C-PVC Hot and Cold Water System

C-PVC Hot and Cold Water System

Uploaded by

arjun 11Copyright:

Available Formats

C-PVC Hot and Cold Water System

C-PVC Hot and Cold Water System

Uploaded by

arjun 11Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

C-PVC Hot and Cold Water System

C-PVC Hot and Cold Water System

Uploaded by

arjun 11Copyright:

Available Formats

...

Based on Japanese Material and Technology

C-PVC

Hot and Cold water system

... The latest and reliable plumbing system The Supreme is the acknowledged leader of India’s plastic

industry. With a portfolio of over 7500 diverse products, the

IS 15778:2007 most comprehensive range in the industry, we cater to almost

every conceivable need and application of the customer in

piping. While helping the country transit from conventional to

CM/L 3684475 modern piping, we have several path breaking products to our

credit making us a trend setter in the industry.

Supreme Lifeline C-PVC, manufactured using world's best

Japanese material and technology, is an ideal solution for hot

and cold water usages. This system is suitable for water supply

and distribution and for industrial applications. It has emerged

as the best substitute for conventional G.I. piping system for

these applications. Choice of raw material and strict quality

control in production, gives these products a high degree of

reliability which makes Lifeline C-PVC a preferred choice of

leading consultants, architects, builders, plumbers and quality

conscious people across the country. This simple and easy to

install, user-friendly and high-performance system is

equipped with many outstanding features and is approved by

M.C.G.M.

Unique Features:

4Excellent resistance to corrosion and chemical attacks

4Suitable for carrying potable water

4Light weight, easy and quick assembly

4Tough and rigid material

4Simple and leak proof joints

4Low thermal expansion

4Superior insulation properties

4Fire resistant

4Maintenance free

4Highly economical in long run

Jeevan bhar ka saath...

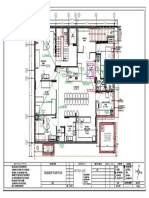

C-PVC Plumbing System for Hot and Cold Water

Fields of Application: Product Range:

Lifeline C-PVC is designed for hot and cold water supply in Pipes: 15 to 50 mm (½" to 2") sizes in SDR 11 and SDR 13.5 as per

residential, commercial and public projects, high and low rise IS:15778. 20 and 25 mm (¾" & 1") sizes in SDR 9 as per company

buildings, corporate houses and academic institutes, solar standards. 65 to 250 mm (2½" to 10") sizes in SCH 40 and SCH 80

heater applications etc. It is highly suitable for all uptake and as per ASTM F-441.

down take lines, terrace looping including concealed pipe work Fittings : 15 to 50 mm (½" to 2") sizes in SDR 11 as per ASTM D-

applications. 2846 and 20 and 25 mm (¾" & 1") sizes in SDR 9 as per company

standards. 65 to 200 mm (2½" to 8") sizes in SCH 40 and SCH 80 as

per ASTM F-438 and F-439 respectively.

Coupler Elbow 90° Elbow 45° Reducing Equal Tee Reducing Cross Tee Union Reducer End Cap

Elbow Tee

Reducing Transition MTA FTA Female Threaded Male Threaded Female Threaded Male Threaded FTA (Brass)

Bush Bush (Plastic) (Plastic) Elbow (Brass) Elbow (Brass) Tee (Brass) Tee (Brass)

MTA (Brass) Single Y Flange Flange Van Blind Ball Valve Union Ball Valve Concealed Concealed Valve Screw Tap with

Adapter Stone Style Flange (Plain & Threaded) Valve (Quarter Turn) Handwheel

Y Strainer Bypass Circuit Testing Elbow Hole Repairing Tank Connector Tank Connector Wall Mixer Solvent Cements &

Bend Plug (N) Holder Coupler (MT/FT & MT/Soc) Long (MT/Spg) Fixture Adhesives

Jointing Instructions:

Cutting the pipe: Cut the pipe at 90° using a hand saw with end. Apply cement quickly to prevent it from drying and make

suitable guide or by pipe cutter. sure to completely cover all jointing surfaces of the pipe and

Joint preparation: Chamfer or deburr pipe or both, fitting. Do not apply excessive cement in bell socket.

approximately at 10-15° angle and remove burrs. Assembly of joint: Immediately after applying the last coat of

Cleaning: Remove any dirt, moisture or grease from pipe and cement to the pipe and while cement is still not dry, say within

fitting sockets with a clean dry rag. 10- 20 second, forcefully bottom the male end of the pipe in

Test Dry fit the joint: Check that the fitemt is correct and the the socket, giving pipe or the fitting ¼th turn (but not after pipe

joint is not too tight or loose. is bottomed) to distribute cement evenly. Remove excess

Application of solvent cement: While making a joint, apply cement from the pipe at the end of fitting socket. The joint

cement lightly but uniformly to inner surface of socket and must not be disturbed immediately after cementing to let it

outer surface of pipe end with a natural bristle nylon brush or a cure properly. Allow cement to cure before pressurizing the

suitable applicator. Apply a second coat of cement to the pipe system for about 12 hours for proper curing. Exact curing time

varies with temperature, humidity etc.

Note : Company does not take guarantee for the performance unless company supplied solvent cement is used.

The Supreme Industries Ltd., (Plastic Piping Division) 1161/1162, Solitair Corporate Park, Building No. 11,167, Andheri Ghatkopar Link Road, Andheri (East)

Mumbai - 400 093. India Tel: 91-22-6771 0000, 4043 0000 Fax: 6771 0099 / 4043 0099. • E-mail pvc-pipes@supreme.co.in • Website www.supreme.co.in

Overseas Office : Sharjah, U.A.E. Tel # + 971 6 557 4484; Fax # + 97165574485

www.supreme.co.in

I & T SIL Gadegaon, Dist-Jalgaon=PC/C-PVCSP/MKG/56=REV.09-08/2017

C-PVC Plumbing System for Hot and Cold Water

Fields of Application: Product Range:

Lifeline C-PVC is designed for hot and cold water supply in Pipes: 15 to 50 mm (½" to 2") sizes in SDR 11 and SDR 13.5 as per

residential, commercial and public projects, high and low rise IS:15778. 20 and 25 mm (¾" & 1") sizes in SDR 9 as per company

buildings, corporate houses and academic institutes, solar standards. 65 to 250 mm (2½" to 10") sizes in SCH 40 and SCH 80

heater applications etc. It is highly suitable for all uptake and as per ASTM F 441.

down take lines, terrace looping including concealed pipe work Fittings : 15 to 50 mm (½" to 2") sizes in SDR 11 as per ASTM D-

applications. 2846 and 20 and 25 mm (¾" & 1") sizes in SDR 9 as per company

standards. 65 to 200 mm (2½" to 8") sizes in SCH 40 and SCH 80 as

per ASTM F 438 and F 439 respectively.

Coupler Elbow 90° Elbow 45° Reducing Equal Tee Reducing Cross Tee Union Reducer End Cap

Elbow Tee

Reducing Transition MTA FTA Female Threaded Male Threaded Female Threaded Male Threaded FTA (Brass)

Bush Bush (Plastic) (Plastic) Elbow (Brass) Elbow (Brass) Tee (Brass) Tee (Brass)

MTA (Brass) Single Y Flange Flange Van Blind Ball Valve Union Ball Valve Concealed Concealed Valve Screw Tap with

Adapter Stone Style Flange (Plain & Threaded) Valve (Quarter Turn) Handwheel

Y Strainer Bypass Circuit Testing Elbow Hole Repairing Tank Connector Tank Connector Wall Mixer Solvent Cements &

Bend Plug (N) Holder Coupler (MT/FT & MT/Soc) Long (MT/Spg) Fixture Adhesives

Jointing Instructions:

Cutting the pipe: Cut the pipe at 90° using a hand saw bristle nylon brush or a suitable applicator. Apply a

with suitable guide or by pipe cutter. second coat of cement to the pipe end. Apply cement

Joint preparation: Chamfer or deburr pipe or both, quickly to prevent it from drying and make sure to

approximately at 10-15° angle and remove burrs. completely cover all jointing surfaces of the pipe and

Cleaning: Remove any dirt, moisture or grease from fitting. Do not apply excessive cement in bell socket.

pipe and fitting sockets with a clean dry rag. Assembly of joint: Immediately after applying the last

Test Dry fit the joint: Check that the fitemt is correct coat of cement and while cement is still not dry,

and the joint is not too tight or loose. forcefully bottom the male end of the pipe in the socket,

Application of solvent cement: While making a joint, giving pipe or the fitting ¼th turn to distribute cement

apply cement lightly but uniformly to inner surface of evenly. Remove excess cement and let the joint cure

socket and outer surface of pipe end with a natural properly. Allow cement to cure before pressurizing the

system for about 12 hours.

Note : Company does not take guarantee for the performance unless company supplied solvent cement is used.

The Supreme Industries Ltd., (Plastic Piping Division) 1161/1162, Solitair Corporate Park, Building No. 11,167, Andheri Ghatkopar Link Road, Andheri (East)

Mumbai - 400 093. India Tel: 91-22-6771 0000, 4043 0000 Fax: 6771 0099 / 4043 0099. • E-mail pvc-pipes@supreme.co.in • Website www.supreme.co.in

Overseas Office : Sharjah, U.A.E. Tel # + 971 6 557 4484; Fax # + 97165574485

www.supreme.co.in

I & T SIL Gadegaon, Dist-Jalgaon=PC/C-PVCSP/MKG/56=REV.09-08/2017

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Katalog HDPE GFDocument12 pagesKatalog HDPE GFArief Prabowo100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Stress Analysis of Gre PipingDocument69 pagesStress Analysis of Gre PipingGoutham Dhanaraj100% (3)

- Excel 97 Workbook PDFDocument2 pagesExcel 97 Workbook PDFKyleNo ratings yet

- 12 Column Pipe For Submersible PumpsDocument4 pages12 Column Pipe For Submersible PumpsEmac AutomationNo ratings yet

- PVC Casing PipesDocument8 pagesPVC Casing Pipesamit kumar pandeyNo ratings yet

- Plumb ExDocument21 pagesPlumb ExJugno ShahNo ratings yet

- Applications: Complete Piping Solutions ForDocument8 pagesApplications: Complete Piping Solutions ForShree Swapna UllengalaNo ratings yet

- Apex Piping Revised 2Document36 pagesApex Piping Revised 2Eng Aggrey OsumaNo ratings yet

- Apex Piping Catalogue 2020Document36 pagesApex Piping Catalogue 2020Insta PumpsNo ratings yet

- SMART Product Range and PropertiesDocument20 pagesSMART Product Range and Propertiesinfratek.makmurbersamaNo ratings yet

- 9 Polyethylene Piping SystemDocument4 pages9 Polyethylene Piping SystemPrashant PatilNo ratings yet

- Purohit Pipes Industries CatalougeDocument19 pagesPurohit Pipes Industries Catalougepandey12udayNo ratings yet

- 3 Lifeline CPVC Hot and Cold Plumbing SystemDocument4 pages3 Lifeline CPVC Hot and Cold Plumbing SystemsaranNo ratings yet

- 63mm Supreme PVC U PipeDocument8 pages63mm Supreme PVC U Piperajeshdas.vidvattaNo ratings yet

- Al Bilad Company Profile PDFDocument53 pagesAl Bilad Company Profile PDFQuerubin R Yolando Jr.No ratings yet

- Plastics Piping Systems: Jeevan Bhar Ka Saath..Document28 pagesPlastics Piping Systems: Jeevan Bhar Ka Saath..Ritesh JhaNo ratings yet

- High Pressure Plumbing System Upvc: ... The Easy and Economical SolutionDocument2 pagesHigh Pressure Plumbing System Upvc: ... The Easy and Economical Solutionarjun 11No ratings yet

- 1 Aqua Gold Plumbing SystemDocument4 pages1 Aqua Gold Plumbing SystemAbu Saleh RajaNo ratings yet

- FIL BrochureDocument12 pagesFIL BrochurebnidineshNo ratings yet

- SANFLO PE Manholes CatalogDocument12 pagesSANFLO PE Manholes CataloganandNo ratings yet

- 19 DWC MDocument6 pages19 DWC MNikita KadamNo ratings yet

- SupremeuPVc Pressure Pipes and FittingsDocument8 pagesSupremeuPVc Pressure Pipes and FittingsPranav JayaramNo ratings yet

- Weholite Structured Wall Hdpe Pipe ManualDocument42 pagesWeholite Structured Wall Hdpe Pipe ManualAshley Dillon TothNo ratings yet

- Polymold Catalog 2021 - Polyethylene PipingDocument20 pagesPolymold Catalog 2021 - Polyethylene PipingSachin Sampat100% (1)

- Chezy Product Catalogue 123Document20 pagesChezy Product Catalogue 123Yong QingNo ratings yet

- Sharkbite® Metal Push-Fit Plumbing Solution: Technical InformationDocument36 pagesSharkbite® Metal Push-Fit Plumbing Solution: Technical InformationPubcrawlNo ratings yet

- PDF Version!: GRP Pipe SystemsDocument6 pagesPDF Version!: GRP Pipe Systemstruss85No ratings yet

- Upvc Pressure Pipes and FittingsDocument8 pagesUpvc Pressure Pipes and FittingsjafarkhansfNo ratings yet

- Blu BrochureDocument8 pagesBlu BrochureElvi PapajNo ratings yet

- 2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Document217 pages2016 2017 Shurjoint General Catalog (Rev. SJ CAT 2016 en 3)Q1921No ratings yet

- FLOWTITE Pipe Systems: For Subaqueous InstallationsDocument12 pagesFLOWTITE Pipe Systems: For Subaqueous InstallationsRusu CatalinNo ratings yet

- 1a Aquaflow HDPE Pipe CatalogueDocument12 pages1a Aquaflow HDPE Pipe CatalogueNick Bester100% (1)

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- Hdpe-Pipe Supreme MakeDocument6 pagesHdpe-Pipe Supreme MakeTribes Energy Company TECNo ratings yet

- GRP Pipes Fittings CatalogDocument8 pagesGRP Pipes Fittings CatalogAAF0% (1)

- 6 SWR Drainage SystemDocument4 pages6 SWR Drainage SystemkamleshyadavmoneyNo ratings yet

- PE Technical ManualDocument68 pagesPE Technical ManualMuhammad SalmanNo ratings yet

- ORI Catalogue - PipeDocument18 pagesORI Catalogue - PipeMuhammad Aidil FitrahNo ratings yet

- All Product Eng RevDocument24 pagesAll Product Eng RevZuzer FakhriNo ratings yet

- Catalogo General ROTHENBERGER 2022-2023 - InglesDocument388 pagesCatalogo General ROTHENBERGER 2022-2023 - InglesDiego GutierrezNo ratings yet

- With Your Trust: We BeginDocument16 pagesWith Your Trust: We BeginPaulo BrunoNo ratings yet

- Neoplast Grup Boru English CataloqueDocument14 pagesNeoplast Grup Boru English CataloqueayhanozdemirNo ratings yet

- Double Wall Corrugated Pipes (DWC) HDPE PipesDocument15 pagesDouble Wall Corrugated Pipes (DWC) HDPE Pipesdesign teamNo ratings yet

- CATALOGUEDocument18 pagesCATALOGUEnebiyathannaNo ratings yet

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pages3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaNo ratings yet

- Gfps My Product Range Aquasystem PP R enDocument47 pagesGfps My Product Range Aquasystem PP R enprashanth.t7bhskliaNo ratings yet

- Hydraulic Tube Fittings enDocument16 pagesHydraulic Tube Fittings enAlex PeñaNo ratings yet

- Supreme PVC & PPR BrochuresDocument28 pagesSupreme PVC & PPR BrochuresWeeBooh Wit-aNo ratings yet

- Viega Profipress ManualDocument16 pagesViega Profipress Manualhasmit1No ratings yet

- MS PDF KiTEC Product ManualDocument54 pagesMS PDF KiTEC Product ManualDeepak Builders Ludhiana Railway StationNo ratings yet

- Jain PVC Pipe CatalogDocument92 pagesJain PVC Pipe CatalogwaseemybNo ratings yet

- PDF Version!: Flowtite Pipe SystemsDocument0 pagesPDF Version!: Flowtite Pipe SystemsDeva RajNo ratings yet

- Marley Polyethylene ManualDocument80 pagesMarley Polyethylene ManualHamish Laing100% (1)

- PP-R and PP-RCT Pipe Systems: Hot and Cold Water Systems and Heating ApplicationsDocument24 pagesPP-R and PP-RCT Pipe Systems: Hot and Cold Water Systems and Heating ApplicationsKwadwo Siaw-MarfoNo ratings yet

- ITT Grinnell Products Standard and Line Pipe Catalog 2008Document69 pagesITT Grinnell Products Standard and Line Pipe Catalog 2008ITT GRINNELLNo ratings yet

- 1 - Flowtite Product Guide PDFDocument56 pages1 - Flowtite Product Guide PDFShepherd NhangaNo ratings yet

- CPI Technical-EngDocument22 pagesCPI Technical-EngMazwan Che MansorNo ratings yet

- Brochure UPI 2016Document24 pagesBrochure UPI 2016ashishNo ratings yet

- Water: Verification of Calculation Method Using Monte Carlo Method For Water Supply Demands of Office BuildingDocument21 pagesWater: Verification of Calculation Method Using Monte Carlo Method For Water Supply Demands of Office Buildingarjun 11No ratings yet

- Plumbing Checklist: Slab RoughDocument1 pagePlumbing Checklist: Slab Rougharjun 11No ratings yet

- Model: FB Junior Series - Technical Data Sheet (Page 1) Model: FB Junior Series - Technical Data Sheet (Page 1)Document3 pagesModel: FB Junior Series - Technical Data Sheet (Page 1) Model: FB Junior Series - Technical Data Sheet (Page 1)arjun 11No ratings yet

- Civil & Environmental Preliminary Design Guide: For Undeveloped SitesDocument38 pagesCivil & Environmental Preliminary Design Guide: For Undeveloped Sitesarjun 11No ratings yet

- Maintenance Matters 06 Decks BalconiesDocument6 pagesMaintenance Matters 06 Decks Balconiesarjun 11No ratings yet

- Clamps & Hangers PDFDocument4 pagesClamps & Hangers PDFarjun 11No ratings yet

- 02 Arch - Stru CoordinationDocument70 pages02 Arch - Stru Coordinationarjun 11No ratings yet

- Rigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..Document8 pagesRigid PVC Pressure Pipes and Fittings: Jeevan Bhar Ka Saath..arjun 11No ratings yet

- Basement Floor Drainage & Sump Plan - 30-6-20Document1 pageBasement Floor Drainage & Sump Plan - 30-6-20arjun 11No ratings yet

- Special CablesDocument115 pagesSpecial Cablesjav071No ratings yet

- Fluoroelastomer Stress Induced CrackingDocument22 pagesFluoroelastomer Stress Induced CrackingSid ShahNo ratings yet

- Fluid Mechanics and MachineryDocument1 pageFluid Mechanics and Machineryபாலரத்தினம் தமிழன்No ratings yet

- SPARC Architecture NotesDocument13 pagesSPARC Architecture NotesKhang VuNo ratings yet

- Puerto Rico Startup Showcase ReleaseDocument4 pagesPuerto Rico Startup Showcase ReleaseMarcos PolancoNo ratings yet

- 73 Shortcuts For Virtual DJDocument3 pages73 Shortcuts For Virtual DJRap King BrownNo ratings yet

- 9852 2396 01 Settings COP 2560,2560EXDocument1 page9852 2396 01 Settings COP 2560,2560EXAndres MoenaNo ratings yet

- Avtron IR Bullet CCTV Camera AA 4545P FSR3Document2 pagesAvtron IR Bullet CCTV Camera AA 4545P FSR3Avtron TechnologiesNo ratings yet

- Shutdown: No Equipment Selected No Equipment SelectedDocument6 pagesShutdown: No Equipment Selected No Equipment SelectedFrezgi BirhanuNo ratings yet

- Construction Management PDFDocument93 pagesConstruction Management PDFMary SandraNo ratings yet

- Summer Training Project Report - HDPEDocument39 pagesSummer Training Project Report - HDPESubhankar Roy50% (2)

- Butterfly Valves - Figure 611 & 612: FeaturesDocument7 pagesButterfly Valves - Figure 611 & 612: FeaturesAli KianersiNo ratings yet

- GulfSea Diesel GE 40 PDFDocument2 pagesGulfSea Diesel GE 40 PDFObydur RahmanNo ratings yet

- TOFD Technique For Weld InspectionDocument31 pagesTOFD Technique For Weld InspectionJennifer FrenchNo ratings yet

- RRLDocument3 pagesRRLk15014998No ratings yet

- Recognizing Arabic Handwritten Script USIng SVMDocument6 pagesRecognizing Arabic Handwritten Script USIng SVMPrasad RudrawarNo ratings yet

- Motores 3054 PerkinsDocument30 pagesMotores 3054 PerkinsClever Alex Soliz CalderonNo ratings yet

- Itu Seminar Isdb-T 001108Document26 pagesItu Seminar Isdb-T 001108Rogerio Robson SacconiNo ratings yet

- F C C (FCC) W DOC N: Ederal Ommunications Ommission Arning Instruction To Users OticeDocument10 pagesF C C (FCC) W DOC N: Ederal Ommunications Ommission Arning Instruction To Users OticeAbubakar SidikNo ratings yet

- 35b2e47c-50ff-48a9-b3e2-03abc33d76a5Document11 pages35b2e47c-50ff-48a9-b3e2-03abc33d76a5sasikalaNo ratings yet

- OSD PrintoutDocument18 pagesOSD PrintoutDSAO AmravatiNo ratings yet

- Broadband TransformersDocument6 pagesBroadband Transformersflegias100% (1)

- Setup - Building A Linux Server Using WebminDocument570 pagesSetup - Building A Linux Server Using WebminnisheednairNo ratings yet

- Promaster Tough Setting GuideDocument14 pagesPromaster Tough Setting Guidemeor3705No ratings yet

- Project OS2Document2 pagesProject OS2smily ranaNo ratings yet

- Mattie Heffron: - Fashion Merchandising-Objective EducationDocument1 pageMattie Heffron: - Fashion Merchandising-Objective Educationapi-365143520No ratings yet

- Airvents SteamDocument16 pagesAirvents SteamEdwin CruzNo ratings yet

- Green Economy and TradeDocument302 pagesGreen Economy and TradeKarpagam MahadevanNo ratings yet