Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Uploaded by

Silvian IonescuCopyright:

Available Formats

Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Uploaded by

Silvian IonescuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Vacon NX, Non-Regenerative Front End FI9 UD01217B PDF

Uploaded by

Silvian IonescuCopyright:

Available Formats

user’s manual

non-regenerative front end unit (nfe)

2 • vacon

AT LEAST THE 11 FOLLOWING STEPS OF THE START-UP QUICK GUIDE MUST BE PERFORMED DUR-

ING THE INSTALLATION AND COMMISSIONING.

IF ANY PROBLEMS OCCUR, PLEASE CONTACT YOUR LOCAL DISTRIBUTOR.

Start-up Quick Guide

1. Check that the delivery corresponds to your order, see Chapter 3

2. Before taking any commissioning actions, read carefully the safety instructions

in Chapter 1.2

3. Before the mechanical installation, check the minimum clearances around the

unit and check the ambient conditions in Chapter 5

4. Check the size of the supply cable/bus bar, DC output cable/bus bar, and mains

fuses, DC fuses and check the cable connections.

5. Follow the installation instructions, see Chapter 5.

6. The sizes and earthing of control connections are explained in Chapter 5.

7. All parameters have factory default values. No any changes need to make for

proper operation.

8. The Vacon NX Non-Regenerative Front End is now ready for use.

Vacon Plc is not responsible for the use of the Non-Regenerative Front End against

the instructions.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 3

CONTENTS

VACON NXN USER’S MANUAL

INDEX

1 SAFETY

2 EU DIRECTIVE

3 RECEIPT OF DELIVERY

4 Non-REGENERATIVE FRONT END UNIT (NFE)

5 INSTALLATION

6 CONTROL KEYPAD

7 APPENDICES

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

4 • vacon

ABOUT THE VACON NXN USER'S MANUAL

Congratulations for choosing Vacon NX Non-Regenerative Front End!

The User's Manual will provide you with the necessary information about the installation, commissioning

and operation of Vacon NX Non-Regenerative Front End. We recommend that you carefully study these in-

structions before powering up the Non-Regenerative Front End for the first time.

In the Non-Regenerative Front End Application Manual you will find information about the Non-

regenerative Front End application. Should that application not meet the requirements of your process,

please contact the manufacturer for information on special application.

This manual is available in both paper and electronic editions. We recommend you to use the electronic

version if possible. If you have the electronic version at your disposal, you will be able to benefit from the

following features:

The manual contains several links and cross-references to other locations in the manual, which makes it

easier to move around in the manual. The reader can thus easily find and check things.

The manual also contains hyperlinks to web pages. To visit these web pages through the links, you must

have an internet browser installed on your computer.

This manual is applicable only for Non-Regenerative Front End unit, AC choke and optional components

that are introduced in this manual.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 5

Vacon NXN User’s Manual

Contents

Document code: UD01217B

Date edited: 30.10.2008

1. Safety ............................................................................................................................ 7

1.1 Warnings ........................................................................................................................................ 7

1.2 Safety Instructions ........................................................................................................................ 7

1.3 Earthing.......................................................................................................................................... 7

1.4 Warning symbols ........................................................................................................................... 7

2. EU DIRECTIVE ................................................................................................................ 8

2.1 CE marking .................................................................................................................................... 8

2.2 EMC directive ................................................................................................................................. 8

2.2.1 Introduction ..........................................................................................................................8

2.2.2 Technical criteria..................................................................................................................8

2.2.3 Vacon Non-Regenerative Front End EMC classification ...................................................8

2.2.4 Manufacturer’s declaration of conformity ..........................................................................9

3. RECEIPT OF DELIVERY ................................................................................................. 10

3.1 Type designation code for the NFE unit ..................................................................................... 10

3.2 Type designation code for the AC choke .................................................................................... 11

3.3 Storage ......................................................................................................................................... 12

3.4 Maintenance ................................................................................................................................ 12

3.5 Lifting the modules ..................................................................................................................... 13

3.6 Lifting the AC choke .................................................................................................................... 14

3.7 Warranty ...................................................................................................................................... 14

4. NON-REGENERATIVE FRONT END (NFE) ...................................................................... 15

4.1 Introduction ................................................................................................................................. 15

4.2 Non-Regenerative Front End frame sizes ................................................................................. 17

4.3 Non-Regenerative Front End unit technical data ..................................................................... 18

4.4 Application ................................................................................................................................... 18

4.5 Diagrams...................................................................................................................................... 19

4.5.1 Connection between control unit and power unit ............................................................19

4.6 Non-Regenerative Front End power ratings ............................................................................. 19

4.6.1 Vacon NXN; DC voltage 460–800V .....................................................................................19

4.6.2 Vacon NXN; DC voltage 640–1100V ...................................................................................20

4.7 Non-Regenerative Front End unit – Dimensions ...................................................................... 20

4.8 AC choke – Dimensions .............................................................................................................. 20

4.9 Non-Regenerative Front End – Fuse selection ......................................................................... 20

4.9.1 Introduction ........................................................................................................................20

4.9.2 Fuses; mains voltage 380–690V ........................................................................................21

4.9.2.1 AC fuses........................................................................................................................21

4.9.2.2 DC fuses .......................................................................................................................21

4.10 Non-Regenerative Front End unit – Circuit breaker selection ................................................ 21

4.11 Non-Regenerative Front End unit – Main contactor ................................................................. 22

4.12 Pre-Charging ............................................................................................................................... 22

4.13 Paralleling ................................................................................................................................... 22

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

6 • vacon

4.14 12-pulse solution......................................................................................................................... 22

4.15 Derating ....................................................................................................................................... 23

4.15.1 As the Ambient Temperature ............................................................................................23

4.15.2 As the Installation altitude.................................................................................................23

5. Installation .................................................................................................................. 25

5.1 Mounting ...................................................................................................................................... 25

5.1.1 Non-Regenerative Front End Unit.....................................................................................25

5.1.2 AC choke .............................................................................................................................26

5.1.3 Control Box .........................................................................................................................27

5.2 Cooling ......................................................................................................................................... 27

5.2.1 Non-Regenerative Front End unit ....................................................................................27

5.2.2 AC choke .............................................................................................................................29

5.2.3 Arranging ventilation of the enclosure .............................................................................30

5.2.4 Steering air flow .................................................................................................................31

5.3 Power connection ........................................................................................................................ 33

5.3.1 AC connection .....................................................................................................................33

5.3.2 DC connection.....................................................................................................................34

5.4 I/O terminals and I/O signals...................................................................................................... 34

6. Control keypad ............................................................................................................. 37

6.1 Navigation .................................................................................................................................... 38

6.1.1 Monitoring menu ................................................................................................................38

6.1.2 Parameter menu ................................................................................................................39

6.1.3 Fault history menu .............................................................................................................41

7. Appendices .................................................................................................................. 43

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 7

1. SAFETY

ONLY A COMPETENT ELECTRICIAN MAY CARRY OUT

THE ELECTRICAL INSTALLATION

1.1 Warnings

1 The components of the power unit circuit are live when the Non-

Regenerative Front End is connected to AC supply. Coming into contact

with this voltage is extremely dangerous and may cause death or severe

injury. The control unit is isolated from mains potential.

2 The control I/O-terminals are isolated from the mains potential. Howev-

er, the relay outputs and other I/O-terminals may have dangerous control

voltage present even when the Non-Regenerative Front End is discon-

! nected from the AC supply.

WARNING 3 Do not touch the components on the circuit boards. Static voltage dis-

charge may damage the components.

1.2 Safety Instructions

1 The Non-Regenerative Front End, AC choke and optional components are

meant for fixed installations only.

2 Do not perform any measurements when the Non-Regenerative Front

End is connected to the AC supply.

3 After having disconnected the Non-Regenerative Front End from the AC

supply, wait until the fan stops. Wait 5 more minutes before doing any

work on the Non-Regenerative Front End connections. Do not even open

the cover before this time has expired.

4 Do not perform any voltage withstand tests on any part of the Non-

Regenerative Front End. There is a certain procedure according to which

the tests shall be performed. Ignoring this procedure may result in dam-

aged product.

5 Before connecting the Non-Regenerative Front End to AC supply, make

sure that the Non-Regenerative Front End front and cable covers are

closed.

6 Before doing any work on Common DC bus, system shall be earthen.

1.3 Earthing

The Non-Regenerative Front End unit and AC choke must always be earthed with an earthing conductor

connected to the earthing terminal.

1.4 Warning symbols

For your own safety, please pay special attention to the instructions marked with the following symbols:

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

8 • vacon

= Dangerous voltage

= General warning

WARNING

= Hot surface – Risk of burn

HOT SURFACE

2. EU DIRECTIVE

2.1 CE marking

The CE marking on the product guarantees the free movement of the product within the EEA (European

Economic Area). It also guarantees that the product complies with applicable directives (for example, the

EMC directive and other possible so-called new method directives). Vacon NX Non-Regenerative Front End

carries the CE label as a proof of compliance with the Low Voltage Directive (LVD) and the Electro Magnetic

Compatibility (EMC) directive. SGS FIMKO has acted as the Notified Body.

2.2 EMC directive

2.2.1 Introduction

The EMC Directive provides that the electrical apparatus must not excessively disturb the environment it is

used in, and, on the other hand, it shall have an adequate level of immunity toward other disturbances from

the same environment.

The compliance of Vacon NX Non-Regenerative Front End with the EMC directive is verified with Technical

Construction Files (TCF) and checked and approved by SGS FIMKO, which is a Notified Body. The Technical

Construction Files are used to authenticate the conformity of Vacon NX Non-Regenerative Front End with

the Directive because it is impossible to test such a large product family in a laboratory environment and

because the combinations of installation vary greatly.

2.2.2 Technical criteria

Our basic idea was to develop a range of Vacon NX Non-Regenerative Front End offering the best possible

usability and cost efficiency. EMC compliance was a major consideration from the outset of the design.

2.2.3 Vacon Non-Regenerative Front End EMC classification

Factory delivered Vacon NX Non-Regenerative Front End are Class T equipment, which fulfills all EMC im-

munity requirements (standard EN 61800-3).

Class T:

Class T equipment have a small earth leaking current and can be used with floating DC input.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 9

Warning: This product is of the restricted sales distribution class according to IEC 61800-3. In resi-

dential areas, this product may cause radio interference in which case the user may be required to

take adequate measures.

2.2.4 Manufacturer’s declaration of conformity

The following page presents the photocopy of the Manufacturer's Declaration of Conformity assuring the

compliance of Vacon NX Non-Regenerative Front End with the EMC-directives.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

10 • vacon

3. RECEIPT OF DELIVERY

Vacon NX Non-Regenerative Front End has undergone scrupulous tests and quality checks at the factory

before they are delivered to the customer. However, after unpacking the product, check that no signs of

transportation damage are to be found on the product and that the delivery is complete (compare the type

designation of the product to the codes below, see Figure 3-1 and Figure 3-2).

Should the product have been damaged during the shipping, please contact primarily the cargo insurance

company or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

3.1 Type designation code for the NFE unit

In Vacon type designation code for Common DC Bus components, the Non-Regenerative Front End Unit is

characterized by letter N and letter N or S. If the Non-Regenerative Front End unit is ordered by letter N

delivery is not include anything else than the unit itself. If letter S is used delivery include the unit, the AC

choke.

NOTE! Delivery NOT includes in any case auxiliary devices which are needed for proper operation (the AC

or DC fuses, the fuses bases, the main contactor or circuit breaker etc.) These shall be take care by the

customer.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 11

Figure 3-1. Type designation code for the Non-Regenerative Front End.

3.2 Type designation code for the AC choke

AC choke has one version which is suitable for 380-500V and 525-690V voltages.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

12 • vacon

Figure 3-2. Type designation code for the AC choke.

3.3 Storage

If Vacon NX Non-Regenerative Front End is to be stored before use, make sure that the ambient conditions

are acceptable:

Storage temperature –40…+70°C

Relative humidity <95%, no condensation

3.4 Maintenance

All technical devices, drives as well, need a certain amount of care-taking and failure preventive mainten-

ance. To maintain trouble-free operation of the Vacon NX Non-Regenerative Front End, environmental

conditions, as well as load, line power, process control, etc. have to be within specifications, determined by

manufacturer.

If all conditions are in accordance with the manufacturer's specifications, there are no other concerns, but

to provide a cooling capacity high enough for the power- and control circuits. This requirement can be met

by making sure, that the cooling system works properly. Operation of cooling fans and cleanness of the

heat sink should be verified regularly.

Regular maintenance is recommended to ensure trouble free operation and long lifetime of Vacon NX Non-

Regenerative Front End. At least the following things should be included in the regular maintenance.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 13

Table 3-3. Maintenance interval

It may also be necessary to check the tightening torques of terminals at certain intervals.

It is also recommended to record all actions and counter values with dates and time for follow up of main-

tenance. It may also be necessary to check the tightening torques of terminals at certain intervals.

3.5 Lifting the modules

The modules can be lifted by the holes on top. Place the lifting hooks symmetrically in at least four holes.

The maximum allowed lifting angle is 45 degrees. For frames FI9, see Figure 3-4.

The lifting equipment must be able to carry the weight of the module.

Figure 3-4. Lifting points for FI9 module.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

14 • vacon

3.6 Lifting the AC choke

The AC choke can be lifted by the holes on top. Place the lifting hooks symmetrically in two holes. The

maximum allowed lifting angle is 45 degrees. Lifting points for the AC choke, see Figure 3-5.

Figure 3-5. Lifting points for AC choke.

3.7 Warranty

Only manufacturing defects are covered by the warranty. The manufacturer assumes no responsibility for

damages caused during or resulting from transport, receipt of the delivery, installation, commissioning or

use.

The manufacturer shall in no event and under no circumstances be held responsible for damages and fail-

ures resulting from misuse, wrong installation, unacceptable ambient temperature, dust, corrosive sub-

stances or operation outside the rated specifications.

Neither can the manufacturer be held responsible for consequential damages.

The Manufacturer's warranty period is 18 months from the delivery or 12 months from the commissioning

whichever expires first (General delivery terms NL92/Orgalime S92).

The local distributor may grant a warranty time different from the above. This warranty time shall be spe-

cified in the distributor's sales and warranty terms. Vacon assumes no responsibility for any other warran-

ties than that granted by Vacon itself.

In all matters concerning the warranty, please contact your distributor first.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 15

4. NON-REGENERATIVE FRONT END (NFE)

4.1 Introduction

The Vacon NX Non-Regenerative Front End is used to transfer power between the AC input and intermedi-

ate DC circuit. The Vacon NX Non-Regenerative Front End has only a one-way function. This means that

when power can only transferred from the AC input to the intermediate DC circuit. If braking is needed

brake chopper has to be connected to the intermediate DC circuit.

In a typical Vacon NX Non-Regenerative Front End configuration, the desired number of Inverters, Figure

4-1, are connected to the intermediate DC circuit.

The Non-Regenerative Front End configuration consists of the unit itself, AC choke, AC fuses, main contac-

tor and DC fuses, Figure 4-2.

NFE* FFE* AFE*

3 3

2 2 2

* alternative

Common DC bus 2 2 2 2

3 3 3 2

INU INU INU BCU

Figure 4-1. Typical Non-Regenerative Front End configuration.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

16 • vacon

Figure 4-2. Vacon Non-Regenerative Front End Single Unit connections

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 17

4.2 Non-Regenerative Front End frame sizes

Figure 4-3. Vacon NXN, FI9. Protection class IP00

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

18 • vacon

4.3 Non-Regenerative Front End unit technical data

Mains connec- Input voltage Uin 380 - 690 Vac; -15%...+10%, EN 60204-1

tion Input frequency 45…66 Hz

Continuous input current IH: Ambient temperature max. +40°C,

overload 1.5 x IH (1 min./10 min.)

IL: Ambient temperature max. +40°C,

overload 1.1 x IL (1 min./10 min.)

Connection to mains Unlimited (internal overload protections)

Current THD Depend on additional chokes ( normal case < 40%)

Starting delay Depend on dc bus capacitance (max 10 s)

Unexpected input power Shorter breaks than 40ms works normally if DC does not

break drop remarkably. Longer break means normal starting

operation (charging current varies according to load).

DC Output voltage Uout 465...800Vdc ( 380-500 Vac);

connection 640...1100Vdc ( 525-690 Vac);

Efficiency >98%

DC bank capasitance 6,8µF (included 10 M discharging resistor)

Control charac- Control method NFE is an independent power unit. Charging and pro-

teristics tections controlled by NFE itself.

Ambient condi- Ambient operating tem- –10°C (no frost)…+40°C: IH

tions perature –10°C (no frost)…+40°C: IL

Storage temperature –40°C…+70°C

Relative humidity 0 to 95% RH, non-condensing, non-corrosive,

no dripping water

Air quality:

- chemical vapours IEC 721-3-3, unit in operation, class 3C2

- mechanical particles IEC 721-3-3, unit in operation, class 3S2

Altitude 100% load capacity (no derating) up to 1,000 m

1-% derating for each 100m above 1000.; max. 2000m

Vibration 5…150 Hz

EN50178/EN60068-2-6 Displacement amplitude 0,25 mm (peak) at 5…31 Hz

Max acceleration 1 G at 31…150 Hz

Shock UPS Drop Test (for applicable UPS weights)

EN50178, EN60068-2-27 Storage and shipping: max 15 G, 11 ms (in package)

Cooling air required 1150 m3/h

Enclosure class IP00

EMC Immunity Fulfil all EMC immunity requirements. Can be chosen N-

(at default set- , L- or T-level.

tings)

Safety CE, UL, CUL

EN 61800-5-1 (2003); (see unit nameplate for more de-

tailed approvals)

Control con- Display 7-segment (optional)

nections Trip information Relay I/O (optional)

Protections Unit over temperature Trips if temperature rising over trip level (default)

protection

Current measurement Trips if current over trip level (default)

Supply phase supervision Trips if any of the output phases is missing (default)

Table 4-1. Technical specification for Vacon NX Non-Regenerative Front End unit

4.4 Application

The Vacon NX Non-Regenerative Front End needs special application. The unit is delivered with that appli-

cation. If application code is needed please contact please contact the manufacturer. More information

about application can be found from this manual.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 19

4.5 Diagrams

4.5.1 Connection between control unit and power unit

The communication connections between the Non-Regenerative Front End power unit and the control unit

is established using serial cable, Figure 4-4. The control unit is located under the front cover of the power

unit. The control unit cannot place outside of the power unit.

Figure 4-4. NFE power and control connections.

4.6 Non-Regenerative Front End power ratings

4.6.1 Vacon NXN; DC voltage 460–800V

Unit Low oveload High oveload DC Power

(AC current) (AC current) (continuous)

Type Code Frame

IL-cont [A] I1min [A] IH-cont [A] I1min [A] 400V mains 500 V mains

P [kW] P [kW]

NFE NXN_0650 6 FI9 650 715 507 793 390 488

Table 4-2. Power ratings of Vacon NXN, supply voltage 460–800Vdc

For dimensions of NXN units, see Table 4-4 and AC choke Table 4-5.

Note: The rated currents in given ambient (+40°C).

Note: The motor output power: Pout=Pdc x ( INU x Motor ).

Pdc =NFEs DC power

INU=efficiency of the inverter

Motor=efficiency of the motor

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

20 • vacon

4.6.2 Vacon NXN; DC voltage 640–1100V

Unit Low oveload High oveload DC Power

(AC current) (AC current) (continuous)

Type Code Frame

IL-cont [A] I1min [A] IH-cont [A] I1min [A] 690V mains

P [kW]

NFE NXN_0650 6 FI9 650 715 507 793 673

Table 4-3. Power ratings of Vacon NXN, supply voltage 640–1100Vdc

For dimensions of NXN unit, see Table 4-4 and AC choke Table 4-5.

Note: The rated currents in given ambient (+40°C).

Note: The motor output power: Pout=Pdc x ( INU x Motor ).

Pdc =NFEs DC power

INU=efficiency of the inverter

Motor=efficiency of the motor

4.7 Non-Regenerative Front End unit – Dimensions

Module Module Dimension

Type Frame Height Width Depth Weight

[mm] [mm] [mm] [kg]

NFE FI9 1030 239 372 67

Table 4-4. The NXN unit dimensions

Note: More detailed dimensions can be found Appendix 7-4.

4.8 AC choke – Dimensions

Module Module Dimension

Type Frame Height Width Depth Weight

[mm] [mm] [mm] [kg]

AC choke CHK-650 449 497 249 130

Table 4-5. AC choke dimensions

Note: More detailed dimensions can be found Appendix 7-5.

4.9 Non-Regenerative Front End – Fuse selection

4.9.1 Introduction

AC fuses are used to protect the input network in case the Non-Regenerative Front End unit or the AC

choke is faulty. DC fuses are used to protect the Non-Regenerative Front End unit and the AC choke in case

there is a short circuit in the DC buses. If DC fuses are not used, short-circuit in the DC buses will cause a

loading of the Non-Regenerative Front End unit. Vacon Plc will not assume any responsibility for damages

caused by insufficient protection.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 21

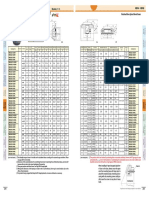

4.9.2 Fuses; mains voltage 380–690V

4.9.2.1 AC fuses

Module AC fuses

Type Code Frame UN

Ferraz Shawmut [V] IN [A] Size Q'ty

type [aR]*

NFE NXN_0650 6 FI9 NH3UD69V1000PV 690 1000 3 3

Table 4-6. Ferraz Shawmut AC fuse selection, mains voltage 380–690Vac

Module AC fuses

Type Code Frame UN

Bussman [V] IN [A] Size Q'ty

type [aR]*

NFE NXN_0650 6 FI9 170M6466 690 1250 3BKN/50 3

Table 4-7. Bussman AC fuse selection, mains voltage 380–690Vac

Note: All fuses are blade type. If some other type is needed please contact Vacon.

4.9.2.2 DC fuses

Module DC fuses

Type Code Frame UN

Ferraz Shawmut [V] IN [A] Size Q'ty

type [aR]*

NFE NXN_0650 6 FI9 PC73UD11C13CTF 1100 1250 73(LR) 2

Table 4-8. Ferraz Shawmut DC fuse selection, mains voltage 465–1100Vdc

Module DC fuses

Type Code Frame UN

Bussman [V] IN [A] Size Q'ty

type [aR]*

NFE NXN_0650 6 FI9 170M8610 1000 1000 3BKN/75 2

Table 4-9. Bussman DC fuse selection, mains voltage 465–1100Vdc

Note: All fuses are flush-end type. If some other type is needed please contact Vacon.

4.10 Non-Regenerative Front End unit – Circuit breaker selection

The Non-Regenerative Front End can also be protected by a circuit-breaker. The recommended type of cir-

cuit-breaker is shown in Table 4-10. If a circuit-breaker from another manufacturer is used, it must be

equivalent to the circuit-breaker shown. Further information on the circuit-breaker shown is available

from the manufacturer. Circuit-breaker does not provide the same level of protection as fuses. A circuit-

breaker can be used without a main contactor. The circuit-breakers shown are suitable for equipment

rated at 380–690 V.

Table 4-10. Circuit breaker for Vacon NXN

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

22 • vacon

4.11 Non-Regenerative Front End unit – Main contactor

If a main contactor is to be used, the type shown in Table 4-11 are recommended. If a contactor from an-

other manufacturer is used, it must be equivalent to the types shown. Further information on the contactor

shown is available from the manufacturer.

Table 4-11. Recommended main contactor type.

4.12 Pre-Charging

External pre-charging circuit is not needed with the Non-Regenerative Front End. Pre-charging is done by

controlling thyristors and the DC link voltage is charged smoothly. Pre-charging is current limit controlled.

Due to this, the charging time varies depending on DC link capacitance. The Non-Regenerative Front End

performs charging without any additional control when the main contactor is closed. If Non-regenerative

Front Ends are parallelly connected, each module charges DC link voltage independently. Parallelly con-

nected modules can be connected to the supply simultaneously or one module at a time. See Appendix 7-2

for the circuit diagram of parallelly connected NFE modules.

The Non-Regenerative Front End monitors the pre-charging process. If the time of charging is over the ad-

justable pre-charging monitoring time (default 10s) a fault is indicated. If the DC link capacitance is so high

that the default value for charging monitoring is not enough, the value can be increased.

4.13 Paralleling

The power of the input group can be increased by connecting several Non-Regenerative Front End units in

parallel. No communication between the units is required; they work independently.

Each Non-Regenerative Front End unit connected in parallel must have its own short-circuit protection on

AC and DC sides. The fuses are selected in accordance with Section 4.9. When paralleling, attention must

be paid to the sufficient short-circuit capacity of the system.

The derating of Non-Regenerative Front End units connected in parallel is 5% of the DC power; this should

be taken into account when selecting the input unit.

If a device is to be isolated from the AC and DC voltages, and other Non-Regenerative Front End units con-

nected in parallel are also to be used, separate isolators are required in the AC input and DC output. The

AC input can be isolated using a compact circuit-breaker, an ordinary circuit-breaker or a fuse switch.

Contactors are not suitable for isolating the AC input because they cannot be locked in the safe position.

The DC output can be isolated using a fuse switch. A load isolation switch or safety isolation switch can be

used for this. The device can also be connected to mains even when the other devices connected in parallel

are already connected and running. After this, the device can be connected to the intermediate circuit.

Note: Parallel connection means that the AC supply of more than one units connected together from DC link is cou-

pled with the same supply transformer.

4.14 12-pulse solution

In 12-pulse solution the supply transformer has two galvanically separated secondary circuits, see Appen-

dix 7-3. The 12-pulse solution can reduce the effect of harmonic waves of the current in the supply net-

work. In order to reduce the effect of harmonics, there must be a phase displacement of 90º between the

secondary circuits of the transformer. The phase displacement is implemented by connecting one second-

ary circuit to triangle and the other to star. In 12-pulse solution there must be an equal number of non-

regenerative units connected to the both secondary coils of the supply transformer.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 23

4.15 Derating

The output power has to be derated if one of following cases:

Ambient temperature is more than 40ºC

Installation altitude is more than 2000 m

4.15.1 As the Ambient Temperature

The power rating of the Non-Regenerative Front End unit is valid for an ambient temperature of 40ºC. If the

device is to be used in higher ambient temperatures, its power rating must be subjected to derating. The

derating coefficient is 1.5%/1ºC, for ambient temperatures not exceeding 50ºC. The reduced power is cal-

culated using the formula:

Pde Pn * ((100% (t 40º C) * x)/100)

Pn = nominal power of the unit

t = ambient temperature

x = derating coefficient

Derating as a function of ambient temperature

110

100

90

Loadability, %

80 Loadability %

70

60

50

0 10 20 30 40 50 60

Ambient te mperature, ºC

Figure 4-5. Derating as the ambient temperature.

4.15.2 As the Installation altitude

The power rating of the Non-Regenerative Front End unit is valid for a maximum installation altitude of

3,000 m (380-690 V). If the device is to be used in higher installation altitudes temperatures, its power rat-

ing must be subjected to derating. The derating coefficient is 1.5%/100m. The power rating of the device

can be reduced to a maximum installation altitude of 3,000 m. The reduced power is calculated using the

formula:

Pde Pn * ((100% (hinst hbase ) * x)/100)

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

24 • vacon

Pn = nominal power of the unit

hinst = intended installation altitude

hbase = 1,000 m

x = derating coefficient

Derating as a function of installation altitude

120

100

80

Loadability, %

60 Loadability %

40

20

0

0 500 1000 1500 2000 2500 3000 3500

Installation altitude, m

Figure 4-6. Derating as the installation altitude 380-500V.

Derating as a function of installation altitude

102

100

98

96

Loadability, %

94

Loadability %

92

90

88

86

84

0 500 1000 1500 2000 2500

Installation altitude, m

Figure 4-7. Derating as the installation altitude 525-690V.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 25

Note: If higher installation altitude than 3,000 m is required please contacts your nearest Vacon office to get more

information.

5. INSTALLATION

5.1 Mounting

The equipment mounting must be sturdy enough to carry the weight of the equipment. The enclosure class

of the equipment will depend on the mounting and solutions to be used. The equipment mounting must

provide sufficient shielding for contact of the live parts (IP2x). The installation and mounting must comply

with local laws and regulations.

5.1.1 Non-Regenerative Front End Unit

The Non-Regenerative Front End can be mounted in a vertical position on the back plane of a cubicle.

Enough space must be reserved around the Non-Regenerative Front End to ensure sufficient cooling, see

Figure 5-5. Follow the minimum dimensions for installation, see Table 5-1. Required cooling air capacity

and minimum air holes on the switchgear, see Table 5-2. Also make sure that the mounting plane is rela-

tively even. The Non-Regenerative Front End is fixed with four bolts, Figure 5-1.

Figure 5-1. Mounting points of FI9 NFE unit.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

26 • vacon

5.1.2 AC choke

The AC choke can only be mounted in a vertical position on the floor of a cubicle. Enough space must be

reserved around the AC choke to ensure sufficient cooling, see Figure 5-7. Follow the minimum dimen-

sions for installation, see Table 5-3. Required cooling air capacity and minimum air holes on the switch-

gear, see Table 5-4. Also make sure that the floor is relatively even. AC choke must be attached properly

so that it will not be able to move.

AC choke can be mounted so that the connectors face forward or so that they face to the side. Figure 5-2

presents a mounting where the connectors face forward. Figure 5-3 presents a mounting where the con-

nectors face to the side. This mounting is recommended if the Non-Regenerative Front End units are par-

allelly connected. In this case it must be assured that the connectors face to the same direction and that

there is enough space between the connectors and the AC choke.

Figure 5-2. Mounting of AC choke.

Figure 5-3. Mounting of parallel connected AC chokes.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 27

5.1.3 Control Box

The Control unit of the Non-Regenerative Front End unit is mounted under the front cover of module, see

Figure 5-4. Vacon an alphanumeric display and the navigation wheel can be used to control the Non-

Regenerative Front End unit.

Figure 5-4. Mounting of the control unit.

5.2 Cooling

5.2.1 Non-Regenerative Front End unit

Enough free space must be left around the Non-Regenerative Front End unit to ensure sufficient air circu-

lation and cooling. You will find the required dimensions for free space in the table below. You will find the

required cooling air, minimum air holes and heat dissipation in the Table 5-2.

When planning the cooling for the space, take into consideration that the Non-Regenerative Front End unit

heat loss is approx. 1% of the nominal capacity. Air flow, see Figure 5-6.

Table 5-1. Mounting space dimensions.

A = free space above the unit

B = distance between inverter and cabinet wall

C = free space underneath of the units

D = distance between two units

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

28 • vacon

Figure 5-5. Installation space for FI9.

Figure 5-6. Cooling airflow for FI9 NFE unit.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 29

Type Heat Cooling air re- Minimum air holes on

dissipation quired switchgear (mm2)

(W) (m3/h)

NXN_0650 6 2450 1150 65000

Table 5-2. Required cooling air for the Non-Regenerative Front End unit.

5.2.2 AC choke

Enough free space must be left around the AC choke to ensure sufficient air circulation and cooling. You

will find the required dimensions for free space in the table below. You will find the required cooling air,

minimum air holes and heat dissipation in the Table 5-4.

When planning the cooling for the space, take into consideration that the AC choke heat loss is approx.

0,5% of the nominal capacity.

Table 5-3. Mounting space dimensions.

A = free space above the AC choke

B = distance between AC choke and cabinet wall

C = free space under the AC choke

D = distance between AC choke and cabinet wall

E = distance between AC choke and cabinet wall

Figure 5-7. Installation space.

Type Heat Minimum air holes on

dissipation switchgear (mm2)

(W)

CHK-0650-6 890 30000

Table 5-4. Required cooling air for the AC choke.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

30 • vacon

5.2.3 Arranging ventilation of the enclosure

The enclosure door must be provided with air gaps for air intake. To achieve sufficient cooling inside the

cabinet, the dimensions for the total area of free openings for incoming air given in Table 5-2 and Table 5-4

must be followed. For instance, there could be two screened gaps as presented in Figure 5-8 (Vacon's rec-

ommendation). This layout ensures a sufficient air flow to the module fans as well as cooling of the addi-

tional components.

Air outlet gaps must be situated on top of the cabinet. The minimum effective air outlet area per unit frame

is given in Table 5-2 and Table 5-4. The cooling arrangements inside the cabinet must be such that they

prevent hot output air from mixing with the incoming fresh air (see Chapter Steering air flow).

The ventilation gaps must fulfill the requirements set by the selected IP class. The examples in this ma-

nual apply to protection class IP21.

During operation, air is sucked in and circulated by a fan blower at the bottom of the power unit. If the

power unit is placed in the upper part of the cabinet, the fan blower will be in the mid of the cabinet, at the

height of the upper ventilation grid. In case of the AC choke is installed below the Non-Regenerative Front

End unit air inlet 1.1 in Figure 5-8 cannot be used.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 31

1.1

1.2

Figure 5-8. Cabinet openings for cooling.

1. Cooling air inlets

2. Hot air exhaust

5.2.4 Steering air flow

Cooling air must be taken in through the ventilation gaps on the door and blown out at the top of the enclo-

sure. To steer the hot air from the power unit to the outlet at the top of the enclosure and prevent it from

circulating back to the fan blower, use either of the following arrangements:

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

32 • vacon

A. Install a closed air duct from the power unit to the outlet on top of the enclosure (A in figures

below).

B. Install shields in the gaps between the power unit and the cabinet walls (B in figures below).

Place the shields above the air outlet gaps at the sides of the module.

Figure 5-9. Cabinet cooling airflow guides.

The sheet metal airflow guides (deflectors) prevents air circulation between different sections of the equipment.

The shield guides in prevent air circulation inside a section. The exhaust air holes must not be covered, nor

must anything be placed above them to stop the free exit of warm air from inside the equipment. The cooling air

intake holes must not be blocked in any way.

The materials used for preventing the circulation of air inside the equipment must be fire-restraining. The

edges must be sealed to prevent the formation of gaps. When the deflectors are made according to the instruc-

tions, no separate cooling fan is required.

NOTE! The deflectors must be installed above the air intake holes on the top (in the front) of the unit.

NOTE! If a flat roof is used, mount a V-shaped air guide on the underside of the roof to direct the air flow

horizontally. See Figure 5-10.

Figure 5-10. Roof structure seen from the side

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 33

5.3 Power connection

5.3.1 AC connection

The 3-phase input is connected to the input terminals of the AC choke (L1, L2 and L3), see Figure 5-12.

Used input terminal are selected by supply voltage. The output terminals of the AC choke (L1, L2 and L3)

are connected to the input terminals of the NFE unit (L1, L2 and L3), see Figure 5-11. The AC input of the

NFE input group must be protected against short circuit. The fuses suitable for protection are shown in

Section 4.9. A circuit breaker can also be used for protection, see Section 4.10. The best short-circuit pro-

tection is achieved by using fuses. The short-circuit protection must be on the input side when seen from

the AC choke, Figure 4-2.

A cable or busbar designed for the purpose must be used to make the connection. The connection must be

dimensioned according to the nominal current rating of the Non-Regenerative Front End. The necessary

overloading allowance must also be used. The connection must also have the same short-circuit capacity

as the whole system. The connecting cable or busbar may be of copper or aluminium. When aluminium is

used, steps must be taken to prevent corrosion. The dimensions of the terminals in the unit are indicated

in Appendix 7-6.

Figure 5-11. FI9 unit AC connection.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

34 • vacon

Terminals for

supply cables

Cables/ Cables/busbars to

busbars to NFE unit

NFE unit

L1 L2 L3

Voltage / Frequency

500V/50Hz

525V/50Hz

575V/60Hz

690V/50Hz

Voltage / Frequency

400V/50Hz

480V/60Hz

Figure 5-12. AC choke connections.

5.3.2 DC connection

The DC connection of the Non-Regenerative Front End unit is connected to the terminals at the top, see

Figure 5-13. The terminals are marked as B+ for connection to DC+ and B- for connection to DC-. The DC

connection must be protected using DC fuses, see Section 4.9. The terminal dimensions are shown in Ap-

pendix 7-6.

Figure 5-13. FI9 unit DC connection.

5.4 I/O terminals and I/O signals

I/O terminals can be found under the cover of Control box, see Error! Reference source not found. and

Error! Reference source not found.. Descriptions of I/O signals see Error! Reference source not found..

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 35

Figure 5-14. Open the cover.

Control cable

tightening

torque: 0.4 Nm

Strip the plastic

cable coating for

360°earthing

Figure 5-15. Cabling.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

36 • vacon

Figure 5-16. I/O signals.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 37

6. CONTROL KEYPAD

The control keypad is the link between Vacon NX Non-Regenerative Front End and the user. The control

keypad features an alphanumeric display and indicators for the status (READY, RUN, STOP, ALARM,

FAULT) and four indicators for the active menu (REF, MON, PAR, FLT). There are also three Status Indica-

tor LED’s (green – green – red).

The control information, i.e. the menu number, description of the menu or the displayed value and the nu-

meric information are presented on three text lines.

The navigation wheel is used for navigating on the panel display. The wheel has two separate functions;

- rotating the wheel e.g. for changing parameter value (12 steps / round)

- pressing the wheel e.g. for accepting the new value.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

38 • vacon

6.1 Navigation

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

REFERENCE

MENU REF REF

Displays the MON MON

keypad reference

value PAR PAR

regardless of PUSH

the selected FLT Hz FLT Hz

control place. FWD REV I/O KEYPAD BUS

FWD REV I/O KEYPAD BUS

ROTATE

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

MONITORING REF REF

MENU MON

In this menu MON

you can PAR PAR

browse the

monitoring FLT PUSH FLT

values.

FWD REV I/O KEYPAD BUS FWD REV I/O KEYPAD BUS

ROTATE

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

PARAMETER REF

MENU REF

In this menu MON MON

you can

browse and PAR PAR

edit the

parameters. FLT PUSH FLT

FWD REV I/O KEYPAD BUS FWD REV I/O KEYPAD BUS

ROTATE

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

FAULT MENU REF REF

Here you will MON MON

be able

to browse PAR PAR

through the

faults occurred. FLT PUSH FLT

FWD REV I/O KEYPAD BUS FWD REV I/O KEYPAD BUS

Figure 6-1. Navigation

6.1.1 Monitoring menu

Monitoring values mean actual values of measured signals as well as statuses of some control settings.

Monitoring values are listed in Table 6-1.

Pushing the navigation wheel once in this menu takes the user to the next level, where the monitoring

value, e.g. M1.1 and value is visible (see Figure 6-2). The monitoring values can be browsed by rolling the

navigation wheel clockwise.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 39

Alternates

in the display

READY RUN STOP ALARM FAULT

REF

MON

PAR

Hz

FLT

FWD REV I/O KEYPAD BUS

Browse

M1.1 - M1.20

Figure 6-2. Monitoring menu

Code Parameter Scale Unit Description

M1.1 U_DCLINK_REF 10 V

DC reference voltage

M1.2 U_DCLINK 10 V

DC voltage

M1.3 IL1 10 A

Current of phase 1

M1.4 IL2 10 A

Current of phase 2

M1.5 IL3 10 A

Current of phase 3

M1.6 UL12 10 V

Voltage between phases L1-L2

M1.7 UL23 10 V

Voltage between phases L2-L3

M1.8 UL31 10 V

Voltage between phases L3-L1

M1.9 Isum 10 A

Summary current

M1.12 Temp 1 C

Temperature

M9.6 API SW version

M9.7 NFE SW version

M9.8 Application (API) version

Table 6-1. Monitoring signals.

6.1.2 Parameter menu

In Parameter menu all settable parameters are visible. The parameters can be browsed by rolling the

navigation wheel clockwise. Pushing the navigation wheel once in this menu takes the user to the next

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

40 • vacon

level, where the parameter value, e.g. P3.1 and value is visible (see Figure 6-3). Parameters are listed be-

low.

The following figure shows the parameter menu view:

Alternates

in the display

READY RUN STOP ALARM FAULT

REF

MON

PAR

Hz

FLT

FWD REV I/O KEYPAD BUS

Browse Push to enter Change Push to

P1.1 -> edit mode value confirm

Figure 6-3. Parameter menu

Digital outputs

Code Parameter Min Max Default Unit Description

P1.1 Relay output 1 0 5 0 0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = No faults active

5 = Warning active

P1.2 Relay output 2 0 5 0 0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = No faults active

5 = Warning active

P1.3 Digital output 1 0 5 0 0 = Not used

1 = Ready

2 = Running

3 = Fault active

4 = No faults active

5 = Warning active

Analog outputs

Code Parameter Min Max Default Unit Description

P2.1 Analog output 0 2 0 0 = Not used

funtion 1 = DC voltage

2 = Sum current

P2.2 Analog output 0 1 0 0 = 0mA

minimum 1 = 4mA

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 41

NFE parameters

Code Parameter Min Max Default Unit Description

P3.1 Load time 1 20

limit 10 s

P3.2 Over voltage 440 1200

limit 1200 V

P3.3 Under voltage 333 621

limit 486 V

P3.4 Earth fault 200 300

limit 200 A

P3.5 Over current 51 1014

limit 780 A

P3.1 Load time limit

If the pre-charging is longer than the level set by this parameter then loading time fault is trig-

gered.

P3.2 Over voltage limit

If the DC link voltage is higher than the level set by this parameter then over voltage fault is trig-

gered.

P3.3 Under voltage limit

If the DC link voltage is lower than the level set by this parameter then under voltage fault is trig-

gered.

P3.4 Earth fault limit

If the sum of the supply phase currents is higher than the level set by this parameter then earth

fault is triggered. The typical value for earth fault current monitoring is 5% of drive nominal cur-

rent.

P3.5 Over current limit

If the input current is higher than the level set by this parameter then over current fault is trig-

gered.

6.1.3 Fault history menu

In Fault history menu you can browse through 9 latest faults (see Figure 6-4). If a fault is active, the rele-

vant fault number (e.g. F2) alternates in the display with main menu. When you browse between the faults,

the fault codes of active faults are blinking. The active faults can be reset by pressing the STOP button for

1 second. If the fault cannot be reset, the blinking continues. It is possible to navigate in the menu struc-

ture also when there are active faults present, but the display returns automatically to the fault menu if

buttons or navigation wheel are not pressed or navigation is not rotated. The operating hour, minute and

second values at the fault instant are shown in the value menu (operating hours = displayed reading x 1000

h). Fault codes are listed in Table 6-2.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

42 • vacon

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

REF REF

MON MON

PAR PAR

FLT FLT

FWD REV I/O KEYPAD BUS Push FWD REV I/O KEYPAD BUS

Browse

faults 1-9

READY RUN STOP ALARM FAULT READY RUN STOP ALARM FAULT

REF REF

MON MON

PAR PAR

FLT FLT

Push

FWD REV I/O KEYPAD BUS FWD REV I/O KEYPAD

Browse

for hours (H),

minutes (M)

and seconds (S)

Figure 6-4. Fault history menu

Note! The whole fault history can be cleared by pressing STOP button for 5 sec

time when the drive is stopped and Fault history menu is selected in the display.

Fault Description Default limit value

F13 Under temp <-10 / C

F14 Over temp >80 / C

F2 Over voltage 1200 Vdc

F9 Under voltage(400V * 0,9*1,35= 486V) 486 Vdc

F32 Inverter fault -

F11 Input phase loss

F3 Earth fault 200 A

F1_1 Loading time fault 10 s

F1_2 Over current fault 780A

Table 6-2. Fault codes.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 43

7. APPENDICES

Appendix 7-1. Circuit diagram for NFE.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

44 • vacon

Appendix 7-2. Circuit diagram for parallel connected NFE.

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 45

Appendix 7-3. Circuit diagram for 12- pulse solution with NFE.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

46 • vacon

Appendix 7-4. FI9 Dimensions

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

vacon • 47

Appendix 7-5. AC choke dimensions

IL

Frame Type DC terminal AC Terminal

[A]

6 x 40

40

13

13

NXN_0650 6 FI9 650

16 17

35 38

PE: M8×25

Appendix 7-6.Terminal sizes for Vacon NX Non-regenerative Front End unit.

24-hour support +358 (0)40 837 1150 • Email: vacon@vacon.com

head office and production: production: production:

Vaasa Suzhou, China Chambersburg, USA

Vacon Plc Vacon Suzhou Drives Co. Ltd. 3181 Black Gap Road

Runsorintie 7 Building 11A Chambersburg, PA 17202

65380 Vaasa 428# Xinglong Street, SIP TB Wood's (India) Pvt. Ltd.

firstname.lastname@vacon.com Suchun Industrial Square #27, 'E' Electronics City

telephone: +358 (0)201 2121 Suzhou 215126 Hosur Road

fax: +358 (0)201 212 205 telephone: + 86 512 62836630 Bangalore - 560 100

fax: + 86 512 62836618

India

Naturno, Italy Tel. +91-80-30280123

Vacon S.R.I Fax. +91-80-30280124

Via Zone Industriale, 11

39025 Naturno

sales companies and representative offices:

finland germany slovakia

Helsinki Vacon GmbH Vacon s.r.o. (Branch)

Vacon Plc Gladbecker Strasse 425 Seberiniho 1

Äyritie 8 45329 Essen 821 03 Bratislava

01510 Vantaa telephone: +49 (0)201 806 700 Tel. +421 243 330 202

telephone: +358 (0)201 212 600 fax: +49 (0)201 806 7099

Fax. +421 243 634 389

fax: +358 (0)201 212 699 Vacon OEM Business Center GmbH

Industriestr. 13 spain

Tampere

51709 - Marienheide Vacon Drives Ibérica S.A.

Vacon Plc

Germany Miquel Servet, 2. P.I. Bufalvent

Vehnämyllynkatu 18

Tel. +49 02264 17-17 08243 Manresa

33560 Tampere

Fax. +49 02264 17-126 telephone: +34 93 877 45 06

telephone: +358 (0)201 2121 fax: +34 93 877 00 09

fax: +358 (0)201 212 750 india

Vacon Drives & Control Plc sweden

australia

Plot No 352 Vacon AB

Vacon Pacific Pty Ltd

Kapaleeshwar Nagar Anderstorpsvägen 16

5/66-74, Micro Circuit

East Coast Road 171 54 Solna

Dandenong South, VIC 3175

Neelangarai telephone: +46 (0)8 293 055

telephone: +61 (0)3 9238 9300 fax: +46 (0)8 290 755

fax: +61 (0)3 92389310 Chennai-600041

Tel. +91 44 244 900 24/25 thailand

austria

italy Vacon South East Asia

Vacon AT Antriebssysteme GmbH

Vacon S.p.A. 335/32 5th-6th floor

Aumühlweg 21

Via F.lli Guerra, 35 Srinakarin Road, Prawet

2544 Leobersdorf

42100 Reggio Emilia Bangkok 10250

telephone: +43 2256 651 66

telephone: +39 0522 276811 Tel. +66 (0)2366 0768

fax: +43 2256 651 66 66

fax: +39 0522 276890 ukraine

belgium

Vacon Benelux NV/SA

the netherlands Vacon Drives Ukraine (Branch)

Interleuvenlaan 62 Vacon Benelux BV 42-44 Shovkovychna Str.

3001 Heverlee (Leuven) Weide 40 Regus City Horizon Tower

telephone: +32 (0)16 394 825 4206 CJ Gorinchem Kiev 01601, Ukraine

fax: +32 (0)16 394 827 telephone: +31 (0)183 642 970 Tel. +380 44 459 0579

fax: +31 (0)183 642 971 Fax +380 44 490 1200

china

norway

Vacon Suzhou Drives Co. Ltd. united arab emirates

Beijing Branch Vacon AS

Vacon Middle East and Africa

A528, Grand Pacific Garden Mansion Bentsrudveien 17

Block A, Office 4A 226

8A Guanghua Road 3080 Holmestrand

P.O.Box 54763

Beijing 100026 telephone: +47 330 96120

Dubai Airport Free Zone

telephone: + 86 10 51280006 fax: +47 330 96130

Dubai

fax: +86 10 65813733 romania Tel. +971 (0)4 204 5200

czech republic Vacon Romania - Reprezentanta Fax: +971 (0)4 204 5203

Vacon s.r.o. Cuza Voda 1

united kingdom

Kodanska 1441/46 400107 Cluj Napoca

Tel. +40 364 118 981 Vacon Drives (UK) Ltd.

110 00 Prague 10 18, Maizefield

telephone: +420 234 063 250 Fax. +40 364 118 981

Hinckley Fields Industrial Estate

fax: +420 234 063 251 russia Hinckley

france ZAO Vacon Drives LE10 1YF Leicestershire

Vacon France Ul. Letchika Babushkina 1, telephone: +44 (0)1455 611 515

ZAC du Fresne Stroenie 3 fax: +44 (0)1455 611 517

1 Rue Jacquard - BP72 129344 Moscow

united states

91280 Saint Pierre du Perray CDIS telephone: +7 (495) 363 19 85

fax: +7 (495) 363 19 86 Vacon, Inc.

telephone: +33 (0)1 69 89 60 30 3181, Black Gap Road

fax: +33 (0)1 69 89 60 40 ZAO Vacon Drives

Chambersburg, PA 17202

2ya Sovetskaya 7, office 210A

191036 St. Petersburg telephone: +1 (877) 822-6606

telephone: +7 (812) 332 1114 fax: +1 (717) 267-0140

fax: +7 (812) 279 9053

Vacon distributor:

You might also like

- VACON NC1131-3 Engineering: File: 1 03/29/21/KHDocument11 pagesVACON NC1131-3 Engineering: File: 1 03/29/21/KHEugenNo ratings yet

- Vacon 100 Flow BrochureDocument12 pagesVacon 100 Flow BrochureZeh Garcia JuniorNo ratings yet

- Vacon NXL Multicontrol Application Manual DPD01447A UKDocument63 pagesVacon NXL Multicontrol Application Manual DPD01447A UKAbijith100% (1)

- PDS - HPB Servo Manual PDFDocument63 pagesPDS - HPB Servo Manual PDFcarm8402100% (1)

- Vacon DriversDocument99 pagesVacon DriversAlyson Batista100% (1)

- LV 7000Document225 pagesLV 7000Sidnei PereiraNo ratings yet

- Vacon NX Inverters FI9 14 User Manual DPD00909A enDocument106 pagesVacon NX Inverters FI9 14 User Manual DPD00909A enTanuTiganuNo ratings yet

- ForewordDocument199 pagesForeworddavid mauricio0% (2)

- Tool For Fan Replacement, Enclosure Size B3: VLT® FC Series, FC 102, FC 103, FC 202, FC 301/FC 302Document8 pagesTool For Fan Replacement, Enclosure Size B3: VLT® FC Series, FC 102, FC 103, FC 202, FC 301/FC 302Fakhreddine HammoudiNo ratings yet

- VACON 100 IP00 Drive Modules Installation Manual DPD01665D UKDocument128 pagesVACON 100 IP00 Drive Modules Installation Manual DPD01665D UKscribdhas2006100% (1)

- Design of A Synchronous Reluctance DriveDocument9 pagesDesign of A Synchronous Reluctance DriveroyourboatNo ratings yet

- HB UCM 2018-10 enDocument44 pagesHB UCM 2018-10 enNaeem HussainNo ratings yet

- Vacon NX OPTC3 C5 Profibus Board User Manual DPD00Document42 pagesVacon NX OPTC3 C5 Profibus Board User Manual DPD00Jessica Brown100% (1)

- Manual Bien Tan Yaskawa GA700 SeriesDocument11 pagesManual Bien Tan Yaskawa GA700 Seriesasplelectrical94No ratings yet

- Vacon NX Position Control APFIFF12 Application ManDocument114 pagesVacon NX Position Control APFIFF12 Application ManTanuTiganuNo ratings yet

- Vacon Opte3 E5 Profibus DP User Guide Dpd00997e enDocument114 pagesVacon Opte3 E5 Profibus DP User Guide Dpd00997e enKaffka KorchaginNo ratings yet

- Vacon NX All in One Application Manual DPD00903C UDocument392 pagesVacon NX All in One Application Manual DPD00903C UMahmoud KhattabNo ratings yet

- NXP Рук-во по установке Габариты FR10-FR14 enDocument59 pagesNXP Рук-во по установке Габариты FR10-FR14 enAlexandr GalaganNo ratings yet

- Operating Guide: VLT Midi Drive FC 280Document70 pagesOperating Guide: VLT Midi Drive FC 280Mr.K chNo ratings yet

- Vacon CX Modbus Board User ManualDocument23 pagesVacon CX Modbus Board User ManualIrfan AshrafNo ratings yet

- Vacon NXC User Manual DPD00890B UKDocument112 pagesVacon NXC User Manual DPD00890B UKirfanWPKNo ratings yet

- VFD BasicsDocument18 pagesVFD Basicsabinash pradhan100% (1)

- Quick Guide: VLT Micro Drive FC 51Document32 pagesQuick Guide: VLT Micro Drive FC 51YuvarajNo ratings yet

- Dotech Sensing & ControlDocument15 pagesDotech Sensing & ControlAnsari1918No ratings yet

- NXC - 450 KW BC00167FDocument24 pagesNXC - 450 KW BC00167FIBJSC.com100% (1)

- VACON NX All in One Application Guide DPD00903H enDocument354 pagesVACON NX All in One Application Guide DPD00903H enSaasiNo ratings yet

- LH4 SRV05 4HTG D LittelfuseDocument6 pagesLH4 SRV05 4HTG D LittelfuseaNo ratings yet

- Encoder Signal Splitter ManualDocument10 pagesEncoder Signal Splitter ManualSANKPLY100% (1)

- Vacon 100 and 100FLOW ManualDocument104 pagesVacon 100 and 100FLOW ManualRajkumar KateelNo ratings yet

- CS 530Document146 pagesCS 530TruongAnNo ratings yet

- User's Manual: NX Frequency ConvertersDocument41 pagesUser's Manual: NX Frequency ConvertersEugenNo ratings yet

- NHB NX100 TRB 3.0 PDFDocument257 pagesNHB NX100 TRB 3.0 PDFErwin E. CanalesNo ratings yet

- Vacon NXL - The - Easy - and - Impressive - AC - DriveDocument21 pagesVacon NXL - The - Easy - and - Impressive - AC - Driveaslam77zNo ratings yet

- AC Servo Drive: Operation ManualDocument116 pagesAC Servo Drive: Operation ManualjassemNo ratings yet

- Getting Started GuideDocument23 pagesGetting Started GuideTOPOTRONIKNo ratings yet

- Combivert: Instruction Manual Pitch Inverter P6 Rated Current 45 A/52ADocument48 pagesCombivert: Instruction Manual Pitch Inverter P6 Rated Current 45 A/52AJiJi LinNo ratings yet

- Uputstvo EDS800 PDFDocument139 pagesUputstvo EDS800 PDFrzrasaNo ratings yet

- POwered Pallet Trucks - Manuals - AtlasCopco - FBW - FBW2440RevADocument16 pagesPOwered Pallet Trucks - Manuals - AtlasCopco - FBW - FBW2440RevAEduardo.s. EurolevaNo ratings yet

- Anyhz FST 610Document113 pagesAnyhz FST 610pphau.electricNo ratings yet

- GAITRONICS - 723-001 Remote SKU-GTC-Manual-42004-145EDocument6 pagesGAITRONICS - 723-001 Remote SKU-GTC-Manual-42004-145Eelectrician 15No ratings yet

- Vacon Nxs NXP User Manual Dpd00910d UkDocument166 pagesVacon Nxs NXP User Manual Dpd00910d UkGigi ZitoNo ratings yet

- Powtran Pi8100Document150 pagesPowtran Pi8100Marco Antonio Alvarez Loza100% (2)

- Ud01059n Marine APFIFF09Document251 pagesUd01059n Marine APFIFF09Laur Iri100% (1)

- PXR Series Catalog & Technical DatasheetDocument36 pagesPXR Series Catalog & Technical DatasheetNiten GuptaNo ratings yet

- ED-2016 As On 12 Apr 16 PDFDocument117 pagesED-2016 As On 12 Apr 16 PDFanimesh8672777100% (1)

- EM11 User's Manual 2014Document94 pagesEM11 User's Manual 2014nikola gNo ratings yet

- CHF100EnglishmanualINVT 1.4.1Document136 pagesCHF100EnglishmanualINVT 1.4.1Luis CampagnoliNo ratings yet

- Vacon NX OPTCP Profinet IO Board User Manual DPD00Document44 pagesVacon NX OPTCP Profinet IO Board User Manual DPD00TanuTiganuNo ratings yet

- 1 General Information: Model Number Short Description Servo DrivesDocument14 pages1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- FC102 - Control Pi EjemploDocument2 pagesFC102 - Control Pi Ejemplojose_balcazar89No ratings yet

- Vacon NXP IP00 Modules Installation Manual DPD0088Document60 pagesVacon NXP IP00 Modules Installation Manual DPD0088TanuTiganuNo ratings yet

- FC 1 Do 12Document12 pagesFC 1 Do 12veroljubdjNo ratings yet

- Ib 0600368 EngdDocument295 pagesIb 0600368 EngdAnonymous FqWJo7No ratings yet

- DGHDocument8 pagesDGHEdison F Montaluisa100% (1)

- Rdi 3000va 48vdc Kat List en v052009 PDFDocument2 pagesRdi 3000va 48vdc Kat List en v052009 PDFFermin MoicheNo ratings yet

- Frenic Mega ErrorDocument1 pageFrenic Mega Errorphth411No ratings yet

- Baker ST112A-ST106A-ST103A DatasheetDocument2 pagesBaker ST112A-ST106A-ST103A DatasheetJose LiraNo ratings yet

- 701-302 ManualDocument5 pages701-302 ManualWendy CassidyNo ratings yet

- CP400 Soft Technical ManualDocument333 pagesCP400 Soft Technical ManualVõ AnNo ratings yet

- Vacon NXN Nfe User Manual Dpd01172c UkDocument53 pagesVacon NXN Nfe User Manual Dpd01172c UkAnil YadavNo ratings yet

- User's Manual: NXS/P Frequency ConvertersDocument118 pagesUser's Manual: NXS/P Frequency Convertersoctav12No ratings yet

- Vacon NX Products For Common DC Bus SystemsDocument20 pagesVacon NX Products For Common DC Bus SystemsSilvian IonescuNo ratings yet

- User's Manual: NX Inverters Fi9Document102 pagesUser's Manual: NX Inverters Fi9Silvian IonescuNo ratings yet

- User's Manual: NX Inverters Fi9Document102 pagesUser's Manual: NX Inverters Fi9Silvian IonescuNo ratings yet

- Iguzzini - Sistemi Di Illuminazione Per Esterni - 2012 PDFDocument556 pagesIguzzini - Sistemi Di Illuminazione Per Esterni - 2012 PDFSilvian IonescuNo ratings yet

- Installation Devices 2018Document268 pagesInstallation Devices 2018Silvian IonescuNo ratings yet

- Moulded Case Circuit Breakers 2018Document128 pagesMoulded Case Circuit Breakers 2018Silvian IonescuNo ratings yet

- 4-Protecție La Supratensiune, Surse de Alimentare Și Întrerupătoare de ProtecțieDocument424 pages4-Protecție La Supratensiune, Surse de Alimentare Și Întrerupătoare de ProtecțieSilvian IonescuNo ratings yet

- 2-Cablare Senzori - Actuatoare Și ConectoriDocument766 pages2-Cablare Senzori - Actuatoare Și ConectoriSilvian IonescuNo ratings yet

- 3-Sisteme de Marcare, Unelte Și Materiale de InstalareDocument696 pages3-Sisteme de Marcare, Unelte Și Materiale de InstalareSilvian IonescuNo ratings yet

- Post Pyro Ip01Document56 pagesPost Pyro Ip01Durga PrasadNo ratings yet

- DTMF Door LockingDocument43 pagesDTMF Door LockingBasheer T MNo ratings yet

- Lecture-04, Adv. Computer Architecture, CS-522Document39 pagesLecture-04, Adv. Computer Architecture, CS-522torabgullNo ratings yet

- RD - TI.027.E.ENG v.C01Document104 pagesRD - TI.027.E.ENG v.C01Akhil NairNo ratings yet

- Boomer104 SpecDocument4 pagesBoomer104 SpecLucho MoraNo ratings yet

- Clear-Com RS-500 Series DatasheetDocument4 pagesClear-Com RS-500 Series DatasheetHenry PalNo ratings yet

- 4 TransmissionDocument163 pages4 TransmissionBaciu Nicolae100% (2)

- LED Lightboxes SpecsDocument14 pagesLED Lightboxes SpecsShibu KavullathilNo ratings yet

- Excavator: Parts CatalogDocument237 pagesExcavator: Parts CatalogAdil HanNo ratings yet

- Plumbing Materials and Fixtures ReportingDocument125 pagesPlumbing Materials and Fixtures ReportingChristine De JesusNo ratings yet

- E3S-CL: Distance Setting Photoelectric Sensor in Metal HousingDocument9 pagesE3S-CL: Distance Setting Photoelectric Sensor in Metal HousingAnggi PrasetyoNo ratings yet

- Livechek: Vehicle Inspection ReportDocument8 pagesLivechek: Vehicle Inspection Reportnilesh chandrakarNo ratings yet

- KDP 205 KLP 1000 ManualDocument2 pagesKDP 205 KLP 1000 ManualInterlogyc De MexicoNo ratings yet

- ZF 8000 SeriesDocument4 pagesZF 8000 SeriesBatti100% (1)

- Manual Service Mx5203ms 18Document1 pageManual Service Mx5203ms 18yudiw74No ratings yet

- QG15 - Sist Vent ElectrDocument7 pagesQG15 - Sist Vent ElectranghyholindoNo ratings yet

- Servofighter: The Fire Alarm System For The FutureDocument4 pagesServofighter: The Fire Alarm System For The FutureMayerlis MartinezNo ratings yet

- Mitsubishi 1540 FD Owner's ManualDocument24 pagesMitsubishi 1540 FD Owner's ManualgrantNo ratings yet

- LMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceDocument2 pagesLMS 07.1 - LMS 16.1: Technical Data Anti-Backdrive DeviceTrong Hung NguyenNo ratings yet

- Finished Bore Spiral Bevel Gears: Mbsa MbsaDocument2 pagesFinished Bore Spiral Bevel Gears: Mbsa Mbsamoath farrajNo ratings yet

- Brother Bas 300G 484 484SF 04-2012 English CatalogueDocument2 pagesBrother Bas 300G 484 484SF 04-2012 English CatalogueNguyen Hoang HaiNo ratings yet

- R/A Cable, Gen2, BLK Plastic Conn: FerriteDocument1 pageR/A Cable, Gen2, BLK Plastic Conn: FerriteAhmed ShawkiNo ratings yet

- 12 13Document2 pages12 13Amir JoonNo ratings yet

- INVOICEDocument133 pagesINVOICEnadyanjuni10No ratings yet

- Retrieval Tool Manual PDFDocument21 pagesRetrieval Tool Manual PDFpandeyamriteshNo ratings yet

- Test Certificate For Transformer: Ratio:11000/240 VDocument1 pageTest Certificate For Transformer: Ratio:11000/240 Vsanjayprakash1979No ratings yet

- EPD Unit 4 SlidesDocument79 pagesEPD Unit 4 SlidesAdvaith S . KumarNo ratings yet

- Computer Hardware - WikipediaDocument51 pagesComputer Hardware - WikipediaNaniNo ratings yet

- Truck Tralkkiuf PDFDocument134 pagesTruck Tralkkiuf PDFfrank mutaleNo ratings yet