type Hydraulic (Inbuilt with actuator)

46 Gland Bush 13% Cr. 89 Positioner Input Signal 4-20mA HART,24 VDC

POSITIONER

47 90 Gauge Required

48 Design Code Refer General Note 22,23 91 Positioner Action Direct

CODES AND STANDARD

49 Dimension ASME B16.10 92 Cable Entry 1/2" NPT (1 No.) VTA

50 Flange Dimension ASME B16.5 93 IP Rating/Electrical Certification IP 65 min. / EEx-'i'

51 Certification Reference BS EN 10204 3.1 94

52 Testing and Inspection Standard API 598 / BS EN 12266-1 95

53 96

TRANSMITTE

Certification / Stamp PESO Position Transmitter Type SMART

POSITION

54 97 Output Signal 4-20mA HART

55 98

R

56 100

57 101

B 20/3/2017 Issued For Information ATAI MAHY MAHY

A 15/3/2017 Issued For Squad Check ATAI MAHY MAHY

Rev Date Issue Description Originated Checked Approved Client

HINDUSTAN PETROLEUM CORPORATION LIMITED (HPCL)

VVSPL CAPACITY AUGMENTATION PROJECT

Project No: 403102-14495 SHEET

Datasheet No: 14495-10-IC-DAS-0001 4 of 5

Notes: NA - Not applicable, VTA - Vendor to Advise REV

1. The products properties to be considered (as per DFR Report Doc No: 0071-00-RPT-9002 Rev 0.) are as follows:

Product Sp. Gravity at 150 C Viscosity at 380 C Viscosity at 200 C Vapour Pressure at 380 C

- Cst Cst kg/cm2a

-HSD 0.821 – 0.845

2.15@ 40 ° C 4.5 0.1

- MS 0.729-0.773 0.51 0.7 0.6

- SKO 0.790 -0.830 1.18 1.53 0.3

- NAPTHA 0.6965 0.45 0.7 0.7

- ATF 0.8105 1.18 1.53 0.3

Holds:

1. Maximum shutoff pressure drop to be confirmed based on inline Vizag Mainline pump vendor inputs.

HINDUSTAN PETROLEUM CORPORATION LIMITED (HPCL)

VVSPL CAPACITY AUGMENTATION PROJECT

Project No: 403102-14495 SHEET

Datasheet No: 14495-10-IC-DAS-0001 5 of 5

You might also like

- Manual SC30TDocument60 pagesManual SC30Tdetrusitol75% (16)

- Sumitomo CatalogueDocument146 pagesSumitomo CatalogueKyaw KhNo ratings yet

- SPLMV9Install ChecklistDocument3 pagesSPLMV9Install Checklistanon_908554203No ratings yet

- Advanced Cylinder Configuration: Options TabDocument4 pagesAdvanced Cylinder Configuration: Options TabJose RattiaNo ratings yet

- Temprature GaugeDocument1 pageTemprature GaugeKenneth EmbeleNo ratings yet

- GMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1Document20 pagesGMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1prihartono_diasNo ratings yet

- EPC Engineering Sequence PDFDocument1 pageEPC Engineering Sequence PDFveena100% (1)

- Pipeline Lowering CalculationDocument5 pagesPipeline Lowering Calculationveena100% (1)

- FM200Document6 pagesFM200zshehadehNo ratings yet

- Control ValvesDocument2 pagesControl ValvesJuan Pablo MarvalNo ratings yet

- Pressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeDocument2 pagesPressure Drop Equivalent Length of Pipes and Fittings - Engineers EdgeallovidNo ratings yet

- Instrumentation Part1omkarDocument173 pagesInstrumentation Part1omkaromkarvadlooriNo ratings yet

- Vendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation DiagramDocument11 pagesVendor Document / Document Front Sheet: Diesel Engine Generator Set Overall Piping & Instrumentation Diagramshoghi wisesa100% (1)

- Control ValveDocument22 pagesControl Valvesantoshsapan25No ratings yet

- 028120-SPT-006 Control Valve and Regulator SpecificationDocument23 pages028120-SPT-006 Control Valve and Regulator SpecificationBang JaliNo ratings yet

- Datasheet Pressure Indicating Controller PDFDocument5 pagesDatasheet Pressure Indicating Controller PDFHimawan Sigit NugrohoNo ratings yet

- Datasheet PSV PDPDEDocument8 pagesDatasheet PSV PDPDERicardo NapitupuluNo ratings yet

- Instrument Installation Material List (BM Bulk Material List), Rev 1Document1 pageInstrument Installation Material List (BM Bulk Material List), Rev 1Mathivanan AnbazhaganNo ratings yet

- Positioner SpecsDocument1 pagePositioner Specsbiswasdipankar05No ratings yet

- Process Group Spreadsheet-Based SoftwareDocument10 pagesProcess Group Spreadsheet-Based SoftwareAnonymous iCFJ73OMpDNo ratings yet

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Document2 pagesA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNo ratings yet

- Anubar SpecDocument8 pagesAnubar SpecSHIVAJI CHOUDHURYNo ratings yet

- Pump Station Sample PagesDocument5 pagesPump Station Sample PagesHedi Ben MohamedNo ratings yet

- Actuator Sizing ProgramDocument11 pagesActuator Sizing ProgramAttyubNo ratings yet

- CI Injection P&ID (Printable)Document2 pagesCI Injection P&ID (Printable)Mehtab Alam ShaikhNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Separator NadobyDocument15 pagesSeparator NadobyVidyasenNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- JD Qatar Long Term BasisDocument38 pagesJD Qatar Long Term BasisMuhamad SyamsudinNo ratings yet

- I-Et-3010.00-5140-700-P4x-003 - J - Electrical Requirements For Packages For...Document27 pagesI-Et-3010.00-5140-700-P4x-003 - J - Electrical Requirements For Packages For...everton maldonadoNo ratings yet

- STG Instrument Hook-Up Material ListDocument4 pagesSTG Instrument Hook-Up Material Listraobabar21No ratings yet

- Previews MSS SP 61 2013 PreDocument4 pagesPreviews MSS SP 61 2013 PreHoàng Vinh0% (1)

- Operation Philosophy ZLD-1 R-01Document11 pagesOperation Philosophy ZLD-1 R-01Ayon BoseNo ratings yet

- Trip and Alarm Schedule-Rev-0Document8 pagesTrip and Alarm Schedule-Rev-0anbesivam87_49857255No ratings yet

- Level Sketch QuestionsDocument3 pagesLevel Sketch Questionstusharmha100% (1)

- Appendix 5 - Control and Alarm SetpointsDocument20 pagesAppendix 5 - Control and Alarm SetpointsCù Xuân HuyNo ratings yet

- PICV Guide SpecificationDocument7 pagesPICV Guide Specificationrio jeffryNo ratings yet

- S10332300-3010 - 0 Control ValvesDocument29 pagesS10332300-3010 - 0 Control Valvesappril26No ratings yet

- 3600 - Hi-Lo Pilot SwitchDocument10 pages3600 - Hi-Lo Pilot Switchsumesh19778933No ratings yet

- Spec ReferenceDocument40 pagesSpec ReferencesohaibNo ratings yet

- Pressure Releaving StationDocument11 pagesPressure Releaving StationSreejesh Sundaresan100% (1)

- Cover TEG Contactor (V-1100)Document1 pageCover TEG Contactor (V-1100)Elias EliasNo ratings yet

- PB TW10 GBDocument6 pagesPB TW10 GBfebri_bontangNo ratings yet

- Automation General Specification For Skid Packaged Equipment Nao-Spc-D-Ic-001 April 2011Document35 pagesAutomation General Specification For Skid Packaged Equipment Nao-Spc-D-Ic-001 April 2011mahdi_gNo ratings yet

- Selection Guide EmersonDocument16 pagesSelection Guide Emersonmmrjbi9412No ratings yet

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDocument3 pagesBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNo ratings yet

- I-Et-3010.90-1200-800-Ppc-005 - e - Field InstrumentationDocument46 pagesI-Et-3010.90-1200-800-Ppc-005 - e - Field InstrumentationAlan ReisNo ratings yet

- Test Separator Trailer Prices 2013Document3 pagesTest Separator Trailer Prices 2013hermit44535No ratings yet

- Nioec SP 00 89 (R0) (Ed1)Document8 pagesNioec SP 00 89 (R0) (Ed1)aminNo ratings yet

- MOL-FPSO-PR-RPT-3006 - DB1 - Process Line ListDocument49 pagesMOL-FPSO-PR-RPT-3006 - DB1 - Process Line ListYusri FakhrizalNo ratings yet

- 305.icm-Ou-11.07 Programmable Logic ControllerDocument28 pages305.icm-Ou-11.07 Programmable Logic ControllerTpNo ratings yet

- Literature Pressure GaugesDocument5 pagesLiterature Pressure GaugesHardik AcharyaNo ratings yet

- Control Valve Selection For Multi Phase Flow KentintrolDocument18 pagesControl Valve Selection For Multi Phase Flow Kentintrolandy131078No ratings yet

- Datasheet Threaded ThermowellDocument7 pagesDatasheet Threaded ThermowellEdward ColemnaNo ratings yet

- Hassi Messaoud Peripheral Fields Development Front End Engineering and Design (Feed)Document14 pagesHassi Messaoud Peripheral Fields Development Front End Engineering and Design (Feed)toudja sidaliNo ratings yet

- Valves SpecsDocument3 pagesValves SpecsTareq AlsadiNo ratings yet

- Control Narrative TAR 13 09 Rev2Document17 pagesControl Narrative TAR 13 09 Rev2Anonymous t12LV5No ratings yet

- Fdocuments - in - Hook Up Flow Aramco PDFDocument14 pagesFdocuments - in - Hook Up Flow Aramco PDFjosejohn1No ratings yet

- 1.2. Sample - Datasheet Antisurge ValveDocument1 page1.2. Sample - Datasheet Antisurge ValveMuhammad FauzanNo ratings yet

- Instrumentation and Control (I&C) DesignDocument13 pagesInstrumentation and Control (I&C) DesignAdnan NawazNo ratings yet

- Structured What If Technique A Complete Guide - 2020 EditionFrom EverandStructured What If Technique A Complete Guide - 2020 EditionNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- Data Sheet & Sizing SheetDocument3 pagesData Sheet & Sizing SheetazitaggNo ratings yet

- AnnexureDocument391 pagesAnnexureTommy ArjanggiNo ratings yet

- EIL Standard For Painting and Surface PreparationDocument59 pagesEIL Standard For Painting and Surface PreparationASHISH GORDE0% (1)

- Mov EIL SpecsDocument10 pagesMov EIL SpecsveenaNo ratings yet

- RPPP Project PresentationDocument12 pagesRPPP Project PresentationveenaNo ratings yet

- PCV Data Sheet PDFDocument5 pagesPCV Data Sheet PDFveenaNo ratings yet

- AJME - Aug2016 HDD AnalisisDocument11 pagesAJME - Aug2016 HDD AnalisisFelipeNo ratings yet

- Existing Outfall - 6019Document1 pageExisting Outfall - 6019veenaNo ratings yet

- TDS MasterRheobuilld-623Document2 pagesTDS MasterRheobuilld-623Taposh PaulNo ratings yet

- Bomba Gorman RuppDocument15 pagesBomba Gorman RuppdenisNo ratings yet

- The Impact of Grape Variety On The AromaticDocument9 pagesThe Impact of Grape Variety On The AromaticjjmilonNo ratings yet

- Decanter SiebtechnikDocument14 pagesDecanter Siebtechnikzeppilli23No ratings yet

- Oils, Fats and WaxesDocument23 pagesOils, Fats and WaxesIvy JoyceNo ratings yet

- Acanthopanax Trifoliatus, A Potential ....Document18 pagesAcanthopanax Trifoliatus, A Potential ....Thảo PhạmNo ratings yet

- Industrial Woven Wire Cloth: Standard Specification ForDocument30 pagesIndustrial Woven Wire Cloth: Standard Specification ForErikson GallardoNo ratings yet

- Color and Finishing Layer Changes of Five Wood Species Due To Weather ExposureDocument14 pagesColor and Finishing Layer Changes of Five Wood Species Due To Weather Exposureeti.marsaulinaNo ratings yet

- Review Immersed Membrane Bioreactors AnDocument10 pagesReview Immersed Membrane Bioreactors AnGraziella NavacciNo ratings yet

- Chapter Solid WasteDocument45 pagesChapter Solid Wastenazlie1707100% (1)

- Transition Metal Ions in Biological SystemsDocument19 pagesTransition Metal Ions in Biological Systemsnotme100% (1)

- PEM Fuel Cell PDFDocument16 pagesPEM Fuel Cell PDFEldhose Shaju100% (1)

- The Republic Act 8423 or Traditional and Alternative Medicine Act (TAMA)Document4 pagesThe Republic Act 8423 or Traditional and Alternative Medicine Act (TAMA)Micha AndreaNo ratings yet

- Shell Gadus S3 T100Document2 pagesShell Gadus S3 T100Beryl FernandesNo ratings yet

- Chronology of Major Tailings Dam FailuresDocument16 pagesChronology of Major Tailings Dam FailuresFlorentina SuduNo ratings yet

- McqsDocument4 pagesMcqsWajid Hussain100% (2)

- Jumbo ShapesDocument12 pagesJumbo ShapesamokhtaNo ratings yet

- DBT-JRF BET Part B Agricultural Biotechnology PDFDocument3 pagesDBT-JRF BET Part B Agricultural Biotechnology PDFambu100% (2)

- Ecology Notes PDFDocument12 pagesEcology Notes PDFvenkat_nsn100% (2)

- Harrington 2009Document7 pagesHarrington 2009Arrhenius343No ratings yet

- Fred Basolo - Ronald C. Johnson-Coordination Chemistry-Science Reviews (1986) PDFDocument148 pagesFred Basolo - Ronald C. Johnson-Coordination Chemistry-Science Reviews (1986) PDFbrunoespostoNo ratings yet

- How To Make A Lava LampDocument5 pagesHow To Make A Lava LampJonna SapiterNo ratings yet

- Che 112F Problem Set #7 Solutions November 9, 2016Document8 pagesChe 112F Problem Set #7 Solutions November 9, 2016mh sepahdarNo ratings yet

- Microplastics Presentation-1Document15 pagesMicroplastics Presentation-1yousuf zaheerNo ratings yet

- Epoxy Resin Adhesive For Mbrace (Fibre Reinforced Polymer) Laminate SystemDocument2 pagesEpoxy Resin Adhesive For Mbrace (Fibre Reinforced Polymer) Laminate SystemSetyo poernomoNo ratings yet

- Green Chilli ReportDocument3 pagesGreen Chilli ReportPankaj GaikwadNo ratings yet

- GENERAL TEST From Actual BGAS ExamsDocument8 pagesGENERAL TEST From Actual BGAS Examsmahmoud ali100% (1)