0 ratings0% found this document useful (0 votes)

39 viewsPSTCL

PSTCL

Uploaded by

xiaomiThis document provides specifications for cooling equipment and insulating oil for transformers. It states that overload and single phase protection shall be provided for the RTCC panel, but no volt release shall not be fitted. It also requires installing a single phase preventor on the main supply circuit to shut off all three phases if single phasing occurs. Insulating oil used for transformers must be of napthenic base and conform to various standards. The supplier must provide 5% extra oil and deliver it free of moisture in epoxy coated steel drums. The transformer design must include attention to suppressing harmonic voltages like the 3rd and 5th harmonics. The tank and cover of the transformer must be fabricated from good commercial grade low carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

PSTCL

PSTCL

Uploaded by

xiaomi0 ratings0% found this document useful (0 votes)

39 views1 pageThis document provides specifications for cooling equipment and insulating oil for transformers. It states that overload and single phase protection shall be provided for the RTCC panel, but no volt release shall not be fitted. It also requires installing a single phase preventor on the main supply circuit to shut off all three phases if single phasing occurs. Insulating oil used for transformers must be of napthenic base and conform to various standards. The supplier must provide 5% extra oil and deliver it free of moisture in epoxy coated steel drums. The transformer design must include attention to suppressing harmonic voltages like the 3rd and 5th harmonics. The tank and cover of the transformer must be fabricated from good commercial grade low carbon steel.

Original Description:

pstcl oil

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides specifications for cooling equipment and insulating oil for transformers. It states that overload and single phase protection shall be provided for the RTCC panel, but no volt release shall not be fitted. It also requires installing a single phase preventor on the main supply circuit to shut off all three phases if single phasing occurs. Insulating oil used for transformers must be of napthenic base and conform to various standards. The supplier must provide 5% extra oil and deliver it free of moisture in epoxy coated steel drums. The transformer design must include attention to suppressing harmonic voltages like the 3rd and 5th harmonics. The tank and cover of the transformer must be fabricated from good commercial grade low carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

39 views1 pagePSTCL

PSTCL

Uploaded by

xiaomiThis document provides specifications for cooling equipment and insulating oil for transformers. It states that overload and single phase protection shall be provided for the RTCC panel, but no volt release shall not be fitted. It also requires installing a single phase preventor on the main supply circuit to shut off all three phases if single phasing occurs. Insulating oil used for transformers must be of napthenic base and conform to various standards. The supplier must provide 5% extra oil and deliver it free of moisture in epoxy coated steel drums. The transformer design must include attention to suppressing harmonic voltages like the 3rd and 5th harmonics. The tank and cover of the transformer must be fabricated from good commercial grade low carbon steel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

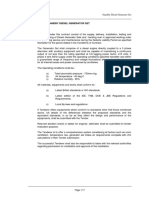

shall be provided in RTCC Panel.

Over load and single phase

protection shall be provided but no volt release shall not be fitted. A

single phase preventor should be installed on the main supply to

cooler circuit so that in case of single phasing all the three phases are

put off, thus, preventing single phasing. A single metal clad main

isolating switch with H.R.C. fuses shall be provided for the main

supply.

The switching in or out of cooling equipment shall be

controlled by temperature indicators and there shall be provision for

automatic switching in or out at pre-determined temperature level

which should be capable of adjustment and setting at will. The cooler

control scheme shall be so designed that :-

a) it shall be possible to run all fans, including stand-by fans, on manual

b) there should be provision to change over any fan to stand-by

The tenderer shall specify the loading capacity of the

transformers in case of failure of one or more sets of fans. Provisions

should be made to avoid hunting of fans.

A complete remote control equipment of coolers and the

equipment for remote control of ON Load Tap changer shall be

supplied by the tenderer for installation in the control room.

20. INSULATING OIL:

i) The TRANSFORMER Insulating oil used for the Transformer Testing

during Manufacturing and inspection by PSTCL at the works of the

firm shall be of Napthenic base. The inspector can take a sample and

test it for its Naphthenic base characteristics.

ii) Sufficient insulating oil of NAPTHENIC TYPE (made from NAPTHENIC

CRUDE) conforming to BS:148/IEC:296 class-1/PSTCL SPEC. shall be

supplied for first filling of each transformer.

iii) 5% extra oil of the total quantity of oil shall also be supplied.

iv) Particular attention shall be paid to deliver the oil at site free from

moisture and of uniform quality through out in non-returnable epoxy

coated steel drums.

v) The quantity of oil for first filling of each transformer shall be stated in

tender, alongwith trade mark of the oil to be supplied.

vi) Use of inhibitors in oil shall not be resorted to.

21. SUPRESSION OF HARMONICS:

The transformer shall be designed with particular attention to

suppression of harmonic voltages especially the 3rd. and 5th.

Percentage of harmonics at normal voltage and at maximum system

voltage shall be stated in the tender. Harmonics shall be measured

during final testing of the transformer.

22. TANK: (BELL TYPE DESIGN):

The transformer tank and cover shall be oil tight and shall be

fabricated from good commercial grade low carbon steel of adequate

thickness. The weld procedure and performance shall be in line with

37

You might also like

- Electrical Permit PDFDocument2 pagesElectrical Permit PDFRebecca Leyson78% (9)

- TS - 25 KV Current TransformerDocument9 pagesTS - 25 KV Current TransformerbinodeNo ratings yet

- 011 Chapter 9Document10 pages011 Chapter 9xiaomiNo ratings yet

- Technical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsDocument46 pagesTechnical Specification 315 MVA 400/220KV AUTO Transformer FOR All Projects Except World Bank and Jbic ProjectsanuragpugaliaNo ratings yet

- Technical Specification: Technical Specification, Section - Autotransformer Page - I C/ENGG/SPEC/TRF Rev. No.: 04Document53 pagesTechnical Specification: Technical Specification, Section - Autotransformer Page - I C/ENGG/SPEC/TRF Rev. No.: 04PremBhushanNo ratings yet

- GT DatasheetDocument24 pagesGT DatasheetNaraen GandhiNo ratings yet

- 19MV Guide Specification (202406)Document8 pages19MV Guide Specification (202406)Angga HardiyantomoNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document5 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- 6i.sect.3.9 CO2Document10 pages6i.sect.3.9 CO2nabiha2211No ratings yet

- CL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00Document9 pagesCL NG 6460 0002 018 Checklist For Oil Immersed Transformer Rev00MohamedElmahdyNo ratings yet

- 1 Power TransformerDocument8 pages1 Power TransformerJason HebertNo ratings yet

- VFDDocument9 pagesVFDVenkatesh RaoNo ratings yet

- CL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02Document8 pagesCL-NG-6460-002-018 Checklist For Oil-Immersed Transformer Rev02WajahatNo ratings yet

- National Grid: Checklist For Commissioning of Oil-Immersed Power TransformerDocument8 pagesNational Grid: Checklist For Commissioning of Oil-Immersed Power TransformerSanthosh Kumar VinayagamNo ratings yet

- MVAC02 chillersDocument12 pagesMVAC02 chillersphuongdao11071006No ratings yet

- Technical Specification - S20 Fuel Storage and Supply SystemDocument9 pagesTechnical Specification - S20 Fuel Storage and Supply SystemEric Steven MargateNo ratings yet

- Fire Prevention Nitrogen Injection SystemDocument11 pagesFire Prevention Nitrogen Injection SystemEngr Muhammad Abu BakrNo ratings yet

- TR Filter TDS FlowerDocument7 pagesTR Filter TDS FlowerBinod KafleNo ratings yet

- 19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020Document10 pages19DV Guide Specifications, 350 To 800 Nominal Tons (1231 To 2814 Nominal KW) - Published Date 8.4.2020anganNo ratings yet

- Gs 18ms 1pdDocument11 pagesGs 18ms 1pdRitesh JhaNo ratings yet

- 630 KVA Distribution TransformerDocument4 pages630 KVA Distribution TransformerusmanaliNo ratings yet

- DiselgeneratorDocument6 pagesDiselgeneratorsanjayt0No ratings yet

- Tender - II-100Document113 pagesTender - II-100krcdewanewNo ratings yet

- CFS51 Fuel Oil Accessories 4 7 20Document9 pagesCFS51 Fuel Oil Accessories 4 7 20infra structionNo ratings yet

- Checklist For Shunt Reactor Rev01Document4 pagesChecklist For Shunt Reactor Rev01Santhosh Kumar VinayagamNo ratings yet

- CL-NG-6460-002-018 Checklist For Oil-Immersed Power Transformer Rev04Document9 pagesCL-NG-6460-002-018 Checklist For Oil-Immersed Power Transformer Rev04ahmed.fawzy.alalfy2050No ratings yet

- HVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralDocument4 pagesHVAC Guide Specifications Commercial Air-Cooled Condensing Units 63 To 87 KW (18 To 25 Tons), Nominal 38AH Part 1 GeneralcarlosorizabaNo ratings yet

- GS 30RB 27PDDocument9 pagesGS 30RB 27PDKike PadillaNo ratings yet

- Checklist For Shunt ReactorDocument4 pagesChecklist For Shunt ReactorSanthosh Kumar VinayagamNo ratings yet

- General Specifications For Power TransformersDocument18 pagesGeneral Specifications For Power Transformers54045114No ratings yet

- 2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)Document22 pages2.2.4 Air Pre Heaters and Steam Coil Air Pre Heaters 2.2.4.1 Air Pre Heaters (Aphs)sabrila wandaNo ratings yet

- Specification For D G Set - 250 KVADocument6 pagesSpecification For D G Set - 250 KVATiffany Nunez100% (1)

- G7.1 Air Conditioning EquipmentDocument12 pagesG7.1 Air Conditioning EquipmentAlex ChoongNo ratings yet

- Is.1180.2.1989 2 PDFDocument10 pagesIs.1180.2.1989 2 PDFkrk231No ratings yet

- HVAC Guide Specifications Variable Speed Screw ChillerDocument11 pagesHVAC Guide Specifications Variable Speed Screw ChillerNirav PatelNo ratings yet

- 8mva Power XmerDocument30 pages8mva Power XmerHamayoun MurtazaNo ratings yet

- Chiller Tech - EIL DelhiDocument9 pagesChiller Tech - EIL DelhibmanojNo ratings yet

- 26 12 71 02-A Iec (16325)Document23 pages26 12 71 02-A Iec (16325)Nhan HuynhNo ratings yet

- Pwer TransformerDocument17 pagesPwer Transformerrossikada100% (2)

- Technical Specifications A) Diesel Generating SetDocument17 pagesTechnical Specifications A) Diesel Generating SetS SNo ratings yet

- TS TransformerDocument7 pagesTS TransformerAmit SinghNo ratings yet

- Mechanical Works Technical Specifications University BaghdadDocument60 pagesMechanical Works Technical Specifications University BaghdadLiliana-Gabriela IoneteNo ratings yet

- Technical Specification - PumpDocument7 pagesTechnical Specification - PumpBalasundaramSrinivasaRajkumarNo ratings yet

- 3.26 Lv-GensetDocument17 pages3.26 Lv-Gensetjinfong upcNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- Tech Specification VSDDocument9 pagesTech Specification VSDDony SaputraNo ratings yet

- Station Service TransformerDocument13 pagesStation Service TransformerpvenkyNo ratings yet

- Technical Specifications Valve Actuators ScopeDocument6 pagesTechnical Specifications Valve Actuators ScopeBilalPervez100% (1)

- 5.25.55 - Pneumatic Control SystemsDocument5 pages5.25.55 - Pneumatic Control SystemsChrisman Eko MaradonaNo ratings yet

- Chillers BOQDocument16 pagesChillers BOQmohammad altafNo ratings yet

- ZEF Elevated Flare Specifications JohnzinkDocument8 pagesZEF Elevated Flare Specifications JohnzinkcandratrikusumaNo ratings yet

- CL-NG-6460-002-019 Checklist For Oil-Immersed Shunt Reactor Rev02Document11 pagesCL-NG-6460-002-019 Checklist For Oil-Immersed Shunt Reactor Rev02ahmed.fawzy.alalfy2050No ratings yet

- REACTOR - Rev-6Document21 pagesREACTOR - Rev-6Anwar BegNo ratings yet

- Especificaciones Tecnicas Apc Aa InrowDocument6 pagesEspecificaciones Tecnicas Apc Aa InrowWilder Phill Arzapalo GinesNo ratings yet

- Part II) - 1981 3.5 Isolation-: Also 4.5)Document1 pagePart II) - 1981 3.5 Isolation-: Also 4.5)Dinesh KumarNo ratings yet

- CFS21 Fuel Oil Pump Set 4 6 20Document5 pagesCFS21 Fuel Oil Pump Set 4 6 20infra structionNo ratings yet

- CD M&W 2008 Ed - Sect 4 - Dedicated CD ECS ComponentsDocument13 pagesCD M&W 2008 Ed - Sect 4 - Dedicated CD ECS ComponentsThamaraiselvan RamadossNo ratings yet

- REACTOR - Rev-2Document20 pagesREACTOR - Rev-2samarbtechNo ratings yet

- TS - 400kVA Earthing TransformerDocument8 pagesTS - 400kVA Earthing TransformerViswanathan VNo ratings yet

- Reactor: Engineering DepartmentDocument20 pagesReactor: Engineering DepartmentAnurag PugaliaNo ratings yet

- 63 15 25 KVA Single Phase Dist XmerDocument21 pages63 15 25 KVA Single Phase Dist XmerPrashant NankarNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Umang Boards: Electrical Grade Pre Compressed Press Boards/ Transformer BoardsDocument4 pagesUmang Boards: Electrical Grade Pre Compressed Press Boards/ Transformer BoardsxiaomiNo ratings yet

- Chapter 5: Optimum Circumscribing Circle Division Method (Occdm) To Get The Optimized Design of The Core Through Maximum Fill FactorDocument9 pagesChapter 5: Optimum Circumscribing Circle Division Method (Occdm) To Get The Optimized Design of The Core Through Maximum Fill FactorxiaomiNo ratings yet

- Chapter 7: Transformer Design Optimization Using Evolutionary AlgorithmsDocument38 pagesChapter 7: Transformer Design Optimization Using Evolutionary AlgorithmsxiaomiNo ratings yet

- Chapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design OptimizationDocument17 pagesChapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design Optimizationxiaomi0% (1)

- 010 Chapter 8Document5 pages010 Chapter 8xiaomiNo ratings yet

- Protect Transformer Assets: Serveron TM8Document6 pagesProtect Transformer Assets: Serveron TM8xiaomiNo ratings yet

- Chapter 3: ObjectivesDocument1 pageChapter 3: ObjectivesxiaomiNo ratings yet

- SITRAM Multisense 9: Customer Services For TransformersDocument2 pagesSITRAM Multisense 9: Customer Services For Transformersxiaomi0% (1)

- HYDROCAL 1009 English - R02 (11.2019)Document4 pagesHYDROCAL 1009 English - R02 (11.2019)xiaomiNo ratings yet

- Chapter 1: Introduction: 1.1 Transformer Engineering and Its Importance in Power SystemDocument9 pagesChapter 1: Introduction: 1.1 Transformer Engineering and Its Importance in Power SystemxiaomiNo ratings yet

- No. Title No.: List of TablesDocument1 pageNo. Title No.: List of TablesxiaomiNo ratings yet

- Protect Transformer Assets: Serveron TM3Document6 pagesProtect Transformer Assets: Serveron TM3xiaomiNo ratings yet

- Hve 2018 5028 FinalDocument7 pagesHve 2018 5028 FinalxiaomiNo ratings yet

- Dissolved Gas Analysis - OELCHECKDocument5 pagesDissolved Gas Analysis - OELCHECKxiaomiNo ratings yet

- Online Calculator - Density of OilDocument2 pagesOnline Calculator - Density of OilxiaomiNo ratings yet

- Sigma 70MM D.C.Document1 pageSigma 70MM D.C.xiaomiNo ratings yet

- NTPC SpecsDocument2 pagesNTPC SpecsxiaomiNo ratings yet

- Printers Are Displayed But Print Button Is Disabled in vb6 - Google SearchDocument2 pagesPrinters Are Displayed But Print Button Is Disabled in vb6 - Google SearchxiaomiNo ratings yet

- Power9 Performance Best Practices 0Document2 pagesPower9 Performance Best Practices 0rajans1999No ratings yet

- TLS-450PLUS, TLS4, & TLS4B Automatic Tank Gauges: Specification SheetDocument2 pagesTLS-450PLUS, TLS4, & TLS4B Automatic Tank Gauges: Specification SheetkahyeeNo ratings yet

- Call For Papers Open - Asia Pacific Unconventional Resources SymposiumDocument2 pagesCall For Papers Open - Asia Pacific Unconventional Resources SymposiumbayuNo ratings yet

- LogDocument97 pagesLogsunarti0236No ratings yet

- 7.0java Switch StatementDocument26 pages7.0java Switch Statementrobsonchungu5No ratings yet

- Unit 7: Inverse Trigonometr-Ic FunctionsDocument31 pagesUnit 7: Inverse Trigonometr-Ic FunctionsTamo TalasasaNo ratings yet

- CATIA V4 To V5 File MigrationDocument9 pagesCATIA V4 To V5 File MigrationSam AntonyNo ratings yet

- Bridge Management in Malaysia - 4Document9 pagesBridge Management in Malaysia - 4Gillan Siang Kwang LioNo ratings yet

- CS401 Mcqs MidTerm By Vu Topper RM-2Document79 pagesCS401 Mcqs MidTerm By Vu Topper RM-2mishalaslam17No ratings yet

- Flap DampersDocument16 pagesFlap DampersvinayakbunNo ratings yet

- Software Suite To Support STM32 DevelopmentDocument12 pagesSoftware Suite To Support STM32 DevelopmentMasood AlamNo ratings yet

- ISO - IEC - TR 29119-11-2020 Testing of AI Based SystemsDocument60 pagesISO - IEC - TR 29119-11-2020 Testing of AI Based SystemsSubhasis MallikNo ratings yet

- 2023-LECTURE 4-Common Safety Features of Commercial BuildingsDocument3 pages2023-LECTURE 4-Common Safety Features of Commercial BuildingsJoshua C. JosonNo ratings yet

- Matha Kalavarankal SrilankaDocument15 pagesMatha Kalavarankal SrilankaK. MayooranNo ratings yet

- Grow JAN Offerlist-2Document15 pagesGrow JAN Offerlist-2Jyotsna LingayatNo ratings yet

- Chapter 2 Python Revision Tour Ii NotesDocument36 pagesChapter 2 Python Revision Tour Ii Notessharma20keshavNo ratings yet

- Quality Assurance, Open and Distance Learning, and Australian UniversitiesDocument14 pagesQuality Assurance, Open and Distance Learning, and Australian UniversitiesDevNo ratings yet

- A Restful Approach: Clean Upnp Without SoapDocument6 pagesA Restful Approach: Clean Upnp Without Soapm.banduNo ratings yet

- Ug36 - Ug46Document5 pagesUg36 - Ug46ALEXISORTIZ20No ratings yet

- Arduino - Photographic DroneDocument23 pagesArduino - Photographic DroneEthan BlackNo ratings yet

- BV CvxslidesDocument402 pagesBV Cvxslidesshriya pandeyNo ratings yet

- Flappy Bird: CSEE 4840 Embedded System DesignDocument88 pagesFlappy Bird: CSEE 4840 Embedded System DesignAdiwena0putraNo ratings yet

- Poster Presentations ISMOA 2023 RevDocument7 pagesPoster Presentations ISMOA 2023 Revalifia zahiraNo ratings yet

- Clipsal Submittal - Indus HospitalDocument47 pagesClipsal Submittal - Indus HospitalMuteeb KhanNo ratings yet

- SCM - Enhanced Production Scheduling in Oracle Fusion Cloud Supply PlanningDocument39 pagesSCM - Enhanced Production Scheduling in Oracle Fusion Cloud Supply PlanningdavidjqNo ratings yet

- Giraffe 1 XDocument2 pagesGiraffe 1 Xjhon cenaNo ratings yet

- Chapter 5 Question Bank ITN6Document6 pagesChapter 5 Question Bank ITN6sherinNo ratings yet

- Module7 ch7 STDDocument29 pagesModule7 ch7 STDنسيبة الحميدانيNo ratings yet

- Cat A3wmyaf 2102Document8 pagesCat A3wmyaf 2102moukarjunnNo ratings yet