Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Uploaded by

Juan Jose PerdomoCopyright:

Available Formats

Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Uploaded by

Juan Jose PerdomoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Truck/Tractor System Trailer System: Trucks and Truck Tractors: Trailers

Uploaded by

Juan Jose PerdomoCopyright:

Available Formats

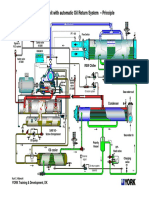

System Trailer Trailer

Park Park Release

MV-3 Control

Module

TRUCK/TRACTOR SYSTEM TRAILER SYSTEM

PP-1 TP-3 Tractor Protection Service Line

DS-2

Double Check

& Stop Light Supply Line

PP-1

PP-7

Brake Trailer

Chambers Air Dryer

SR-1

Spring

Brake Valve

E7,

E6

LQ-5

Bobtail Trailer

Ratio Control Valve

Valve

DC-4 Anti-Compound

BP-R1

Double Line R-12

QR-1 Gauge Bobtail

Check LP-3 Anti-Compound

Relay

Quick Line Proport.

Valve R-14 Valve

Release Relay

Relay Valve

Valve SR-5

Air Front Axle Trailer Spring

Dryer Safety Service Reservoir Brake Valve

Valve

LP-3

Supply

Low Pressure

Reservoir

Indicator

Check

Gauge

Valve

Rear Axle

D-2 Governor Service Reservoir

Compressor Spring Brakes Spring Brakes

TOWING TRAILER CONVERTER DOLLY

R-12P Pilot Relay Valve

R-12P Pilot

Relay Valve Service

Line

Service Line

Check

Valve PR-3 Reservoir

Service Control

Line

SR-5

RE-6NC Relay

Emergency

Valve

R-12 (Non-Charging)

Quick

Release Pintle Hook Supply SV-1 Synchro

Clamping Line Check Valve

Chamber Valve

Supply

Line

Supply

Line

PP-1

Control

TRUCKS AND TRUCK TRACTORS: TRAILERS:

Charging Primary Secondary Park (Supply) Parking (Control) Trailer (Supply) Trailer (Control) Trailer (Park)

DUAL CIRCUIT BRAKE SYSTEM TROUBLESHOOTING

Test 1 Check List 2 Test 4

GOVERNOR CUT-OUT / LOW PRESSURE WARNING / PRESSURE BUILD-UP IF THERE IS EXCESSIVE LEAKAGE IN THE SUPPLY SIDE OF THE PNEUMATIC SYS- MANUAL EMERGENCY SYSTEM

TEM, ONE OR MORE OF THE FOLLOWING DEVICES COULD BE CAUSING THE FULL PRESSURE, ENGINE IDLING 600-900 RPM NOT

VEHICLE PARKED, WHEELS CHOCKED NOT PROBLEM:

OK OK OK OK

NOTE: (A leak detector or soap solution will aid in locating the faulty component) FOR STRAIGHT TRUCKS, BUSES AND BOBTAIL TRACTOR:

1. Drain all reservoir to 0 PSI

1. Supply lines and fittings (tighten) 1. Manually operate the park control valve and note that parking brakes

2. Start engine (run at fast idle) (Low pressure warning should be on. 2. Low pressure indicator(s) apply and release promptly as control valve button is pulled out and

Note: on some vehicles with anti-lock, warning light will also come on 3. Relay valves (antilock modulators) pushed in. ❑ ❑

momentarily when ignition is turned on.) ❑ ❑

4. Relay valve (an option for spring brakes) FOR TRACTOR/TRAILER COMBINATIONS:

3. Low pressure warning (Dash warning light should go off at or above 5. Dual brake valve 1. Manually operate tractor protection control valve (trailer supply valve

60 PSI) ❑ ❑ 6. Trailer control valve usually red octagonal button). Note that trailer brakes apply and release

7. Park control valve promptly as control button is pulled out and pushed in. ❑ ❑

4. Build up time (Pressure should build from 85-100 PSI within 40 sec-

❑ ❑ 8. Tractor protection valve

onds) 2. Manually operate system park control (usually yellow diamond button)

9. Spring brake actuators

5. Governor cut-out Cuts out at correct pressure (Check manufacturers 10. Safety valve in supply reservoir and note all parking brakes (tractor and trailer) apply promptly. ❑ ❑

recommendations; usually between 100-130 PSI) ❑ ❑ 11. Governor MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 5; SEE CHECK-

6. Governor cut-in Reduce service air pressure to governor cut-in. The 12. Compressor discharge valves LIST 4 FOR COMMON CORRECTIONS

difference between cut-in and cut-out pressure must not exceed 25 *RETEST TO CHECK OUT ALL ITEMS REPAIRED OR REPLACED

PSI. ❑ ❑ Check List 4

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 2; SEE CHECK- Test 3 If sluggish performance is noted in either test, check for:

LIST 1 FOR COMMON CORRECTIONS. LEAKAGE SERVICE AIR DELIVERY 1. Dented or kinked lines

2. Improperly installed hose fitting

FULL PRESSURE, ENGINE STOPPED NOT

Check List 1 PARKING BRAKES RELEASED OK OK

3. A faulty relay emergency valve

4. A faulty modulator(s)

If the low pressure warning light or buzzer doesn’t come on:

1. Make and hold brake application (A block of wood can be used to hold If the trailer brakes do not actuate and the trailer supply line remains charged, check

1. Check wiring. the foot valve down during these tests) the:

2. Check bulb. 2. Allow pressure to stabilize for 1 minute; then begin timing for 2 min- 1. Tractor protection control

3. Repair or replace the buzzer, bulb or low pressure warning switch(es). utes while watching the dash gauges for a pressure drop. 2. Trailer spring brake valve

A. Pressure Drop: Single Vehicle (A 4 PSI drop within 2 minutes is *RETEST TO CHECK OUT ALL ITEMS REPAIRED OR REPLACED

If governor cut-out is higher or lower than specified by the vehicle manual:

allowable for either service reservoir) ❑ ❑

1. Adjust the governor using a gauge of known accuracy,

B. Pressure Drop: Tractor/Trailer (A 6 PSI drop within 2 minutes is

Test 5

2. Repair or replace governor as necessary after being sure compressor unloader mech- allowable for either service reservoir) ❑ ❑ AUTOMATIC EMERGENCY SYSTEM

anism is operating correctly. FULL PRESSURE, ENGINE STOPPED NOT

C. Pressure Drop: Tractor/2 Trailers (An 8 PSI drop within 2 min-

If low pressure warning occurs below 60 PSI: OK OK

utes is allowable for either service reservoir) ❑ ❑

1. Drain front axle reservoir to 0 PSI.

1. Check dash gauge with test gauge known to be accurate, 3. Check brake chamber push rod travel (Refer to chart for allowable tol- A. Rear axle reservoir should not lose pressure ❑ ❑

2. Repair or replace the faulty low pressure indicator. erances) B. On combination vehicles, the trailer air system should remain

If build up time exceeds 40 seconds or is considerably greater than the permanent Brake Maximum Stroke charged ❑ ❑

record figure: Chamber Before C. Tractor and trailer brakes should not apply automatically ❑ ❑

Size Readjustment 2. With no air pressure in the front axle reservoir make a brake application.

1. Examine the compressor air strainer and clean or replace. 12 13/8" A. Rear axle brakes should apply and release ❑ ❑

2. Check for restricted inlet line if compressor does not have strainer, repair or replace as 16 13/4" B. On combination vehicles the trailer brakes should also apply and

necessary. 20 13/4" release ❑ ❑

24 13/4" C. The stop lamps should light ❑ ❑

3. Check compressor discharge port and line for excessive carbon. Clean or replace as

necessary. 30 2" 3. Slowly drain rear axle reservoir pressure.

A. Spring brake push pull valve should pop out between 35 & 45 PSI. ❑ ❑

4. With system charged and governor compressor in unloaded mode, listen at the com- 4. Check the angle formed between the brake chamber push rod and B. Tractor protection valve should close between 45 PSI and 20 PSI

pressor inlet for leakage. If leakage can be heard apply a small amount of oil around slack adjuster arm. (It should be at least 90° in the fully applied and trailer supply hose should be exhausted ❑ ❑

unloader pistons. If no leakage is indicated, then leakage is through the compressor dis- Position) ❑ ❑ C. Trailer brakes should apply after tractor protection closes ❑ ❑

charger valves. MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO 4. Close drain cocks, recharge system and drain rear axle reservoir to 0

5. Check the compressor drive for slippage. TEST 4; SEE CHECKLIST 3 FOR COMMON CORRECTIONS PSI.

RETEST TO CHECK OUT ALL ITEMS REPAIRED OR REPLACED A. Front axle reservoir should not lose pressure ❑ ❑

Check List 3 B. On combination vehicles the trailer air system should remain

Test 2 If there is excessive leakage in the service side of the pneumatic system, one or charged ❑ ❑

more of the following devices could be causing the problem. 5. With no air pressure in the rear axle reservoir, make a brake applica-

LEAKAGE (RESERVOIR AIR SUPPLY)

NOTE: A leak detector or soap solution will aid in locating the faulty component tion. ❑ ❑

FULL PRESSURE, ENGINE STOPPED, NOT A. Front axle brakes should apply and release

1. Service lines and fittings (tighten)

PARKING BRAKES APPLIED OK OK B. On combination vehicles the trailer brakes should also apply and ❑ ❑

2. Trailer control valve

1. Allow pressure to stabilize for at least 1 minute. release

3. Stoplight switch

C. If the vehicle is equipped with an inverting relay spring brake con- ❑ ❑

2. Observe the dash gauge pressures for 2 minutes and note any pres- 4. Brake chamber diaphragms

trol valve, the rear axle brakes should also apply and release

sure drop. 5. Tractor protection valve

6. Relay valves (antilock modulators)

A. Pressure Drop: Single Vehicle (A 2 PSI drop within 2 minutes is 7. Service brake valve

Check List 5

allowable for either service reservoir) ❑ ❑ 8. Front axle ratio valve (optional) If the vehicle fails to pass the tests outlined, then check the following components for

9. Inverting relay spring brake control valve (optional) straight trucks and busses leakage and proper operation:

B. Pressure Drop: Tractor/Trailer (A 6 PSI drop within 2 minutes is

allowable for either service reservoir) ❑ ❑ 10. Double check valve. 1. Fittings

If the angle between the brake chamber push rod and slack adjuster arm is less than 2. Kinked hose or tubing

C. Pressure Drop: Tractor/2 Trailers (An 8 PSI drop within 2 minutes 3. Single check valves

❑ ❑ 90° then adjust slack adjuster arm to obtain desired setting.

is allowable for either service reservoir) 4. Double check valves

If brake chamber push rod travel exceeds the allowable tolerance, then adjust

MAKE ALL NECESSARY REPAIRS BEFORE PROCEEDING TO TEST 3; SEE CHECK 5. Tractor protection valve

adjuster arm to obtain desired setting.

LIST 2 FOR COMMON CORRECTIONS. 6. Tractor protection control valve

*RETEST TO CHECK OUT ALL ITEMS REPAIRED OR REPLACED 7. Parking control valve

8. Relay valves (antilock modulators)

9. Trailer spring brake control valve

BW1396 © Bendix Commercial Vehicle Systems LLC 2/00 Printed in U.S.A. 10. Inverting relay spring brake control valve (optional) straight trucks and buses

*RETEST TO CHECK OUT ALL ITEMS REPAIRED OR REPLACED

You might also like

- Manual Electrico T300Document44 pagesManual Electrico T300Juan Jose Perdomo100% (5)

- Cat 9.3 Engine OnlyDocument30 pagesCat 9.3 Engine Onlymat.aaasandNo ratings yet

- VERMEER SC852 - MaINTENANCE MANUALDocument98 pagesVERMEER SC852 - MaINTENANCE MANUALAbel NuñzNo ratings yet

- PM 299868 000 NBT45 PartsDocument649 pagesPM 299868 000 NBT45 Partspedro northNo ratings yet

- Wiring C11Document12 pagesWiring C11Maya OlmecaNo ratings yet

- TX1202423-UN: Transmission Harness (W9) Wiring DiagramDocument1 pageTX1202423-UN: Transmission Harness (W9) Wiring DiagramgenaroNo ratings yet

- Manual de Partes Diferencial MT 45-145Document7 pagesManual de Partes Diferencial MT 45-145thermodynevialNo ratings yet

- Maintenance Manual Airglide 200 Air Spring Suspension: (06/03) KM817030 Page 1 of 44Document45 pagesMaintenance Manual Airglide 200 Air Spring Suspension: (06/03) KM817030 Page 1 of 44EDILBERTO MACHORRO MARTINEZNo ratings yet

- Schematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic SystemDocument2 pagesSchematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic Systemlevinton jose tobias genesNo ratings yet

- RSW UNIT - Automatic Oil Return SystemDocument1 pageRSW UNIT - Automatic Oil Return SystemMauricioNo ratings yet

- 1150 - 1155 Hydraulic and Wiring Diagrams S.N. 0191 and UpDocument12 pages1150 - 1155 Hydraulic and Wiring Diagrams S.N. 0191 and UpJason CrowleyNo ratings yet

- Railway Units: Railway Axles and Transmissions For Rail Maintenance VehiclesDocument8 pagesRailway Units: Railway Axles and Transmissions For Rail Maintenance VehiclesMarusya KlimovaNo ratings yet

- High Flow Cold Planer - Series IIDocument141 pagesHigh Flow Cold Planer - Series IIJJC MaquinariasNo ratings yet

- Formacion Valvulas PVG32 (Bobcat)Document25 pagesFormacion Valvulas PVG32 (Bobcat)HANSELL MIRANDA ALVANo ratings yet

- Instructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36siDocument2 pagesInstructions For 35si HP 36si HP Replacing Delco Remy 21si, 22si, 23si, 33si, 34si, 35si and 36sishinichie100% (1)

- Eaton Fuller RTLO 16918B Transmission Parts ManualDocument40 pagesEaton Fuller RTLO 16918B Transmission Parts ManualEdgar Leonel CortésNo ratings yet

- Speed Sensor - AdjustDocument6 pagesSpeed Sensor - AdjustЕвгений АбрамовNo ratings yet

- Eatonroadranger RTLO-14610BDocument48 pagesEatonroadranger RTLO-14610BSalvador CrespoNo ratings yet

- Alarms and Warnings CADocument7 pagesAlarms and Warnings CAHalil KaraNo ratings yet

- Bendix Duraflo 596 Air Compressor: DescriptionDocument40 pagesBendix Duraflo 596 Air Compressor: DescriptionSebastian OlayaNo ratings yet

- ch8 Mbe4000Document10 pagesch8 Mbe4000Duy KhaNo ratings yet

- Plano Eléctrico 795F PDFDocument54 pagesPlano Eléctrico 795F PDFGabo GaboNo ratings yet

- AirValves 2013 PDFDocument268 pagesAirValves 2013 PDFSergio Sebastian Ramirez GamiñoNo ratings yet

- Crane ManualDocument56 pagesCrane ManualCarlos Ernesto Flores Albino100% (1)

- 904B Compact Wheel LoaderDocument40 pages904B Compact Wheel LoaderSaid TouhamiNo ratings yet

- Pac56 Mx13specsheet 2021 Final DigitalhiresDocument2 pagesPac56 Mx13specsheet 2021 Final Digitalhiresgaurao.pandeNo ratings yet

- Timing Calibration Harness AssemblyDocument5 pagesTiming Calibration Harness Assemblyflordeliz jimenez rodriguezNo ratings yet

- JCB 214e Series 4 Backhoe Loader: F A S T - F A C T SDocument8 pagesJCB 214e Series 4 Backhoe Loader: F A S T - F A C T SFanatrailer FanatrailerNo ratings yet

- CAT 336E Excavator Hydrolic SystemDocument5 pagesCAT 336E Excavator Hydrolic SystemAbdul KhaliqNo ratings yet

- The Harbor TugDocument2 pagesThe Harbor TugFahim Le MajesticNo ratings yet

- Modelo Terex Txc140lc-1Document1 pageModelo Terex Txc140lc-1DarioNo ratings yet

- Blackline Push Buttons Brochure 1 PDFDocument5 pagesBlackline Push Buttons Brochure 1 PDFamruthkiranbabuji100% (1)

- HDMI Chevrolet MyLink ManualDocument31 pagesHDMI Chevrolet MyLink ManualosvaldolomelisotoNo ratings yet

- TS 35Document4 pagesTS 35Philippine Bus Enthusiasts SocietyNo ratings yet

- File 1016 PDFDocument48 pagesFile 1016 PDFSimon CooperNo ratings yet

- International: Quality Tested Replacement ComponentsDocument48 pagesInternational: Quality Tested Replacement ComponentsEduardo SantanaNo ratings yet

- Wtec Ii: Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogDocument35 pagesWtec Ii: Allison MD/B 300/B 400 Series On-Highway Transmissions Parts CatalogZafiro Feliz GalanNo ratings yet

- Bul 947015aDocument14 pagesBul 947015asssydorenkoNo ratings yet

- Ec300d Bric Hyd Eng-Gb20025147b HDocument30 pagesEc300d Bric Hyd Eng-Gb20025147b Hgamalsuam9No ratings yet

- L220G - Hyd Pump-1Document5 pagesL220G - Hyd Pump-1Vinod SekharNo ratings yet

- Service Manual Automatic Slack AdjusterDocument15 pagesService Manual Automatic Slack AdjusterEdho RidhoNo ratings yet

- Isuzu - 4JJ1 Tier 4 (2011)Document12 pagesIsuzu - 4JJ1 Tier 4 (2011)Ebied YoussefNo ratings yet

- Diagnostic Report: ENGINE #1 - J1939 Active Fault CodesDocument3 pagesDiagnostic Report: ENGINE #1 - J1939 Active Fault CodesDiesel L1mayoNo ratings yet

- Chassis Module Output PinsDocument3 pagesChassis Module Output PinsEdwin Alfonso Hernandez MontesNo ratings yet

- Detroit 6 110 Engine Service ManualDocument10 pagesDetroit 6 110 Engine Service ManualRenan ZambonNo ratings yet

- E-10 Dual Brake ValvesDocument8 pagesE-10 Dual Brake Valvesjgomez30No ratings yet

- Preliminary: Idle Validation Switch Circuit - TestDocument2 pagesPreliminary: Idle Validation Switch Circuit - TestJose Cruz Martinez MedinaNo ratings yet

- C3000-C5000 Electric Circuit PLC GM LPG Tier 4 (22.05.16)Document3 pagesC3000-C5000 Electric Circuit PLC GM LPG Tier 4 (22.05.16)David CraigNo ratings yet

- Celect Plus Faults: A Complete List of All Celect Plus Codes For The Cummins Celect ECMDocument3 pagesCelect Plus Faults: A Complete List of All Celect Plus Codes For The Cummins Celect ECMEduardo TorresNo ratings yet

- Brochure bl60b bl70bDocument28 pagesBrochure bl60b bl70bMichael Puma ZeaNo ratings yet

- Air Governor TrucksDocument4 pagesAir Governor TrucksMaldwin MenorcaNo ratings yet

- Cummins: Fault Code: 375 PID: P0602, S254 SPN: FMI: 2Document3 pagesCummins: Fault Code: 375 PID: P0602, S254 SPN: FMI: 2Enrrique LaraNo ratings yet

- 2011 Ford F650 6.7 Headlight Wiring DiagramDocument1 page2011 Ford F650 6.7 Headlight Wiring DiagramDenton Rohrer100% (1)

- Detroit Diesel - Series 50 - Service Manual - 6SE50 - 1995 - OCR - 1044 PagesDocument1,044 pagesDetroit Diesel - Series 50 - Service Manual - 6SE50 - 1995 - OCR - 1044 Pagesnahomigandara493100% (1)

- Fabco PTO 180 PTO 180 23 Parts ManualDocument27 pagesFabco PTO 180 PTO 180 23 Parts Manualeliseo cardosoNo ratings yet

- CX35 On-Highway Transmission Electrical SystemDocument2 pagesCX35 On-Highway Transmission Electrical Systemabduallah muhammadNo ratings yet

- G4a ElDocument6 pagesG4a ElEvan Valentine CalderwoodNo ratings yet

- Prev Maintenance ScaniaDocument57 pagesPrev Maintenance Scaniamaintenancetrainer2No ratings yet

- Ford AODDocument10 pagesFord AODMohammed MochrifNo ratings yet

- F4A-El / 4Eat-F / If4E / F4Eiii: FWD 4 Speed (1 Pan)Document5 pagesF4A-El / 4Eat-F / If4E / F4Eiii: FWD 4 Speed (1 Pan)andres guerraNo ratings yet

- L60063 Valve Interchange Wall Chart 1-09Document1 pageL60063 Valve Interchange Wall Chart 1-09spontaneus07No ratings yet

- Maintenance Manual Eliminating Brake Squeal: Possible Cause RemedyDocument1 pageMaintenance Manual Eliminating Brake Squeal: Possible Cause RemedyJuan Jose PerdomoNo ratings yet

- Manual Servicio Cámaras de FrenoDocument2 pagesManual Servicio Cámaras de FrenoJuan Jose PerdomoNo ratings yet

- Manual de Servicio CampanasDocument8 pagesManual de Servicio CampanasJuan Jose PerdomoNo ratings yet

- Maintenance Manual Lubrication Chart - K100 SeriesDocument5 pagesMaintenance Manual Lubrication Chart - K100 SeriesJuan Jose PerdomoNo ratings yet

- Manual Bomba SheppardDocument10 pagesManual Bomba SheppardJuan Jose PerdomoNo ratings yet

- Medición BateríaDocument1 pageMedición BateríaJuan Jose PerdomoNo ratings yet

- Designación Código Cableado 2009Document21 pagesDesignación Código Cableado 2009Juan Jose Perdomo100% (1)

- Manual Cardan SpicerDocument152 pagesManual Cardan SpicerJuan Jose PerdomoNo ratings yet

- Unidad 2: Paso 3: Modos de Propagación Y Polarización en Las Ondas ElectromagnéticasDocument16 pagesUnidad 2: Paso 3: Modos de Propagación Y Polarización en Las Ondas ElectromagnéticasJuan Jose PerdomoNo ratings yet

- Manual Dirección MecánicaDocument15 pagesManual Dirección MecánicaJuan Jose PerdomoNo ratings yet

- Explain How Refraction and Reflection Phenomenon Could Be Used in Transmission SystemsDocument10 pagesExplain How Refraction and Reflection Phenomenon Could Be Used in Transmission SystemsJuan Jose PerdomoNo ratings yet

- PDFDocument42 pagesPDFJuan Jose PerdomoNo ratings yet

- Guia Integradora de Actividades CSS 1Document7 pagesGuia Integradora de Actividades CSS 1Juan Jose PerdomoNo ratings yet

- Heavyduty Kits Catalog 2017Document8 pagesHeavyduty Kits Catalog 2017panamapuro100% (1)

- Assignment 02 - Basics of PythonDocument5 pagesAssignment 02 - Basics of Pythonhina InamNo ratings yet

- Operating Manual - ASC 150 Murphy Cummins Tier 3 - enDocument1 pageOperating Manual - ASC 150 Murphy Cummins Tier 3 - enIhorNo ratings yet

- MasterTop BSFDocument3 pagesMasterTop BSFnawazkhan23No ratings yet

- 3 Spool Control Valve 1 3Document2 pages3 Spool Control Valve 1 3Anonymous cS9UMvhBqNo ratings yet

- WBJEE 2012 Mathematics Question Paper With SolutionDocument41 pagesWBJEE 2012 Mathematics Question Paper With SolutionPremKumarKalikiri100% (3)

- Gallup Analytics and ReportingDocument25 pagesGallup Analytics and Reportingrsingh16No ratings yet

- Torsiona-Flange SAE J744Document3 pagesTorsiona-Flange SAE J744Jamin SmtpngNo ratings yet

- D71862GC10 1001 UsDocument4 pagesD71862GC10 1001 UsbugzbinnyNo ratings yet

- An Introduction To LexicologyDocument28 pagesAn Introduction To LexicologyCati BuragaNo ratings yet

- 4.3:4.4 GizmoDocument5 pages4.3:4.4 GizmoJaedyn C100% (1)

- Posobie Guide To Analytical Reading HandoutDocument112 pagesPosobie Guide To Analytical Reading HandoutInsomniaNo ratings yet

- FS 4Document92 pagesFS 4nissi guingab87% (15)

- Elastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresDocument4 pagesElastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresVictor Manuel BonettoNo ratings yet

- Mathematical ModelDocument11 pagesMathematical Modelhasan jamiNo ratings yet

- Classification of Human RightsDocument8 pagesClassification of Human RightsRahul PatilNo ratings yet

- Condition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBDocument2 pagesCondition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBloulou_beNo ratings yet

- Ipaml FinalsDocument3 pagesIpaml FinalsQuenneeNo ratings yet

- Problems: Circuitos Eléctricos Avanzados Ingeniería MecatrónicaDocument18 pagesProblems: Circuitos Eléctricos Avanzados Ingeniería MecatrónicaGonzalo Daniel Ramos MenaNo ratings yet

- Cambridge International AS & A Level: Biology October/November 2023 2 HoursDocument24 pagesCambridge International AS & A Level: Biology October/November 2023 2 HoursZhemaiah OzeNo ratings yet

- Dawn of A New DayDocument6 pagesDawn of A New Dayhatakekakashi981150No ratings yet

- Parabola and Ellipse ApplicationsDocument1 pageParabola and Ellipse ApplicationsJuanita Domínguez100% (1)

- HDD Hitachi HTS547564A9E384Document170 pagesHDD Hitachi HTS547564A9E384scrib3dsNo ratings yet

- RE18325-03 Solenoid Valve With Feedback OD15051841YZDocument4 pagesRE18325-03 Solenoid Valve With Feedback OD15051841YZMujahidin AhmadNo ratings yet

- PDF Sample Problem1Document34 pagesPDF Sample Problem1ERVIN JAMES ABULOCNo ratings yet

- 2024-JEE Advanced Full Test-1 - Paper-2 - Solutions PDFDocument16 pages2024-JEE Advanced Full Test-1 - Paper-2 - Solutions PDFSamNo ratings yet

- Delta VFD E User Manual PDFDocument403 pagesDelta VFD E User Manual PDFInfoprime CharqueadasNo ratings yet

- Search Algorithms in Artificial IntelligenceDocument13 pagesSearch Algorithms in Artificial IntelligencenandhiniNo ratings yet

- IP QB (Itscholar - Codegency.co - In)Document2 pagesIP QB (Itscholar - Codegency.co - In)faiyaz pardiwalaNo ratings yet