G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

Uploaded by

Paulo GomesCopyright:

Available Formats

G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

Uploaded by

Paulo GomesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

G7 Selected Layer G9 Subgrade The Following Results Were Calculated With Elsym5: Foseg4 1.3' V G7

Uploaded by

Paulo GomesCopyright:

Available Formats

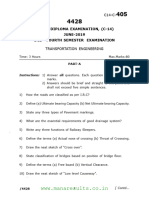

(c) What are the advantages and disadvantages of using the Canadian PCA design

method for unreinforced jointed rigid pavements in comparison with that of the South

African mechanistically and risk based method. Give four aspects.

(d)

(4)

(i) Sketch a concrete pavement to show the positions of dowel and tie bars,

(ii) Describe the function of dowel bars and tie bars.

4.(a) (iii) Describe how stepping or faulting is formed on concrete pavements, and how this

can be prevented.

(b) (5)

Describe, with the aid of a sketch showing normal distributions of material properties

and loadings, the importance of applying good quality control on light pavement

(c)

structures, and the dangers inherent in reducing standards without adequate control.(3)

Under v/hat circumstances should extreme care be taken in the use of lighter

(d) pavement stmctures^Nfame four circumstances.

(2)

Name 6 unpaved road defects, and describe how these defects can be avoided at the

design stage.

(3)

5. Briefly explain the method for predicting rutting as developed by Wolff, and explain how

it differs from the mechano lattice method.

(3)

OPEN BOOK [48] Clearly state and

motivate any assumptions made

Determine the remaining life of the following Category B pavement in a dry region:

40 mm Continuously graded asphalt surfacing

G1 Crushed stone base

C4 Cement stabilised subbase in an EG4 state

G7 selected layer

G9 subgrade The following results were

calculated with ELSYM5:

et asphalt= 300uE

Sigmal = 400 kPa Sigma3 = 40 kPa

FoSEG4= 1.3'

sv G7 -

Ev G9 =

What could be done to give the pavement a longer life of 3 million E80s? (6)

Determine the most economic design over 30 years for the following:

Alternative A: Construction cost R24 per sq m

Special maintenance after 10 years @ R8 per sq m

Recycle after 20 years @ R15 per sq m

Alternative B: Construction cost R29 per sq m

Overlay after 20 years @ R12 per sq rn

Use a discount rate of 10%. Accept that there is no salvage value. -

(4)

ATV/SGC78I/

You might also like

- Last Yr Transportation Question PapersDocument11 pagesLast Yr Transportation Question PapersAditya RanaNo ratings yet

- Answer Any Two Full Questions, Each Carries 15 Marks.: Pages: 4Document4 pagesAnswer Any Two Full Questions, Each Carries 15 Marks.: Pages: 4Hima SNo ratings yet

- Cet433 QPDocument3 pagesCet433 QPREMYA Y.KNo ratings yet

- RTU Previous Years PapersDocument41 pagesRTU Previous Years PapersDinesh Kumar0% (1)

- National University of Science and Technology: All Questions Carry 25 Marks EachDocument5 pagesNational University of Science and Technology: All Questions Carry 25 Marks EachNyashah FelixNo ratings yet

- SBT443-BDocument4 pagesSBT443-BK RNo ratings yet

- SBT443-DDocument2 pagesSBT443-DK RNo ratings yet

- SBT443-ADocument4 pagesSBT443-AK RNo ratings yet

- Ce2255 Highway Engineering r8Document2 pagesCe2255 Highway Engineering r8Dhivya RaviNo ratings yet

- D F1076 Pages: 3: Answer Any Two Full Questions, Each Carries 15 MarksDocument3 pagesD F1076 Pages: 3: Answer Any Two Full Questions, Each Carries 15 MarksSivakumarNo ratings yet

- 2019 Dec. CE467-C - Ktu QbankDocument2 pages2019 Dec. CE467-C - Ktu QbankAthira RaghavanNo ratings yet

- Finalexambfc31802sem 2 20222023.r3docxDocument14 pagesFinalexambfc31802sem 2 20222023.r3docxliehans.santosoNo ratings yet

- Course Code: CET 407 Irjq/Ms - 19 / 8603 Eighth Semester B. E. (Civil Engineering) ExaminationDocument2 pagesCourse Code: CET 407 Irjq/Ms - 19 / 8603 Eighth Semester B. E. (Civil Engineering) ExaminationRajput Ayush ThakurNo ratings yet

- Wa0001 PDFDocument275 pagesWa0001 PDFsatydeshNo ratings yet

- Be 2013Document275 pagesBe 2013rupesh kumar jhaNo ratings yet

- Be Winter 2021Document2 pagesBe Winter 2021aarjav112004No ratings yet

- Pemm - 12146Document3 pagesPemm - 12146katragadda_kNo ratings yet

- 2022 Summer Question Paper (Msbte Study Resources)Document3 pages2022 Summer Question Paper (Msbte Study Resources)bat93728No ratings yet

- 2019 Summer Question Paper (Msbte Study Resources)Document4 pages2019 Summer Question Paper (Msbte Study Resources)tainy1756No ratings yet

- Code No: V3206/R07 III B. Tech II Semester Regular Examinations, Apr/May 2010Document8 pagesCode No: V3206/R07 III B. Tech II Semester Regular Examinations, Apr/May 2010sreenathNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document27 pagesElective - II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)FalgunNo ratings yet

- Eighth SemesterDocument31 pagesEighth SemesterRajput Ayush ThakurNo ratings yet

- Metrologyand Surface EngineeringDocument4 pagesMetrologyand Surface EngineeringshivkrnNo ratings yet

- TED End of Trimester Test Paper 2021Document13 pagesTED End of Trimester Test Paper 2021Jemmy RobertNo ratings yet

- Elective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Document12 pagesElective - II: Pavement Analysis & Design: B.E.Eighth Semester (Civil Engineering) (C.B.S.)Uday PatilNo ratings yet

- M. Tech. Semester - II: Transportation Planning (IBMCETE806)Document14 pagesM. Tech. Semester - II: Transportation Planning (IBMCETE806)saurabh1116No ratings yet

- 15CV552 1Document2 pages15CV552 1Teju D GowdaNo ratings yet

- Transportation Put Set1Document2 pagesTransportation Put Set1swapnilsunny5No ratings yet

- Finalexambfc31802sem 1 2022 2023 QuestionDocument14 pagesFinalexambfc31802sem 1 2022 2023 Questionliehans.santosoNo ratings yet

- Ece 2412 Highway Engineering IiDocument3 pagesEce 2412 Highway Engineering IiJoseph NjugunaNo ratings yet

- Production Technology-Ii: Part-ADocument3 pagesProduction Technology-Ii: Part-ARkrishna ANo ratings yet

- B E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksDocument2 pagesB E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksRahul KorothNo ratings yet

- Answer Question 1 and Any Other 3 QuestionsDocument2 pagesAnswer Question 1 and Any Other 3 QuestionsNyashah FelixNo ratings yet

- CTE 313322 70M PaperDocument2 pagesCTE 313322 70M Paperroshan chavanNo ratings yet

- TRE QP & QB For UT2Document6 pagesTRE QP & QB For UT2priyankaNo ratings yet

- Be 1 Sem Basic of Civil Engineering 3285 Summer 2019Document1 pageBe 1 Sem Basic of Civil Engineering 3285 Summer 2019Devashish SahasrabudheNo ratings yet

- Pavement Analysis and DesignDocument1 pagePavement Analysis and DesignRanjith KumarNo ratings yet

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document4 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- University of Zimbabwe: Transportation Systems and Structures December 2009 Engin. CE 407Document4 pagesUniversity of Zimbabwe: Transportation Systems and Structures December 2009 Engin. CE 407kundayi shavaNo ratings yet

- B.E (2015 Pattern)Document523 pagesB.E (2015 Pattern)prajaNo ratings yet

- Ce - Ii - 1Document50 pagesCe - Ii - 1saurabh1116No ratings yet

- 15 HE May-2018Document2 pages15 HE May-2018Ujjval SolankiNo ratings yet

- Answer Any FOUR Questions Time: 3 Hours Total Marks: 100Document2 pagesAnswer Any FOUR Questions Time: 3 Hours Total Marks: 100Nyashah FelixNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument2 pages3 Hours / 70 Marks: Seat NoKundan SalunkeNo ratings yet

- Elective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Document6 pagesElective-II: Pavement Analysis & Design: B.E. (Civil Engineering) Eighth Semester (C.B.S.)Adesh DeshbhratarNo ratings yet

- OCT 09 T E CivilDocument42 pagesOCT 09 T E CivilAmit RahejaNo ratings yet

- 22375 (4)Document2 pages22375 (4)asadansarims05No ratings yet

- May 2019 CE362 - Ground Improvement Techniques - Ktu QbankDocument2 pagesMay 2019 CE362 - Ground Improvement Techniques - Ktu QbankDinekarNo ratings yet

- Btech Ce 6 Sem Transportation Engineering 1 36152 2020Document3 pagesBtech Ce 6 Sem Transportation Engineering 1 36152 2020Aditya RanaNo ratings yet

- Tutorial 33290 Highway Design and Analysis 2016Document20 pagesTutorial 33290 Highway Design and Analysis 2016Sarah HaiderNo ratings yet

- CL 92210Document3 pagesCL 92210David ThomsonNo ratings yet

- Production Technology-IIDocument3 pagesProduction Technology-IIDL 26PankajNo ratings yet

- TED Exam 6-February-2014-15-QuestionsDocument9 pagesTED Exam 6-February-2014-15-QuestionsJemmy RobertNo ratings yet

- WWW - Manaresults.co - In: JUNE-2019Document2 pagesWWW - Manaresults.co - In: JUNE-2019ravitripathi1221No ratings yet

- Dhi - 17124Document2 pagesDhi - 17124Gundrathi Narendra GoudNo ratings yet

- Railways, Harbours and Airport EngineeringDocument2 pagesRailways, Harbours and Airport Engineeringsaikonatham86No ratings yet

- Final Exam HighwayDocument14 pagesFinal Exam HighwayzsNo ratings yet

- 22375 (2)Document2 pages22375 (2)asadansarims05No ratings yet

- TPG3700 - S1 - Major Test #2 - 2022Document4 pagesTPG3700 - S1 - Major Test #2 - 2022asanda123mkhwanaziNo ratings yet

- Boolean Circuit Rewiring: Bridging Logical and Physical DesignsFrom EverandBoolean Circuit Rewiring: Bridging Logical and Physical DesignsNo ratings yet

- Paulo Gomes ApplicationDocument2 pagesPaulo Gomes ApplicationPaulo GomesNo ratings yet

- Resumgo: Education ProfileDocument2 pagesResumgo: Education ProfilePaulo GomesNo ratings yet

- Curriculum Vitae: Neves JalavuraDocument1 pageCurriculum Vitae: Neves JalavuraPaulo GomesNo ratings yet

- Experience: Job TitleDocument2 pagesExperience: Job TitlePaulo GomesNo ratings yet

- ID Photo: Graphic DesignerDocument2 pagesID Photo: Graphic DesignerPaulo GomesNo ratings yet

- 3D Artist ResumeDocument1 page3D Artist ResumePaulo GomesNo ratings yet

- Universiteit Van Pretoria Department of Civil and Bfosystems EngineeringDocument1 pageUniversiteit Van Pretoria Department of Civil and Bfosystems EngineeringPaulo GomesNo ratings yet

- Jane Resumgo: ID PhotoDocument2 pagesJane Resumgo: ID PhotoPaulo GomesNo ratings yet

- Free Resume TemplateDocument1 pageFree Resume TemplatePaulo GomesNo ratings yet

- J//CF / - $ Cy R Cjti: " ' (Vkvjl-1. - Yrsi'Ji'F 4Document1 pageJ//CF / - $ Cy R Cjti: " ' (Vkvjl-1. - Yrsi'Ji'F 4Paulo GomesNo ratings yet

- Foseg4 1.3 Vg7 950ne ' L - 7 Vg9 ": T Ef RDocument2 pagesFoseg4 1.3 Vg7 950ne ' L - 7 Vg9 ": T Ef RPaulo GomesNo ratings yet

- Universiteitvan Pretoria Department of Civil and Biosystems EngineeringDocument2 pagesUniversiteitvan Pretoria Department of Civil and Biosystems EngineeringPaulo GomesNo ratings yet

- Foseg4 1.3 Vg7 950ne ' L - 7 Vg9 ": T Ef RDocument2 pagesFoseg4 1.3 Vg7 950ne ' L - 7 Vg9 ": T Ef RPaulo GomesNo ratings yet

- Universitelt Van Pretoria" Department of Civil Engineering: Pavement Design), Sgc7R1Document1 pageUniversitelt Van Pretoria" Department of Civil Engineering: Pavement Design), Sgc7R1Paulo GomesNo ratings yet

- Vehicle System/Component Service Notes Check Monthly Check Every 9 Months/ 9,000 MilesDocument1 pageVehicle System/Component Service Notes Check Monthly Check Every 9 Months/ 9,000 MilesPaulo GomesNo ratings yet

- Checking Procedure For Plant Layout & PipingDocument5 pagesChecking Procedure For Plant Layout & PipingAnang ZubaidiNo ratings yet

- Usw Arbtc Expo Mar STB 15 Rev00 PDFDocument89 pagesUsw Arbtc Expo Mar STB 15 Rev00 PDFnoufalNo ratings yet

- Elizebathen ArchitectureDocument11 pagesElizebathen ArchitectureSamreen KhanNo ratings yet

- Total Quality Management: January 2017Document11 pagesTotal Quality Management: January 2017Arun Nalamara100% (1)

- PG3 Rect-BeamDocument28 pagesPG3 Rect-BeammuruNo ratings yet

- Bill of Quantity: PIU Name & No:-Project Implementation Unit 01, PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADADocument5 pagesBill of Quantity: PIU Name & No:-Project Implementation Unit 01, PRADHAN MANTRI GRAM SADAK YOJNA DANTEWADALucky TraderNo ratings yet

- Anchorbolt For Pole DesignDocument3 pagesAnchorbolt For Pole DesignJayNo ratings yet

- 2051Document1 page2051zaheerNo ratings yet

- Demolition of ShadesDocument6 pagesDemolition of ShadesahmadNo ratings yet

- Scaffold Basic PartsDocument57 pagesScaffold Basic PartsSn Carbonel100% (1)

- Presented By:-Group 5 Arpan Jain Asim Babbar Kapil Kaushik Pramod Malik Raj Kamal Maurya Rajat Chopra Taruna Arora Yatharth ChoudharyDocument51 pagesPresented By:-Group 5 Arpan Jain Asim Babbar Kapil Kaushik Pramod Malik Raj Kamal Maurya Rajat Chopra Taruna Arora Yatharth ChoudharyAaditya AgarwalNo ratings yet

- Structural Design of Pump House and SumpDocument312 pagesStructural Design of Pump House and Sumpabhi arote100% (2)

- Pakistan Engineering Council Code DetailsDocument11 pagesPakistan Engineering Council Code DetailsaountariqNo ratings yet

- Metal Roofs: Introduction To Steel RoofsDocument31 pagesMetal Roofs: Introduction To Steel RoofsKalsoom RazaNo ratings yet

- News Release: Aisi Publishes 2013 Edition of Cold-Formed Steel Design ManualDocument3 pagesNews Release: Aisi Publishes 2013 Edition of Cold-Formed Steel Design ManualBONDHON-2 APARTMENT0% (1)

- Etp - 30 KLDDocument18 pagesEtp - 30 KLDsubramanyam kumarNo ratings yet

- Field Trip's Report: Student ID: 10573046 Name: Ashari Fitra RachmannullahDocument2 pagesField Trip's Report: Student ID: 10573046 Name: Ashari Fitra RachmannullahMuhammad Ashari Fitra RachmannullahNo ratings yet

- Inspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksDocument3 pagesInspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksjitendraNo ratings yet

- Ipc-01 - 233Document172 pagesIpc-01 - 233Chathuranga PriyasamanNo ratings yet

- Concrete Foundation Systems and Footings: The Scientific World Journal July 2017Document18 pagesConcrete Foundation Systems and Footings: The Scientific World Journal July 2017aNo ratings yet

- Introduction of Material HandlingDocument14 pagesIntroduction of Material HandlingsankasturkarNo ratings yet

- Yashas sp2.0Document55 pagesYashas sp2.0Nikhil SnNo ratings yet

- Work Method Statement FOR Reinforced Concrete Retaining WallDocument4 pagesWork Method Statement FOR Reinforced Concrete Retaining WallLynn MailNo ratings yet

- 1) Glass Lined Steel Panels: Data Sheet Tank WallDocument6 pages1) Glass Lined Steel Panels: Data Sheet Tank WalltounsiNo ratings yet

- Pranjal LayoutDocument25 pagesPranjal Layoutgupta photocopiersNo ratings yet

- Balochistan Building Control and Town Planning Rules, 2022Document142 pagesBalochistan Building Control and Town Planning Rules, 2022baloch47No ratings yet

- Punalur Suspension BridgeDocument5 pagesPunalur Suspension BridgeJOFIN JO RAJINo ratings yet

- MHDDocument1 pageMHDDustin GrimaresNo ratings yet

- THE Card: R E A LDocument4 pagesTHE Card: R E A LMohamed Ahmed RezkNo ratings yet

- Named Government AccountsDocument518 pagesNamed Government AccountsNilabh SharmaNo ratings yet