Stacker Preventive Maintenance Weekly: Clean and Inspect

Stacker Preventive Maintenance Weekly: Clean and Inspect

Uploaded by

Fabio GonzalezCopyright:

Available Formats

Stacker Preventive Maintenance Weekly: Clean and Inspect

Stacker Preventive Maintenance Weekly: Clean and Inspect

Uploaded by

Fabio GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Stacker Preventive Maintenance Weekly: Clean and Inspect

Stacker Preventive Maintenance Weekly: Clean and Inspect

Uploaded by

Fabio GonzalezCopyright:

Available Formats

STACKER PREVENTIVE MAINTENANCE WEEKLY

WW Machine S/N

PM Date Next PM Date

Verify

- Tray Present Sensor Sensitivity

- Robot Calibration Sensitivity

( Each Robot has two Calibration Sensor Amps and two fiber optic sensor with focal lens.

Insure the fiber optic sensor and focal lens are present, not damaged and operational )

- Nest Sensor Sensitivity

( The Nest on Table sensors use through beam technology, so ensure that the transmit and receive

lenses are aligned and facing each other )

- Check Temperature Controller parameter setting.

Zone# 1 : 220° ± 5°C, Zone# 2 : 210° ± 5°C, Zone# 3 : 200° ± 5°C, Zone# 4 : 210° ± 5°C, Zone# 5 : 220° ± 5°C

Clean and Inspect

- Main Air regulator Set Point

- Clean Top on Machine.

Wipe dust and debris from the top on the machine with EDS cleaner and a blue Tex-wipe.

- Nest Fixtures

i. Check fixture hours and inspect for cleanliness. Clean off any dirt and debris with a tech swab

or tech wipe. Do not use Isopropyl Alcohol

ii. Inspect the Nest Fixtures for integrity. Insure that the two(2) dowel pins are installed.

Replace or install dowel pins if damaged or missing. Insure that the base plate screws are

tight and flush. Tighten if needed with hex wrench.

- Clean ID fixture ( send thru again washing machine after sand blasting ).

Switches

- Check to ensure all door safety switches and emergency stops switch function properly.

Part Replacement

- Inspect and replace the End Effector Suction Cups for damage.

Lubrication

- Lubricate Robot shaft with Mobil grease.

NOTE : 1. If anything unusual, contact your supervisor immediately.

2. For more detail explanation regarding the Preventive Maintenance, please refer to the

Equipment Manufacturer Technical Reference Manual.

3. Do not use Isopropyl Alcohol to clean any stainless steel parts. Isopropyl Alcohol will cause the

stainless steels parts to rust

COMMENTS :

Serviced By

Maintenance Group

Checked By

Page 1of 1 SF3088PN, Rev. A

Unless otherwise specified, if this is a paper copy, it is uncontrolled and you must verify the current revision.ECO 0403-705-RRAM

You might also like

- Actual Board Profed 2022Document242 pagesActual Board Profed 2022Eunice Grace Galvez90% (10)

- Maseve Training Matrix - ConstructionDocument1 pageMaseve Training Matrix - ConstructiongrantNo ratings yet

- Eng Aad Ul Cert E28476 20090527 C1 FDocument16 pagesEng Aad Ul Cert E28476 20090527 C1 FLeon SellersNo ratings yet

- IKEA Catalogue 2012Document189 pagesIKEA Catalogue 2012nguyễn thăng vănNo ratings yet

- F048-QC Earth Pit ChecklistDocument1 pageF048-QC Earth Pit ChecklistGopal Nagal - PadamsNo ratings yet

- Factory Inspection ChecklistDocument1 pageFactory Inspection ChecklistYoung BoyNo ratings yet

- Carpenter Routine Checklist: Maintenance Department AL FANAR Facility ManagementDocument7 pagesCarpenter Routine Checklist: Maintenance Department AL FANAR Facility ManagementMohamed GamalNo ratings yet

- Sop For Electrical Maintenance FurnaceDocument2 pagesSop For Electrical Maintenance FurnaceMurali Krishnan NairNo ratings yet

- 7 Method of Statement FF - FM 200Document6 pages7 Method of Statement FF - FM 200hazro lizwan halimNo ratings yet

- Air Compressor NotesDocument10 pagesAir Compressor NotesIrfan Shaikh0% (1)

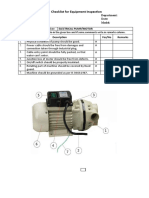

- Checklist For Equipment Inspection Electrical Pump MotorDocument1 pageChecklist For Equipment Inspection Electrical Pump MotorKaif Siddique100% (1)

- AC Check List Every MonthDocument2 pagesAC Check List Every Monthhamed hassanNo ratings yet

- Inspection Checklist For Spill KitsDocument1 pageInspection Checklist For Spill KitsMd Altaf ShamimNo ratings yet

- EMP ChecklistDocument1 pageEMP ChecklistAmirul ArifNo ratings yet

- Cable Trench and Bedding Quality Control and Inspection Report FormDocument1 pageCable Trench and Bedding Quality Control and Inspection Report FormHesham Helal100% (1)

- Eyewashinspection Checklist 2012 - 0Document1 pageEyewashinspection Checklist 2012 - 0perezismaelNo ratings yet

- Sop For DG SetsDocument11 pagesSop For DG SetsArun SarmaNo ratings yet

- Alikraft Elevator - O&m ManualDocument28 pagesAlikraft Elevator - O&m Manualamarsingh choudhary100% (1)

- Electric Generator Inspection Checklist (Insert Your Logo)Document1 pageElectric Generator Inspection Checklist (Insert Your Logo)Kevin MichaelNo ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- Standard Operating Procedure: Induction Motor (HT)Document3 pagesStandard Operating Procedure: Induction Motor (HT)asyyasNo ratings yet

- Basic Diesel Generator Maintenance Checklist - SafetyCultureDocument4 pagesBasic Diesel Generator Maintenance Checklist - SafetyCulturedaneNo ratings yet

- Checklist - Inspection of Wate Cum Foam MonitorDocument1 pageChecklist - Inspection of Wate Cum Foam Monitorshubhankar.patidar05No ratings yet

- 2.0 Mock Drill - Power FailureDocument5 pages2.0 Mock Drill - Power Failure00083583rfNo ratings yet

- DEPRECIATION RATE FOR MES INSTALLATIONS AMENDMENT 20 Mar 17 PDFDocument4 pagesDEPRECIATION RATE FOR MES INSTALLATIONS AMENDMENT 20 Mar 17 PDFAnimesh SahaNo ratings yet

- Checklist OHCDocument2 pagesChecklist OHCNicolas RobinNo ratings yet

- SMP of Earthing Resistance MeasurementDocument2 pagesSMP of Earthing Resistance MeasurementJitendra kumarNo ratings yet

- Cooling Towers: Hvac Plant Do'S and Don'TsDocument11 pagesCooling Towers: Hvac Plant Do'S and Don'TsSYED SHAHBAZ100% (1)

- Sop of HT Breaker 250 MWDocument1 pageSop of HT Breaker 250 MWVikashJain100% (1)

- RH-1 Log-Bvar TBT & PTW 19Document4 pagesRH-1 Log-Bvar TBT & PTW 19Syed Mohd MehdiNo ratings yet

- Pre - Start Up Checklist: S.No. DescriptionDocument2 pagesPre - Start Up Checklist: S.No. DescriptionAziz UllahNo ratings yet

- Emergency Eyewash Shower Sop FinalDocument8 pagesEmergency Eyewash Shower Sop FinalDominic EmerencianaNo ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- ChecklistDocument14 pagesChecklistInstrument SCINo ratings yet

- F-HR-21 Lux Level StanadardDocument10 pagesF-HR-21 Lux Level StanadardHarikesh YadavNo ratings yet

- Adobe Scan 15 Feb 2022Document2 pagesAdobe Scan 15 Feb 2022B&R HSE BALCO SEP SiteNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005100% (1)

- SOP - Fan Coil UnitDocument27 pagesSOP - Fan Coil UnitMEERAN NAINAR MOHAMEDNo ratings yet

- Standard Operating Procedure For Earth Pit MaintenanceDocument2 pagesStandard Operating Procedure For Earth Pit MaintenanceMANOJ KUMARNo ratings yet

- CS 3 Phase Inverters Commissioning Checklist FINALDocument5 pagesCS 3 Phase Inverters Commissioning Checklist FINALarunghandwalNo ratings yet

- Engineering Technology Notes Form4Document16 pagesEngineering Technology Notes Form4Dylan Hon100% (1)

- Panasonic Timer SwitchDocument3 pagesPanasonic Timer SwitchChristian SantamariaNo ratings yet

- Specification For Battery and Battery Charger (Tripping Unit) For 11Kv Indoor Switchgear OfferedDocument1 pageSpecification For Battery and Battery Charger (Tripping Unit) For 11Kv Indoor Switchgear OfferedAnas MemonNo ratings yet

- 7 QC ToolsDocument155 pages7 QC Toolswintoday01No ratings yet

- BDBDocument2 pagesBDBPrabagaran PrtNo ratings yet

- 13 Fan Coil Unit: Location: - No.Document1 page13 Fan Coil Unit: Location: - No.JIJUNo ratings yet

- Smoke Detector CheclistDocument1 pageSmoke Detector CheclistZaidanp100% (1)

- Appendix - Fire Protection Preventive Maintenance ScheduleDocument5 pagesAppendix - Fire Protection Preventive Maintenance Schedulemohamed attiaNo ratings yet

- Risk Assessment For Gypsum Board Installation WorksDocument9 pagesRisk Assessment For Gypsum Board Installation WorksMurtada OmerNo ratings yet

- 238424908-JSA-for-Electrical-Testing-đã chuyển đổiDocument5 pages238424908-JSA-for-Electrical-Testing-đã chuyển đổiMon Trang NguyễnNo ratings yet

- E 001B1 MotorDocument2 pagesE 001B1 MotorBhihi RajaNo ratings yet

- PFI Panel Erection ChecklistDocument2 pagesPFI Panel Erection ChecklistMohammad NasarNo ratings yet

- 08354C T640 User ManualDocument86 pages08354C T640 User ManualwebeoalpeNo ratings yet

- Building Works at Hougang Town: Daily Housekeeping ChecklistDocument4 pagesBuilding Works at Hougang Town: Daily Housekeeping ChecklistALFREDO JR. ARIOS CLARONo ratings yet

- Earth PitDocument2 pagesEarth PitJayam KondanNo ratings yet

- Membrane CleanerDocument2 pagesMembrane CleanerJoselito Cortes100% (1)

- Sop Grinder Angle GrinderDocument2 pagesSop Grinder Angle Grindernur syamimiNo ratings yet

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 pagesSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNo ratings yet

- Elec Check List - Earthing SystemDocument1 pageElec Check List - Earthing Systemcherif yahyaouiNo ratings yet

- Auto Buff PM Check ListDocument1 pageAuto Buff PM Check ListPiyush VyasNo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Vibration Meter User's Manual: Model Gm63ADocument10 pagesVibration Meter User's Manual: Model Gm63Ayvan.waylandNo ratings yet

- Daily AFF Inspection ChecklistDocument1 pageDaily AFF Inspection ChecklistFabio GonzalezNo ratings yet

- Amistar #: Daily Amistar Checklist: Inspection TasksDocument1 pageAmistar #: Daily Amistar Checklist: Inspection TasksFabio GonzalezNo ratings yet

- Daily Stacker Inspection ChecklistDocument2 pagesDaily Stacker Inspection ChecklistFabio Gonzalez0% (1)

- CHART BY LINE (March)Document5 pagesCHART BY LINE (March)Fabio GonzalezNo ratings yet

- Map To Kelly PenangDocument1 pageMap To Kelly PenangFabio GonzalezNo ratings yet

- Lean Overview For OrientationDocument14 pagesLean Overview For OrientationFabio GonzalezNo ratings yet

- Downtime Pareto-MAR'09Document37 pagesDowntime Pareto-MAR'09Fabio GonzalezNo ratings yet

- Map To Kelly PenangDocument1 pageMap To Kelly PenangFabio GonzalezNo ratings yet

- E060 Manual of Evaluation Process 6-01-07Document8 pagesE060 Manual of Evaluation Process 6-01-07Fabio GonzalezNo ratings yet

- SMT Downtime: B C D E G Total HrsDocument1 pageSMT Downtime: B C D E G Total HrsFabio GonzalezNo ratings yet

- COP 15: The Copenhagen Accord: A Positive Step But Not Ambitious EnoughDocument16 pagesCOP 15: The Copenhagen Accord: A Positive Step But Not Ambitious EnoughFabio GonzalezNo ratings yet

- Downtime Pareto-FEB'09Document37 pagesDowntime Pareto-FEB'09Fabio GonzalezNo ratings yet

- Juki Revised Top BotDocument12 pagesJuki Revised Top BotFabio GonzalezNo ratings yet

- Linked To Loading Plan NEW SMT UPHDocument39 pagesLinked To Loading Plan NEW SMT UPHFabio GonzalezNo ratings yet

- Juki Revised New Uph (Latest 28.2.10 12.10PM)Document95 pagesJuki Revised New Uph (Latest 28.2.10 12.10PM)Fabio GonzalezNo ratings yet

- Sistem of EquetionDocument22 pagesSistem of EquetionArif KuncoroNo ratings yet

- Economical Metal Anchor For Drywall and Hollow BlockDocument3 pagesEconomical Metal Anchor For Drywall and Hollow BlockPedro LanuzaNo ratings yet

- Surpresa para Ni KikoDocument20 pagesSurpresa para Ni KikoLara Montera100% (1)

- Mooc ReportDocument16 pagesMooc ReportSparsh DhamaNo ratings yet

- Beginner Guide For Primavera Part 1Document6 pagesBeginner Guide For Primavera Part 1meshmeshNo ratings yet

- 2017 SP The Killing of A Sacred Deer Final ScriptDocument102 pages2017 SP The Killing of A Sacred Deer Final ScriptjasonbkohlNo ratings yet

- Philips 29PT5642 CH L04L AA 312278514440Document94 pagesPhilips 29PT5642 CH L04L AA 312278514440whatthecussNo ratings yet

- War of Roses Research PaperDocument6 pagesWar of Roses Research Papermoykicvnd100% (1)

- EXAMEN PARCIAL N°2 CUESTIONARIO - Revisión Del Intento FinalDocument6 pagesEXAMEN PARCIAL N°2 CUESTIONARIO - Revisión Del Intento FinalcladavidNo ratings yet

- Technical Specification For The Purchase of 1 Unit of 240HP Crawler TractorDocument14 pagesTechnical Specification For The Purchase of 1 Unit of 240HP Crawler TractoragegnehutamiratNo ratings yet

- 1st Quarter Performance Task FREE FALLDocument28 pages1st Quarter Performance Task FREE FALLNimrod KoNo ratings yet

- Module 3 1Document25 pagesModule 3 1Luke aronNo ratings yet

- An 3100D AnnunciatorDocument4 pagesAn 3100D AnnunciatorscribdkhatnNo ratings yet

- ANT282 Doc 9Document8 pagesANT282 Doc 9Cagas, Alexa Jean CamachoNo ratings yet

- Porter Ch01Document40 pagesPorter Ch01navin9849No ratings yet

- EuphoriaDocument2 pagesEuphoriaAmit MalhotraNo ratings yet

- Recent Applications of Phased Array Inspection For Turbine Components and Welded StructuresDocument8 pagesRecent Applications of Phased Array Inspection For Turbine Components and Welded Structureskoohestani_afshinNo ratings yet

- Root Cause Investigation of A Transformer Surge Arrester FailureDocument29 pagesRoot Cause Investigation of A Transformer Surge Arrester Failuresulemankhalid0% (1)

- Installment Payment AgreementDocument1 pageInstallment Payment AgreementBaisy VillanozaNo ratings yet

- Fire Safety Easy Quiz - BrainPOP JRDocument1 pageFire Safety Easy Quiz - BrainPOP JRleduylamNo ratings yet

- The Oring and Historical Development of Comparative EducationDocument5 pagesThe Oring and Historical Development of Comparative Educationndubissi88% (8)

- Quiz Exercises 9 Reported Speech 9Document2 pagesQuiz Exercises 9 Reported Speech 9Joséphine NancasseNo ratings yet

- Conclusion and RecommendationsDocument3 pagesConclusion and RecommendationsRomelyn Suyom PingkianNo ratings yet

- Power Power Point PresentationDocument15 pagesPower Power Point PresentationShashie Mae BalanzaNo ratings yet

- Uponor Folder Ecoflex Quick and Easy en 1089189Document8 pagesUponor Folder Ecoflex Quick and Easy en 1089189ciocarda andreeaNo ratings yet

- IMSLP345125 PMLP453875 SATB - Score PDFDocument57 pagesIMSLP345125 PMLP453875 SATB - Score PDFJuanesCastroNo ratings yet

- Lab Sheet 6Document6 pagesLab Sheet 6padmaNo ratings yet