1) Glass Lined Steel Panels: Data Sheet Tank Wall

1) Glass Lined Steel Panels: Data Sheet Tank Wall

Uploaded by

tounsiCopyright:

Available Formats

1) Glass Lined Steel Panels: Data Sheet Tank Wall

1) Glass Lined Steel Panels: Data Sheet Tank Wall

Uploaded by

tounsiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1) Glass Lined Steel Panels: Data Sheet Tank Wall

1) Glass Lined Steel Panels: Data Sheet Tank Wall

Uploaded by

tounsiCopyright:

Available Formats

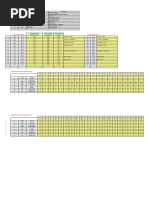

Data sheet Version: 1.

Tank wall page: 1 of 6

valid from 15.09.2014

A GLS tank kit includes 4 main components:

1) glass lined steel panels

panel thickness 2/2,5/2,99 mm 3,40/4/5/6/7/8/10/12 mm

row steel quality S 235 - DIN 17.100 (EN 10025)* S380 - S 420 - DIN 17.100 (EN 10025)*

steel type special enamelable special enamelable

recast cold rolled hot rolled

tensile strength (Rm) min. 340 N/mm2 490 N/mm² bis 620 N/mm²

gross size 1 length 1737 mm x height 1500 mm

net size 1 length 1571 mm x height 1440 mm

gross size 2 length 2260 mm x height 1500 mm

net size 2 length 2094 mm x height 1440 mm

* quality of the glass lined steel acc. proofable static

2) panel bolts

Option „HDG-Special“ Option „V2A“

Hot-dip galvanized with PP Stainless steel V2A

bolts head (1.4301)

dimension M 12 M 12

bolts

strength category 8.8 A2-80

Tensile strength (Rm) min. 800 N/mm2 min. 800 N/mm2

Yield point Rp 0,2% min. 600 N/mm2 min. 600 N/mm2

Stainless steel V2A

nut Hot-dip galvanized (1.4301)

Stainless steel V2A

washer Hot-dip galvanized (1.4301)

gasket (EPDM) Yes Yes

Klingersil disk Yes Yes

Nut cap optional (in PP)

3) sealant

Depending on the agreement and application, permanently elastic sealant is used for:

Panel bonding, joint connection coverage, joint seam bottom/wall, joint seam wall/roof, flange

sealing, manhole sealing, coverage of bolt heads. For the adhesion of the sealant to the

concrete and the steel necessary bonding agents (Primer), cleaners and cleaning rags are

included in our scope of supply.

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 1 of 6

Data sheet Version: 1.4

Tank wall page: 2 of 6

valid from 15.09.2014

4) steel construction components

Bottom angle (at the bottom)

Purpose: connecting the tank to the foundation by the use of anchor bolts

Steel: S 235

Profile shape: L-profile

Possible dimensions: 70/70/7; 100/75/7; 120/80/10

Welding execution: EN 1090 EXC1, as per ONR 21090

Top angle (on top)

Purpose: for stiffening the panel ring on top; connection possibility for roofs

Steel: S 235

Profile shape: L-profile

Possible dimensions: 70/70/7; 100/75/7; 120/80/10; 150/75/9

Welding execution: EN 1090 EXC1, as per ONR 21090

Wind stiffener

Purpose: protect the tank against denting by wind if the tank is empty

Steel: S 235

Profile shape: flat profile

Possible dimensions: 70/6; 80/8; 100/8; 100/10; 100/12; 120/10; 140/10; 160/10

Welding execution: EN 1090 EXC1, as per ONR 21090

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 2 of 6

Data sheet Version: 1.4

Tank wall page: 3 of 6

valid from 15.09.2014

other:

a) Anchor bolts

The choice of the anchor bolts is done by the GLS Tanks International GmbH and is based on

the static requirements, the installation location and customer needs.

b) Levelling shims

To compensate the tolerated unevenness of the foundation a certain amount of levelling shims

made of steel or galvanized steel is included.

c) Center point sheets

Thin stainless steel plates which are located in the overlapping area of 4 panels, in order to

guarantee a metal seal.

d) nameplate

Every tank is equipped with a nameplate mentioning following details:

project number of the GLS Tanks International GmbH (E - number)

tank diameter

tank heigth

net volume

content or tank type

e) GLS Logo

In case of non-insulated tanks the GLS logo is adhered to a panel. We can offer you to adhere

your leocustomer’s logo on request.

f) Warning signs

For silos with risk of suffocation

For tank in tank solutions

The client is responsible for any other warning signs!

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 3 of 6

Data sheet Version: 1.4

Tank wall page: 4 of 6

valid from 15.09.2014

Glass lining:

Steel segments are made to glass lined panels because of the enameling according to the

guideline of the European Enamel Authority (EEA). This is done in our factory in AUSTRIA,

A-3860 Heidenreichstein. Link: http://www.european-enamel-authority.org

The certificate can be found on our website. This certificate entitles to enamel tanks for

industrial, commercial purposes, silos for animal feed and manure silos.

In most cases the steel surface must be environmental harmful

pretreated before enameling, but not with modern technic and special

types of steel. With the PUESTA method the enamel powder is applied

onto the steel sheets by electrostatic charging. The charging of the

enamel powder is done by ion atmospheric components which are

formed by a corona discharge at the tip of a spray pistol. 45-100 kV are

applied between the pistol and the earthed work piece. The enamel parts

move preferably along the electric field lines to the panel. A for the

production process sufficient adhesion of the powder is caused by

electrostatic forces. A too fast discharge is prevented by the special preparation of the

powders. The special advantage of the electrostatic enamel powder application is the ability to

achieve a particularly high resistance to mechanical stress of the enameled panel with reduced

but uniform layer thicknesses. After that the panel with the powder applied comes into the

enameling oven. The enamel powder melts with the steel at about 840°C to a strong and

permanent fusion.

Monoglass

According to guideline EEA 7.24 „silos for animal feed“

According to guideline der EEA 7.25 „manure silos“

one layer – one burning process

color: blue similar RAL 5004 (blue-black)

layer thickness acc. standard: 0,18 mm to 0,5 mm

5 defects per squaremeter allowed on the inside

Uniglass

According to guideline EEA 7.20 „tanks for industrial purpose“

Two layeres – two burning processes

colors: blue similar RAL 5004 (blue-black)

white similar RAL 9010 (pure white)

green similar RAL 6020 (chrome green)

layer thickness acc. standard: 0,18 mm to 0,5 mm

No defects allowed on the inside

Ultraglass

According to guideline EEA 7.20 „tanks for industrial purpose“

One layer – one burning process with HR Ultra Enamel (High Resistant)

color: blue similar RAL 5004 (blue-black)

layer thickness acc. standard: 0,18 mm to 0,5 mm

No defects allowed on the inside

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 4 of 6

Data sheet Version: 1.4

Tank wall page: 5 of 6

valid from 15.09.2014

Panel edges:

Rounded edges

We have the possibility to round the edges before enameling to prevent damage from

improper installation. This ensures also that the edges are better sourrounded by the enamel.

Example picture rounded edges

Edge protection

As transport and corrosion protection the panel edges are covered with sealant in the factory

(WITHOUT EXTRA COSTS). This type of edge protection is especially important for long

transport distances or long storage times.

Example picture edge protection

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 5 of 6

Data sheet Version: 1.4

Tank wall page: 6 of 6

valid from 15.09.2014

Static design:

Static design of the tank wall according DIN 18800, Part 1 „Steel structures – Design and

construction“ and EN 28765 „Vitreous and porcelain enamels – Design of bolted steel tanks for

storage or treatment of water or municipal or industrial effluents and sludges“.

Calculation of earthquake loads according DIN 4149 „earthquake design loads“ in combination

with Eurocode 8 „Design of structures for earthquake resistance“ or on request according

AWWA D103/09 „Standard for Factory-Coated Bolted Steel Tanks for Water Storage“.

The proofable static of GLS Tanks does not only consider the filled condition incl. the pressure

conditions but also the buckling caused by wind in case the tank is empty!!!

It is not allowed to place a tank in another tank, unless it is specifically allowed in the contract.

The calculation of the proofable static is based on following load information:

Specific weight of medium

Minimum freeboard

Wind load

Snow load

Maximum soil acceleration factor for earthquakes

Loads of the roof in case it is not from GLS (incl. snow load)

Average biogas pressure

Maximum biogas pressure

Maximum vacuum in the tank

Mixer loads of central mixers on the roof

other*

* other: Loads of on-site attachements may not be induced or only after consultion with GLS.

Only the loads mentioned in the quotations load data are calculated in the quotation and

therefore also in the proofable static.

Following varies depending on the provided load information:

panel thickness

size and execution of the bottom and top angles

size, execution and quantity of wind stiffeners

quantity and execution of anchor bolts

size of the roof beams for the glass lined roof

It is important to know that not only the thickness of the panels is crucial for the strength of

the tank. You always have to pay attention to the design of the steel structures.

Company: GLS Tanks International GmbH; Industriestraße 6, 3860 Heidenreichstein

Contact: Tel: +43286253187-0; Fax: +43286253187-820; Email: office@glstanks.com; Web: www.glstanks.com

Bank details: Bank und Sparkassen AG Waldviertel-Mitte, Sparkassenplatz 3, 3910 Zwettl;

IBAN: AT542027200000425090, BIC: SPZWAT21;

UID-Nr.: ATU67138867; Commercial register-Nr.: FN378557b; Tax-Nr.: FA Waldviertel: 213/5723

Place of jurisdiction: Gmünd, Handelsgericht Krems an der Donau

Page 6 of 6

You might also like

- Jar Test Lab ReportDocument14 pagesJar Test Lab Reportilasensei97% (176)

- Title Block A4 PDFDocument1 pageTitle Block A4 PDFsifuszNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- ASTM D-5102 Unconfined Compressive Strenght of Soil-Lime MixturesDocument7 pagesASTM D-5102 Unconfined Compressive Strenght of Soil-Lime MixturesJuanma GarcesNo ratings yet

- LCP Purlins GirtsDocument16 pagesLCP Purlins GirtsGarfieldNo ratings yet

- ReportDocument172 pagesReportAnonymous MBsUH11tNo ratings yet

- Permastore Capacity ChartDocument3 pagesPermastore Capacity ChartMangatur SimamoraNo ratings yet

- Design Report - Chaubara - Rev00Document197 pagesDesign Report - Chaubara - Rev00FAHAD HASSANNo ratings yet

- Storage Tank Sample CalculationDocument28 pagesStorage Tank Sample CalculationDianna LambertNo ratings yet

- Design PDF BommakurDocument113 pagesDesign PDF BommakurRama KrishnaNo ratings yet

- Fram Master LinkDocument2 pagesFram Master LinknamasralNo ratings yet

- Comparision - R2Document57 pagesComparision - R2dhanarajNo ratings yet

- 13130-D-20 Rev 0Document29 pages13130-D-20 Rev 0Hari HaranNo ratings yet

- SPACE TRUSS (Wind Applied+no EqDocument68 pagesSPACE TRUSS (Wind Applied+no EqRamla QureshiNo ratings yet

- Tank 5 m3 API 650 Calculation Report 2024 06 11 14 32 38 V0Document42 pagesTank 5 m3 API 650 Calculation Report 2024 06 11 14 32 38 V0deni prastikoNo ratings yet

- CD Module Datasheet PDFDocument8 pagesCD Module Datasheet PDFunconformistNo ratings yet

- Enquiry Form For Expansion JointsDocument1 pageEnquiry Form For Expansion Jointshcsharma1967No ratings yet

- Car Parking 12196Document18 pagesCar Parking 12196Shaikh Muhammad AteeqNo ratings yet

- Retirement Home Exhaust Stack: Structural CalculationsDocument4 pagesRetirement Home Exhaust Stack: Structural CalculationsMario Sajulga Dela CuadraNo ratings yet

- Ash Water Recovery Sump & Settling Tank-Design Report: Doc. No.: REL-BGCPP-VES-144-R-00813 & - R-00820Document18 pagesAsh Water Recovery Sump & Settling Tank-Design Report: Doc. No.: REL-BGCPP-VES-144-R-00813 & - R-00820Akhilesh Kajarekar100% (1)

- Dome Roof TableDocument1 pageDome Roof Tablejojo_323No ratings yet

- Compartment SiloDocument7 pagesCompartment Siloafzal samaNo ratings yet

- Zn-Al Tank Nozzels ScheduleDocument5 pagesZn-Al Tank Nozzels SchedulePravin BoteNo ratings yet

- DES_204_0551_14635_SGP INDUSTRIAL _BLDG A_REV00Document11 pagesDES_204_0551_14635_SGP INDUSTRIAL _BLDG A_REV00chandra mohanNo ratings yet

- DmTank Ring Wall Foundation+&+Annular+RaftDocument5 pagesDmTank Ring Wall Foundation+&+Annular+RaftRM PaduaNo ratings yet

- VALLEY Civil Design CriteriaDocument40 pagesVALLEY Civil Design Criteriaraj vaddi100% (1)

- Water Tank Structures DrawingsDocument2 pagesWater Tank Structures Drawingsvaibhav dahiwalkarNo ratings yet

- Standing Seam Systems Product Data Sheet PDFDocument7 pagesStanding Seam Systems Product Data Sheet PDFCal MoranNo ratings yet

- Calculation of Crackwidth: Inputs To Be Given by User Outputs From ExcelDocument10 pagesCalculation of Crackwidth: Inputs To Be Given by User Outputs From Excelnaveenpnaidu1No ratings yet

- Beam End Force SummaryDocument1 pageBeam End Force SummaryAloNo ratings yet

- API Standard Storage Tank Data Sheet Rev 0Document3 pagesAPI Standard Storage Tank Data Sheet Rev 0Laura Carvajal100% (1)

- Unipole Design OutputDocument5 pagesUnipole Design OutputDanial JohanesNo ratings yet

- S-08 Stair Cabin and L.M Room Layout DetailsDocument1 pageS-08 Stair Cabin and L.M Room Layout DetailsHardik SorathiyaNo ratings yet

- Reference Description of Problem Values Units: Infomile SolutionsDocument3 pagesReference Description of Problem Values Units: Infomile SolutionsdhawanaxitNo ratings yet

- Stoplog Staad ReportDocument6 pagesStoplog Staad Reportvinay1999No ratings yet

- CNA PresentationDocument27 pagesCNA PresentationMayur KhirodeNo ratings yet

- Free Resume For Experienced Software Engineer TemplateDocument1 pageFree Resume For Experienced Software Engineer TemplateMohammad IkkoNo ratings yet

- N-15323 H 5100 J 9619 RaDocument31 pagesN-15323 H 5100 J 9619 RaanoginNo ratings yet

- (P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456Document25 pages(P0) R C Columns-Rectangular-Biaxial Bending-Section design-IS456KhanthavelNo ratings yet

- Sand Asphalt Base Course 2260Document4 pagesSand Asphalt Base Course 2260Tinh HuynhNo ratings yet

- Bolted Water Tank SpecsDocument7 pagesBolted Water Tank SpecsMakulay Ang BuhayNo ratings yet

- Esdep Lecture Note (Wg15)Document23 pagesEsdep Lecture Note (Wg15)mabuhamdNo ratings yet

- Drawing of Pumphouse and Water TankDocument7 pagesDrawing of Pumphouse and Water TankNguyễn Đức HữuNo ratings yet

- RCC41 Continuous Beams (A & D)Document17 pagesRCC41 Continuous Beams (A & D)Zayyan RomjonNo ratings yet

- Typical TemplateDocument4 pagesTypical TemplateНемања КараклајићNo ratings yet

- Foundations Ambient Temperature Storage Tanks: ContentsDocument8 pagesFoundations Ambient Temperature Storage Tanks: Contentszoran cukovicNo ratings yet

- Failure Modes in BeamsDocument5 pagesFailure Modes in BeamsADMIN AAONo ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- IA-PB-10162 - R0 Design Report - 20-01-2016Document52 pagesIA-PB-10162 - R0 Design Report - 20-01-2016consultantvj2010No ratings yet

- Monorail Overhead CraneDocument8 pagesMonorail Overhead Cranesherwinpons2003100% (1)

- Design Philosophy For 120X40M Peb ShedDocument6 pagesDesign Philosophy For 120X40M Peb ShedabbasamuNo ratings yet

- 181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFDocument17 pages181-F Secondary Reformer Jacket Cooling Water Pit - R0 (1) - 12082018 PDFManish542No ratings yet

- Design Simple Support Beam With 2-Load (Created by Bundit S.)Document2 pagesDesign Simple Support Beam With 2-Load (Created by Bundit S.)Nopparut100% (1)

- Lighting PolesDocument32 pagesLighting PolesSanthosh OsNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- Weight+&+Bolting LseDocument38 pagesWeight+&+Bolting LseAlexandre Freitas0% (1)

- Zatvarač 4201504 Dokaz o KvalitetuDocument2 pagesZatvarač 4201504 Dokaz o KvalitetuElvedina DelićNo ratings yet

- Quotation A-180164Document15 pagesQuotation A-180164MantenimientoNo ratings yet

- D8C18 0304 08rimbaDocument3 pagesD8C18 0304 08rimbaAnonymous lv8SNRyNo ratings yet

- PG 45-48 Strainers PDFDocument4 pagesPG 45-48 Strainers PDFChamitha MadushanNo ratings yet

- 017 - Gas Solutions - 16-01-2024 - ShibinDocument5 pages017 - Gas Solutions - 16-01-2024 - ShibinAshish KatiyarNo ratings yet

- Chemistry (PT-2) : Topic: SolutionDocument2 pagesChemistry (PT-2) : Topic: SolutionchitranshNo ratings yet

- PPSC Exam Past Paper 2Document4 pagesPPSC Exam Past Paper 2Muhammad RawasNo ratings yet

- International Perspectives On Green and Sustainable Chemistry Education Via Systems ThinkingDocument11 pagesInternational Perspectives On Green and Sustainable Chemistry Education Via Systems ThinkingShorihatul InayahNo ratings yet

- Class 11 Chemistry Sample PaperDocument6 pagesClass 11 Chemistry Sample PaperDamodar KasukurthiNo ratings yet

- Deluge ValveDocument10 pagesDeluge ValvevpnrrajaNo ratings yet

- Paper 2: Science TestDocument54 pagesPaper 2: Science Testptt b20No ratings yet

- Material GradeDocument8 pagesMaterial Gradegabeng2023No ratings yet

- Introduction To BioinformaticsDocument17 pagesIntroduction To BioinformaticsPraneeth VNo ratings yet

- Spic Group ProfileDocument15 pagesSpic Group ProfileAmbrose JayasinghNo ratings yet

- Rate of Reaction Between Sodium Thiosulphate and Hydrochloric AcidDocument3 pagesRate of Reaction Between Sodium Thiosulphate and Hydrochloric Acidfezilezulu315No ratings yet

- 61ed603c67fcea0018b77554 - ## - CH 16 Chemistry in Everyday LifeDocument7 pages61ed603c67fcea0018b77554 - ## - CH 16 Chemistry in Everyday LifeABHISHEK SINGH THAKURNo ratings yet

- Biosci 203 Lab 1Document5 pagesBiosci 203 Lab 1govicky565No ratings yet

- Ceran XM 220Document14 pagesCeran XM 220noar anwarNo ratings yet

- Step by Step Protocol For Multiplex PCR With The FastStartHigh Fidelity PCR System and The PCR Optimization KitDocument28 pagesStep by Step Protocol For Multiplex PCR With The FastStartHigh Fidelity PCR System and The PCR Optimization KittanjentNo ratings yet

- Cat 2 ScienceDocument11 pagesCat 2 ScienceAubreyNo ratings yet

- Sodium Formate 98% Msds InnoasDocument6 pagesSodium Formate 98% Msds Innoasjooyaa30No ratings yet

- C5 - The Microbiology of Food PreservationDocument59 pagesC5 - The Microbiology of Food Preservationalmanguyen133No ratings yet

- DPP - Cell The Unit of LifeDocument9 pagesDPP - Cell The Unit of LifeKisna guptaNo ratings yet

- United States Patent: Finley Et AlDocument44 pagesUnited States Patent: Finley Et AlM FNo ratings yet

- Chemical Hazard Inventory Identification Form: Custodial Contact: Gregorio Montejo Work AreaDocument3 pagesChemical Hazard Inventory Identification Form: Custodial Contact: Gregorio Montejo Work AreaidahssNo ratings yet

- Geo Environmental Assessment of Al RamthDocument12 pagesGeo Environmental Assessment of Al RamthytrisNo ratings yet

- Differences Between ASTM A53 B and ASTM A106 B Steel PipeDocument4 pagesDifferences Between ASTM A53 B and ASTM A106 B Steel PipeAmeer uddinNo ratings yet

- and Electro Dialysis VIT CCDocument10 pagesand Electro Dialysis VIT CClalithkumaran LNo ratings yet

- Journal of Water Process Engineering: SciencedirectDocument6 pagesJournal of Water Process Engineering: SciencedirectDBS AuthorityNo ratings yet

- LECT 11 - 15 Proteins and Amino Acids Objectives - DescriptivesDocument24 pagesLECT 11 - 15 Proteins and Amino Acids Objectives - DescriptivesNivedhaNo ratings yet

- BIO108-Lab03 Diffusion & OsmosisDocument9 pagesBIO108-Lab03 Diffusion & OsmosisABBIE KIETH V. AGUILARNo ratings yet

- Lecture 1 - Introduction To Drug DeliveryDocument32 pagesLecture 1 - Introduction To Drug DeliveryASMANo ratings yet

- UACE Biology 2015 Paper 2 Marking Guide 1Document13 pagesUACE Biology 2015 Paper 2 Marking Guide 1jowickjNo ratings yet