HS 069 Operational Control

HS 069 Operational Control

Uploaded by

grantCopyright:

Available Formats

HS 069 Operational Control

HS 069 Operational Control

Uploaded by

grantCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

HS 069 Operational Control

HS 069 Operational Control

Uploaded by

grantCopyright:

Available Formats

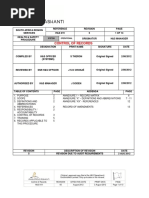

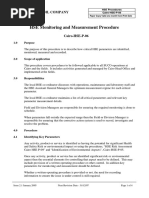

SOUTHERN AFRICA REFERENCE REVISION PAGE

DIVISIONAL SERVICES H&S 069 1 1 OF 15

HEALTH & SAFETY SYSTEM OPERATIONAL ORIGINATOR H&S MANAGER

PROCEDURE

OPERATIONAL CONTROL

DESIGNATION PRINT NAME SIGNATURE DATE

COMPILED BY SNR H&S OFFICER E JUNGMANN Original Signed 05/10/2009

REVIEWED BY SNR H&S OFFICER R TUPPER Original Signed 05/10/2009

AUTHORISED BY H&S MANAGER J SODEN Original Signed 05/10/2009

TABLE OF CONTENTS PAGE ADDENDA PAGE

1. PURPOSE 2 ANNEXURE 1 6–8

2. SCOPE 2 ANNEXURE “X” – DEFINITIONS AND ABBREVIATIONS 9 - 13

3. DEFINITIONS AND

2 ANNEXURE “XX” - REFERENCES 14

ABBREVIATIONS

4. REFERENCES 2 RECORD OF AMENDMENTS 15

5. RESPONSIBILITY /

2

ACCOUNTABILITY

6. OPERATIONAL CONTROL 3

7. RECORDS APPLICABLE TO

5

THIS PROCEDURE

REVISION DESCRIPTION OF REVISION DATE

1 REVISION DUE TO SEPTEMBER ’09 AUDIT REQUIREMENTS 3 OCTOBER ‘09

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 1 of 15

1. PURPOSE

The purpose and objective of this document is to provide guidance to SA Divisional Services for

harmonisation and common understanding in terms of activities and operations associated with

identified hazards within SA Divisional Services, and where the implementation of controls is

necessary to manage those risks, and comply with OH&S legal and other requirements and in the

absence of those operational controls, could lead to injury or harm.

2. SCOPE

The scope of this procedure will deal with the development of operational controls consistent with the

hierarchy of controls to prevent injury or ill health.

3. DEFINITIONS AND ABBREVIATIONS

Refer to Annexure “X”

4. REFERENCES

Refer to Annexure “XX”

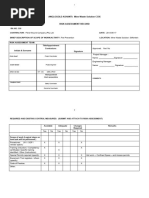

5. RESPONSIBILITY / ACCOUNTABILITY

DESIGNATION RESPONSIBILITIES AND ACCOUNTABILITIES

Manager • Ensure that a procedure is established, implemented and

maintained dealing with the operations and activities that are

associated with identified hazards.

Health and Safety • Develop a system to identify and maintain all documentation

Manager regarding operations and activities associated with the

identified hazards where the implementation of controls is

necessary to manage the OHS risks.

• These documentation to be implemented and maintained

ensuring where identified hazards do exist, control procedures

are maintained – Baseline Risk rankings used as a guideline

for implementation/revision of procedures .

• Identify what and when operating procedures are required to

deal with identified hazards and associated risks as and when

required

Commercial Services • Facilitate a purchasing process

Management • Ensure availability of resources to implement the OH&S

Representative programme

• Ensure that analysis is made of information pertinent to OH&S

• Compare information with objectives, evaluate effectiveness of

controls and where targets are not met change controls to

achieve desired results

• Ensure information is distributed and communicated to

employees relevant to the work they perform

• Ensure that personnel are aware of applicable legal and other

requirements

• Ensure H&S Officer (Systems) keep and maintain records

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 2 of 15

Snr H&S Officer / HOD’s • Generate concise, easily understood procedure documents.

• Identify what and when operating procedures are required to

deal with identified hazards and associated risks as and when

required.

• Reviewed operating procedures when significant changes

are made to People, Equipment, Material, Environment and to

the Process

H&S Officer (Systems) • Maintain the procedures and ensure regular updates/reviews.

• During process change update the electronic database with

the latest authorised documents.

• Distribute new and latest documentation via the acknowledge

receipt document – as per Control of Documents (H&S 023).

• Retrieve and dispose of obsolete procedure documents.

Employees • Know what is expected of them in order to achieve the

organization’s goals.

• Implement and adhere to operational procedures at all times.

• Be aware of the Hazards in his/her workplace.

6. OPERATIONAL CONTROL

SA Divisional Services H&S department shall establish, implement, and maintain a procedure that

deals with operations and activities that are associated with the identified hazards where the

implementations of controls are necessary to manage the OH&S risks. This will include management

of change. Managing documentation within SA Divisional Services is subdivided into operational

controls related to the following categories ie.:

• SA Divisional Services Safety System

• Purchased goods, equipment and services – Commercial Services

• Contractors and other visitors to the workplace

• Documented operational procedures to cover specific situations and processes where their

absence could lead to deviations from the OHS Policy and their objectives. Operational

procedures will be risk ranked.

• Stipulated operating criteria where their absence could lead to deviations from the OHS policy and

objectives

6. SA Divisional Services Safety System Documents

Safety System documentation deals with documents related to the monitoring and

implementation of operational controls related to the Safety System and Operational Issues.

The operational controls were designed by identifying operations and activities associated with

identified risks where control measures are needed as per the Baseline Risk assessment or

when ever required.

Operational controls are made up of a suite of activities and processes which starts with the

baseline risk assessment and continue down to day to day continuous risk assessment. (Refer

to H&S (014,018 and 028)

Formal controls have been established for planned maintenance (where required); purchasing;

significant tasks; significant equipment; hazardous materials; provision and control of Personal

Protective Equipment; Planned task observations; Planned Inspections and Occupational health,

etc. The CMMIS program / Baseline Risk assessment aids including identification and pre-use

inspection checklists deals with engineering issues regarding inspection of all units.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 3 of 15

Documented procedures are available for operations and activities for which they require to

ensure adherence to the occupational health and safety standards.

6.2 Documents Related to Purchased Goods, Equipment and Services

The entire purchasing process is governed by CS/CORP/001 – Procedure for the Acquisitioning

of Goods, Equipment, Site works, Services, and Technical acquisitions.

Section 21 of the Mine Health and Safety Act 29 of 1996, deals with the manufacturer’s and

supplier’s duty for health and safety. Every supplier shall ensure that appropriate risk

assessment accompanies equipment supplied to SA Divisional Services.

The procedure defines the purchasing of material and equipment prior to arriving to SA

Divisional Services. This is integrated into the purchasing department being Commercial

Services who does the buying - an effective purchasing system is in place that restricts the flow

of unnecessary items throughout SA Divisional Services.

To ensure that only the correct quality and specification equipment can be purchased, a

representative of Southern Africa Division H&S sits in at the Standards Committee meetings

where purchasing processes are discussed and finalized – A H&S representative attends the

SAD standards meeting.

Material safety data sheets must be supplied to the mine for every chemical. This allows the

occupational hygiene department to assess the anticipated hazards and risks associated with

the use of the chemical on the user as well as the environment, in which case less critical

alternatives is sought. A MSDS inventory exists at Commercial Services and is available on the

Web.

6.3 Documents Related to Contractors and Other Visitors to the Working Place

Documents related to Contractors and other visitors to the working place deals with the proper

documentation required to ensure all contractors and visitors are conversant with associated

hazards and risks. (H&S 066 – Contractor Health & Safety Requirements SA Divisional

Services)

6.4 Permits and Exemptions

The Engineer must acknowledge the availability of the required permit / exemption prior to

allowing work to be performed involving new processes or systems.

Should a process or system change, a risk assessment must be conducted and approved by the

H&S department and then a permit document must be drafted.

6.5 Establishing and Implementing Operational Controls

To give effect to the management of identified risks the following information should be considered

when establishing and implementing operational controls:

a. Health and Safety policy and objectives

b. Results of hazard identification, risk assessment, evaluation of existing controls and

determination of new controls

c. Management of change processes

d. Information on existing standard operating procedures (Applicable to the task)

e. Legal and other requirements to which the organization subscribes

f. Product supply chain controls related to purchased goods, equipment and services

g. Feedback from participation and consultation

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 4 of 15

h. The nature of and extent to which tasks are to be performed by contractors and other

external personnel

i. Access to the workplace by visitors, delivery personnel, service contractors, etc.

See Annexure 1 for examples of associated control measures and operating criteria that could be

used as guidance when establishing and implementing operational controls.

7. RECORDS APPLICABLE TO THIS PROCEDURE

RECORDS LOCATION

Purchasing documents Financial department/Commercial Services

Contractual records Commercial Services/Properties department

Permits and exemption Health and Safety department

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 5 of 15

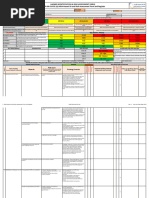

Annexure 1 (Could be used as guidance)

Examples of areas in which Health and Safety risks typically arise, and examples of their associated control

measures include:

a) General control measures

• Regular maintenance and repair of facilities, machinery and equipment to prevent unsafe

conditions from developing;

• Housekeeping and maintenance of clear walkways

• Access Control

• Contractor Procedure (H&S 066)

• Maintenance of the thermal environment (temperature, air quality)

• Maintenance of the ventilation systems and electrical safety systems;

• Maintenance of emergency plans

• Policies related to travel, bullying, sexual harassment, drug and alcohol abuse, etc.

• Health programs (medical surveillance programmes)

• Legal appointments

• Induction

b) Performance of hazardous tasks

• Use of procedures, work instructions, or approved working methods and Safe working practices.

• Use of appropriate equipment

• Pre-qualification and/or training of personnel or contractors for hazardous tasks - Competency

• Use of permit-to-work systems, pre-approvals, or authorisations (Refer to Procedure H&S 016)

• Controls to prevent ill health

c) Use of hazardous materials

• Identification of approved inventory levels, storage locations and storage conditions;

• Conditions of use for hazardous materials

• Limitations of areas where hazardous materials can be used;

• Secure and safe storage provisions and control of access;

• Provision of and access to material safety data and other relevant information.

• Shielding of radiation sources

• Isolation of biological contaminants

• Knowledge in the use of and availability of emergency equipment

• Availability of MSDS.

d) Facilities and equipment

• Regular maintenance and repair of facilities, machinery and equipment to prevent unsafe

conditions from developing;

• Housekeeping and maintenance of clear walkways, and traffic management

• Provision, control of PPE (Personal Protective Equipment - H&S 003 procedure);

• Inspection and testing of OH&S equipment such as guarding, fall arrest systems, shutdown

systems, rescue equipment for confined spaces, lock-out systems, fire detection and suppression

equipment, exposure monitoring devices, ventilation systems and electrical safety systems by the

appropriate supervisor;

• Inspection and testing of material handling equipment (cranes, forklifts, hoists and other lifting

devices).

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 6 of 15

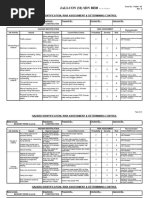

e) Purchase of goods, equipment and services

• Establishment of OH&S requirements for goods, equipment and services to be purchased

• Communication of the organization's own OH&S requirements to suppliers

• Pre-approval requirements for the purchase or transport/transfer of hazardous chemicals,

materials and substances;

• Pre-approval requirements and specifications for the purchase of new machinery and equipment;

• Pre-approval of procedures for the safe operation of machinery, equipment, and/or the safe

handling of materials prior to their use by Engineer/HOD (Operational procedures by disciplines);

• Inspection and verification of received goods, equipment (Commercial Services)

• Evaluation, and periodic re-evaluation, of the OH&S performance of vendors and/or suppliers

(Commercial Services/HOD’s);

• Selection and monitoring of contractors and other service providers.

f) Contractors

• Establish criteria for the selection of contractors

• Communication of the organization's own OH&S requirements to contractors

• Evaluation, monitoring and periodic re-evaluation, of the OH&S performance of contractors;

g) Other external personnel or visitors in the workplace

As the knowledge and capabilities of visitors or other external personnel vary greatly, this should be

considered when developing controls. Examples may include

• Contractor controls

• Establishing their knowledge and capabilities prior to permitting the use of equipment

• Provision of advice, training as necessary

• Warning signage/administrative controls

• Methods for monitoring and supervising their activities

• Site specific induction

Examples of operating criteria include:

a) For hazardous tasks

• Risk assessment

• Use of specified equipment, and procedures/work instructions for its use

• Competency of operators for such equipment

• Authorities/guidelines/instructions/procedures for individual task based risk assessment prior to

immediate commencement of the task

b) For hazardous chemicals:

• Approved chemical and MSDS lists

• Exposure limits

• Specific inventory limits

• Specified storage locations and conditions

c) For task involving entry into hazardous areas:

• Induction

• Specification of personal protective equipment requirements

• Specified conditions for entry (permits)

• Health and fitness conditions

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 7 of 15

d) For tasks involving work performed by contractors:

• Specification of OH&S performance criteria

• Specification of competency and/or training requirements for contractor personnel

• Specification/inspection of contractor provided equipment

e) For OH&S hazards to visitors

• Supervision

• PPE requirements

• Orientation

• Emergency requirements

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 8 of 15

Annexure X

DEFINITIONS AND ABBREVIATIONS

DEFINITIONS:

DOCUMENT

Information and its supporting medium (The medium can be paper, magnetic, electronic or optical computer

disc, photograph or master sample, or a combination thereof.)

RECORD

Document stating results achieved or providing evidence of activities performed

CONTROLLED DOCUMENT

Any document that needs to be controlled in terms of its distribution and use, such as the Policy and

documented procedures. These documents are either signed in original ink and/or signed for on a

distribution list. These documents will be signed off after evaluation has been done to determine that they

are adequate for purpose. The document will be signed off by the relevant members as depicted on the

distribution list.

Once copies are printed of the database, they are considered to be “uncontrolled”.

OBSOLETE DOCUMENTS

Documents that have been replaced by later revisions or those that is no longer relevant or valid, and has

been cancelled from the system. These documents will be identified either by crossing them out and writing

obsolete or rubber stamp obsolete document.

UNCONTROLLED DOCUMENTS

Any documents that have not been issued under the circumstances under “controlled documents” are

categorised as uncontrolled. This includes, but may not be limited to:

• Documents that do not need to be controlled such as the monthly safety topic.

• Documents not distributed by the authorised person as per the procedures “authority and

responsibility” table and signed for by the recipient.

• Documents printed from the electronic database. (Watermarked “uncontrolled document)

• Documents duplicated or photocopied from controlled documents.

• Photocopies of the Occupational Health and Safety policy as issued to the public or other

Interested and Affected Parties

It is not possible to judge from an uncontrolled copy whether it is the latest version. It is the responsibility of

the person holding the documentation to ensure that (s) he has the latest version.

INJURY

Physical harm or damage

OCCUPATIONAL HEALTH AND SAFETY

Conditions and factors that affect, or could affect the health and safety of employees or other workers

(including temporary workers and contractor personnel), visitors, or any other person in the workplace

OH&S MANAGEMENT SYSTEM

Part of an organization’s management system used to develop and implement its OH&S policy and manage

its OH&S risks

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 9 of 15

SEVERITY / CONSEQUENCE

Outcome of an event. There may be one or more consequences from an event. May be expressed

qualitatively or quantitatively may range from positive to negative (Speculative).

FREQUENCY

Occurrence per unit time, (May be expressed qualitatively or quantitatively).

EXPOSURE

How often and for how long employees are exposed to a hazard/s.

LIKELIHOOD

Means the chance of an event occurring.

DUE DILIGENCE

Taking reasonable care to protect the health and safety of all employees. Provide equipment, maintain the

equipment, use equipment as prescribed, provide information relating to the equipment, and provide

competent supervision.

INCIDENT

An undesired event which under slightly different circumstances could result in harm to people. Damage to

property or loss to process or an undesired event that could or does result in a loss.

RISK MATRIX

A Risk index can be determined by plotting likelihood and severity indices on the y and x-axis respectively

and then using them to obtain a risk ranking.

HIRA

Process of recognizing that a hazard exists and defining its characteristics

• H = HAZARD

Anything around us that we can see as well as those energy sources we cannot see e.g. Gas and

radiation that can cause harm

• I = IDENTIFICATION

Identify the significant hazards (Process and recognition)

• R = RISK

Risk imagining (Likelihood and consequence if risk materializes)

• A = ASSESSMENT

Determine the magnitude of the risk if materialized

ROUTINE ACTIVITY

An activity which is performed on a regular basis (day to day)

NON ROUTINE

An activity performed on an adhoc basis

ACCOUNTABILITY

Principle that, individuals, organizations, and the community are responsible for their actions and may be

required to explain them to others.

RESPONSIBLE

Liable to be called to respond to a person for issues to be done.

ILL HEALTH

Identifiable adverse physical or mental condition arising from and/or made worse by a work activity and/or

work-related situation.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 10 of 15

INTERESTED PARTIES

Person or group, inside or outside the workplace, concerned with or affected by the SADSSS performance.

NONCONFORMITY

Non-fulfilment of a requirement – can be any deviation from:

Relevant work standards, practices, procedures, legal requirements.

SADSSS OBJECTIVES

SADSSS goals, in terms of OHS performance, that SA Divisional Services sets itself to achieve. Objectives

are quantified wherever practical.

SADSSS PERFORMANCE

Measurable results of SA Divisional Services management of its risks.

Note: Performance measurement includes measurement the effectiveness of controls.

OHS POLICY

Overall intention and direction which will be followed for the management of health and safety.

RECORD

Document stating results achieved or providing evidence of activities performed

HAZARD

A condition or practice with the potential to cause harm, or exposure to danger. (Immediate Causes,

Substandard Act or Substandard Condition)

RISK ASSESSMENT

Process of evaluating the risk(s) arising from a hazard(s), taking into account the adequacy of any existing

controls, and deciding whether or not the risk(s) is acceptable

PREVENTATIVE ACTION

Action to eliminate the cause of a potential nonconformity or other undesirable potential situation.

CORRECTIVE ACTION

Action taken to rectify a non-conformance or deviation

CONTINUAL IMPROVEMENT

To constantly improve on current Health and Safety standards

PROCEDURE

Specified way to carry out an activity or a process.

RISK ASSESSMENT

Process of evaluating the risk arising from a hazard, taking into account the adequacy of any existing

controls, and deciding whether or not the risk is acceptable.

WORKPLACE

Any physical location in which work related activities are performed under the control of SA Divisional

Services.

AUDIT

Independent and documented process for obtaining “audit evidence” and evaluating it objectively to

determine the extent to which “audit criteria” are fulfilled.

SAFETY MONTH

Period from the 20th of a particular month up to the 19th of the following month.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 11 of 15

EFFORT BASED OBJECTIVES

Objectives set to improve program related issues

EFFECT BASED OBJECTIVES

Objectives set to improve severity or injury rates

MANCOM

Management Committee

EXCO

Executive Committee

SUPERVISOR

Within SA Divisional Services – One who supervise or has charge and direction of i.e. Foreman, Clerk of

works, Training Officer, Residence Manager, Security Officer etc.

EMPLOYEE

Person working under the control of the organisation and includes contractors.

MANAGEMENT REPRESENTATIVE

A Person appointed in writing ensuring that the OH&S management system is established, implemented

and maintained in accordance with this OHSAS Standard;

and ensuring that reports on the performance of the OH&S management system are presented to top

management for review and used as a basis for improvement of the OH&S management system.

VISITOR

Any person who enters the premises of the mine who is not a full time employee or Contractor paid by the

mine

CONTRACTOR

Any person who perform work for the mine and is paid for his/her service.

ACCEPTABLE RISK

Risk that has been reduced to a level that can be tolerated by the organization having regard to its legal

obligations and its own

HEALTH AND SAFETY COMMITTEE

A committee as required by law M H & S Act Section 25(2)

VERIFICATION

Verification is the act of reviewing, inspecting, testing, etc. to establish and document that a product, service,

or system meets the regulatory, standard, or specification requirements.

VALIDATION

Validation refers to meeting the needs of the intended end-user or customer to

prove the truth or to determine or test the accuracy. Also, validation is the process of checking if something

satisfies a certain criterion.

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 12 of 15

ABBREVIATIONS:

M H & S Act - Mine Health & Safety Act

MA&R - Mineral Act & Regulations

OHASA - Occupational Health and Safety Act

DMR - Department of Mineral Resources

DOL - Department of Labour

SADS - Southern Africa Divisional Services

ESW - Engineering Services Workshops

WITW - Wellness in the Workplace

H&S - Health and Safety

LTIFPD - Loss Time Injury Free Production Days

IFPD - Injury Free Production Days

AGAH - AngloGold Ashanti Health

TMM - Trackless Mobile Machinery

COP - Code of Practice

ATDS - AngloGold Ashanti Training and Development Services

CRA - Continuous Risk Assessment

SADSSS - Southern Africa Divisional Services Safety System

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 13 of 15

Annexure XX

REFERENCES

• Roles and responsibilities are depicted in each system procedure and updated as and when

required in table format

• OHSAS 18001:2007 (Occupational Health and Assessment Series)

• The Mine Health and Safety Act 29 of 1996

• The Minerals Act 50 of 1991

• Occupational Health and Safety Act (Act 86 of 1993)

• COIDA

• AGA Strategic Objectives

• Implex Legal Register

• ATDS Training Matrix

• AGA RCAT

• Corporate Procedure Directive

• Health and Safety Agreement

• SAR/OESH/P/A/001.01 – AGA Incident reporting

• H&S 004 – Incident investigation

• H&S 006 – Emergency preparedness and response

• H&S 014 – Issue based risk assessment

• H&S 018 – Baseline risk assessment H&S 019 – Control of records

• H&S 023 – Control of documents

• H&S 027 – Competence, training and awareness

• H&S 028 – Continuous risk assessment

• H&S 029 – Communication, participation and consultation

• H&S 030 – Management review

• H&S 031 – Internal audit

• H&S 037 – Management of change

• H&S 055 – SA Divisional Services Scope

• H&S 058 – Legal and other requirements

• H&S 059 – Performance measurement and monitoring

• H&S 060 – Evaluation of compliance

• H&S 061 – Nonconformity, corrective and preventative action

• H&S 065 – Objectives and programme(s)

• H&S 067 – Resources, roles, responsibility, accountability and authority

• H&S 069 – Operational control

• H&S 070 – Documentation

• H&S 071 – H&S Policy

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 14 of 15

RECORDS OF AMENDMENTS

PROCEDURE DATE OF

CHANGES TO PROCEDURE

REVISION NUMBER APPROVAL

Added risk ranking of operational procedures

H&S 069 – Revision 1 (p3 point 6) 3 October 2009

(Original, approved copy filed at the H&S Department)

Uncontrolled if printed. Only up-to-date on the intranet.

Operational Control REVISION EFFECTIVE DATE PRINT DATE PAGE

H&S 069 01 October 2009 5 October 2009 Page 15 of 15

You might also like

- 1 - Site Clearing & EarthworksDocument2 pages1 - Site Clearing & EarthworksRafee Pie100% (14)

- 0006 - 033 Simultaneous Operations (Simops)Document8 pages0006 - 033 Simultaneous Operations (Simops)baseet gazali100% (1)

- P3-Procedure For Establishing Operational ControlDocument2 pagesP3-Procedure For Establishing Operational ControlSamsu Sams50% (2)

- MTC-IMS-PR-14-Procedure For HSE Monitoring & MeasurementDocument6 pagesMTC-IMS-PR-14-Procedure For HSE Monitoring & Measurementsouravrobin100% (2)

- BSCI New Version-2 Audit ChecklistDocument6 pagesBSCI New Version-2 Audit ChecklistJahazi100% (3)

- 0.method Statement Surveying and Setting Out PDFDocument4 pages0.method Statement Surveying and Setting Out PDFشاز إياسNo ratings yet

- HS 019 Control of RecordsDocument13 pagesHS 019 Control of RecordsgrantNo ratings yet

- HS 060 Evaluation of ComplianceDocument12 pagesHS 060 Evaluation of CompliancegrantNo ratings yet

- PPS HSE Internal PolicyDocument25 pagesPPS HSE Internal PolicyPioneer Power SystemsNo ratings yet

- Participation & ConsultationDocument1 pageParticipation & ConsultationK S KumaraNo ratings yet

- Procedure For Objectives and TargetsDocument6 pagesProcedure For Objectives and TargetsDaniel Cheng MahsaNo ratings yet

- How To Set Up Objectives and Targets For ISO 14001Document2 pagesHow To Set Up Objectives and Targets For ISO 14001Kaushal SutariaNo ratings yet

- Operational ControlDocument3 pagesOperational ControljeyaseelanaNo ratings yet

- MS-P01 Management Responsibility ProcedureDocument8 pagesMS-P01 Management Responsibility ProcedureMuhammad ZafarNo ratings yet

- Safety, Health and Environmental Execution Plan: Installation of Fall Protection Lifeline (Fall Protection)Document29 pagesSafety, Health and Environmental Execution Plan: Installation of Fall Protection Lifeline (Fall Protection)Thato KebuangNo ratings yet

- ISO 9001, 14001 and 4001 Context of The OrganizationDocument8 pagesISO 9001, 14001 and 4001 Context of The OrganizationJordin SladekNo ratings yet

- P 01 - Procedure For CommunicationDocument6 pagesP 01 - Procedure For CommunicationganrashNo ratings yet

- Procedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowDocument3 pagesProcedure Manual - IMS: Locomotive Workshop, Northern Railway, LucknowMarjorie Dulay Dumol100% (1)

- ISO 45001 Audit ChecklistDocument2 pagesISO 45001 Audit ChecklistMasoom QureshiNo ratings yet

- MOC FormDocument1 pageMOC FormahmedNo ratings yet

- 3 Product StewardshipDocument24 pages3 Product StewardshiphamidNo ratings yet

- OSH-PRO-01 Procedure For Hazard Identification, Risk Assessment and Risk ControlDocument8 pagesOSH-PRO-01 Procedure For Hazard Identification, Risk Assessment and Risk ControlDaniel Cheng MahsaNo ratings yet

- Omcl Quality Management Guideline On Management of Documents and RecordsDocument5 pagesOmcl Quality Management Guideline On Management of Documents and RecordsHans LeupoldNo ratings yet

- SANG-COW-POL-001 APPENDIX 9 C2 Competency Training RequirementsDocument14 pagesSANG-COW-POL-001 APPENDIX 9 C2 Competency Training RequirementsvladNo ratings yet

- 205 Setting & Tracking of Objectives ProcedureDocument3 pages205 Setting & Tracking of Objectives ProcedureMayowa RichardNo ratings yet

- 12 Steps For Implementation and Certification Against ISO 45001Document3 pages12 Steps For Implementation and Certification Against ISO 45001Moshiur RahmanNo ratings yet

- Management of Change MOC Procedure 1Document4 pagesManagement of Change MOC Procedure 1Brijgopal Yadav100% (1)

- HSEQ-HQ-11-03-00 HSE CommitteesDocument6 pagesHSEQ-HQ-11-03-00 HSE CommitteesAHMED AMIRANo ratings yet

- HSEQ-HQ-08-01-00 Annual and Three Year Planning HSEQ PDFDocument5 pagesHSEQ-HQ-08-01-00 Annual and Three Year Planning HSEQ PDFAHMED AMIRANo ratings yet

- 02-005 Hazardous Chemical Substance PolicyDocument6 pages02-005 Hazardous Chemical Substance PolicyJoachimNo ratings yet

- HSE Objectives-Targets HoneywellDocument3 pagesHSE Objectives-Targets HoneywellBalaji ThiaguNo ratings yet

- Control of WorkDocument51 pagesControl of WorkHamza ShehzadNo ratings yet

- Contractor ManagementDocument4 pagesContractor ManagementKhairul HazwanNo ratings yet

- HSE MGT - System PDFDocument70 pagesHSE MGT - System PDFNaveen Chaudhary100% (2)

- HSED - P09-Emergency Response PlansDocument4 pagesHSED - P09-Emergency Response PlansLeslie ReeveNo ratings yet

- Chevron: Chevron Enhances Safety Culture With Enterprise-Wide Incident Analysis and Reporting SystemDocument2 pagesChevron: Chevron Enhances Safety Culture With Enterprise-Wide Incident Analysis and Reporting SystemBrian HughesNo ratings yet

- JIG Learning From Incidents LFI Pack 20Document9 pagesJIG Learning From Incidents LFI Pack 20Pratiek RaulNo ratings yet

- 06 Procedure For Addressing Risks and Opportunities Risk Preview enDocument3 pages06 Procedure For Addressing Risks and Opportunities Risk Preview enRahul SiwakotiNo ratings yet

- EOHSP 07 Communication Consultation Participation PDFDocument5 pagesEOHSP 07 Communication Consultation Participation PDFSyafiq Khalil100% (1)

- HSE Exception Request Form Rev.1Document1 pageHSE Exception Request Form Rev.1Dhimaz YudiNo ratings yet

- V1 FWE SWP F-03 Emergency Drill ProceduresDocument3 pagesV1 FWE SWP F-03 Emergency Drill ProceduresMartahanManurungNo ratings yet

- PR Training & CompetencyDocument9 pagesPR Training & CompetencyMuhammad ImranNo ratings yet

- 4.2 Understanding Interested Parties NeedsDocument3 pages4.2 Understanding Interested Parties NeedsYen Trang Vo NhiNo ratings yet

- 7.1.4 Environment For The Operation of ProcessesDocument2 pages7.1.4 Environment For The Operation of ProcessesGVS RaoNo ratings yet

- Guidelines For Prevention of Dropped / Unsecured Objects at HeightsDocument22 pagesGuidelines For Prevention of Dropped / Unsecured Objects at HeightsMashur Al JunaibiNo ratings yet

- Behavioural Gap Analysis PDFDocument2 pagesBehavioural Gap Analysis PDFAli WaqasNo ratings yet

- AzSPU Internal and External Material Release Reporting ProcedureDocument19 pagesAzSPU Internal and External Material Release Reporting ProcedureAmir M. ShaikhNo ratings yet

- Contractor Company Name: Southernglow Venures Limited: Nma Sbu - Chesm Evaluation QuestionnaireDocument14 pagesContractor Company Name: Southernglow Venures Limited: Nma Sbu - Chesm Evaluation QuestionnaireAF Dowell MirinNo ratings yet

- Contractor Management ProcedureDocument13 pagesContractor Management ProcedureNaba majeadNo ratings yet

- Iso Awareness Weekend Staff Training Programme: RegistrationDocument12 pagesIso Awareness Weekend Staff Training Programme: RegistrationKakira Lions ClubNo ratings yet

- 2-Procedure For Control of DocumentsDocument3 pages2-Procedure For Control of DocumentsRichu PaliNo ratings yet

- VQHSE MS ProcedureDocument22 pagesVQHSE MS ProcedureSyahrul RizalNo ratings yet

- HSE-P-06 Monitoring and Measurement Issue 2.1Document4 pagesHSE-P-06 Monitoring and Measurement Issue 2.1eng20072007No ratings yet

- Standard Operating Procedure Covid-19 Mitigation SkvinDocument7 pagesStandard Operating Procedure Covid-19 Mitigation SkvinAdib Ikhwan100% (1)

- Objective Target Responsible AccountabilityDocument1 pageObjective Target Responsible AccountabilityMehrab AliNo ratings yet

- AzSPU Objectives Targets and Management ProgramsDocument6 pagesAzSPU Objectives Targets and Management ProgramsAmir M. ShaikhNo ratings yet

- Legislative Compliance RegisterDocument26 pagesLegislative Compliance Registerlancekim21No ratings yet

- Health, Safety and Environment Framework For Telstra Suppliers of Services and Products 017861A01Document29 pagesHealth, Safety and Environment Framework For Telstra Suppliers of Services and Products 017861A01nissreenbarakat100% (1)

- Hazard Identification TABLEDocument6 pagesHazard Identification TABLEjason a. unNo ratings yet

- ESCL-SOP-017, Procedure For Control of Workshop-Project OperationsDocument8 pagesESCL-SOP-017, Procedure For Control of Workshop-Project Operationsadiqualityconsult100% (1)

- HSE - Operation Controls ABE-HSE-OP-01Document6 pagesHSE - Operation Controls ABE-HSE-OP-01Faisal RazaNo ratings yet

- HSE-P-17 Setting and Reviewing HSE Objectives Issue 1.1Document5 pagesHSE-P-17 Setting and Reviewing HSE Objectives Issue 1.1eng20072007No ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- Health and Safety PlanDocument6 pagesHealth and Safety PlangrantNo ratings yet

- 217 Confined Space LaminatingDocument11 pages217 Confined Space LaminatinggrantNo ratings yet

- 216 Fire PreventionDocument12 pages216 Fire PreventiongrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- Prj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundDocument2 pagesPrj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundgrantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- 218 Site EstablishmentDocument14 pages218 Site EstablishmentgrantNo ratings yet

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- 4.RAMS Machine Installations 2023Document14 pages4.RAMS Machine Installations 2023grantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- Section 9 - Check Out - Test & Acceptance Certificates - REVISED JHLDocument3 pagesSection 9 - Check Out - Test & Acceptance Certificates - REVISED JHLgrantNo ratings yet

- Amc She Env Pro 0007 Hazardous Materials ManagementDocument29 pagesAmc She Env Pro 0007 Hazardous Materials ManagementgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- Section 6 - Index - Revised JHLDocument1 pageSection 6 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Execution Plan - REVISED JHLDocument1 pageSection 2 - Execution Plan - REVISED JHLgrantNo ratings yet

- 1.conveyors Risk AssessmentDocument19 pages1.conveyors Risk Assessmentgrant100% (1)

- Amc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpDocument8 pagesAmc She Env Pro 0013 Hydrocarbon and Chemical Spills Clean UpgrantNo ratings yet

- Risk Assessment Process For Occupational Dive Work ExampleDocument12 pagesRisk Assessment Process For Occupational Dive Work ExampleravindraNo ratings yet

- Team Leader, HSE (Process Safety) (11862) ADNOC RefiningDocument5 pagesTeam Leader, HSE (Process Safety) (11862) ADNOC Refiningkhater.ahmed9900No ratings yet

- Fdocuments - in Chief Security Officer Cso Organizational Standard Is Designed As A Tool To EducateDocument28 pagesFdocuments - in Chief Security Officer Cso Organizational Standard Is Designed As A Tool To EducateFernandoFerreiraNo ratings yet

- Broadway Industrial Group: Singapore Company Flash NoteDocument3 pagesBroadway Industrial Group: Singapore Company Flash NoteTerence Seah Pei ChuanNo ratings yet

- Nasc SG34-17Document24 pagesNasc SG34-17raziul.aliNo ratings yet

- Assignment Of: International Business ManagementDocument20 pagesAssignment Of: International Business Managementalaina zamirNo ratings yet

- 0368 Van Brabant GPR 8 Operational Security Management in Violent EnvironmentsDocument191 pages0368 Van Brabant GPR 8 Operational Security Management in Violent EnvironmentsAntonios MarkogiannakisNo ratings yet

- OHS-PR-09-03-F02 HIRA - 006 Access Road and Structure Pad Preparation For High Terrain AreaDocument10 pagesOHS-PR-09-03-F02 HIRA - 006 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- Hybrid Machine Learning Risk Assesment in Gender Based CrimeDocument15 pagesHybrid Machine Learning Risk Assesment in Gender Based CrimecacotaNo ratings yet

- IND - HMGPP - OPS - 043 Final For Circulation (HT)Document8 pagesIND - HMGPP - OPS - 043 Final For Circulation (HT)debabrata goswamiNo ratings yet

- Masonry Work Risk AssessmentDocument3 pagesMasonry Work Risk AssessmentMunaku TafadzwaNo ratings yet

- Track. Safety Protection On The Track During Work. Part 1Document90 pagesTrack. Safety Protection On The Track During Work. Part 1Kirioth MatoyiNo ratings yet

- She Strategy DocumentDocument30 pagesShe Strategy DocumentEarnest A. Bartlett100% (2)

- Note Emshe - Hazard Identification ControlDocument38 pagesNote Emshe - Hazard Identification ControlMel Yusoff100% (1)

- Quantify Risk 1889127Document8 pagesQuantify Risk 1889127Ravi KumawatNo ratings yet

- PI 041 1 Draft 3 Guidance On Data Integrity 1Document52 pagesPI 041 1 Draft 3 Guidance On Data Integrity 1Yolanda PerezNo ratings yet

- Laboratory Biorisk Management CWA 15793Document46 pagesLaboratory Biorisk Management CWA 15793LESP COLIMA50% (2)

- Risk AssessmentDocument25 pagesRisk Assessmentgsnagar330No ratings yet

- Cisa 1 ($i - I..) PDFDocument48 pagesCisa 1 ($i - I..) PDFSweeto SaniNo ratings yet

- Muthu Irulappan EHS Professional 13 06 2021Document5 pagesMuthu Irulappan EHS Professional 13 06 2021HeisenbergNo ratings yet

- FAO Manual 3rd Edition FinalDocument298 pagesFAO Manual 3rd Edition FinalSuyog patil100% (1)

- Block Work MSDocument19 pagesBlock Work MSjonesNo ratings yet

- Infection Prevention and Control Policy (England)Document9 pagesInfection Prevention and Control Policy (England)KingKLRNo ratings yet

- Ecological ConceptsDocument2 pagesEcological ConceptsJesse Jones SeraspeNo ratings yet

- Student Assessment Feedback Form: (Do Not Convert or Tamper The Document.)Document5 pagesStudent Assessment Feedback Form: (Do Not Convert or Tamper The Document.)Masood Ibn UbaidNo ratings yet

- Environmental Decision Making - HardingDocument29 pagesEnvironmental Decision Making - HardingamicidipinoNo ratings yet