Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Uploaded by

Kai FrankCopyright:

Available Formats

Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Uploaded by

Kai FrankOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Code of Practice RC 50002 Registration of Crushed Rock Mix Designs July 2017 PDF

Uploaded by

Kai FrankCopyright:

Available Formats

Code of Practice

Registration of RC 500.02

Crushed Rock Mixes June 2017

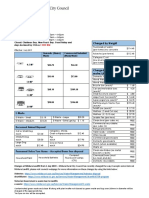

Table 1A - Classes of Crushed Rock

1. Introduction

This Code of Practice describes the process to be undertaken Material Description

when registering any crushed rock mix (including cement

treated crushed rock) for use in conjunction with relevant A premium cohesive pavement base material for

VicRoads Standard Specification for Roadworks and unbound pavements where a very high standard

Bridgeworks (including Sections 812, 815 and 818). of surface preparation for a sprayed sealed or

A crushed rock is a material composed of graded coarse and Class 1 thin asphalt surfacing is required. It has a

fine aggregate components produced by the crushing, scalping minimum plasticity index requirement and can

and screening of a raw rock feed source, Newer Basalt Surface have an additional requirement for maximum

Spalls (NBSS) and/or crushed concrete, and may also be a permeability when used for heavy duty unbound

blend of components which includes limited quantities of pavements.

supplementary materials.

A high quality pavement base material for

A crushed rock mix must be registered for any crushed rock unbound flexible pavements in locations where

product supplied to VicRoads funded works. This includes a very high standard of surface preparation may

Class 1, 2, 3 and 4 crushed rock and manufactured Type A not be required. Class 2 crushed rock does not

material. Class 2

have a minimum plasticity index or a maximum

The registration of a crushed rock mix will not be permitted, permeability requirement.

where it is intended that different source rock types be Recycled materials are permitted for Class 2

combined during the primary or secondary crushing processes. crushed rock.

Registration in accordance with this Code of Practice does not

warrant the adequacy of the production, delivery, placement or A high quality upper subbase material for heavy

compaction processes and does not guarantee the handling duty unbound flexible pavements. It may have a

properties or performance of the crushed rock mix. minimum permeability requirement to provide

positive drainage to the sub-surface drains and

Submitted mixes must comply with the relevant physical overlying unbound pavement layer. Where

properties in Section 3 and any other specified requirements specified, Class 3 may be used as base for

applicable for that particular class of crushed rock, unless lightly trafficked pavements provided the

otherwise approved by VicRoads. Class 3 material produces sufficient cohesive fines

during compaction.

Registration of a crushed rock or crushed concrete mix does

not guarantee the handling properties or performance of the It is also commonly used with the addition of

mix nor relieve the Contractor/Supplier of any contractual cement as a subbase layer in deep strength

obligations in regard to rectification of defects. asphalt pavements.

Contractors/Suppliers are reminded that all specified Recycled materials are permitted for Class 3

requirements for the crushed rock or crushed concrete product crushed rock.

must still be consistently met.

A lower subbase material for heavy duty

2. Definitions unbound and/or bound pavements or a subbase

Class 4 for most other types of pavements. It may have

2.1. Classes of Crushed Rock a maximum permeability requirement.

Recycled materials are permitted for Class 4

Table 1A provides a description of the crushed rock classes crushed rock.

that are covered by this Code of Practice.

RC 500.02 Page 1 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

2.2. Other Definitions 3. Crushed Rock Mix

Assigned Los Angeles Value (LAV) Crushed rock mixes nominated for use on VicRoads funded

projects shall be registered and current prior to the

The assigned Los Angeles Value is a hardness rating derived

commencement of the supply to any works.

from Los Angeles Value test results on representative crushed

rock products during VicRoads accreditation process. The Sources used in crushed rock mixes must conform to the

value is assigned to each source by VicRoads on an annual applicable requirements in VicRoads Standard Section 801 -

basis. Source Rock for the Production of Crushed Rock and

Aggregates.

Cement Treated Crushed Rock (CTCR)

CTCR is a registered mixture of crushed rock, cement and Crushed rock mixes submitted for registration must comply

water produced at a controlled mixing plant to close tolerances with the applicable requirements of this Code (refer Section 3)

of grading, moisture content and binder content. and where relevant, any other requirements contained in

VicRoads Standard Sections 801, 812, 815, and 204, unless

Coarse & Fine Aggregates otherwise approved by VicRoads.

For the purposes of this Code, fine aggregate shall be the Crushed rock mixes submitted using accredited quarry sources

portion of the crushed rock mixture passing the 4.75 mm AS will be registered for all classes of crushed rock. Those mixes

sieve, and coarse aggregates shall be the portion of the which contain appreciable recycled material components

crushed rock mixture retained on the 4.75 mm AS sieve. (including NBSS) will be registered only for Class 2 crushed

Crushed Brick rock or lesser products and conditions may apply.

A recycled crushed brick is a material which principally consists Class 2 crushed rock containing recycled materials (> 10% in

of crushed fired brick, but may also contain crushed concrete, total) will be generally registered for light duty pavements only.

aggregate and concrete paste. Mud brick or non fired brick Any component of a crushed rock mix which is imported from

shall not be used. either a different source or location within a quarry/recycling

Electric Arc Furnace (EAF) Slag facility, or manufactured from a different sources to that of the

primary coarse aggregate source will be regarded as a

EAF slag is a recycled slag by-product from the production of supplementary material.

steel using an electric arc furnace. Once cooled, the slag by-

product is crushed, graded and suitably conditioned (by Crushed rock products may contain crushed or appropriately

weathering to reduce free lime content) to produce a non processed supplementary materials (such as concrete, brick,

expansive aggregate. recycled glass, RAP, EAF slag, clayey sand, clay filler, etc)

provided the permitted maximum percentage (by mass) of

Glass Fines supplementary material for that class of crushed rock and that

Glass fines are recycled glass cullet crushed to a cubic shape registered mix is adhered to.

and passing the 4.75 mm AS sieve. Components of crushed rock blends must individually comply

with the relevant requirements of Section 3, prior to blending,

Light Duty Base Pavement unless otherwise approved by VicRoads.

Light duty base pavement is the layer directly beneath the Where an accredited quarry source produces a manufactured

bituminous surfacing on lightly trafficked roads (i.e. roads Type A material, the material produced shall meet the

carrying < 3500 Average Annual Daily Traffic (AADT) and requirements for Type A material in VicRoads Standard

< 10% heavy vehicles). Section 204 and any contract specific requirements.

Note: Any blend of recycled materials proposed for use as

Plant Mixed Wet Mix Crushed Rock (PMWMCR) earthworks fill material on VicRoads contracts shall be registered

Plant mixed wet mix crushed rock is a mixture of crushed rock to meet VicRoads Standard Section 204 requirements.

and water, produced at a controlled mixing plant to close All testing associated with crushed rock mixes, crushed rock

tolerances of moisture content based on the modified Optimum products and crushed rock components shall be undertaken in

Moisture Content (OMC) of the material. accordance with the relevant test method(s) for the application

Reclaimed Asphalt Pavement (RAP) as listed in VicRoads Codes of Practice (including RC 500.16 -

Selection of Test Methods for the Testing of Materials and

Reclaimed asphalt pavement is asphalt removed from an Work), and any referenced VicRoads Standard Specification

existing asphalt pavement, and re-processed by crushing Sections and Test Methods as specified in VicRoads Standard

and/or screening for recycling into new asphalt. Section 175 at the time of contract award.

Recycled Material In some cases, the registration of a crushed rock mix may only

apply to a specific project or pavement construction application,

Materials obtained from a construction and/or demolition site

e.g. where requirements, such as permeability, are specified.

which are crushed and re-processed to produce a crushed

rock or a supplementary material. A crushed rock mix can be registered with or without submitting

permeability values. However, where a crushed rock mix is

Supplementary Material

proposed for use on a VicRoads contract with specified

A durable material added to a crushed rock to improve its permeability requirements, the Supplier will be required to

workability and physical properties. A recycled material may be submit test reports with conforming permeability values to

used as a supplementary material. VicRoads Technical Services.

RC 500.02 Page 2 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

VicRoads shall be notified promptly of any changes to the all results conform within the limits of these tables;

components of a registered mix. VicRoads will assess whether and

the registered mix can be amended or if the registration of a

the averages of the test results for each specified

new mix will be required. No more than two amendments can

sieve size consistently lie either towards the coarser

be made to any particular mix design before that design is

or the finer limit of the specified grading envelope,

considered to be no longer valid.

i.e. do not vary from coarser to finer for different

sieve sizes.

4. Frequency of Testing 4.4. Departures from Limits

If any subsequent test result falls within the specification limits,

4.1. Default Testing

but outside the nominated two thirds of the specified limits, this

The frequency of testing of crushed rock products shall be in shall be considered a minor departure.

accordance with the requirements of VicRoads Standard

Section 812, Clause 812.12 (Table 812.121) and VicRoads If any subsequent test result falls outside the specification

Standard Section 815, Clause 815.14 (Table 815.141). limits, this shall be considered a major departure.

Testing undertaken at this frequency for material which is Table 1B outlines the actions to take if a minor or major

shown to meet specification requirements is considered to have departure occurs.

demonstrated that the specified physical properties of the

registered crushed rock mix have been consistently met by the Table 1B – Actions to take in case of minor or major

departures

supplier.

Result of Resulting Test

Departure Action Frequency

Retest

4.2. Reduced Testing

The supplier may elect to halve the frequency of testing for Pass Continue

specified tests in accordance with the above clauses, where Revert to 1 test per

Minor

10 successive passes are achieved. If any subsequent test Minor Retest Departure 1000 tonnes #

result fails, refer to VicRoads Standard Sections 812.12 or

Major Revert to 1 test per

815.14, as applicable for process requirements. 500 tonnes ##

Departure

4.3. Further Reduced Testing Pass Continue

A supplier may apply for a further reduction in test frequency Minor Revert to 1 test per

for “grading” and/or “unsound rock content” for a specific Major Retest Departure 500 tonnes ##

crushed rock mix to 1 test per 2,000 tonnes or part thereof if it

Major Revert to 1 test per

can be demonstrated that the supplier can consistently produce Departure 500 tonnes ##

within two thirds of the allowed “grading” and/or “unsound and

marginal” range as specified in Tables 2, 3, 4, 5, 6 and 8 of this # the supplier shall not return to one test per

document. The application for this further reduction is to be 2,000 tonnes until a further 25 successive test

results fall within the nominated two thirds of

submitted with the registration of the crushed rock mix, unless the allowed range

otherwise approved by VicRoads.

## the supplier shall not return to one test per

To demonstrate this process capability, the supplier must submit: 1,000 tonnes until a further ten successive test

results comply with the specified requirements

a minimum of 50 consecutive results complying with

the specification limits of Tables 2, 3, 4, 5, 6 and 8;

and

the most recent 25 consecutive results, all falling within

two thirds of the allowed “grading” and “unsound”

range as specified in Tables 2, 3, 4, 5, 6 and 8.

For gradings, the supplier shall nominate a range within two

thirds of the allowed range for each sieve size, as

demonstrated by the most recent 25 consecutive test results.

The middle (average) of this nominated range need not be the

middle of the allowed range as specified in Tables 2, 3, 4, 5,

and 6, provided that:

RC 500.02 Page 3 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

5. Grading of Uncompacted Crushed Rock & 5.2. Class 3 Crushed Rock

PMWMCR

The grading of 20 mm Class 3 crushed rock shall comply with

After completion of production, but before compaction, Class 1, Table 4.

2, 3 and 4 crushed rock products and PMWMCR must comply

with the relevant grading requirements of Tables 2, 3, 4, 5 and Table 4 – Grading Limits for 20 mm Class 3 CR

6 corresponding to the assigned LAV of the material source.

Test Value before Compaction –

Sieve Size

5.1. Class 1 and 2 Crushed Rock AS (mm)

Limits of Grading

(% Passing by mass)

The grading of 20 mm Class 1 and Class 2 crushed rock with

an assigned Los Angeles Value ≤ 25 shall comply with the LAV ≤ 25 LAV ≥ 26

requirements of Table 2, and all other sources with LAV ≥ 26

shall comply with Table 3. 26.5 100 100

Table 2 – Grading Limits for 20 mm Class 1 or 2 CR for 19.0 95 – 100 95 – 100

sources with a LAV ≤ 25

13.2 75 – 95 75 – 95

Test Value before Compaction

9.5 60 – 90 60 – 90

Sieve Size

Retained between

AS (mm) Limits of Grading 4.75 42 – 76 42 – 76

Sieves

(% Passing by Mass)

(% by Mass)

2.36 28 – 60 28 – 60

26.5 100

0-5 0.425 14 – 28 10 – 28

19.0 95 - 100

7 – 18 0.075 6 – 13 2 - 10

13.2 78 – 92

10 – 16

9.5 63 – 83

The grading of 40 mm Class 3 crushed rock shall comply with

14 – 24

4.75 44 – 64

Table 5.

10 – 20

2.36 30 – 48 Table 5 – Grading Limits for 40 mm Class 3 CR

14 – 28

0.425 14 - 22 Test Value before Compaction –

Sieve Size

6 - 13 Limits of Grading

AS (mm)

0.075 7 – 11 (% Passing by mass)

LAV ≤ 25 LAV ≥ 26

53.0 100 100

Table 3 – Grading Limits for 20 mm Class 1 or 2 CR for

37.5 95 – 100 95 - 100

sources with a LAV ≥ 26

26.5 75 – 95 75 – 95

Test Value before Compaction

Sieve Size 19.0 64 - 90 64 - 90

Retained between

AS (mm) Limits of Grading

Sieves

(% Passing by Mass)

(% by Mass) 9.5 42 - 78 42 - 78

26.5 100 4.75 28 – 64 28 – 64

0-5

19.0 95 - 100

2.36 20 – 50 20 – 50

7 – 18

13.2 78 – 92

10 – 16 0.425 10 – 23 7 – 23

9.5 63 – 83

14 – 24 0.075 6 – 12 2-9

4.75 44 – 64

10 – 20

2.36 29 – 48

15 – 29

0.425 13 - 21

7 - 14

0.075 5–9

RC 500.02 Page 4 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

5.3. Class 4 Crushed Rock

6. Physical Property Requirements of

Class 1, 2, 3 & 4 Crushed Rock

Class 4 crushed rock of nominal size differing from that

specified may be accepted for registration provided it meets the The registered crushed rock mix shall comply with the physical

grading requirements of Table 6 corresponding to a nominal property requirements listed in Table 7, where applicable, for

size adjacent to that specified. that class of crushed rock.

Additional testing of the crushed rock mix may also be

Table 6 – Grading Limits for Class 4 CR specified as part of the conditions for registration of the

submitted crushed rock mix.

Sieve

Test Value before Compaction – Limits of

Size These typical physical properties include Liquid Limit, Plasticity

Grading (% Passing by mass)

AS Index, California Bearing Ratio (CBR) and Flakiness Index as

(mm) per Table 7.

Nominal Size (mm)

40 30 25 20 14

75.0

53.0 100

37.5 100 100

26.5 100

19.0 64-90 100

9.5 48-70 54-75

4.75 42-76 54-75

2.36

0.425 7-23 9-24 10-26 10-28 15-32

0.075 2-12 2-12 2-13 2-14 6-17

Table 7 – Crushed Rock Requirements

Test Value

Test

Class 1 Class 2 Class 3 Class 4

Liquid Limit % (max) 30 30 35 40

Plasticity Index (range) (1)

2-6 0-6 0 - 10 0 - 20

California Bearing Ratio (%) (min) (3) (2) (2)

- 100 80 20

Flakiness Index (%) (max) 35 35 - -

PI x % passing 0.425 mm sieve (max) - - - 450

Maximum Percentage of 15% 50%

(4) 5% 10%

Supplementary Materials permitted

Notes:

(1) Unless otherwise advised as a part of the Crushed Rock mix design registration

process, the Plasticity Index shall be targeted to the lower end of the range.

(2) Value applicable to Crushed Rock containing crushed concrete.

(3) Value applicable to material passing 19.0 mm sieve: initially at optimum moisture

content and 98% of maximum dry density as determined by test using Modified

compactive effort, but then soaked for four days prior to the CBR test. (Refer

AS1289.6.1.1)

(4) Maximum permitted clay filler ≤ 2.0% of total dry mass, however a higher % of

supplementary materials may be permitted in a specific crushed rock mix.

RC 500.02 Page 5 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

Clayey sands and clay filler used as supplementary materials

7. Unsound Rock & Foreign Materials Content must comply with the requirements of Table 10.

(a) Unsound rock and marginal rock in that fraction of the

crushed rock product retained on a 4.75 mm AS sieve shall Table 10 – Grading & Other Requirements for

not exceed the percentages specified in Table 8. Clayey Sand and Clay Filler

Supplementary Material

Table 8 - Unsound and Marginal Rock Content

Sieve Size

Clayey Sand Clay Filler

AS (mm)

Total of Marginal (% Passing by (% Passing by

Unsound Rock Mass) Mass)

Class and Unsound Rock

% (max)

% (max)

9.5 100 100

1 10 5

4.75 90 - 100 100

2 10 7 2.36 75 - 95 95 - 100

3 20 10 0.425 45 – 65 70 - 100

4 N/A N/A 0.075 30 – 50 50 - 100

Plasticity

10 – 20 30 - 55

Index

(b) Foreign materials in that fraction of the crushed rock product Emerson

N/A >6

retained on a 4.75 mm sieve shall not exceed the Class No.

percentages by mass specified in Table 9.

The amount of any clay filler added must not exceed 2% of the

Table 9 – Foreign Material Content total dry mass of the crushed rock product.

Foreign Material Type Class 2 Class 3 Class 4 Glass fines are recycled glass cullet crushed to a cubic shape

Allowable % (max)

and passing the 4.75 mm AS sieve. Glass cullet shall be

primarily container glass and shall not include glass from

High density materials such as 2 3 5 ceramics, cathode ray tubes, fluorescent light fittings and

metal, brick (1), ceramic laboratory glassware. Glass fines shall:

whiteware, masonry materials,

glass(1) and RAP(1) be cubical in shape, not sharp edged or elongated

Low density materials such as 0.5 1 3 be generally free of contaminants such as paper,

plastic, rubber, plaster, clay lumps

and other friable material

corks, metals, and other harmful materials (maximum

limit of 2% by mass)

Wood and other vegetable or 0.1 0.2 0.5

decomposable matter Recycled crushed products which contain higher percentages

of crushed brick and glass than those specified in Table 9 shall

(1) Higher percentages of crushed brick, glass, and/or RAP have a wet strength not less than 100 kN and a wet/dry

may be permitted as a supplementary material in a strength variation not greater than 45 when tested in

registered crushed rock mix. accordance with AS 1141.22.

(c) Blended Crushed Rock - where a Crushed Rock is a blend 9. Cement Treated Crushed Rock

of crushed rock and crushed concrete, both of the above

tests shall be undertaken on the individual components prior Registration of mixes will require the applicable requirements of

to blending. the Code to be met prior to the addition of any binder.

Where a registered mix allows a higher percentage of The submission of cement treated crushed rock mixes

crushed brick or glass fines to be used; the percentage of containing supplementary materials such as crushed brick and

unsound rock or foreign materials is to be determined on glass fines shall be limited to light duty pavements only.

the total dry mass of the test sample, and exclude the brick

and glass components. 10. Mix Registration

Applications to register a crushed rock mix shall be submitted

8. Supplementary Materials by the Supplier to VicRoads (Technical Services, 12 Lakeside

Supplementary materials may be included into a crushed rock Drive Burwood East) at least two weeks prior to the proposed

mix to improve its workability and physical properties. date for the commencement of supply of the mix and shall be

Supplementary materials must be durable and not subject to accompanied by the information listed in Clause 6 - Submission

appreciable breakdown. of Mix for Registration.

Where supplementary materials are included as a component The Supplier shall nominate a mix identification number for

in a crushed rock mix, the maximum limits set out in Table 7 each mix and this number shall be used to identify the mix for

shall apply, unless otherwise approved by VicRoads. A higher all future job records and communications.

percentage of supplementary materials may be permitted as a Registered crushed rock mixes nominated for use on VicRoads

part of a registered crushed rock mix. funded projects shall appear on the VicRoads Crushed Rock

RC 500.02 Page 6 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

Mixes database current at the time of the commencement of Section 818 - Crushed Scoria for Pavement Base and

the supply of the mix to the project. Subbase.

The registration of the crushed rock mix shall remain current for The required tests and the testing frequency for supplementary

a period of two years subject to there being no changes to the materials incorporated in any crushed rock mix shall be as

source or grading of the aggregate components or the source specified in the individual registered crushed rock mix.

or nature of any supplementary material. Registration can be

extended beyond two years with the agreement of VicRoads 12.2. Information Required

Technical Services.

The following information shall be submitted for each new

New crushed rock mixes shall be submitted for registration crushed rock mix (The Supplier may use Appendix A to provide

where it is proposed to change the source, grading or nature of a guide to the information to be submitted):

the components; and current registered crushed rock mixes are

more than two years old. 1. Supplier Identification;

The Supplier will be advised in writing of the result of the 2. Crushed Rock Class;

application to register a crushed rock mix and any conditions

attached to the registration. 3. Supplier’s crushed rock mix number;

If a registered mix has unsatisfactory handling or field 4. Proposed date of commencement of supply if

performance, the Supplier or Contractor using the product may applicable;

request VicRoads to withdraw the mix. Alternatively, VicRoads 5. Components proposed and source of each component

may withdraw the mix pending a review of its field performance including supplementary materials;

and immediately advise the Contractor of action taken.

6. Assigned Los Angeles Value (Hardness) of source

11. Mix Status rocks from which components are to be supplied;

All crushed rock mixes registered with VicRoads are issued a 7. Proportion of each component in the mix;

status according to compliance as: 8. Unsound and marginal rock content and/or foreign

General materials content of the coarse aggregate

A crushed rock mix which fully complies with the requirements components;

of this Code of Practice. 9. Grading and Plasticity Index of the combined mix;

Conditional 10. CBR values for the proposed mix where applicable;

A crushed rock mix which does not comply in all respects with

the requirements of this Code of Practice, but is considered 11. Binder type, target binder content and Unconfined

appropriate for use subject to conditions attached to the Compressive Strength results for cement treated

registration. crushed rock mixes;

Expired 12. Flakiness Index of coarse aggregate fraction of 10mm

A crushed rock mix that has passed its expiry date or a mix that and above;

has not been re-registered. 13. For crushed river gravels, the proportion of crushed

Withdrawn particles in coarse aggregate;

A crushed rock mix that has been withdrawn from use due to 14. Degradation Factor and Plasticity Index for crusher

unsatisfactory field performance, but whose details are retained fines components;

for record purposes.

15. Grading and Plasticity Index of any supplementary

12. Submission of Mix for Registration material component;

16. Where specified, the permeability of the mix;

12.1. Compliance Requirements 17. Maximum Dry Density and Optimum Moisture Content

All components of the crushed rock mix shall comply with the of crushed rock product using the combined mix and

relevant requirements of the Code and where applicable the modified compactive effort; and

requirements VicRoads Standard Specification Sections. 18. Post compaction grading and PI results, if applicable.

Section 801 - Source Requirements for Crushed Rock and All test results shall be current (not more than 3 months old) at

Aggregates. the time of submission of the crushed rock mix.

Section 812 - Production of Crushed Rock for Pavement

Base and Subbase.

Section 815 - Production of Cementitious Treated Crushed

Rock for Pavement Subbase.

RC 500.02 Page 7 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

If you would like to receive this publication in an accessible format, please contact: vicroadstechnicalservices@roads.vic.gov.au,

or request it using VicRoads website feedback form.

VicRoads Code of Practice - Revision Summary

RC 500.02 - Registration of Crushed Rock Mixes

Date Clause Description of Revision Authorised by

June 2017 4 Clause added detailing conditions for further reduced testing Principal Advisor – Pavements,

frequency Geotech. & Materials

July 2016 Full Document Full revision and addition of requirements from Sections 812 Principal Advisor – Pavements,

and 815, which have had corresponding text removed, and Geotech. & Materials

from Sections 820 and 821 which are to be discontinued.

1 Revised to reflect changes

2 Added relevant definitions

3, 4, 5, 6, 7, 8 Added requirements for Classes 1, 2, 3, 4 crushed rock.

December 2012 Full document Re-styled with minor corrections made Principal Advisor – Pavements and

2.1 Added Class 4 and descriptive text Materials

6.1 & Appendix A Added Appendix A (informative)

July 2009 Full document Initial Release

RC 500.02 Page 8 of 9 Final June 2017

VicRoads Code of Practice RC 500.02 – Registration of Crushed Rock Mixes

Appendix A - Crushed Rock Mix Registration Form (informative)

CRUSHED ROCK MIX REGISTRATION FORM

Complete one form sheet for every product to be registered

SUPPLIER DETAILS

Supplier Name & Date Submitted

(e.g. XY Resources P/L)

Quarry / Site Location

Product to be Registered

(e.g. 20mm Cl3 CR)

Crushed Rock Mix Number

(your reference number to identify this product)

Name of Person Completing Form

Contact Phone No.

Contact Email Address

CRUSHED ROCK DETAILS#

Optimum Moisture Content & Test Report Attached?

Maximum Dry Density Yes No

Test Reports Attached?

Proposed Target Grading*

Yes No

Test Reports Attached?

Proposed Target Plasticity Index (PI)*

Yes No

Test Report Attached?

Degradation Factor Crusher Fines (if applicable)

Yes No

Test Report Attached?

Class 1 / Class 2 Flakiness Index

Yes No

Unsound and Marginal Rock Content and/ or Foreign Test Reports Attached?

Materials* as applicable. Yes No

CBR Strength Values Test Report Attached?

(if specified / applicable) Yes No

Permeability Test Report Attached?

(if specified / applicable) Yes No

Proposed Binder Type and Binder Content for CTCR Test Report Attached?

(if specified / applicable) Yes No

Unconfined Compressive Strength @ 7days (if specified / Test Report Attached?

applicable) Yes No

SUPPLEMENTARY MATERIALS

Are any supplementary materials added? Yes No

If yes, please supply proposed percentage and

description of any supplementary materials

Test Report Attached?

Supplementary Material Grading

Yes No

Test Report Attached?

Supplementary Material PI

Yes No

Wet & Dry Strength Variation on Final Product Test Report Attached?

(if applicable) Yes No

*These should be realistic targets for production. Attach available test reports as supporting evidence.

# Test results must be less than 3 months old at the time of submission

RC 500.02 Page 9 of 9 Final June 2017

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- A Catalogue of Details on Pre-Contract Schedules: Surgical Eye Centre of Excellence - KathFrom EverandA Catalogue of Details on Pre-Contract Schedules: Surgical Eye Centre of Excellence - KathNo ratings yet

- Structural Engineering DocumentsFrom EverandStructural Engineering DocumentsJorge de BritoNo ratings yet

- Section 812 - Crushed Rock For Pavement Base and Subbase: 812.01 DescriptionDocument13 pagesSection 812 - Crushed Rock For Pavement Base and Subbase: 812.01 Descriptionrvim0002No ratings yet

- Botswana - Guideline 9 - Traffic Data Collection and Analysis (2004)Document185 pagesBotswana - Guideline 9 - Traffic Data Collection and Analysis (2004)Helena KiyengiNo ratings yet

- HIGHWAY II - Unbounded Pavement MaterialsDocument43 pagesHIGHWAY II - Unbounded Pavement MaterialsMul'ataa Vission AbdiisaaNo ratings yet

- Chapter - 05 Highway IIDocument42 pagesChapter - 05 Highway IIhashimahmed9235No ratings yet

- Technical Specifications For Sand As Per BIS: August 29, 2016 10497Document16 pagesTechnical Specifications For Sand As Per BIS: August 29, 2016 10497Kanikaa B KaliyaNo ratings yet

- Is 383 2016Document22 pagesIs 383 2016Meena MurmuNo ratings yet

- Irc 060-1976Document12 pagesIrc 060-1976harivennelaNo ratings yet

- 2016 IS 383 NSandDocument21 pages2016 IS 383 NSandproscokeNo ratings yet

- Investigation Into The Quality and Suitability of Aggregates Commonly Used in Construction Work Talata Mafara Area Zamfara State, NigeriaDocument8 pagesInvestigation Into The Quality and Suitability of Aggregates Commonly Used in Construction Work Talata Mafara Area Zamfara State, NigeriaOMOTOSO AJEWOLENo ratings yet

- Lecture 5 Highway Construction MaterialsDocument15 pagesLecture 5 Highway Construction MaterialsCherylNo ratings yet

- HW II - Chapter 5 - Unbound Pavement MaterialsDocument45 pagesHW II - Chapter 5 - Unbound Pavement Materialsbulcha100% (1)

- HW II - Chapter 5 - Unbound Pavement MaterialsDocument45 pagesHW II - Chapter 5 - Unbound Pavement Materialsabenezer abrhamNo ratings yet

- 383 - Course & Fine AgggregateDocument21 pages383 - Course & Fine AgggregateDebabrata PalNo ratings yet

- Pavement and Materials Design Manual 1999 - CHAPTER 7Document19 pagesPavement and Materials Design Manual 1999 - CHAPTER 7Kisali SarakikyaNo ratings yet

- 1542 Sand For PlasterDocument5 pages1542 Sand For Plasterpankaj guptaNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudParmar RashmikaNo ratings yet

- Is 383 - 2016Document21 pagesIs 383 - 2016L V Laxmipathi Rao83% (40)

- Colgrout PDFDocument14 pagesColgrout PDFadhirajn4073No ratings yet

- Code of Practice RC 50000 Source Rock InvestigationsDocument6 pagesCode of Practice RC 50000 Source Rock InvestigationsAkatwijuka AllanNo ratings yet

- Sec 821Document6 pagesSec 821id21resch11031No ratings yet

- Is: 383-2016Document21 pagesIs: 383-2016yurendraNo ratings yet

- Is Coarse Aggregate and Fine AggregateDocument21 pagesIs Coarse Aggregate and Fine AggregateVishow SharmaNo ratings yet

- Chapter 4 - FoundationsDocument22 pagesChapter 4 - FoundationsJuliet Lobrino RozosNo ratings yet

- 650 - Standard Sand For Testing CementDocument7 pages650 - Standard Sand For Testing CementDebabrata PalNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH Ekudrumman231654No ratings yet

- Standard Specifications AND Code of Practice FOR Road BridgesDocument28 pagesStandard Specifications AND Code of Practice FOR Road BridgesSohomDebroyNo ratings yet

- Equivalency of Crushed Rock and Three Industrial By-Products Used For Working Platforms During Pavement ConstructionDocument11 pagesEquivalency of Crushed Rock and Three Industrial By-Products Used For Working Platforms During Pavement Constructionhans_conanNo ratings yet

- Steps For Better Quality Control of Road WorksDocument63 pagesSteps For Better Quality Control of Road WorksRajib ChattarajNo ratings yet

- Road Materials: Reporter: Shiela Mae T. Ranoco Ariel Umek Christian Jay SalutanDocument44 pagesRoad Materials: Reporter: Shiela Mae T. Ranoco Ariel Umek Christian Jay SalutanJoan-na may MontañoNo ratings yet

- Paper Loni KotDocument4 pagesPaper Loni KotMushtaque AhmedNo ratings yet

- 3466Document8 pages3466sk m hassanNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudocsspectroNo ratings yet

- Slope Protection and StabilizationDocument18 pagesSlope Protection and StabilizationTarik PihuraZßNo ratings yet

- 7e Building Technology 2Document10 pages7e Building Technology 2Gilbert DavidNo ratings yet

- Study On Behaviour of Concrete Partially Replacing Quartz Sand As Fine Aggregate.Document6 pagesStudy On Behaviour of Concrete Partially Replacing Quartz Sand As Fine Aggregate.shivanand hippargaNo ratings yet

- Geom at 2012Document6 pagesGeom at 2012Sami Manjh RajpoutNo ratings yet

- CivilDocument182 pagesCivilnaveed ahmedNo ratings yet

- C & D WasteDocument9 pagesC & D WasteHarpreet SinghNo ratings yet

- F 2270 - 04 - RjiynzaDocument5 pagesF 2270 - 04 - Rjiynzad.i.petrushevNo ratings yet

- CG24-24.1-Z12 Earthworks Testing SpecifcationsDocument17 pagesCG24-24.1-Z12 Earthworks Testing Specifcationsvincent NavarceNo ratings yet

- Section 407 - Hot Mix Asphalt: 407.01 GENERALDocument25 pagesSection 407 - Hot Mix Asphalt: 407.01 GENERALDaiNo ratings yet

- IRC 19-1977 Standard Specification and Code of Practice ForDocument9 pagesIRC 19-1977 Standard Specification and Code of Practice ForPartha Sarathi DasNo ratings yet

- Significance of Subgrade PropertiesDocument4 pagesSignificance of Subgrade PropertiesRajesh Khadka0% (1)

- Chapter - 2-1 Highway IIDocument59 pagesChapter - 2-1 Highway IIAssfachew BeleteNo ratings yet

- 1195 Specification For Bitumen Mastic For FlooringDocument14 pages1195 Specification For Bitumen Mastic For FlooringRakesh RanjanNo ratings yet

- CMT ReviewerDocument5 pagesCMT ReviewerJerine Nicoleigh PomarNo ratings yet

- Daøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudDocument21 pagesDaøhv Osq Fy, Eksvs O Eghu Feykok Fof'Kf"V: HKKJRH EkudMahendraSinghNo ratings yet

- Ujjain SC-4304Document4 pagesUjjain SC-4304MiteshSuneriyaNo ratings yet

- Table 6-1: Properties of Unbound Materials: Nbound Avement AterialsDocument8 pagesTable 6-1: Properties of Unbound Materials: Nbound Avement AterialsSmart EngineeringNo ratings yet

- Irjet A Study On Compressive Strength ofDocument4 pagesIrjet A Study On Compressive Strength ofshivanand hippargaNo ratings yet

- Irc 19-1977 WBMDocument9 pagesIrc 19-1977 WBMKarki2No ratings yet

- Chapter - 5 Highway IiDocument60 pagesChapter - 5 Highway IiIbrahim AbdiNo ratings yet

- 650-Standard Sand For Testing CementDocument7 pages650-Standard Sand For Testing CementShweta MahajanNo ratings yet

- A Guide To Good Quality Control Practices OnAsphalt Production and ConstructionDocument59 pagesA Guide To Good Quality Control Practices OnAsphalt Production and ConstructionAmirrudin Johari100% (1)

- Application For A Licence To Decommission A Bore(s) : Privacy Collection StatementDocument6 pagesApplication For A Licence To Decommission A Bore(s) : Privacy Collection StatementKai FrankNo ratings yet

- Original Tip Opening Times 2019 2020Document1 pageOriginal Tip Opening Times 2019 2020Kai FrankNo ratings yet

- Mildura Landfill Fees 2019 PDFDocument1 pageMildura Landfill Fees 2019 PDFKai FrankNo ratings yet

- Victorian Interstate Infrastructure Lease Public Transport Victoria 26 March 2012 PDFDocument111 pagesVictorian Interstate Infrastructure Lease Public Transport Victoria 26 March 2012 PDFKai FrankNo ratings yet

- Code of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Document33 pagesCode of Practice RC 50022 Selection and Design of Pavement and Surfacings December 2018Barry LibertyNo ratings yet

- Summarise Spoken TextDocument1 pageSummarise Spoken TextKai FrankNo ratings yet

- Consolidation Test ReportDocument4 pagesConsolidation Test ReportKai FrankNo ratings yet

- Patient Progress Report: Personal InformationDocument2 pagesPatient Progress Report: Personal InformationKai FrankNo ratings yet

- FORM 29A - Application Form 2006Document2 pagesFORM 29A - Application Form 2006Kai FrankNo ratings yet

- Consolidation Test ReportDocument4 pagesConsolidation Test ReportKai FrankNo ratings yet

- Week 8 - Tutorial - Shear Strength of SoilsDocument2 pagesWeek 8 - Tutorial - Shear Strength of SoilsKai FrankNo ratings yet

- Isc 2SC6090: Isc Silicon NPN Power TransistorDocument2 pagesIsc 2SC6090: Isc Silicon NPN Power TransistorCipto EdiNo ratings yet

- ST-2 Test ReportDocument5 pagesST-2 Test ReportAruljyothy PCNo ratings yet

- Eran Volte Feature Parameter Descriptionpdf PDFDocument312 pagesEran Volte Feature Parameter Descriptionpdf PDFMyo Lwin Soe100% (1)

- C Style Guide PDFDocument118 pagesC Style Guide PDFc1367443No ratings yet

- Course ObjectivesDocument4 pagesCourse ObjectivesSreekanth KuNo ratings yet

- ISO-Lecture 03 - Internal Is and Enterprise SystemsDocument4 pagesISO-Lecture 03 - Internal Is and Enterprise SystemsFadika Malick Christ ElyséeNo ratings yet

- Optiplex 5400 AIODocument7 pagesOptiplex 5400 AIOKandaNo ratings yet

- Second Generation Computers: Group 2Document21 pagesSecond Generation Computers: Group 2Cleofe Jane PatnubayNo ratings yet

- Silicon N-Channel Power MOSFET: General DescriptionDocument10 pagesSilicon N-Channel Power MOSFET: General DescriptionMhd DamNo ratings yet

- Ai Board PaperDocument6 pagesAi Board PaperMerlin WarlockNo ratings yet

- Caribbean Studies Group Member Responsibility Agreement Form and Chosen TopicsDocument6 pagesCaribbean Studies Group Member Responsibility Agreement Form and Chosen TopicsEthan BompartNo ratings yet

- CRISP - ML (Q) - Business Understanding AssignmentDocument11 pagesCRISP - ML (Q) - Business Understanding AssignmentAnakha PrasadNo ratings yet

- BSBMKG624 Project PortfolioDocument20 pagesBSBMKG624 Project PortfolioMohd Faizal Bin AyobNo ratings yet

- Blu-Ray Home Theater Set HT-H5500K PDFDocument103 pagesBlu-Ray Home Theater Set HT-H5500K PDFQUYEN TRANNo ratings yet

- Scheme of Studies For Class VIII (Plain Station)Document30 pagesScheme of Studies For Class VIII (Plain Station)Sappurd Ali SaqibNo ratings yet

- All Fonts MyFontsDocument1 pageAll Fonts MyFontsAkbar AhmadiNo ratings yet

- CertificateDocument28 pagesCertificateKhaldi KaisNo ratings yet

- Panic Alarm Station: User ManualDocument49 pagesPanic Alarm Station: User ManualGeorge Braham Victoria RiveraNo ratings yet

- F2F Applied Business Tools HM 213 Brandon Rey Arante First Semester 2021Document12 pagesF2F Applied Business Tools HM 213 Brandon Rey Arante First Semester 2021Crizz Oracion MedijaNo ratings yet

- Resetting The Keep Alive Memory (KAM) : Idle Air Trim Learning Modes Transmission Range Air Conditioning ModeDocument1 pageResetting The Keep Alive Memory (KAM) : Idle Air Trim Learning Modes Transmission Range Air Conditioning ModeFabio SierraNo ratings yet

- Flash Calculations (Low P & T)Document8 pagesFlash Calculations (Low P & T)RubensBoerngenNo ratings yet

- Introduction To PropellerDocument12 pagesIntroduction To Propellersaumya irugalbandaraNo ratings yet

- Requests Readthedocs Io en v2.0.0Document78 pagesRequests Readthedocs Io en v2.0.0Penghakiman Dunia AkhiratNo ratings yet

- IoT LeafletDocument7 pagesIoT LeafletkiranNo ratings yet

- Fault Modeling and Test Algorithm Creation Strategy For FinFET-based MemoriesDocument6 pagesFault Modeling and Test Algorithm Creation Strategy For FinFET-based MemoriesRuqaiya KhanamNo ratings yet

- Ethics in Information Technology: An Overview of EthicsDocument87 pagesEthics in Information Technology: An Overview of EthicsnageshmcackmNo ratings yet

- Esr 21 SeriesDocument40 pagesEsr 21 SeriesJoaquim FerreiraNo ratings yet

- Chrome User AgentsDocument10 pagesChrome User Agentstest2589No ratings yet

- Development of Android Application For Pest Infestation Early Warning SystemDocument5 pagesDevelopment of Android Application For Pest Infestation Early Warning SystemNalla Paiyan TamilDonuNo ratings yet

- CH18 COA11eDocument40 pagesCH18 COA11eninosensei1999No ratings yet