T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

Uploaded by

tailieuxaydung2019Copyright:

Available Formats

T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

Uploaded by

tailieuxaydung2019Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

T.9.1.4 Punching Shear To EUROCODE2: RAPT User Manual

Uploaded by

tailieuxaydung2019Copyright:

Available Formats

RAPT User Manual Copyright PCDC

T.9.1.4 Punching Shear to EUROCODE2

Section 4.3.4 of the code defines the punching shear requirements used by RAPT.

The critical perimeter is defined at a point 1.5 d from the loaded area. The code has limits defining acceptable loaded

areas. To comply with the code the

1. Shape must be within the following limits (where d is the effective depth of the slab)

circular, with diameter < 3.5 d

rectangular, with perimeter < 11 d and the ratio of length to breadth < 2

any shape, the limiting dimensions being fixed by analogy with the shape mentioned above.

2. Loaded area can not have its critical perimeter intersect with another critical perimeter from another load.

If the loaded area does not comply with the conditions above (ie for wall or rectangular column supports) then the

following diagram will define the critical perimeter.

Figure T.9.3

Moment Transfer

The total design shear force is calculated from

where

Vsd = total design shear force

u = the perimeter of the critical section

b = a coefficient which takes account of the effects of eccentricity of loading. (Moment transfer to

column)

= 1.50 for corner columns

= 1.40 for edge columns

= 1.15 for internal columns

The shear resistance of slabs are calculated as follows

(i) Non Prestressed slab

where

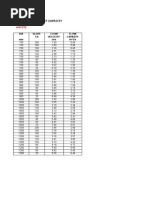

τRd varies according to concrete strength f ck ie

fckck 12 16 20 25 30 35 40 45 50

τRd 0.18 0.22 0.26 0.30 0.34 0.37 0.41 0.44 0.48

Rd

Values for τRd (N/mm2) Table 4.8 Eurocode2

k = (1.6 - d) >= 1.0 (d in meters)

ρ1 = reinforcement ratio of the tension steel < 0.015

d = effective depth of the slab ie (depth to the centroid of the tension reinforcement but d shall not

be taken as < 0.8D

T.9.1.4 Theory: Punching Shear to EUROCODE2 1

RAPT User Manual Copyright PCDC

(ii) For Prestressed Slabs the same equation applies but

where

(ie P/A)

fyd = design yield stress of the reinforcement

The maximum design shear resistance for a slab containing shear reinforcement is (per unit length of critical

perimeter)

vRd2 = 1.6 x vRd1

The design shear resistance for a slab containing shear reinforcement is (per unit length of critical perimeter)

RAPT calculates the minimum reinforcement based on

Asv min = ρw x (Acrit - Aload)

where

Acrit = the area within the critical perimeter

Aload = the area within the loaded area.

ρw = reinforcement ratio taken from clause 5.4.2.2 and 5.4.3.3

RAPT assumes that (Acrit - Aload) = 1.5 x u

T.9.1.4 Theory: Punching Shear to EUROCODE2 2

RAPT User Manual Copyright PCDC

T.9.2 Beam Shear

RAPT designs Beam Shear in accordance with each code. For specific information see

• AS3600 Clause 8.2 (and section T.9.2.2 to 4 of this manual)

• BS8110 and CP65 Clause 3.4.5 and 4.3.8

• ACI318 Chapter 11

• Eurocode2 Section 4.3.2

• SABS 0100 Clause 4.3.4 & 5.3.4

• CP2004 clause 6.1.2.5 and 12.3.8

• IS456 and IS1343 clause 40 and 22.4

It should be noted that RAPT assumes that all loads are applied at the top and centre of the members. If this is not the

case then the designer should ensure that their design accounts for this condition. ie Add hanging shear reinforcement

to transfer the load to the top and torsion reinforcement to transfer the load to the centre of the member.

Note: ACI318 and AS3600 limit the effective depth to 0.8D for beam shear calculations. Thus in

theory it is possible to design the shear requirements for a beam assuming that tensile

reinforcement exists at 0.8D when there is no tension reinforcement at all. Users should

acknowledge this and consider placing some tension reinforcement in the tension face when these

parameters occur.

Critical Sections

For all code types RAPT places the critical shear section at 0.8D from the face of the columns.

T.9.2 Theory: Beam Shear 1

RAPT User Manual Copyright PCDC

T.9.2.1 RAPT Summary

The summary output details

1. the required spacing of 3 bar sizes (relevant bar specifications used for each code)

2. when minimum STIRRUP spacing is controlling

3. when no stirrups are required

4. the shear steel area divided by the shear steel spacing, Asv/s, required for strength ie before spacings are

checked.

5. the web shear width used, bv

The width of the ducts for the shear width, bv, are assumed to be

• For duct diameters of 18 to 26 mm, RAPT assumes a duct width b w of

70 mm if strand dia <= 13 mm and

< 5 strands in duct

70 mm if strand dia >14.5 mm and

< 4 strands in duct

for all other cases RAPT assumes a duct width bw of 90 mm.

• For duct diameters > 27 mm RAPT defaults bw to the duct diameter.

RAPT conservatively assumes all ducts detailed are within the web width.

RAPT calculates the required shear reinforcement based on the maximum reinforcement in the tension face for each

moment region as calculated from "Detail Flexural Reinforcement".

A warning will also be printed if a section fails in beam shear due to crushing of the compressive strut of the truss

model, ie if V* > φVu.max.

Other decisions made by the program are

• If V* < 1 kNm then Pv is added to the sections design capacity in shear.

• If P/A = 0 at a section then principal tensile checks are not carried out. In this case RAPT will default the

principal tensile stress to a large number ie 9999.

The decompression bending moment is calculated taking due account of secondary bending moments.

If the principal tensile failure check does not need to be made at the flange / web junction ie. the neutral axis of the

gross-section does not lie within the flange, then the principal tensile force is still calculated at the flange / web

junction but is not compared with the force calculated at the centroid.

T.9.2.1 Theory: RAPT Summary 1

RAPT User Manual Copyright PCDC

T.9.2.2 Principal Tensile Strength

There are essentially two forms of shear failures: one in which the cracking of the concrete starts in the web as a

result of high principal tension and another in which vertical flexural cracks occur first and gradually develop into

inclined shear cracks. AS3600, BS8110 and ACI318 check each of these failure modes. The Eurocode uses other

methods, described later in this chapter.

The failure is due to high tensile stresses exceeding the concrete's inherent tensile strength, which is approximately

10% of its compressive strength, acting on a plane inclined (at approximately 45 degrees) to the axis of the member.

The plane on which the failure occurs is known as the principal tensile plane and its orientation may be found from

elastic strength of materials theory for a homogeneous, uncracked section. Mohrs circle of stresses is a convenient tool

for this calculation. Note that in the creation of Mohrs circle the axial compressive force from prestress and the axial

and shear stresses from the applied loading should be considered.

It is worth noting that as the foregoing relies on the section being uncracked then, at high overload, the strength limit

state, a higher factor of safety may be appropriate. However it is usually found that principal tensile failure occurs at

regions of low bending moment and hence the section may be essentially uncracked at these regions.

Both the current and previous Australian codes, American, British and South African codes do not require principal

tensile stress checks to be made for sections which are not prestressed.

The maximum principal tensile stress does not necessarily occur at the centroidal axis, where the maximum vertical

shearing stress occurs. For I-sections the junction of the flange and the web is frequently the critical location. ACI 318

(ref 23) and AS1481 both state that the check at the web / flange intersection need only be made when the neutral

axis lies within the flange itself.

Principal tensile failure is sudden and is very rarely preceded by a noticeable crack forming in the web of the member.

The calculation of the applied ultimate shear force, Vt required to induce the allowable principal tensile stress proceeds

as follows.

We define Vt as the shear force we need to apply to the cross-section in order to produce, in combination with the

applied service loads, a principal tensile stress equal to the tensile strength of the concrete. The assumption is made

that the applied bending moment does not increase with an increase in the applied shear force. This simplification is

not strictly correct. However the shear force we calculate, V t, when compared to the applied ultimate shear force, V*,

will yield a measure of the factor of safety for the loads as applied to the section.

If we set the principal tensile stress, s1 equal to the code maximum allowable stress (tensile positive)

s1

AS3600

=

(i) clause (T.9.9)

0.33

8.2.7.2

√f'c

BS8110

s1

and

=

(ii) CP65

0.24

clause

√f'cu

4.3.8.4

s1

ACI318 =

(iii)

R11.4.2 0.33

√f'c

SABS s1

0100 =

(iv)

clause 0.23

5.3.4.2.1 √f'cu

s1

CP2004

=

(v) clause

0.24

12.3.8.4

√f'cu

s1

IS1343

=

(vi) clause

0.24

22.4.1

√f'ck

The applied longitudinal axial stress is given by

T.9.2.2 Theory: Principal Tensile Strength 1

RAPT User Manual Copyright PCDC

where

P = the total axial force from the prestress

A = the gross cross-sectional area of the concrete

y = the distance from the centroidal axis to the cut

I = the gross second moment of area

Ms = is the total applied service bending moment and therefore must include secondary bending

moments, Msec, from the prestress (due to frame continuity).

= MSW + MDL + ysMLL + Mp

Mp = (S P.e) + Msec

= total prestress bending moment

= the bending moment obtained from the frame run of the continuous structure with the

equivalent prestress loads applied.

Af = Axial force applied to the structure. (Compression / Tension force on members)

In all equations where the sign is optional as positive or negative one must assess whether the design action is placing

compressive stress at the level of the cut (-ve) or tensile stress (+ve).

The shearing stress is given by

where

Vt = the shear force to cause principal tensile cracking.

Q = first moment of area above or below the cut with respect to the centroidal axis.

I = second moment of area of the total cross-section

t = shear width of the section at the cut

= bv ie. allowance must be made for the presence of prestressing ducts crossing the shear plane.

bv = bw - 0.5 Σdd AS3600 clause 8.2.6

= bw - Σdd BS8110 clause 4.3.8 for ungrouted tendons

= bw - 0.667 Σdd BS8110 clause 4.3.8 for grouted tendons

= bw ACI318 gives no adjustment for tendons in the web width.

With reference to Mohrs circle shown in Figure T.9.4 we find that

(tensile +ve)

rearranging

multiply through by s1 / s1

T.9.2.2 Theory: Principal Tensile Strength 2

RAPT User Manual Copyright PCDC

Figure T.9.4

Figure T.9.5

then (remembering compression is -ve)

The web-shear cracking strength at the centroidal axis may be checked by

Vt = bv do [ 0.292 √(f'c) + 0.33 σ ]

The above equation (ref 23) is based on a straight line simplification of the previous equation. This was given in a

more conservative form in the draft of AS3600 at the centroidal axis as

Vt = bv do ( 0.25 √(f'c) + 0.25 P/A ) ± Pv

The vertical component of the prestressing force, Pv, must be included as an additional force component. P v is

calculated by multiplying the prestress force by the inclination of the tendon (in radians). In the usual case this will

increase the shear capacity of the section as shown in figure T.9.5. As a general rule where the sign of V* and P v are

opposite then Pv increases the sections shear capacity.

In summary for principal tensile failure to occur

φVt < V*

where

φ is the capacity reduction factor for shear of 0.70. AS3600 table 2.3

Partial safety factors are used BS8110. Table 2.2 gives a γm factor of 1.25

φ is the capacity reduction factor for shear of 0.85. ACI318 clause 9.3.22

Equation T.9.13 is the equation used by RAPT to calculate the Principal Tensile Failure shear force. If necessary RAPT

will calculate this value at the centroid and web / flange intersection. (As discussed prior). RAPT will present the

results in the Detailed Shear Report. Each code uses different notation to describe the same shear force. Below is a

summary of the different code notation.

T.9.2.2 Theory: Principal Tensile Strength 3

RAPT User Manual Copyright PCDC

• AS3600 Vut

• BS8110 Vco

• ACI318 Vcw

T.9.2.2 Theory: Principal Tensile Strength 4

RAPT User Manual Copyright PCDC

T.9.2.3 Flexure-Shear Strength AS3600

For lightly reinforced sections, the common economical design solution, and in regions where the bending moment is

large with respect to the shear force (towards centre-span) flexure-shear failure will usually precede principal tensile

failure. The cracks initially form as flexural cracks on the tensile face of the section and as the load increases proceed

up the section. If the section were under the action of bending alone the cracks would remain vertical. In the presence

of shear however eg near supports, the cracks diverge towards the plane of principal tensile failure. Failure will

eventually occur when the concrete in compression above the crack crushes.

For beams which contain stirrups this failure may be preceded by buckling of the compressive reinforcement between

the stirrups. This induces spalling of the concrete above the buckle leading to total failure from the sudden loss in the

compressive concrete area. When the flexural cracks begin to develop into inclined tensile cracks, sudden and violent

failure may occur.

The ultimate capacity of a beam in shear is comprised of the shear forces to

(i) firstly initiate a flexural crack, Vo. This will occur under the load which will cause

decompression of the extreme tensile fibre. The decompression bending moment,

Mo, must therefore be calculated. For reinforced sections decompression occurs as

soon as the section is loaded therefore Mo = 0. For prestressed sections Mo is

influenced by the effect of the prestressing overcoming the applied loads. Also for

continuous prestressed beams the effects of secondary actions must also be

accounted for.

The longitudinal stress at the extreme tensile fibre (at decompression) is found by

=0

hence

Due account must be taken here of any secondary bending moments if they exist.

As

If the assumption is made that the ratio of the shear force and the bending moment remains constant for

all loadings states and for simple and continuous spans we may state that the shear force at the

decompression moment will be

(ii) then to cause the crack to develop into an inclined tensile crack extending a distance

do. The formulation of the empirical equation for this capacity is based on extensive

experimental work considering the many variables which effect the shear strength.

For normal design this formula reduces to

T.9.2.3 Theory: Flexure-Shear Strength AS3600 1

RAPT User Manual Copyright PCDC

Vuc may be considered as the shear capacity of the compressive member at the top of an equivalent

concrete truss where the compressive members are comprised of concrete and the tensile members are of

steel as shown in figure T.9.6 and T.9.7.

where

the greater of the depth to the centroid of the outermost layer of steel or

do =

0.8 times the overall depth of the section.

β1 = the larger of 1.1 and 1.6 - do / 2000

β2 = 1 or

for members subjected to significant axial tension

for members subjected to significant axial compression

N* can be applied by users in Input Screen using the Axial forces option.

dd = the sum of the diameters of prestressing ducts crossing the web

bv = the web shear width

= bw - 0.5 Σdd

(iii) The vertical component of the prestressing force, Pv.

Pv = Σ P x θ

Σ = the inclination of the tendon (radians)

As a general rule when the inclination of the tendon is of opposite sign to the applied ultimate shear force,

V*, then Pv will add to the shear capacity of the beam.

In summary for flexural-shear failure to occur

φ(Vuc +Vd + Pv) < V*

where φ is the capacity reduction factor for shear of 0.70.

T.9.2.3 Theory: Flexure-Shear Strength AS3600 2

RAPT User Manual Copyright PCDC

T.9.2.4 Reinforcing for Shear to AS3600

For beams where the stirrups are vertical we may consider the internal actions within the beam to be behaving in a

similar manner to a truss as shown in figure T.9.6. When an inclined shear cracks form at the strength limit state as

shown in figure T.9.7 the vertical tensile force in the truss model must be resisted by the vertical legs of the stirrups.

For a crack inclined at an angle θ the horizontally projected length of the crack will be given by

L = do / TAN θ

The number of stirrup legs crossing this projected length will be

n=L/s

= do / (s tanθ)

If the assumption is made that all the stirrups are at yield then the tensile force resisted by the stirrups will be

Vus =

where

Asv = the area of the stirrups per spacing s

fsy.f = the yield stress of the stirrups

The angle of the inclined crack, q, is dependent upon the level of shear present with respect to the shear capacity of

the cross-section. For lightly stressed sections this approaches 30 degrees and for heavily stressed sections 45

degrees. For intermediate percentages we may linearly interpolate between the two limits.

θ=

where

φVumin = the design strength in shear when minimum stirrups are provided ie where the area of

stirrups per spacing s equals

Asv / s = 0.35 bv / fsy.f

φVu.max = the design strength in shear when the diagonal compressive strut of the truss model

crushes. This is given by the following empirical formula

φVu.max = f ( 0.2 f'c bv do + Pv )

The total design strength in shear is then given by the summation of the shear strength of the concrete, given by the

minimum of the principal tensile strength and the flexural shear strength, plus the capacity of the stirrups. Therefore

for failure to occur

φ(Vuc + Vus) < V*

AS3600 provides rules for the detailing of the stirrups where they are required. Note that in some situations regardless

of whether the applied ultimate shear force is less than the design strength in shear, stirrups must be provided.

Figure T.9.6

T.9.2.4 Theory: Reinforcing for Shear to AS3600 1

RAPT User Manual Copyright PCDC

Figure T.9.7

T.9.2.4 Theory: Reinforcing for Shear to AS3600 2

RAPT User Manual Copyright PCDC

T.9.2.5 Reinforcing for Shear to BS8110 & SABS 0100

BS8110 clause 4.3.8 details beam shear requirements. RAPT calculates the principal tensile and flexure forces as

discussed in sections T.9.2.2 & 3. The following requirements are also specifically met by RAPT for BS8110 and SABS

0100. The shear strength Vc is calculated as the lesser of Vco and Vcr.

Principal Tensile Failure VCO

See T.9.2.2

Flexure - Shear Failure VCR

BS8110 gives the following formulae to calculate this value

where

d = effective depth (distance from the extreme compression fibre to the centroid of the

steel area (Aps + As) in the tension zone).

fpe = effective prestress force in tendons

fpu = characteristic strength of a prestressing tendon

vc = design concrete strength obtained from table 3.9 of code, in which As is replaced by (As + Aps) where As

and Aps are the respective areas of reinforcement and tendons in the tension zone.

where

should not be taken as greater than 3

should not be taken as less than 1

For characteristic concrete strengths greater than 25 N/mm2, the values in table 3.9 may be multiplied by

(fcu/25)1/3. The value of f cu should not be taken as greater than 40.

Mo = moment necessary to produce zero stress in the concrete at the extreme tension fibre. In this calculation

only 0.8 of the stress due to prestress should be taken into account.

V = Applied shear force

M = Applied moment force at that section.

Axial Compression Forces

If axial compression forces are included in the design, RAPT will modify the v c value as follows:

or 5 N/mm2 whichever is the lesser.

where <1

See BS8110 Clause 3.4.5.12

SABS 0100 Clause 4.3.4.4

BS8110 and SABS 0100 do not give any indication of what to do for Axial Tension forces for reinforced members or

axial Tension / Compression forces for prestressed members. RAPT uses the AS3600 formula for these cases (AS3600

Clause 8.2.7.1 or see section T.9.2.3 in this manual).

Minimum Design Shear Stress VUMIN

RAPT specifies a Vumin value which is calculated as

T.9.2.5 Theory: Reinforcing for Shear to BS8110 & SABS 0100 1

RAPT User Manual Copyright PCDC

Vumin = Vc + 0.4 bv d.

This is the minimum shear value possible with a minimum area of ties.

Maximum design shear stress V UMAX

The following formula is given

For BS8110 Vumax = 0.8 √fcu or 5 N/mm2 whichever is the lesser. (This includes an allowance of 1.25 for gm.)

For SABS 0100 Vumax = 0.75 √fcu or 4.75 N/mm2 whichever is the lesser. (This includes an allowance of 1.25 for γm.)

Shear reinforcement

RAPT assumes that the lesser of Vco and Vcr is equal to Vc. RAPT will calculate the required shear ties depending on the

size of the applied shear in comparison to the shear capacity of the member. RAPT gives the user two forms of results

1. (Area of reinforcement divided by spacing of ties)

2. A tie size and spacing using the above ratio for different sized tie bars.

is calculated according to the following rules

• If V < 0.5 Vc then no reinforcement is calculated

• If V < Vc + 0.4 bv d

then

• If V > Vc + 0.4 bv d

then

where

dt = depth from the extreme compression fibre either to the longitudinal bars or to the centroid of the

tendons, whichever is greater.

For reinforcement detailing rules the user should refer to the code.

T.9.2.5 Theory: Reinforcing for Shear to BS8110 & SABS 0100 2

RAPT User Manual Copyright PCDC

T.9.2.6 Reinforcing for Shear to ACI318

RAPT designs shear reinforcement fully to ACI318. Below is a summary of the formulae used by RAPT. The shear

strength Vc is calculated as the lesser of Vcw and Vci.

Principal tensile failure VCW

See T.9.2.2 for theory and calculation method.

Flexure - shear failure VCI

For non prestressed concrete members

where

Vc is not greater than 0.291√f'c bw d

shall not be taken greater than 1.0

Mu is the factored moment occurring simultaneously with V u at the section considered.

For prestressed members

where

Vci need not be taken less than 1.7 √f'c bw d

yt = distance from centroidal axis of gross section, neglecting reinforcement, to extreme fibre in

tension

I = moment of inertia of section resisting externally applied factored loads.

fpe = compressive stress in concrete due to effective prestress forces (after losses) at extreme fibre

of section where tensile stress is caused by externally applied loads.

fd = stress due to unfactored dead load, at extreme fibre of section where tensile stress is caused by

externally applied loads.

Vi = factored shear force at section due to externally applied loads occurring simultaneously with

Mmax.

Mmax= maximum factored moment at section due to externally applied loads

Vd = shear force at section due to unfactored dead load.

Axial Compression / Tension

For Axial Compression, the above equations are modified so that M m is substituted for Mu and Vud/Mu is not limited to

1.0.

h = member thickness

but Vc shall not be greater than

See ACI318 Clause 11.3.2.2

For Axial Tension, the Flexure Shear formula should be modified as follows

T.9.2.6 Theory: Reinforcing for Shear to ACI318 1

RAPT User Manual Copyright PCDC

See ACI318 Clause 11.3.2.3

ACI318 does not give any indication of what to do for Axial Tension or Compression forces for prestressed members.

RAPT uses the AS3600 formulas in these cases. AS3600 Clause 8.2.7.1 or see section T.9.2.3 in this manual.

Minimum Design Shear Stress VUMIN

Vumin is minimum design capacity taking into account minimum ties.

φVumin = φVc + φVs

where

Maximum Design Shear Stress VUMAX

φVumax = φVc + φVs

where

Vs = 0.667√f'c bw d

Shear Reinforcement

If Vu exceeds fVc then ties must be provided as follows

For spacings and detailing users should refer to the code for specifics.

T.9.2.6 Theory: Reinforcing for Shear to ACI318 2

You might also like

- LAA Step Guide: Love Addicts AnonymousDocument147 pagesLAA Step Guide: Love Addicts Anonymouspaul preciadoNo ratings yet

- Creating A Retaining Wall Using Civil 3D Feature Lines and Grading ObjectsDocument6 pagesCreating A Retaining Wall Using Civil 3D Feature Lines and Grading ObjectsMateo AndresNo ratings yet

- Design of Liquid Retaining Concrete StructuresDocument6 pagesDesign of Liquid Retaining Concrete StructuresmoorhouseNo ratings yet

- TJA SANS10400-L-Rev0 RoofsDocument7 pagesTJA SANS10400-L-Rev0 RoofsSiphelele SimelaneNo ratings yet

- Chemical Engineering - Size Safety-Relief Valves For Any ConditionsDocument9 pagesChemical Engineering - Size Safety-Relief Valves For Any Conditionshajar_athirah75% (4)

- Beam Design Summary: Material and Design DataDocument2 pagesBeam Design Summary: Material and Design DatamalsrinivasanNo ratings yet

- Crane LoadingDocument3 pagesCrane LoadingMuhammad HasanNo ratings yet

- A Good Question Considering Shipping Container StructuresDocument4 pagesA Good Question Considering Shipping Container StructuresJohn Rheynor Mayo100% (1)

- Control of Thermal Cracking in Concrete Water Retaining StructuresDocument5 pagesControl of Thermal Cracking in Concrete Water Retaining StructuresAnuraNo ratings yet

- "Sunnik" Pressed Steel Sectional Panel TanksDocument1 page"Sunnik" Pressed Steel Sectional Panel Tanksjoo2585No ratings yet

- Tension Members: Version 2 CE IIT, KharagpurDocument20 pagesTension Members: Version 2 CE IIT, KharagpurAnonymous ptLRLiNNNo ratings yet

- Roof Panel Side Lap Detail: Ceiling LNDocument1 pageRoof Panel Side Lap Detail: Ceiling LNSam Russel SisonNo ratings yet

- Reinforced Masonry DesignDocument4 pagesReinforced Masonry DesignAhad Aziz100% (1)

- SANS1200MMDocument15 pagesSANS1200MMMark D Villanueva100% (1)

- Impact Loading: 5.1 Example 1: Weight Falling On The Flange of A RodDocument6 pagesImpact Loading: 5.1 Example 1: Weight Falling On The Flange of A RodAbhishek SharmaNo ratings yet

- Segmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureDocument4 pagesSegmental Bonding Adhesive (Sba) High Modulus Fibre Reinforced Moisture Insensitive During & After Cure Low Temperature CureAmar Babu ChNo ratings yet

- Circular Reservoir 5mDocument5 pagesCircular Reservoir 5mdjamelskiNo ratings yet

- 6-4 Beams - Lateral Torsional BucklingDocument14 pages6-4 Beams - Lateral Torsional BucklingBrendon GovaNo ratings yet

- LC-1 - Section 1 Civil & Structural Steel Rev.3Document35 pagesLC-1 - Section 1 Civil & Structural Steel Rev.3Dave C100% (1)

- CE 326 Slope Design Project v02 20160202Document2 pagesCE 326 Slope Design Project v02 20160202babsy017No ratings yet

- Cooling Tower DamageDocument7 pagesCooling Tower DamageRodrigo Felicio AdrianoNo ratings yet

- Tips For Avoiding Office Building Floor VibrationsDocument5 pagesTips For Avoiding Office Building Floor Vibrationslazar_mircea_dan_391No ratings yet

- Spread Footing Foundation Pad Size: Without Tie DownsDocument2 pagesSpread Footing Foundation Pad Size: Without Tie DownsSharyn Polley100% (1)

- Practical No. 9 (CBR)Document5 pagesPractical No. 9 (CBR)slawek780303No ratings yet

- Spreadsheets To BS 8110: Single Column BaseDocument15 pagesSpreadsheets To BS 8110: Single Column BaseKamal RaoNo ratings yet

- 3-Liquid Retaining StructuresDocument3 pages3-Liquid Retaining StructuresTabish IslamNo ratings yet

- Truck Loading Platform With Mounting GangwayDocument1 pageTruck Loading Platform With Mounting GangwayprasongNo ratings yet

- Masterseal 588: Description Packaging and ColorsDocument2 pagesMasterseal 588: Description Packaging and ColorsmariaNo ratings yet

- Method Statement On As Thermoplastic Road MarkingsDocument7 pagesMethod Statement On As Thermoplastic Road MarkingsHayle Dela CruzNo ratings yet

- Etc - BD 28-87Document1 pageEtc - BD 28-87arun_angshuNo ratings yet

- Tank Storage Association Tank Storage Association: Conference & Exhibition 22 September 2011Document35 pagesTank Storage Association Tank Storage Association: Conference & Exhibition 22 September 2011António FontesNo ratings yet

- Torsion1 PDFDocument47 pagesTorsion1 PDFalaaNo ratings yet

- Geoweb Material SpecificationDocument15 pagesGeoweb Material Specificationriki187No ratings yet

- Chapter 4 (Design of Beam) PDFDocument45 pagesChapter 4 (Design of Beam) PDFsyafixNo ratings yet

- Pole Base DRM Design ChartsDocument9 pagesPole Base DRM Design Chartsvananhlt18No ratings yet

- Designer's Guide To Wind Loading of Building Structures. Part 2-Static Structures. Chapter 11 - About Part 2 - Static Structures. (2 of 12)Document7 pagesDesigner's Guide To Wind Loading of Building Structures. Part 2-Static Structures. Chapter 11 - About Part 2 - Static Structures. (2 of 12)ferdinand bataraNo ratings yet

- Analysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFDocument5 pagesAnalysis and Design of Substructures Limit State Design Balkema Proceedings and Monographs in Engineering Water and by Swami Saran 0415418445 PDFAmit ShuklaNo ratings yet

- HiltiDocument5 pagesHilticipsiccNo ratings yet

- 1990 - 03 - Mar - Design of Tower Foundations-NS and VasanthiDocument7 pages1990 - 03 - Mar - Design of Tower Foundations-NS and VasanthierjuniorsanjipNo ratings yet

- CE 467 Lesson 5 - Interlocking Concrete Block PavementsDocument39 pagesCE 467 Lesson 5 - Interlocking Concrete Block PavementsReginald AshongNo ratings yet

- Typical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sDocument6 pagesTypical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sJennifer PearsonNo ratings yet

- Simply Supported UDL Beam Formulas - Bending Moment EquationsDocument8 pagesSimply Supported UDL Beam Formulas - Bending Moment EquationsSara AdNo ratings yet

- Bridge Girder Intermediate Diaphragms - 1Document5 pagesBridge Girder Intermediate Diaphragms - 1Anonymous dWa1xtpKmfNo ratings yet

- Guide For Design of Anchorage To Concrete Examples Using Aci 318 Appendix D 3553r 11 by Aci Committee 355 B005pcirlm PDFDocument5 pagesGuide For Design of Anchorage To Concrete Examples Using Aci 318 Appendix D 3553r 11 by Aci Committee 355 B005pcirlm PDFjoshua humirangNo ratings yet

- Lecture 3 & 4 Structural Steel Design MuDocument26 pagesLecture 3 & 4 Structural Steel Design MuPenelope MalilweNo ratings yet

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- B Paper IESLDocument21 pagesB Paper IESLJanaka DineshNo ratings yet

- Bar Bending Schedule of Box CulvertDocument1 pageBar Bending Schedule of Box CulvertUnggul Wahyu100% (1)

- ESDEP LECTURE NOTE (WG14) CraneDocument22 pagesESDEP LECTURE NOTE (WG14) Cranefloi dNo ratings yet

- Geotechnical Engineering-Ii: BSC Civil Engineering - 5 SemesterDocument22 pagesGeotechnical Engineering-Ii: BSC Civil Engineering - 5 SemesterSaid-Mansour MohamedNo ratings yet

- Composite Beams and Slabs1Document9 pagesComposite Beams and Slabs1rameshbabu_1979100% (1)

- History and Developments of Structural Masonry: ReinforcementDocument1 pageHistory and Developments of Structural Masonry: ReinforcementabstickleNo ratings yet

- Advanced Structural Steel Design Advanced Structural Steel DesignDocument10 pagesAdvanced Structural Steel Design Advanced Structural Steel DesignMasudNo ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Maribel Isaura Cunurana YapuchuraNo ratings yet

- Annex 6Document16 pagesAnnex 6Manusha MaureeNo ratings yet

- Unit 43-Hydraulic, A1, KZHDocument35 pagesUnit 43-Hydraulic, A1, KZHXiao QiangNo ratings yet

- Section R8 Double Bituminous Surface DressingDocument13 pagesSection R8 Double Bituminous Surface DressingBALEN KAKLNo ratings yet

- 3 Pile Cap DesignDocument7 pages3 Pile Cap DesignSheikh Mizanur RahmanNo ratings yet

- T.7.7.6 Shrinkage Curvature: RAPT User ManualDocument16 pagesT.7.7.6 Shrinkage Curvature: RAPT User Manualtailieuxaydung2019No ratings yet

- RAPT User ManualDocument16 pagesRAPT User Manualtailieuxaydung2019No ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Nist 3Document10 pagesNist 3tailieuxaydung2019No ratings yet

- P-752 - Reinforced Concrete-2Document30 pagesP-752 - Reinforced Concrete-2tailieuxaydung2019No ratings yet

- P-752 - Reinforced Concrete-3Document30 pagesP-752 - Reinforced Concrete-3tailieuxaydung2019No ratings yet

- P-752 - Reinforced ConcreteDocument30 pagesP-752 - Reinforced Concretetailieuxaydung2019No ratings yet

- NEHRP Seismic Design Technical Brief No-Part 1Document15 pagesNEHRP Seismic Design Technical Brief No-Part 1tailieuxaydung2019No ratings yet

- P-752 - Reinforced Concrete-1Document30 pagesP-752 - Reinforced Concrete-1tailieuxaydung2019No ratings yet

- Nist 1Document15 pagesNist 1tailieuxaydung2019No ratings yet

- 7.3.6.4 Bending Moments - Load Cases: Prestress EffectsDocument16 pages7.3.6.4 Bending Moments - Load Cases: Prestress Effectstailieuxaydung2019No ratings yet

- 7.3.6.4 Bending Moments - Load Cases: Prestress EffectsDocument16 pages7.3.6.4 Bending Moments - Load Cases: Prestress Effectstailieuxaydung2019No ratings yet

- T.2.1 Column Calculations: The Columns Are Modelled As EitherDocument16 pagesT.2.1 Column Calculations: The Columns Are Modelled As Eithertailieuxaydung2019No ratings yet

- T.6 Ultimate Flexure: RAPT User ManualDocument16 pagesT.6 Ultimate Flexure: RAPT User Manualtailieuxaydung2019No ratings yet

- 7.3.12 Reinforcement LayoutDocument16 pages7.3.12 Reinforcement Layouttailieuxaydung2019No ratings yet

- 7.3.5 Prestress 7.3.5.1 Tendon Forces: Text OutputDocument16 pages7.3.5 Prestress 7.3.5.1 Tendon Forces: Text Outputtailieuxaydung2019No ratings yet

- Rapt 19Document16 pagesRapt 19tailieuxaydung2019No ratings yet

- Rapt 18Document14 pagesRapt 18tailieuxaydung2019No ratings yet

- Rapt 19Document16 pagesRapt 19tailieuxaydung2019No ratings yet

- Rapt 14Document16 pagesRapt 14tailieuxaydung2019No ratings yet

- Rapt 12Document16 pagesRapt 12tailieuxaydung2019No ratings yet

- 2013 ILX Maintenance - Xls - MaintenanceDocument1 page2013 ILX Maintenance - Xls - MaintenanceGawker.comNo ratings yet

- Project Synopsis FormatDocument4 pagesProject Synopsis FormatKamil GourNo ratings yet

- NCR Disposition ProposalDocument2 pagesNCR Disposition ProposalKarthik DhayalanNo ratings yet

- Barbara Johnson Anthromorphism in Lyric and LawDocument27 pagesBarbara Johnson Anthromorphism in Lyric and LawEliora AvrahamNo ratings yet

- Hydrogen NIST DataDocument4 pagesHydrogen NIST DataDevansh MehtaNo ratings yet

- Gas CromatogarphDocument42 pagesGas CromatogarphTisnanto Adisatyo WidcaksonoNo ratings yet

- Reading Passage 1Document12 pagesReading Passage 1asyok005No ratings yet

- JEE Main Revision Notes (Unit IV, V, VI)Document248 pagesJEE Main Revision Notes (Unit IV, V, VI)adityakvnov05No ratings yet

- Charles Law LetterDocument4 pagesCharles Law LetterJustine RuizNo ratings yet

- Prácticas Recomendadas para El Uso de Pipetas EppendorfDocument6 pagesPrácticas Recomendadas para El Uso de Pipetas EppendorfCarlos RoqueNo ratings yet

- Shipping Container Structural Components and TerminologyDocument5 pagesShipping Container Structural Components and TerminologyJohn Rheynor MayoNo ratings yet

- Catalogo Iko Linear Lbe, LBD, LBB, LM, Lme, LMBDocument27 pagesCatalogo Iko Linear Lbe, LBD, LBB, LM, Lme, LMBrafacamNo ratings yet

- Fa19-Epe-028 Lab Assignment 06 BDocument9 pagesFa19-Epe-028 Lab Assignment 06 BZabeehullahmiakhailNo ratings yet

- CM 900sfullinstallguidev1 0Document32 pagesCM 900sfullinstallguidev1 0davidwithgreenwayrecyclersNo ratings yet

- ACH550 Commissioning Sheets Cannon Row AHU 4 Fan 1Document8 pagesACH550 Commissioning Sheets Cannon Row AHU 4 Fan 1lister3476No ratings yet

- Chimney Load CombDocument1 pageChimney Load CombAndri SNo ratings yet

- XII Expansion of IdeaDocument11 pagesXII Expansion of Ideavedashree pitre100% (1)

- Cable NetworksDocument32 pagesCable NetworksEsakki Muthuvel VNo ratings yet

- Dil00am Klockner Moeller Manual Datasheet PDFDocument3 pagesDil00am Klockner Moeller Manual Datasheet PDFfulgerNo ratings yet

- Chapter 3.0 - Block DiagramDocument37 pagesChapter 3.0 - Block DiagramAzyan Wafiqah AzmiNo ratings yet

- 07-The Copy Posse Lead Magnet GuideDocument6 pages07-The Copy Posse Lead Magnet GuideSunil Kumar100% (2)

- The Role of Chemistry in Sanitization and Personal Hygiene in Context of Covid-19Document8 pagesThe Role of Chemistry in Sanitization and Personal Hygiene in Context of Covid-19Central Asian StudiesNo ratings yet

- WiSENT 2Document8 pagesWiSENT 2jrigorighiNo ratings yet

- Ikp Eden MachineriesDocument6 pagesIkp Eden MachineriesBhuvanaNo ratings yet

- HRM CaseDocument4 pagesHRM CaseJeeya TamrakarNo ratings yet

- NarrativeDocument25 pagesNarrativemichael.kanNo ratings yet

- Victaulic Fire Protection Specification - March 06Document12 pagesVictaulic Fire Protection Specification - March 06ABELWALIDNo ratings yet

- User's Manual - WCMTV2.0-202312Document11 pagesUser's Manual - WCMTV2.0-202312May Oo MonNo ratings yet