Overall Heat Transfer Coefficient: Physical Properties Units

Uploaded by

Ravindra SinghOverall Heat Transfer Coefficient: Physical Properties Units

Uploaded by

Ravindra SinghDesign an exchanger to sub-cool condensate from methanol condenser from 95*C to 40*C.

Flow rate

Physical properties Units

Heat capacity of Methanol = 2.84 KJ/kg * C

Heat Load = 4338.888889 kW

Heat capacity of water = 4.2 KJ/kg * C

Cooling water flow = 68.8712522 kg/s Methanol density = 750

Log-mean temperature = 30.78301888 *C Viscosity = 0.00034

Density of water = 995 kg/m^3 Heat capacity = 2.84

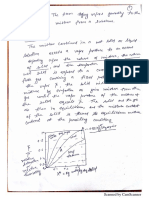

Correction factor Thermal cond. = 0.19

Value of R (for graph) = 3.666666667 Fouling coeff. (M)= 5000

Value of S (for graph) = 0.214285714 Fouling coeff. (H20)= 3000

From graph Ft = 0.85

Corrected temperature = 26.16556605 *C

Assumed U from Literature 500 W/m^2*C

Provisional area (in m2) 331.6487693

Tube dimensions

Inner Diameter = 16 mm

Outer diameter = 20 mm

Length of tube = 4.88 m

Tube sheet thickness = 5 cm

Net length = 4.83 m

Area of one tube = 0.306464 m2

Number of tubes = 1082.178557

Conductivity of tube alloy = 50 W/m*C

Overall heat transfer coefficient

Uo = 535.8872565 W/m2*C

0.001866

Check whether design is perfect for heat transfer?

Check whether design is perfect for heat transfer?

Pressure Drop Calculations

Viscosity of water = 0.0008 mNs/m2 Thermal cond. Water=

Tube side

Reynolds No. 12667.46

From fig. Jf 0.0043

Pressure Drop 5194.734 N/m2

tube side

5.194734 Kpa

Tube side pressure drop verification

Satisfactory pressure drop

ser from 95*C to 40*C. Flow rate of methanol 100,000 kg/h. Brackish water will be used as the coolant, with a temprature rise from 2

Given Data

3.666666667 Flow rate of methanol (Kg/hr) = 100000

Inlet temperature of condensate (*C) = 95

Temperatur reqired at outlet (*C)= 40

kg/m^3 Inlet temperature of brackish water (*C)= 25

Ns/m2 Outlet temperature of brackish water(*C)= 40

kJ/kg*C

W/m2*C

W/m2*C

W/m2*C Bundle Diameter (Db)

for triangular pitch

K1 = 0.249

n1 = 2.207

Db = 890.157 mm

Bundle Clearance = 68 mm

Shell diameter = 958.157 mm

Tube side coefficient

Mean water temperature = 32.5 *C Number of passes =

Tube cross sectional area = 200.96 mm2

Tube per pass = 541.0893

Tube flow area = 0.108737 m2

Water mass velocity = 633.3728 kg/(m2*s)

water linear velocity = 0.636556 m/s

Tube side coefficient,hi = 3361.432 W/m2*C

Shell side ht coefficient

Baffle spacing = 383.2628 mm Reynolds No.

Tube pitch = 25 mm Prandtl No.

Cross flow area = 0.073445 m2

Mass velocity = 378.211 Kg/s*m2

Equivalent diameter = 14.201 mm

Mean shell diameter = 67.5 *C

From fig. for 25 % baffle cut

Heat transfer factor = 0.0033

Heat transfer coeff. shellside = 1199.142 W/m2*C

erfect for heat transfer? Design is perfect

erfect for heat transfer? Design is perfect

Thermal cond. Water= 0.59 W/m*C Density of water = 995 Kg/m3

Shell side

Linear velocity = 0.504281 m/s

From fig. Jf 0.04

Pressure drop = 25947.49 N/m2

shell side

25.94749 Kpa

Shell Side pressure drop verification

Satisfactory Pressure Drop

ant, with a temprature rise from 25* C to 40*C.

Kuldeep Singh Bhati 2011uch1759

Prateek A Sarin 2011uch1804

Aayush Agarwal

Vijendra Kumar Gupta

mber of passes = 2

15796.9847

5.08210526

You might also like

- Basic Principles of Drug Discovery and Development 2nd Edition 2021 Benjamin E. Blass All Chapters Instant Download100% (3)Basic Principles of Drug Discovery and Development 2nd Edition 2021 Benjamin E. Blass All Chapters Instant Download50 pages

- The Thermodynamics of Phase and Reaction Equilibria 2nd Edition Ismail Tosun - Ebook PDF All Chapter Instant Download100% (2)The Thermodynamics of Phase and Reaction Equilibria 2nd Edition Ismail Tosun - Ebook PDF All Chapter Instant Download41 pages

- WL 320 Wet Cooling Tower Gunt 1496 PDF - 1 - en GB0% (1)WL 320 Wet Cooling Tower Gunt 1496 PDF - 1 - en GB3 pages

- Heisler Chart: Heisler Charts Are A Graphical Analysis Tool For The Evaluation ofNo ratings yetHeisler Chart: Heisler Charts Are A Graphical Analysis Tool For The Evaluation of4 pages

- Refrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusNo ratings yetRefrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De Jesus22 pages

- Department of Chemical Technology Chulalongkorn University 2306 334 App Math Chem Eng II September 20, 2021 Classwork VNo ratings yetDepartment of Chemical Technology Chulalongkorn University 2306 334 App Math Chem Eng II September 20, 2021 Classwork V6 pages

- Packed Tower Specification Sheet: Bed NumberNo ratings yetPacked Tower Specification Sheet: Bed Number2 pages

- CHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All QuestionsNo ratings yetCHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All Questions4 pages

- Humidification and Cooling Towers - 2nd 2011No ratings yetHumidification and Cooling Towers - 2nd 201146 pages

- CE 3105 Multicomponent Distillation TutorialNo ratings yetCE 3105 Multicomponent Distillation Tutorial2 pages

- Mini Project On The Design of Heat ExchangerNo ratings yetMini Project On The Design of Heat Exchanger48 pages

- HEAT CONDUCTION IN A STEAM PIPE Introductory Transport Phenomena-Wiley (2014) - R. Byron Bird Et Al100% (1)HEAT CONDUCTION IN A STEAM PIPE Introductory Transport Phenomena-Wiley (2014) - R. Byron Bird Et Al5 pages

- Chapter 2 Single Vapor Compression SystemNo ratings yetChapter 2 Single Vapor Compression System32 pages

- Separation Processes 2019-2020 (Part 1 Exercises) StudPortNo ratings yetSeparation Processes 2019-2020 (Part 1 Exercises) StudPort5 pages

- Performance Analysis of Separating and Throttling Calorimeter To DetermineNo ratings yetPerformance Analysis of Separating and Throttling Calorimeter To Determine5 pages

- Tutorial Heat Exchanger Sem 1 2019 2020 PDFNo ratings yetTutorial Heat Exchanger Sem 1 2019 2020 PDF3 pages

- ML7420A6033, ML7425A6016 (Specification Date)No ratings yetML7420A6033, ML7425A6016 (Specification Date)4 pages

- Week 8 Question 1: Absorption in A Packed Bed: CHE3165 Tutorial Problems Semester One100% (1)Week 8 Question 1: Absorption in A Packed Bed: CHE3165 Tutorial Problems Semester One1 page

- Faculty of Engineering Mass Transfer Cairo M5zncomnewuploads20131003pdfm5znNo ratings yetFaculty of Engineering Mass Transfer Cairo M5zncomnewuploads20131003pdfm5zn4 pages

- Maina Singh Vs So Rajasthan - 20191015000042-1No ratings yetMaina Singh Vs So Rajasthan - 20191015000042-13 pages

- Tata Engineers Limited: General Accessories by Vessel VendorNo ratings yetTata Engineers Limited: General Accessories by Vessel Vendor3 pages

- Cambridge First (FCE) Reading Part 1: Answer All The Questions and Check Your Answers at The EndNo ratings yetCambridge First (FCE) Reading Part 1: Answer All The Questions and Check Your Answers at The End45 pages

- Contractor Daily Activity Pre-Inspection 50-Items Safety ChecklistNo ratings yetContractor Daily Activity Pre-Inspection 50-Items Safety Checklist1 page

- An Insight Into Gothic Arch Tracing: July 2019No ratings yetAn Insight Into Gothic Arch Tracing: July 20197 pages

- Safety Data Sheet: (SDS) No. Bm-Msds 011ANo ratings yetSafety Data Sheet: (SDS) No. Bm-Msds 011A5 pages

- N5. Energy Management and Real-time Control (20245S1)No ratings yetN5. Energy Management and Real-time Control (20245S1)93 pages

- Date of Preparing: 9/9/2023 Date of Teaching: 15/9/2023 Period: 02No ratings yetDate of Preparing: 9/9/2023 Date of Teaching: 15/9/2023 Period: 029 pages

- Water Seepage Investigation Report (Pioneer) 6 Aug 2021No ratings yetWater Seepage Investigation Report (Pioneer) 6 Aug 202145 pages

- OceanofPDF.com the Wrong Alpha - Gertty RudrawNo ratings yetOceanofPDF.com the Wrong Alpha - Gertty Rudraw265 pages

- Download Complete VLSI Physical Design From Graph Partitioning to Timing Closure 2nd Edition Andrew B. Kahng PDF for All Chapters100% (1)Download Complete VLSI Physical Design From Graph Partitioning to Timing Closure 2nd Edition Andrew B. Kahng PDF for All Chapters65 pages

- Basic Principles of Drug Discovery and Development 2nd Edition 2021 Benjamin E. Blass All Chapters Instant DownloadBasic Principles of Drug Discovery and Development 2nd Edition 2021 Benjamin E. Blass All Chapters Instant Download

- The Thermodynamics of Phase and Reaction Equilibria 2nd Edition Ismail Tosun - Ebook PDF All Chapter Instant DownloadThe Thermodynamics of Phase and Reaction Equilibria 2nd Edition Ismail Tosun - Ebook PDF All Chapter Instant Download

- WL 320 Wet Cooling Tower Gunt 1496 PDF - 1 - en GBWL 320 Wet Cooling Tower Gunt 1496 PDF - 1 - en GB

- Heisler Chart: Heisler Charts Are A Graphical Analysis Tool For The Evaluation ofHeisler Chart: Heisler Charts Are A Graphical Analysis Tool For The Evaluation of

- Refrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusRefrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De Jesus

- Department of Chemical Technology Chulalongkorn University 2306 334 App Math Chem Eng II September 20, 2021 Classwork VDepartment of Chemical Technology Chulalongkorn University 2306 334 App Math Chem Eng II September 20, 2021 Classwork V

- CHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All QuestionsCHFEN 3553 Chemical Reaction Engineering: April 28, 2003 1:00 PM - 3:00 PM Answer All Questions

- HEAT CONDUCTION IN A STEAM PIPE Introductory Transport Phenomena-Wiley (2014) - R. Byron Bird Et AlHEAT CONDUCTION IN A STEAM PIPE Introductory Transport Phenomena-Wiley (2014) - R. Byron Bird Et Al

- Separation Processes 2019-2020 (Part 1 Exercises) StudPortSeparation Processes 2019-2020 (Part 1 Exercises) StudPort

- Performance Analysis of Separating and Throttling Calorimeter To DeterminePerformance Analysis of Separating and Throttling Calorimeter To Determine

- Week 8 Question 1: Absorption in A Packed Bed: CHE3165 Tutorial Problems Semester OneWeek 8 Question 1: Absorption in A Packed Bed: CHE3165 Tutorial Problems Semester One

- Faculty of Engineering Mass Transfer Cairo M5zncomnewuploads20131003pdfm5znFaculty of Engineering Mass Transfer Cairo M5zncomnewuploads20131003pdfm5zn

- Tata Engineers Limited: General Accessories by Vessel VendorTata Engineers Limited: General Accessories by Vessel Vendor

- Cambridge First (FCE) Reading Part 1: Answer All The Questions and Check Your Answers at The EndCambridge First (FCE) Reading Part 1: Answer All The Questions and Check Your Answers at The End

- Contractor Daily Activity Pre-Inspection 50-Items Safety ChecklistContractor Daily Activity Pre-Inspection 50-Items Safety Checklist

- N5. Energy Management and Real-time Control (20245S1)N5. Energy Management and Real-time Control (20245S1)

- Date of Preparing: 9/9/2023 Date of Teaching: 15/9/2023 Period: 02Date of Preparing: 9/9/2023 Date of Teaching: 15/9/2023 Period: 02

- Water Seepage Investigation Report (Pioneer) 6 Aug 2021Water Seepage Investigation Report (Pioneer) 6 Aug 2021

- Download Complete VLSI Physical Design From Graph Partitioning to Timing Closure 2nd Edition Andrew B. Kahng PDF for All ChaptersDownload Complete VLSI Physical Design From Graph Partitioning to Timing Closure 2nd Edition Andrew B. Kahng PDF for All Chapters