Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Uploaded by

Alaa saidCopyright:

Available Formats

Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Uploaded by

Alaa saidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Model 3:1 Pilot Ratio, Standard Capacity Counterbalance Valve

Uploaded by

Alaa saidCopyright:

Available Formats

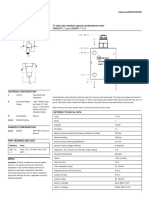

MODEL 3:1 pilot ratio, standard capacity counterbalance valve

CBCA SERIES 1 / CAPACITY: 15 gpm / CAVITY: T-11A

sunhydraulics.com/model/CBCA

3-Port Non-vented

Counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows free flow

from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve controls flow

CONFIGURATION from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate determined by the

pilot ratio.

L Control Standard Screw Adjustment

Other names for this valve include motion control valve and over-center valve.

B Functional 400 - 1500 psi w/4 psi Check

Setting Range (28 - 105 bar w/ 0,3 bar

Check), 1000 psi (70 bar) TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Standard Setting

Cavity T-11A

V Seal Material Viton

Series 1

(none) Material/Coating Standard Material/Coating

Capacity 15 gpm

Pilot Ratio 3:1

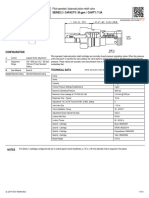

Maximum Recommended Load Pressure at Maximum Setting 3075 psi

Maximum Setting 4000 psi

Factory Pressure Settings Established at 2 in³/min.

Maximum Valve Leakage at Reseat 5 drops/min.

Adjustment - No. of CCW Turns from Min. to Max. Setting 3.75

Operating Characteristic Standard

Reseat >85% of setting

Valve Hex Size 7/8 in.

Valve Installation Torque 30 - 35 lbf ft

Adjustment Screw Internal Hex Size 5/32 in.

Locknut Hex Size 9/16 in.

Locknut Torque 80 - 90 lbf in.

Seal kit - Cartridge Buna: 990011007

Seal kit - Cartridge EPDM: 990011014

Seal kit - Cartridge Polyurethane: 990011002

Seal kit - Cartridge Viton: 990011006

Model Weight 0.35 lb.

c 2019 Sun Hydraulics

1 of 2

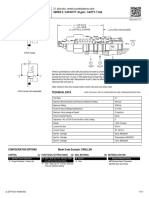

CONFIGURATION OPTIONS Model Code Example: CBCALBV

CONTROL (L) FUNCTIONAL SETTING RANGE (B) SEAL MATERIAL (V) MATERIAL/COATING

L Standard Screw Adjustment B 400 - 1500 psi w/4 psi Check (28 - 105 V Viton Standard Material/Coating

C Tamper Resistant - Factory Set bar w/ 0,3 bar Check), 1000 psi (70 N Buna-N /AP Stainless Steel, Passivated

bar) Standard Setting E EPDM /LH Mild Steel, Zinc-Nickel

H 1000 - 4000 psi w/25 psi Check (70 -

280 bar w/ 1,7 bar Check), 3000 psi

(210 bar) Standard Setting

A 1000 - 4000 psi w/4 psi Check (70 -

280 bar w/ 0,3 bar Check), 3000 psi

(210 bar) Standard Setting

I 400 - 1500 psi w/25 psi Check (28 -

105 bar w/ 1,7 bar Check), 1000 psi (70

bar) Standard Setting

TECHNICAL FEATURES

Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Turn adjustment clockwise to decrease setting and release load.

Full clockwise setting is less than 200 psi (14 bar).

Backpressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

This valve does not have positive seals on the pilot section and will pass up to 3 in³/min.@1000 psi (45 ml/min.@70 bar ) between port 2 and port 3. This is a

consideration in master-slave circuits and in the leak testing of valve-cylinder assemblies.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.

All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel

components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of

Construction page located under TECH RESOURCES.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

PERFORMANCE CURVES

RELATED MODELS

CBCAX Fixed setting, 3:1 pilot ratio, standard capacity counterbalance valve

c 2019 Sun Hydraulics

2 of 2

You might also like

- Pellicon 2 Validation Guide PDFDocument45 pagesPellicon 2 Validation Guide PDFtakwahs12135No ratings yet

- Discover Biology GCE 'O' Level Science 2E Workbook (Teacher's Edn)Document162 pagesDiscover Biology GCE 'O' Level Science 2E Workbook (Teacher's Edn)Hijab100% (11)

- Industrial Rexroth & Vickers Cross ListDocument40 pagesIndustrial Rexroth & Vickers Cross ListAlaa saidNo ratings yet

- Parts Catalog Af1060-1075-2060-2075-2051 (B064-065-140-141-142-143-163-228) PDFDocument312 pagesParts Catalog Af1060-1075-2060-2075-2051 (B064-065-140-141-142-143-163-228) PDFEdwin BautistaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850No ratings yet

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNo ratings yet

- CBCY Full en Us LetterDocument2 pagesCBCY Full en Us LetterVentas Control HidráulicoNo ratings yet

- Valvula Contrabalance CBGA LIN HCLDocument2 pagesValvula Contrabalance CBGA LIN HCLcarlos pachecoNo ratings yet

- CBEALBN Full en Us LetterDocument2 pagesCBEALBN Full en Us Letterangelo.araza0913No ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CBGA Full en Us A4Document2 pagesCBGA Full en Us A4Epul HaqNo ratings yet

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNo ratings yet

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument2 pagesModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNo ratings yet

- CCCALBN Full en Us LetterDocument2 pagesCCCALBN Full en Us Letterisaiahsamsonm_948069No ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESNo ratings yet

- CBCA Es Metric A4Document1 pageCBCA Es Metric A4martin.riosNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument2 pagesModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaDocument1 pageModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedDocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically ReferencedVinit ChoudharyNo ratings yet

- CAEGCGN Full en Us A4Document2 pagesCAEGCGN Full en Us A4david mendozaNo ratings yet

- Sun Hydraulics-Cbca Lan EccDocument5 pagesSun Hydraulics-Cbca Lan EcchendntdNo ratings yet

- CBEALAN Full Es Metric LetterDocument2 pagesCBEALAN Full Es Metric Letternicole tapiaNo ratings yet

- CBEWLJN Full en Metric A4Document2 pagesCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςNo ratings yet

- RVCALCN Full en Us A4Document2 pagesRVCALCN Full en Us A4Felipe DiazNo ratings yet

- CBCALHN-EAC Full en Us LetterDocument5 pagesCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNo ratings yet

- CACLLGN en Us A4Document1 pageCACLLGN en Us A42fqdw8s8yxNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaNo ratings yet

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveDocument1 pageModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriNo ratings yet

- RPGC Full en Us A4Document2 pagesRPGC Full en Us A4zapchasty29No ratings yet

- Contrabalance SunHydraulicDocument2 pagesContrabalance SunHydraulicMatias Oñate ArriagadaNo ratings yet

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24ADocument2 pagesModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9No ratings yet

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDocument4 pages5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNo ratings yet

- Sun Hydraulics MWEB-LJN Technical SpecificationsDocument1 pageSun Hydraulics MWEB-LJN Technical SpecificationsJustinNo ratings yet

- CAIGLGN Full en Us A4Document2 pagesCAIGLGN Full en Us A4david mendozaNo ratings yet

- Sun Hydraulics CWEL Technical SpecificationsDocument1 pageSun Hydraulics CWEL Technical SpecificationsJustinNo ratings yet

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDocument2 pagesModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNo ratings yet

- Modelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaDocument2 pagesModelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaManuel Patricio Gonzalez SanhuezaNo ratings yet

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDocument2 pagesModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNo ratings yet

- Cbcalin ValveDocument2 pagesCbcalin ValveArun51092No ratings yet

- Direct-Acting Relief Valve: DownloadDocument2 pagesDirect-Acting Relief Valve: Downloadaristi51No ratings yet

- RPGC Full en Us LetterDocument3 pagesRPGC Full en Us Letterolive.chowdhuryNo ratings yet

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDocument2 pagesModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNo ratings yet

- SUN RPGC-LAN (Relief Valve)Document3 pagesSUN RPGC-LAN (Relief Valve)ful islamNo ratings yet

- RDHA - Direct-Acting Relief ValveDocument3 pagesRDHA - Direct-Acting Relief ValvezengguoxuanNo ratings yet

- RDJA Full en Us A4Document3 pagesRDJA Full en Us A4GERALD SIMONNo ratings yet

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveDocument1 pageModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparNo ratings yet

- SUN RPGC-JCN (Relief Valve)Document3 pagesSUN RPGC-JCN (Relief Valve)ful islamNo ratings yet

- Sun Hydraulics RDDA-LCNDocument3 pagesSun Hydraulics RDDA-LCNJustinNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- CBIALAN en Metric Letter PDFDocument1 pageCBIALAN en Metric Letter PDFPritesh KoratNo ratings yet

- RDDA - Direct-Acting Relief ValveDocument3 pagesRDDA - Direct-Acting Relief ValveD ŠpokauskasNo ratings yet

- Sun Hydraulics FDBA-LANDocument2 pagesSun Hydraulics FDBA-LANJustinNo ratings yet

- RSBC Full en Us A4Document2 pagesRSBC Full en Us A4Mykola TitovNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Off-Highway Trucks: Hydraulic Pumps & Motors To Suit CATDocument1 pageOff-Highway Trucks: Hydraulic Pumps & Motors To Suit CATAlaa saidNo ratings yet

- Caterpillar Line: (Other Parts Not Listed Are Available)Document23 pagesCaterpillar Line: (Other Parts Not Listed Are Available)Alaa said100% (1)

- Parker - CYL - Cross RefDocument15 pagesParker - CYL - Cross RefAlaa saidNo ratings yet

- Microcontrollers TSD DS Jan-2006 REVDocument2 pagesMicrocontrollers TSD DS Jan-2006 REVAlaa saidNo ratings yet

- Microcontrollers TSD DS Jan-2006 REVDocument2 pagesMicrocontrollers TSD DS Jan-2006 REVAlaa saidNo ratings yet

- 45 Series F Frame Tech-Note (520L0948 Rev AC December 2006)Document36 pages45 Series F Frame Tech-Note (520L0948 Rev AC December 2006)Alaa saidNo ratings yet

- 45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Document48 pages45 Series F Frame 74cc and 90cc Parts Manual (11007197 Rev AA Feb 2007)Alaa saidNo ratings yet

- Orientation To Pharmacy 2014 - Part 1Document26 pagesOrientation To Pharmacy 2014 - Part 1Khairi Mustafa Salem100% (1)

- Latour "Charles Péguy: Time, Space and Le Monde Moderne"Document23 pagesLatour "Charles Péguy: Time, Space and Le Monde Moderne"adeenameyNo ratings yet

- Winter 2023 Experiment CatalogDocument20 pagesWinter 2023 Experiment CatalogThe Experiment100% (1)

- Structural Theory Refresher SetDocument6 pagesStructural Theory Refresher SetLa BeamNo ratings yet

- General SpecificationDocument327 pagesGeneral SpecificationmaymanyassinNo ratings yet

- Baby NameDocument10 pagesBaby NameKachhadiya BhaveshNo ratings yet

- NW Model Question With AnsDocument8 pagesNW Model Question With Ansyisakabera123No ratings yet

- To Study The Digestion of Starch by Salivary AmylaseDocument20 pagesTo Study The Digestion of Starch by Salivary Amylasesureshk98438No ratings yet

- Introduction To Philosophy of The Human NatureDocument44 pagesIntroduction To Philosophy of The Human NatureButterfly Fashion100% (1)

- Measurement of Barkhausen Noise and Its Correlation With Magnetic Permeability PDFDocument6 pagesMeasurement of Barkhausen Noise and Its Correlation With Magnetic Permeability PDFallanromarioNo ratings yet

- Chemistry Investigatory Project Class 12 - ToothpasteDocument20 pagesChemistry Investigatory Project Class 12 - ToothpasteKishoreNo ratings yet

- Tom Bearden - A Case Study in PsychosisDocument20 pagesTom Bearden - A Case Study in Psychosistavdeash2380% (1)

- Functional Biology NOTESDocument113 pagesFunctional Biology NOTESRebecca Amy JennerNo ratings yet

- Functions of The Passive VoiceDocument6 pagesFunctions of The Passive VoiceAl HabsiNo ratings yet

- Week 9-11 (Nutrition)Document6 pagesWeek 9-11 (Nutrition)Yoko Mae YanoNo ratings yet

- Incident 8Document7 pagesIncident 8Naren MukherjeeNo ratings yet

- ECE170: Electronics (1) : LectureDocument40 pagesECE170: Electronics (1) : LectureKhaled MohamedNo ratings yet

- Air Tractor AT-602 Airplane Flight Manual Excerpt-RelDocument1 pageAir Tractor AT-602 Airplane Flight Manual Excerpt-RelJose A. HerreraNo ratings yet

- BU406Document5 pagesBU406Ahmed ZagharyNo ratings yet

- Trench AssaultDocument4 pagesTrench AssaultJim Wallman100% (1)

- Nonlinear Behavior and Design of Mid-To-Highrise Diagrid Structures in Seismic RegionsDocument41 pagesNonlinear Behavior and Design of Mid-To-Highrise Diagrid Structures in Seismic RegionsFATMAF HUSSAINNo ratings yet

- DalistDocument2 pagesDalistDoug8796No ratings yet

- NR600 ParametersDocument26 pagesNR600 ParametersMohit Pal100% (1)

- CONDITIONALDocument25 pagesCONDITIONALShiella Mae Vispo100% (1)

- Course Outline & Timeframe TopicsDocument7 pagesCourse Outline & Timeframe TopicstabilinNo ratings yet

- POV DisplayDocument10 pagesPOV Displaytrex700nNo ratings yet

- Msds CPD SikaLatex UsDocument8 pagesMsds CPD SikaLatex UsmastercssiNo ratings yet