Duct Liner PM: Air Handling Systems

Duct Liner PM: Air Handling Systems

Uploaded by

Emiliuss HernandezCopyright:

Available Formats

Duct Liner PM: Air Handling Systems

Duct Liner PM: Air Handling Systems

Uploaded by

Emiliuss HernandezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Duct Liner PM: Air Handling Systems

Duct Liner PM: Air Handling Systems

Uploaded by

Emiliuss HernandezCopyright:

Available Formats

Air Handling Systems

Duct Liner PM

Fiber Glass Duct Liner

Description

Duct Liner PM is a flexible duct liner insulation made from strong,

glass fibers bonded with a thermosetting resin. The airstream

surface is protected using a durable glass mat facing which

contains an EPA-registered antimicrobial agent. The flexible

glass mat also provides a smooth airstream surface.

Factory-Applied Edge Coating

Edge coating is factory applied to the edges of the liner core,

assuring coverage of the leading edges per NAIMA/SMACNA

requirements. Shop fabrication cuts may be coated with the

SuperSeal® Duct Butter and edge treatment products (refer to

publication AHS-202).

Uses

Duct Liner PM is specifically designed for lining sheet metal Advantages

ducts in air conditioning, heating and ventilating systems, Improves Indoor Building Environment. Duct Liner PM improves

providing superior acoustical and thermal performance. indoor environmental quality by helping to control both

temperature and sound.

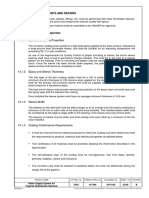

General Properties

Operating temperature (max.) - ASTM C 411 250°F (121°C) Will Not Support Microbial Growth. Permacote coating is

Air velocity (max.) - ASTM C 1071 5000 fpm (25.4 m/sec) formulated with an immobilized, EPA-registered, protective

Fungi resistance - ASTM C 1338 Does not breed or promote agent to protect the coating from potential growth of fungus

Fungi resistance - ASTM G 21 No growth and bacteria.

Bacteria resistance - ASTM G 22 No growth Duct Liner PM duct liner meets all requirements for fungi and

bacterial resistance. Tests were conducted in accordance with

Standard Thicknesses and Packaging ASTM C 1338 and ASTM G 21 (fungi testing) and ASTM G 22

Thickness Roll Length Roll Widths for All Thicknesses* (bacteria resistance testing). Detailed information is available in

in mm lineal feet lineal meters in mm Johns Manville fact sheet HSE-103FS.

1

/2 13 100, 150, 200 31, 46, 61

1 25 50, 100, 150, 200 15, 31, 46, 61 34 to 36 864 to 914 Note: As with any type of surface, microbial growth may occur in

44 to 48 1118 to 1219 accumulated duct system dirt, given certain conditions. This risk

11/2 38 50, 100 15, 31 56 to 60 1422 to 1524

2 51 50 15 66 to 72 1676 to 1829 is minimized with proper design, filtration, maintenance and

*Available in 1⁄4" (6.4 mm) increments. operation of the HVAC system.

Contact your Regional Sales Office for stock items and availability of special sizes.

Cleanability. If HVAC system cleaning is required, the airstream

Surface Burning Characteristics surface may be cleaned with industry-recognized dry methods.

Duct Liner PM meets the Surface Burning Characteristics and See the North American Insulation Manufacturers Association

Limited Combustibility of the following standards: (NAIMA) “Cleaning Fibrous Glass Insulated Air Duct Systems.”

Standard/Test Method

• ASTM E 84 Maximum Flame Spread Index 25

• UL 723 Maximum Smoke Developed Index 50

• NFPA 255

• NFPA 90A and 90B

• NFPA 259

• CAN/ULC S102-M88

UL labels supplied on packages when requested on order.

Specification Compliance

• ASTM C 1071, Type I

• ICC Compliant

• California Title 24

• ASHRAE 62

• SMACNA Application Standards for Duct Liners

• NAIMA Fibrous Glass Duct Liner Installation Standard

• Canada: CGSB 51-GP-11M and CAN/CGSB 51.11

AHS-424 11-08 (New)

Duct Liner PM

Fiber Glass Duct Liner

Installation Thermal Performance

Duct Liner PM installation must be performed in accordance with Thickness R-Value Conductance

the requirements of the NAIMA Fibrous Glass Duct Liner in mm (hr•ft2 •°F)/Btu m2 •°C/W Btu/(hr•ft2 •°F) W/m2 •°C

Standards, or SMACNA HVAC Duct Construction Standard. All 1

/2 13 2.2 0.39 0.46 2.61

transverse edges, or any edges exposed to airflow, must be 1 25 4.2 0.74 0.24 1.36

coated with an approved duct liner coating material, such as 11/2 38 6.3 1.11 0.16 0.91

Johns Manville SuperSeal® products. 2 51 8.0 1.41 0.13 0.74

Minimizes Pre-Installation Damage. Duct Liner PM’s durable R-Value and Conductance are calculated from the material thermal conductivity tested in

accordance with ASTM C 518 at 75°F (24°C) mean temperature.

glass mat facing is resistant to damage that can occur during

in-shop handling, fabrication, jobsite shipping, and installation.

Sound Absorption Coefficients (Type “A” Mounting)

Easy to Fabricate. Duct Liner PM is light in weight and easy to

Sound Absorption Coefficient at Frequency

handle. Clean, even edges can be accurately cut with regular

Thickness (Cycles per Second) of

shop tools.

in mm 125 250 500 1000 2000 4000 NRC

1

/2 13 0.07 0.20 0.44 0.66 0.84 0.93 0.55

1 25 0.08 0.31 0.64 0.84 0.97 – 0.70

11/2 38 0.24 0.51 0.90 0.99 1.01 – 0.85

2 51 0.26 0.69 1.02 1.08 1.03 – 0.95

Coefficients were tested in accordance with ASTM C 423 and ASTM E 795.

ISO 9000 Certification

Johns Manville mechanical insulation products are designed,

manufactured and tested in our own facilities, which are

certified and registered to stringent ISO 9000 (ANSI/ASQC 90)

series quality standards. This certification, along with regular,

independent third-party auditing for compliance, is your

assurance that Johns Manville products deliver consistent high

quality.

The physical and chemical properties of Duct Liner PM listed herein

North American Sales Offices, represent typical, average values obtained in accordance with

Insulation Systems accepted test methods and are subject to normal manufacturing

variations. They are supplied as a technical service and are subject

Eastern Region to change without notice. Numerical flame spread and smoke

P.O. Box 158 developed ratings are not intended to reflect hazards presented by

Defiance, OH 43512

these or any other materials under actual fire conditions. Check with

(800) 334-2399

the Regional Sales Office nearest you to assure current information.

Fax: (419) 784-7866

All Johns Manville products are sold subject to Johns Manville’s

Western Region & Canada standard Terms and Conditions including Limited Warranty and

717 17th St. P.O. Box 5108 Limitation of Remedy. For a copy of the Johns Manville standard

Denver, CO 80202 Denver, CO 80217 Terms and Conditions, Limited Warranty and Limitation of Remedy,

(800) 654-3103 (800) 368-4431 and information on other Johns Manville thermal insulations and

specJM.com Fax: (303) 978-4661 systems, call (800) 654-3103.

AHS-424 11-08 (New) Printed on recycled paper. Copyright © 2008 Johns Manville

Printed in USA

You might also like

- RVS 09.02.31Document38 pagesRVS 09.02.31Nesa MarkovicNo ratings yet

- Afico Faceed InsulationDocument4 pagesAfico Faceed Insulationhello1230No ratings yet

- Fibrous Glass Duct SystemDocument4 pagesFibrous Glass Duct SystemJFBD BuildersNo ratings yet

- AHS 187 - Air Handling Systems Product Selector GuideDocument8 pagesAHS 187 - Air Handling Systems Product Selector GuideKhang NguyenNo ratings yet

- Chemical RraghavanDocument60 pagesChemical RraghavanjoekaledaNo ratings yet

- Acoustic Liner - Linacousticrc en Data SheetDocument2 pagesAcoustic Liner - Linacousticrc en Data SheetraghuragooNo ratings yet

- Specification For SleeveDocument6 pagesSpecification For SleevePipeline EngineerNo ratings yet

- Conseal 250 Method Statement MEGASTARDocument4 pagesConseal 250 Method Statement MEGASTARKieboye AppahNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- PDS Polyken 980 955Document2 pagesPDS Polyken 980 955David100% (1)

- 21.00078 Classic - TDS - CA - v6Document2 pages21.00078 Classic - TDS - CA - v6beattiecNo ratings yet

- PDS Polyken 980 955 V5 Sep20 Aarps 0285Document2 pagesPDS Polyken 980 955 V5 Sep20 Aarps 0285Andrea Pamela León AlgarañazNo ratings yet

- PDS Polyken 980 955 V3 Jan19 Aarps 0285Document2 pagesPDS Polyken 980 955 V3 Jan19 Aarps 0285Irawan FajarNo ratings yet

- Insulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriDocument5 pagesInsulated Roof & Wall Panels Ks103 SSF Data Sheet: Microlambri Superlambri SmoothlambriKhaled GamalNo ratings yet

- Dowsil 785 Sanitary Acetoxy Silicone: Features & Benefits ApplicationsDocument3 pagesDowsil 785 Sanitary Acetoxy Silicone: Features & Benefits Applicationsscribdme123No ratings yet

- PDS Polyken Ygiii Oct13 V2 Aarps 0591Document2 pagesPDS Polyken Ygiii Oct13 V2 Aarps 0591Senthilkumar NarayananNo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- PolykenYG IIIDocument2 pagesPolykenYG IIISenthilkumar NarayananNo ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- Duct Liner (AFICO)Document4 pagesDuct Liner (AFICO)hshoooma65No ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- Firedam 150+ Sell Firma GREDocument2 pagesFiredam 150+ Sell Firma GRERenzo Omar Carrasco TalledoNo ratings yet

- MX 75-98Document2 pagesMX 75-98Compras WConexNo ratings yet

- Ficha Tecnica Cañuela AccoFlexDocument2 pagesFicha Tecnica Cañuela AccoFlexJuan Miguel Castro VargasNo ratings yet

- Centricast CL 2030 Piping System Spec SheetDocument2 pagesCentricast CL 2030 Piping System Spec Sheetrunlin.tianNo ratings yet

- Polyken 930: Product Data SheetDocument2 pagesPolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Delta Protekt KL120Document1 pageDelta Protekt KL120GavinNo ratings yet

- TIGER PDS Series75 1181 enDocument3 pagesTIGER PDS Series75 1181 enKenyDuyệtNo ratings yet

- Self Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2Document5 pagesSelf Adhering Sheet Waterproofing Bituthene 3000 and Bituthene Low Temperature GSWP 003A v2200365530No ratings yet

- Damper Valves: FOR Air & Gases TreatmentDocument9 pagesDamper Valves: FOR Air & Gases TreatmentIrwansyah CahyaNo ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- Atlantic Air Compressor OilsDocument1 pageAtlantic Air Compressor OilsOsman QaasimNo ratings yet

- Vanpanel Wall: External and Internal SheetDocument3 pagesVanpanel Wall: External and Internal SheetMl JainNo ratings yet

- PDS Polyken 930 NOV13 V2 AARPS 0543Document2 pagesPDS Polyken 930 NOV13 V2 AARPS 0543moch ardiansyahNo ratings yet

- Tremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031Document12 pagesTremco 071416.01 - Cold Fluid-Applied Waterproofing, Vertical and Deck Tremproof 250gc - 20141031ali razaNo ratings yet

- Emcekrete 0 A: Routing ConcreteDocument2 pagesEmcekrete 0 A: Routing Concretesunil kumarNo ratings yet

- CCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0Document4 pagesCCW-3751 606939 R2plus Matte Tech Data Sheet 10-7-15 0amanraza.canNo ratings yet

- Vinyl Foam GasketDocument1 pageVinyl Foam Gasketmohammed atyaNo ratings yet

- ESP Cables: Exploration & ProductionDocument2 pagesESP Cables: Exploration & ProductionHimawan Sigit NugrohoNo ratings yet

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev ADocument8 pagesVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- Water Proofing SpecificationDocument2 pagesWater Proofing SpecificationBharat KoraleNo ratings yet

- 2020 Upvc MPVC CatalogueDocument10 pages2020 Upvc MPVC Catalogueaviwetangosc01No ratings yet

- PE Yellow Gas - WebDocument16 pagesPE Yellow Gas - WebGavin KwanNo ratings yet

- Mmihmm: Flowguard CPVCDocument1 pageMmihmm: Flowguard CPVCmohamed fathiNo ratings yet

- CCRR-0467 Omega DiamondWallDocument17 pagesCCRR-0467 Omega DiamondWallj.saiyathNo ratings yet

- DacrometDocument6 pagesDacrometdavideNo ratings yet

- Duct Master Ducting Ranges and AncillariesDocument34 pagesDuct Master Ducting Ranges and AncillariesCatalin StrugariuNo ratings yet

- Rockwool Process Manual - p126-129Document3 pagesRockwool Process Manual - p126-129isogulalebNo ratings yet

- Kingspan ks1000rw Trapezoidal Roof Panel Data Sheet en AuDocument6 pagesKingspan ks1000rw Trapezoidal Roof Panel Data Sheet en AuShane BelongNo ratings yet

- GAMMA-GERMAN PLT-PE-4mmDocument2 pagesGAMMA-GERMAN PLT-PE-4mmEgyp XsNo ratings yet

- Battery Range Summary: Safe SafeDocument2 pagesBattery Range Summary: Safe SaferadikahendryNo ratings yet

- Covalence WPC100M Shrink Sleeves PDFDocument2 pagesCovalence WPC100M Shrink Sleeves PDFJMROMANTNo ratings yet

- Viscoelastic Damping Polymers 112 130Document8 pagesViscoelastic Damping Polymers 112 130jorge villagranNo ratings yet

- Roofliner Pds With FavsDocument5 pagesRoofliner Pds With FavsVasile BudaNo ratings yet

- EN350490 - 1810 2810 BrochureDocument8 pagesEN350490 - 1810 2810 Brochuresf wNo ratings yet

- Rubber Mastic and Sealant Tapes PDFDocument18 pagesRubber Mastic and Sealant Tapes PDFNikhil MathewNo ratings yet

- Mariseal 400 Aqua Version18Document2 pagesMariseal 400 Aqua Version18Chetal BholeNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Ufgs 23 01 30.41Document14 pagesUfgs 23 01 30.41Abo MohammedNo ratings yet

- Cold Storage GuidelinesDocument79 pagesCold Storage Guidelinesn.k.india100% (2)

- DM 090Document60 pagesDM 090Ernesto AriasNo ratings yet

- Integraheader: The Long-Term Chlorine Header SolutionDocument8 pagesIntegraheader: The Long-Term Chlorine Header Solutionmanuel.ape6263No ratings yet

- Jet VentDocument40 pagesJet VentKanaya PradaNo ratings yet

- York R-410 ZF-ZR Series Technical GuideDocument93 pagesYork R-410 ZF-ZR Series Technical Guideedgar_padilla100% (1)

- CH6TL4BX User Manual MULTIDocument27 pagesCH6TL4BX User Manual MULTISergio LAZARONo ratings yet

- YamatakeDocument8 pagesYamatakedo phuongNo ratings yet

- Scope of SupplyDocument12 pagesScope of Supplyreza39No ratings yet

- Oaks MallDocument86 pagesOaks MallWei Yang LimNo ratings yet

- HBFLEX Catalogue ENDocument8 pagesHBFLEX Catalogue ENDuy Phạm VănNo ratings yet

- Earth TunnelingDocument9 pagesEarth TunnelingNishita NaikNo ratings yet

- Basics of Indoor Pool Air DistributionDocument4 pagesBasics of Indoor Pool Air DistributionNebojsa GolubovicNo ratings yet

- GTC Technical Guidelines Electricity Ge Tgi Ig 0015 Vn9.00Document36 pagesGTC Technical Guidelines Electricity Ge Tgi Ig 0015 Vn9.00AjmeerNo ratings yet

- Airways Source Book - Screen PDFDocument100 pagesAirways Source Book - Screen PDFErjon MalajNo ratings yet

- Mason Industries Seismic Guide PDFDocument268 pagesMason Industries Seismic Guide PDFelidstone@hotmail.comNo ratings yet

- Concept Note PSD LAB - PHARMA API PLANTDocument17 pagesConcept Note PSD LAB - PHARMA API PLANTRishabh VermaNo ratings yet

- 1 - Properties of Thermal Insulation MaterialsDocument20 pages1 - Properties of Thermal Insulation Materialsn1186651965No ratings yet

- MCW Chiller: DDC - Digital Diagnostic ControlDocument48 pagesMCW Chiller: DDC - Digital Diagnostic ControlHernando Fang PedrozaNo ratings yet

- NaturalSorb White Paper Rev 2 1 29 15Document14 pagesNaturalSorb White Paper Rev 2 1 29 15Amer GaladNo ratings yet

- FN - Engineering Guide - 115.26-EG3Document28 pagesFN - Engineering Guide - 115.26-EG3Michael FutolNo ratings yet

- HALTONDocument7 pagesHALTONgigimalureanuNo ratings yet

- ATA Task CodeDocument118 pagesATA Task CodeStalin DavidNo ratings yet

- ACO Balcony and Terrace Drainage PDFDocument16 pagesACO Balcony and Terrace Drainage PDFValiNo ratings yet

- Damper Datasheet: Stack Damper Multiple Stack ControlDocument2 pagesDamper Datasheet: Stack Damper Multiple Stack ControlAjay BaggaNo ratings yet

- Manual de Instalação Samsung FJM Duto SlimDocument16 pagesManual de Instalação Samsung FJM Duto SlimRobson FreitasNo ratings yet

- ClassiCool 12K To 72K - R410A - IOM - tcm478-51424Document88 pagesClassiCool 12K To 72K - R410A - IOM - tcm478-51424Dessouki SamakNo ratings yet

- DampersDocument25 pagesDampersmpwasaNo ratings yet

- TM-Block 14: P-OKITM07-10: P-OKITM07-10.EF - HO.SP2.001: Stock Preparation #2Document5 pagesTM-Block 14: P-OKITM07-10: P-OKITM07-10.EF - HO.SP2.001: Stock Preparation #2robby a. malikNo ratings yet