Viking Q4195 1

Viking Q4195 1

Uploaded by

arbiCopyright:

Available Formats

Viking Q4195 1

Viking Q4195 1

Uploaded by

arbiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Viking Q4195 1

Viking Q4195 1

Uploaded by

arbiCopyright:

Available Formats

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.1

SERIES 495, 4195 Issue B

TABLE OF CONTENTS SERIES DESCRIPTION

Features & Benefits....................................................................2 Viking’s Motor Speed Product Line internal gear pumps

represent a technological advance in the science of flow.

Standard Materials of Construction............................................2

Through new techniques of feeding the rotor and idler, Viking

Cutaway View & Pump Features................................................3 has achieved what was once considered impossible – high

Model Number Key.....................................................................4 flow rates operating at motor speeds. The largest size (QS)

operates at reduced speeds, but still faster than other pumps

Specifications..............................................................................4 of similar displacement. Higher speeds mean greater value,

Mounting Options........................................................................5 with the ability to move more fluid with a smaller pump. It

also enables close-coupling to a motor or gearmotor, which

Dimensions – G, GG, H, HJ, HL Sizes (495)................................6

eliminates shaft misalignment and results in longer seal and

Dimensions – AS, AK, AL Sizes (495). .........................................6 bearing life by preventing wear due to misalignment.

Dimensions – G, GG, H, HJ, HL Sizes (4195)..............................7

Dimensions – AS, AK, AL Sizes (4195).........................................7

Dimensions – KE, KKE, LQE, LSE Sizes (4195)..........................8 RELATED PRODUCTS

Dimensions – Q, QS Sizes (4195)................................................8 Steel Externals, 493/4193 Series: Catalog Section 1341

Dimensions – G, GG, H, HJ, HL Sizes – M Drive (495)...............9 Stainless Steel, 4197 Series: Catalog Section 1741

Dimensions – H, HJ, HL Sizes – IEC Frame M Drive (495).........9

Dimensions – AS, AK, AL Sizes – M Drive (495)........................10

Dimensions – KE, KKE, LQE, LSE Sizes –

Pump, M Drive, Motor (4195)...................................................... 11

Dimensions – G, GG, H, HJ, HL, AS, AK, AL Sizes –

D Drive (4195).............................................................................12

Dimensions – KE, KKE, LQE, LSE, Q Sizes – D Drive (4195)...13

Dimensions – Q, QS Sizes – R Drive (4195)..............................13

NPSH Required........................................................................14

Expected Nominal Sound Levels for Motor Speed Pumps......14

G, GG H, HJ, HL AS, AK, AL KE, KKE LQE, LSE Q, QS

OPERATING RANGE

NOMINAL MAXIMUM TEMPERATURE VISCOSITY

FLOW PRESSURE RANGE RANGE*

SERIES GPM m3 h PSI Bar °F °C SSU cSt

495 8 - 115 1.8 - 26 250 17 −40 to +300 −40 to +150 28 to 15,000 1 to 3,300

4195 8 - 580 1.8 - 132 250 17 −40 to +300 −40 to +150 28 to 15,000 1 to 3,300

* 25,000 SSU (5,500 cSt) for KE-LSE & QS, 7,500 SSU (1,700 cSt) for Q

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.2 CAST IRON PUMPS

Issue B SERIES 495, 4195

FEATURES & BENEFITS

• Direct drive with no gear reducer (with 60 Hz 4 pole motor • Gauge ports standard on all sizes.

to 205 GPM / 47 m3/h, 6 pole motor to 350 GPM / 80 m3/h, »» Allows easy application of gauges or transducers

8 pole motor to 460 GPM / 104 m3/h)

• Behind-the-rotor mechanical seals with FKM elastomers

»» Reduces cost of installation and Carbon/SiC faces as standard

»» Eliminates one shaft alignment »» Eliminates bracket bushing, enables use of antifriction

»» Eliminates one set of couplings and coupling guard bearing external to liquid

»» Reduces footprint »» Heavy duty seal provides broad application, long life

»» Eliminates gearbox lubrication and maintenance »» Casing weep hole between seal and forward bearing

enables detection of seal leakage, prevents intrusion

• Close-couple to C-face motor or gearmotor at flows to 350

into sealed bearing

GPM / 80 m3/h

• KE-QS sizes are available with ANSI or DIN flanges. No

»» Eliminates all shaft misalignment and coupling guards

piping adaptors required to conform to local standards

»» Keeps shafts aligned for longer seal and bearing life

• Opposite porting enables easy in-line mounting to almost

»» Simplifies mounting on skid frame without extra any piping system

baseplate

• Pressure lubricated idler pin lubricates the idler pin/bushing

»» Enables vertical mounting for smallest footprint (up to interface to extend life on thin liquids (AS-QS Sizes)

350 GPM / 80 m3/h)

• Static O-ring seals ensure maximum sealing capability on

• Heavy duty design with sealed-for-life bearings thin liquids (flat gaskets furnished on relief valve only on

»» No relubrication required G-HL sizes)

»» Thrust control enables pressures to 250 PSI / 17 BAR • Hardened steel idler on KE-QS sizes provides maximum

(G-AL sizes) or 150 PSI / 10 BAR (KE-QS sizes) service life and helps protect against cavitational wear on

low NPSHa applications

»» Enables end clearance adjustment for viscosity or to

compensate for wear over time

STANDARD MATERIALS OF CONSTRUCTION

Component Standard Material

Bracket / Casing Cast Iron, ASTM A48, Class 35B

Head Cast Iron, ASTM A48, Class 35B

Rotor Shaft Steel, ASTM A108, Grade 1045

Cast Iron, ASTM A48, Class 35B (G, GG, H, HJ, KE, LQE, Q)

Rotor

Ductile Iron, ASTM A536 Grade 60-40-18 (HL, AS, AK, AL, KKE, LSE, QS)

Powdered Metal MPIF 35, FN-0208-45 (G, GG)

Powdered Metal MPIF 35, FC-0208-50 (H, HJ, HL)

Idler Ductile Iron, ASTM A536 Grade 60-40-18 (AS, AK, AL)

Hardened Steel, ASTM A148, Grade 80-50 (KE, KKE, LQE, Q, QS)

Hardened Steel, ASTM A148, Grade 80-40 (LSE)

Idler Pin Hardened Steel, ASTM A108, Grade 1045

Idler Bushing Carbon Graphite

Pressure Relief Valve Cast Iron, ASTM A48, Class 35B

Mechanical Seal Faces Carbon vs. Ni-Resist (G-AL), Carbon vs. Silicon Carbide (KE-QS)

Elastomers FKM

Antifriction Bearings Steel with Buna Seals

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.3

SERIES 495, 4195 Issue B

CUTAWAY VIEW & PUMP FEATURES

NPT available on G-AL Sizes,

Behind the rotor seal, ANSI or DIN flanges on

so shaft and bearings KE-QS sizes, enabling easy

Flange for motor mounting bracket not exposed to media in-line mounting to almost

eliminates the need for drive equipment

any piping system

and provides better unit alignment

(Mounts available for NEMA & IEC motors

(G-LSE Sizes)

Sealed anti-friction

bearings eliminate the

need for relubrication

Threaded one-piece

bearing housing

allows for end

clearance adjustment

Gauge ports for easy

application of gauges or

transducers (location varies

by pump size)

One-piece casing ensures alignment

for maximum bearing and seal life

Pressure lubricated idler pin & bushing

Expanded feeding area & redesigned enhances pin & bushing life (AS-QS sizes)

head allow for higher speed on KE-QS

size pumps (KE-QS pumps are CW only)

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.4 CAST IRON PUMPS

Issue B SERIES 495, 4195

MODEL NUMBER KEY

K K E 4 1 9 5

Displacement: Shaft Seal: Basic Series

(1, 2 or 3 Digits) 4 = Mechanical Seal Configuration

G KE

GG KKE Material of Construction

H LQE 5 = Cast Iron

HJ LSE

HL Q Mounting:

AS QS Blank = Flange for M-Drive Bracket

AK

1 = Foot Mount (KE, KKE, LQE & LSE have foot mount and flange for M-Drive Bracket)

AL

SPECIFICATIONS

① Standard Ports Nominal Pump Rating (100 SSU & below) ③ Maximum ⑤ Maximum Approx.

Differential Hydrostatic Maximum Shipping Weight

60 Hz 50 Hz Pressure Pressure Temperature with Valve

Model Port Port

Number Size Type GPM m3/h RPM GPM m3/h RPM PSIG BAR PSIG BAR °F °C Lbs. Kg.

G4195

1 in. NPT 8 1.8 1750 7 1.5 1450 250 17 400 27 300 150 20 9

② G495

GG4195

1 in. NPT 10 2.3 1750 8 1.9 1450 250 17 400 27 300 150 20 9

② GG495

H4195

1½ in. NPT 15 3.4 1750 12 2.8 1450 250 17 400 27 300 150 44 20

② H495

HJ4195

1½ in. NPT 20 4.5 1750 17 3.8 1450 250 17 400 27 300 150 44 20

② HJ495

HL4195

1½ in. NPT 30 6.8 1750 25 5.6 1450 250 17 400 27 300 150 44 20

② HL495

AS4195

2½ in. NPT 55 12 1750 45 10 1450 250 17 400 27 300 150 85 39

② AS495

AK4195

2½ in. NPT 85 19 1750 70 16 1450 250 17 400 27 300 150 85 39

② AK495

AL4195

3 in. NPT 115 26 1750 95 22 1450 250 17 400 27 300 150 86 39

② AL495

④ KE4195 4 in. (100 mm) ① Flange 150 34 1750 125 28 1450 150 10 300 20 300 150 132 60

④ KKE4195 4 in. (100 mm) ① Flange 205 47 1750 170 39 1450 150 10 300 20 300 150 133 60

④ LQE4195 4 in. (100 mm) ① Flange 235 53 1150 195 44 960 150 10 300 20 300 150 220 100

④ LSE4195 4 in. (100 mm) ① Flange 350 80 1150 290 67 960 150 10 300 20 300 150 222 101

④ Q4195 6 in. (150 mm) ① Flange 460 104 750 460 104 750 150 10 300 20 300 150 443 201

④ QS4195 6 in. (150 mm) ① Flange 580 132 640 580 132 640 150 10 300 20 300 150 450 204

① Flange ports are suitable for use with Class 125 ANSI (inch) or ③ If suction pressures exceed 100 PSI (7 BAR), consult factory.

DIN PN-16 (mm) cast iron companion flanges or flanged fittings. ④ These sizes can only operate in one direction (clockwise only).

Optional Class 250 or DIN PN-25/40.

⑤ Maximum hydrostatic pressure for standard pump construction.

② 495 models require motor mount bracket, do not have Rating is dependent on seal, gaskets and ports.

mounting foot. KE, KKE, LQE, LSE 4195 models have both

mounting flange for motor bracket and a mounting foot.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.5

SERIES 495, 4195 Issue B

MOUNTING OPTIONS

Flange Motor Mount Units (M-Drive)

Pump and motor mounted to a flange

mounting bracket with coupling.

Sizes: G - AL495 & KE-LSE4195

See chart below for pump sizes and flange

mounting brackets available by motor frame.

M-Drive Brackets Available

① Pump Model Number -

Mounting Flange for Motor Bracket NEMA Motor Footed? IEC B-14 Motor Footed?

G495 56C, 143/5TC, 182/4TC No ③ 80, 90 No ③

GG495 56C, 143/5TC, 182/4TC No ③ 80, 90 No

H495 56C, 143/5TC, 182/4TC, 213/5TC No ③ 90, 100/112, 132 Yes

HJ495 56C, 143/5TC, 182/4TC, 213/5TC No ③ 90, 100/112, 132 Yes

HL495 56C, 143/5TC, 182/4TC, 213/5TC No ③ 90, 100/112, 132 Yes

AS495 182/4TC, 213/5TC , 254/6TC, 284/6TC Yes 132, 160 Yes

AK495 182/4TC, 213/5TC , 254/6TC, 284/6TC Yes 132, 160 Yes

AL495 182/4TC, 213/5TC , 254/6TC, 284/6TC Yes 132, 160 Yes

① KE4195 213/5TC, 254/6TC, 284/6TC Yes 132, 160 Yes

① KKE4195 213/5TC, 254/6TC, 284/6TC Yes 132, 160 Yes

① LQE4195 324/6TC Yes 160/180 ② Yes

① LSE4195 324/6TC Yes 160/180 ② Yes

① 495 models require a motor mount bracket, they do not have a mounting foot.

KE, KKE, LQE, LSE 4195 models have both mounting flange for motor bracket and a mounting foot.

② Only available as B5.

③ Requires footed motor.

Direct Drive (D-Drive)

Pump and motor mounted on a base

with coupling and coupling guard.

Sizes: G - LSE4195

Reducer Drive (R-Drive)

Pump, Viking C-reducer and motor

mounted on a base with couplings

and coupling guards.

Sizes: Q & QS4195

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.6 CAST IRON PUMPS

Issue B SERIES 495, 4195

DIMENSIONS – G, GG, H, HJ, HL SIZES (495)

Model A U V

B C E F G H J K N P R T X

Number (in) (in) (in)

G495 in 2.75 2.66 3.00 4.00 0.41 0.50 3.44 2.81 1.12 0.94 2.88 1.12 0.62

1 0.50 FLAT

GG495 mm 70 67 76 102 10 13 87 71 29 24 73 29 16

H495 in 3.75 3.28 4.75 5.88 0.56 0.75 4.50 4.00 1.50 1.50 3.88 1.62 0.62

HJ495 1½ 0.75 .19 x .09

HL495 mm 95 83 121 149 14 19 114 102 38 38 98 41 16

DIMENSIONS – AS, AK, AL SIZES (495)

Model A U V

B C E F G H J K L P R S T W X Y Z

Number (in) (in) (in)

AS495 in 5.00 8.38 4.75 6.25 0.56 0.75 2.00 5.75 0.75 2.25 4.25 12.12 2.50 7.00 1.12 1.00 1.72

2½ 1.00 .25 x .12

AK495 mm 127 213 121 159 14 19 51 146 22 57 108 308 64 178 29 25 40

in 5.00 8.88 4.75 6.25 0.56 0.75 2.50 5.75 0.75 2.25 4.25 12.12 2.50 7.00 1.12 1.00 1.72

AL495 3 1.00 .25 x .12

mm 127 225 121 159 14 19 64 146 22 57 108 308 64 178 29 25 40

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.7

SERIES 495, 4195 Issue B

DIMENSIONS – G, GG, H, HJ, HL SIZES (4195)

Model A U V

B D E F G H J K L M N O P S T W X

Number (in) (in) (in)

G495 in 2.75 2.75 1.62 1.31 4.00 2.44 0.34 0.94 0.03 0.66 1.12 0.31 0.62 7.31 1.12 2.66 0.38

1 0.50 FLAT

GG495 mm 70 70 41 33 102 62 9 24 1 17 29 8 16 186 29 67 10

H495 in 3.75 4.12 1.75 2.00 5.00 3.50 0.41 1.50 1.25 0.88 1.50 0.44 0.62 10.00 1.62 3.28 0.75

HJ495 1½ 0.75 .19 x .09

HL495 mm 95 105 44 51 127 89 10 38 32 22 38 11 16 254 41 83 19

DIMENSIONS – AS, AK, AL SIZES (4195)

Model A U V

B D E F G H J K L M N O P S T W X Y Z

Number (in) (in) (in)

AS4195 in 5.00 5.25 2.88 2.00 6.75 4.00 0.41 2.25 1.25 1.00 2.00 0.44 1.12 12.12 2.50 7.00 0.50 1.00 1.72

2½ 1.00 .25 x .12

AK4195 mm 127 133 73 51 171 102 10 57 32 25 51 11 29 308 60 178 13 25 40

in 5.00 5.25 2.88 2.00 6.75 4.00 0.41 2.25 1.75 1.00 2.50 0.44 1.12 12.12 2.50 7.00 0.50 1.00 1.72

AL4195 3 1.00 .25 x .12

mm 127 133 73 51 171 102 10 57 44 25 64 11 29 308 60 178 13 25 40

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.8 CAST IRON PUMPS

Issue B SERIES 495, 4195

DIMENSIONS – KE, KKE, LQE, LSE SIZES (4195)

S Y

AA N B B

V - KEYWAY

U T

A - PORTS

K

W

AB

4X AC

2X O L 4X J 2X X

R AB

M E E

F

H G

Model U V

A* B D E F G H J K L M N O R S T W X Y AA AB AC

Number (in) (in)

KE4195 in 4 6.69 5.50 2.50 2.50 6.00 4.37 0.53 2.25 1.13 1.37 2.50 0.44 4.25 16.45 2.50 14.42 0.50 7.26 8.20 4.76 0.56

1.13 .25 X .12

KKE4195 mm 100 170 140 64 64 152 111 14 57 29 35 64 11 108 418 64 366 13 184 208 121 14

LQE4195 in 4 8.50 7.00 3.00 2.75 7.24 5.00 0.53 3.25 1.50 1.25 2.75 0.51 5.25 19.03 3.50 19.88 0.62 9.66 9.88 4.76 0.56

1.44 .38 X .19

LSE4195 mm 100 216 178 76 70 184 127 14 83 38 32 70 13 133 483 89 505 16 245 251 121 14

* Inch dimensions for Class 125 ANSI flanged ports, mm dimensions for DIN PN-16 flanged ports.

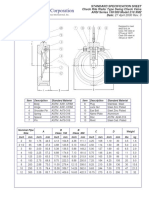

DIMENSIONS – Q, QS SIZES (4195)

S Y

N B B

K

V - KEYWAY

A - PORTS

W

L 4X J 2X X

2X O

M E E

F

G

H

Model U V

A* B D E F G H J K L M N O S T W X Y

Number (in) (in)

Q4195 in 6 10.50 8.75 4.25 3.00 10.35 5.75 0.69 4.36 3.25 2.00 4.00 0.62 25.26 4.44 7.00 1.00 1.72

1.94 .50 X .25

QS4195 mm 150 267 222 108 76 263 146 18 111 83 51 102 16 642 113 178 25 40

* Inch dimensions for Class 125 ANSI flanged ports, mm dimensions for DIN PN-16 flanged ports.

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.9

SERIES 495, 4195 Issue B

DIMENSIONS – G, GG, H, HJ, HL SIZES – M DRIVE (495)

NOTE: Jaw type coupling with straight jaws

recommended to facilitate assembly of motor and

pump to bracket.

COUPLING IS GUARDED WITH PLATES OVER

SIDE OPENINGS ON MOUNTING BRACKET.

MOTOR MOTOR

MODEL A B C J L M N D E F G H K MODEL A B C J L M N D E F G H K

FRAME FRAME

.34 .34

in 2.75 2.66 3.44 .62 .19 1.12 NEMA 3.50 2.44 1.50 2.56 8.88 in

3.75 3.28 4.50 .62 .19 1.50 NEMA 3.50 2.44 1.50 2.56 11.12

SLOT SLOT

56C 56C

mm 70 67 87 16 5 29 89 62 38 65 225 9 mm 95 83 114 16 5 38 89 62 38 65 283 9

in 2.75 2.66 3.44 .62 .19 1.12 NEMA 3.50 2.75 2.00 2.88 8.88 .34 in 3.75 3.28 4.50 .62 .19 1.50 NEMA 3.50 2.75 2.00 2.88 11.12 .34

mm 70 67 87 16 5 29 143TC 89 70 51 73 225 9 mm 95 83 114 16 5 38 143TC 89 70 51 73 283 9

G495

1 in 2.75 2.66 3.44 .62 .19 1.12 NEMA 3.50 2.75 2.50 2.88 8.88 .34 in 3.75 3.28 4.50 .62 .19 1.50 NEMA 3.50 2.75 2.50 2.88 11.12 .34

GG495

mm 70 67 87 16 5 29 145TC 89 70 64 73 225 9 H495 mm 95 83 114 16 5 38 145TC 89 70 64 73 283 9

in 2.75 2.66 3.44 .62 .19 1.12 NEMA 4.50 3.75 2.25 3.38 9.56 .41 HJ495 in 1½ 3.75 3.28 4.50 .62 .19 1.50 NEMA 4.50 3.75 2.25 3.38 11.81 .41

mm 70 67 87 16 5 29 182TC 144 95 57 86 243 10 HL495 mm 95 83 114 16 5 38 182TC 144 95 57 86 300 10

in 2.75 2.66 3.44 .62 .19 1.12 NEMA 4.50 3.75 2.75 3.38 9.56 .41 in 3.75 3.28 4.50 .62 .19 1.50 NEMA 4.50 3.75 2.75 3.38 11.81 .41

mm 70 67 87 16 5 29 184TC 114 95 70 86 243 10 mm 95 83 114 16 5 38 184TC 114 95 70 86 300 10

in 2.75 2.66 3.44 0.62 0.19 1.12 IEC 3.15 2.46 1.97 1.97 4.38 0.39 in 3.75 3.28 4.50 .62 .19 1.50 NEMA 5.25 4.25 2.75 4.25 12.56 .41

G495 mm 69.9 67.6 87.4 15.7 4.8 28.4 80 80.0 62.5 50.0 50.0 111.3 10.0 mm 95 83 114 16 5 38 213TC 133 108 70 108 319 10

1

GG495 in 2.75 2.66 3.44 0.62 0.19 1.12 IEC 3.54 2.76 1.97 2.21 8.71 0.39 in 3.75 3.28 4.50 .62 .19 1.50 NEMA 5.25 4.25 3.50 4.25 12.56 .41

mm 69.9 67.6 87.4 15.7 4.8 28.4 90 90.0 70.0 50.0 56.0 221.2 10.0 mm 95 83 114 16 5 38 215TC 133 108 89 108 319 10

DIMENSIONS – H, HJ, HL SIZES – IEC FRAME M DRIVE (495)

Brackets are designed for IEC motors

with B14 mounting face.

NOTE: Jaw type coupling with straight jaws

recommended to facilitate assembly of motor

and pump to bracket.

COUPLING IS GUARDED WITH PLATES OVER

SIDE OPENINGS ON MOUNTING BRACKET.

A MOTOR

MODEL B C M N P D E F G H J K L O R S

(in) FRAME

in 3.75 3.28 4.50 1.50 0.62 4.62 2.38 6.40 3.52 5.14 0.81 0.57 4.92 0.75 6.61 0.19

IEC 90

H495 mm 95 83 114 38 16 117 61 163 89 131 21 15 125 19 168 5

in 3.75 3.28 4.50 1.50 0.62 4.62 2.38 6.40 3.52 5.14 0.81 0.57 4.98 0.75 7.01 0.19

HJ495 1½ IEC 100/112

mm 95 83 114 38 16 117 61 163 89 131 21 15 129 19 178 5

HL495 in 3.75 3.28 4.50 1.50 0.62 5.32 2.95 7.48 4.50 6.09 0.80 0.57 5.11 0.75 8.16 0.25

IEC 132

mm 95 83 114 38 16 135 75 190 114 155 20 15 130 19 207 6

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.10 CAST IRON PUMPS

Issue B SERIES 495, 4195

DIMENSIONS – AS, AK, AL SIZES – M DRIVE (495)

Model Motor A

B C D E F G H J K L M N O P R S Y

Number Frame (in)

① ①

In 5.00 6.25 2.75 7.00 5.00 7.00 1.00 0.56 6.38 2.00 0.50 1.12 7.00 0.19 1.00

NEMA 19.06 8.44

2½

① ① ①

mm 127 159 70 178 127 178 25 14 162 51 13 29 178 5 25

AS495 484 214

AK495 IEC In 5.00 18.16 6.25 2.75 7.00 5.00 7.24 1.12 0.56 7.75 6.38 2.00 0.50 1.12 7.12 0.25 6.00

2½

132 mm 127 461 159 70 178 127 184 28 14 197 162 51 13 28 181 6 152

IEC In 5.00 19.58 6.50 2.75 7.50 6.00 8.26 1.13 0.56 7.75 6.38 2.00 0.62 1.12 7.12 0.25 6.00

2½

160 mm 127 497 165 70 191 152 210 29 14 197 162 51 16 28 181 6 152

① ①

In 5.00 6.25 2.75 7.00 5.00 7.00 1.00 0.56 6.38 2.50 0.50 1.12 7.00 0.19 1.00

NEMA 19.56 8.44

3

① ① ①

mm 127 159 70 178 127 178 25 14 162 64 13 29 178 5 25

497 214

AL495 In 5.00 18.66 6.25 2.75 7.00 5.00 7.24 1.12 0.56 7.75 6.38 2.50 0.50 1.12 7.12 0.25 6.00

IEC

3

132 mm 127 20 159 70 178 127 184 28 14 197 162 64 13 28 181 6 152

IEC In 5.00 20.08 6.50 2.75 7.50 6.00 8.26 1.13 0.56 7.75 6.38 2.50 0.62 1.12 7.12 0.25 6.00

3

160 mm 127 510 165 70 191 152 210 29 14 197 162 64 16 28 181 6 152

① Dimensions are correct for 182TC through 215TC motors. For 254TC/256TC motors, add .88” to the dimensions shown.

NOTE: Jaw type coupling with straight jaws recommended to facilitate assembly of motor and pump to bracket.

COUPLING IS GUARDED WITH PLATES OVER SIDE OPENINGS ON MOUNTING BRACKET.

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.11

SERIES 495, 4195 Issue B

DIMENSIONS – KE, KKE, LQE, LSE SIZES – PUMP, M DRIVE, MOTOR (4195)

C

N

E E

H

Model

Motor A* B C D E F G H J K L M N O P R S Y

Number

NEMA 4 in 6.69 20.51 6.25 2.75 7.00 5.00 7.24 1.12 0.56 10.14 8.20 2.50 0.50 0.75 8.92 0.19 7.26

213/215 100 mm 169.9 521.0 158.8 69.9 177.8 127.0 183.9 28.4 14.2 257.6 208.3 63.5 12.7 19.1 226.6 4.8 184.4

NEMA 4 in 6.69 21.39 6.25 2.75 7.00 5.00 7.24 1.12 0.56 11.02 8.20 2.50 0.50 0.75 8.92 0.19 7.26

254/256 100 mm 169.9 543.3 158.8 69.9 177.8 127.0 183.9 28.4 14.2 279.9 208.3 63.5 12.7 19.1 226.6 4.8 184.4

KE4195 NEMA 4 in 6.69 22.02 8.00 3.50 9.00 7.00 9.31 1.16 0.56 9.36 8.20 2.50 0.76 2.50 8.92 0.19 7.26

KKE4195 284/286 100 mm 169.9 559.3 203.2 88.9 228.6 177.8 236.5 29.5 14.2 237.7 208.3 63.5 19.3 63.5 226.6 4.8 184.4

IEC 4 in 6.69 18.08 6.25 2.75 7.00 5.00 7.24 1.12 0.56 9.58 8.20 2.50 0.50 0.75 8.92 0.25 7.26

132 100 mm 169.9 459.2 158.8 69.9 177.8 127.0 183.9 28.4 14.2 243.3 208.3 63.5 12.7 19.1 226.6 6.4 184.4

IEC 4 in 6.69 19.40 6.50 2.75 7.50 6.00 8.26 1.13 0.56 9.57 8.20 2.50 0.62 1.00 8.92 0.25 7.26

160 100 mm 169.9 492.8 165.1 69.9 190.5 152.4 209.8 28.7 14.2 243.1 208.3 63.5 15.7 25.4 226.6 6.4 184.4

NEMA 4 in 8.50 25.3 8.25 3.88 10.00 7.25 9.85 1.30 0.88 10.71 9.88 2.75 0.75 1.25 12.88 0.19 9.66

324/326 100 mm 215.9 642.6 209.6 98.6 254.0 184.2 250.2 33.0 22.4 272.0 251.0 69.9 19.1 31.8 327.2 4.8 243.7

LQE4195 IEC 4 in 8.50 21.63 7.50 3.25 9.00 7.25 9.81 1.28 0.88 10.34 9.88 2.75 0.75 0.50 12.88 0.25 9.66

LSE4195 160 100 mm 215.9 549.4 190.5 82.6 228.6 184.2 249.2 32.5 22.4 262.6 251.0 69.9 19.1 12.7 327.2 6.4 243.7

IEC 4 in 8.50 21.63 7.50 3.25 9.00 7.25 9.81 1.28 0.88 10.34 9.88 2.75 0.75 0.50 12.88 0.25 9.66

180 100 mm 215.9 549.4 190.5 82.6 228.6 184.2 249.2 32.5 22.4 262.6 251.0 69.9 19.1 12.7 327.2 6.4 243.7

* Inch dimensions for Class 125 ANSI flanged ports, mm dimensions for DIN PN-16 flanged ports.

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.12 CAST IRON PUMPS

Issue B SERIES 495, 4195

DIMENSIONS – G, GG, H, HJ, HL, AS, AK, AL SIZES – D DRIVE (4195)

A

Model Motor B D E F H J K L M M1 N P S

(in)

NEMA in 2.75 3.50 1.50 20.50 0.75 0.75 8.50 0.38 3.81 0.63 0.63 4.25

1

56 mm 70 89 38 521 19 19 216 10 97 16 16 108

NEMA in 2.75 3.50 1.50 20.50 0.75 0.75 8.50 0.38 3.81 0.63 0.63 4.25

1

G4195 143/145 mm 70 89 38 521 19 19 216 10 97 16 16 108

—

GG4195 NEMA in 2.75 4.50 1.50 20.50 0.75 0.75 8.50 0.38 3.81 0.63 0.63 4.25

1

182/184 mm 70 114 38 521 19 19 216 10 97 16 16 108

NEMA in 2.75 5.25 2.94 29.00 1.00 1.50 9.00 1.90 3.81 0.63 0.63 4.50

1

213/215 mm 70 133 75 737 25 38 229 48 97 16 16 114

NEMA in 3.75 4.12 1.50 20.50 0.75 0.75 8.50 4.78 0.62 0.63 4.25

1½ —

56 mm 95 105 38 521 19 19 216 121 16 16 108

NEMA in 3.75 4.12 1.50 20.50 0.75 0.75 8.50 4.78 0.62 0.63 4.25

1½ —

143/145 mm 95 105 38 521 19 19 216 121 16 16 108

H4195 in 3.75 4.50 2.94 29.00 1.00 1.50 9.00 0.25 4.78 0.62 0.63 4.50

NEMA

HJ4195 1½ —

182/184 mm 95 114 75 737 25 38 229 6 121 16 16 114

HL4195

NEMA in 3.75 5.25 2.94 29.00 1.00 1.50 9.00 0.25 4.78 0.62 0.63 4.50

1½

213/215 mm 95 133 75 737 25 38 229 6 121 16 16 114

NEMA in 3.75 6.50 3.25 28.75 1.00 1.00 17.00 4.78 0.62 0.63 8.50

1½ —

254/256 mm 95 165 83 730 25 25 432 121 16 16 216

NEMA in 5.00 5.25 2.94 29.00 1.00 1.50 9.00 1.75 6.97 1.12 0.63 4.50

2½

143/145T mm 127 133 75 737 25 38 229 45 177 28 16 114

NEMA in 5.00 5.25 2.94 29.00 1.00 1.50 9.00 6.97 1.12 0.63 4.50

2½ —

182/184 mm 127 133 75 737 25 38 229 177 28 16 114

AS4195 in 5.00 5.25 2.94 34.00 1.00 1.50 9.00 6.97 1.12 0.63 4.50

NEMA

AK4195 2½ — —

213/215 mm 127 133 75 864 25 38 229 177 28 16 114

AL4195 *

NEMA in 5.00 6.25 4.00 39.00 1.38 1.38 16.00 3.75 6.97 1.12 0.63 8.00

2½

254/256 mm 127 159 102 991 35 35 406 95 177 28 16 203

NEMA in 5.00 7.00 4.00 39.00 1.38 1.38 16.00 1.75 6.97 1.12 0.63 8.00

2½

284/286 mm 127 178 102 991 35 35 406 45 177 28 16 203

* 3" port on AL4195D.

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

MOTOR SPEED PRODUCT LINE: Section 1441

CAST IRON PUMPS Page 1441.13

SERIES 495, 4195 Issue B

DIMENSIONS – KE, KKE, LQE, LSE, Q SIZES – D DRIVE (4195)

B B

A

M

E

4X P L J S

F H K

Model Motor A* B D E F H J K L M P S

NEMA in 4 6.69 5.50 4.00 37.75 2.00 2.00 14.75 3.37 8.92 0.63 7.38

213/215 mm 100 169.9 139.7 101.6 958.9 50.8 50.8 374.7 85.6 226.6 16.0 187.3

KE4195 NEMA in 4 6.69 6.25 6.00 48.00 2.00 2.00 20.00 3.37 8.92 0.63 10.00

KKE4195 254/256 mm 100 169.9 158.8 152.4 1219.2 50.8 50.8 508.0 85.6 226.6 16.0 254.0

NEMA in 4 6.69 7.00 6.00 48.00 2.00 2.00 20.00 3.37 8.92 0.63 10.00

284/286 mm 100 169.9 177.8 152.4 1219.2 50.8 50.8 508.0 85.6 226.6 16.0 254.0

NEMA in 4 6.69 7.31 6.00 48.00 2.00 2.00 20.00 3.25 12.88 0.63 10.00

284/286 mm 100 169.9 185.7 152.4 1219.2 50.8 50.8 508.0 82.6 327.2 15.9 254.0

LQE4195 NEMA in 4 6.69 8.06 6.00 58.50 2.00 2.00 18.75 3.25 12.88 0.63 9.38

LSE4195 324/326 mm 100 169.9 204.7 152.4 1485.9 50.8 50.8 476.3 82.6 327.2 15.9 238.1

NEMA in 4 6.69 9.06 6.00 58.50 2.00 2.00 18.75 3.25 12.88 0.63 9.38

364/365 mm 100 169.9 230.1 152.4 1485.9 50.8 50.8 476.3 82.6 327.2 15.9 238.1

IEC in 6 10.50 11.37 6.00 68.00 2.00 2.00 32.00 1.00 15.06 0.88 16.00

Q4195

280 mm 150 266.7 288.8 152.4 1727.2 50.8 50.8 812.8 25.4 382.5 22.4 406.4

* Inch dimensions for Class 125 ANSI flanged ports, mm dimensions for DIN PN-16 flanged ports.

DIMENSIONS – Q, QS SIZES – R DRIVE (4195)

J 4X P

B

B K B

S

H L A

F M

C D

E

Model Motor A* B C D E F H J K L M P S

NEMA in 6.00 10.50 6.25 8.75 6.00 59.50 1.50 1.50 19.75 1.50 15.06 0.63 14.07

254/256 mm 150 266.7 158.8 222.3 152.4 1511.3 38.1 38.1 501.7 38.1 382.5 15.9 357.4

Q4195 NEMA in 6.00 10.50 7.00 8.75 6.00 59.50 1.50 1.50 19.75 1.50 15.06 0.63 14.07

QS4195 284/286 mm 150 266.7 177.8 222.3 152.4 1511.3 38.1 38.1 501.7 38.1 382.5 15.9 357.4

NEMA in 6.00 10.50 8.00 8.75 6.00 68.00 2.00 2.00 20.00 1.00 15.06 0.63 14.81

324/326 mm 150 266.7 203.2 222.3 152.4 1727.2 50.8 50.8 508.0 25.4 382.5 15.9 376.2

* Inch dimensions for Class 125 ANSI flanged ports, mm dimensions for DIN PN-16 flanged ports.

These dimensions are average and not for construction purposes. Certified prints on request.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

Section 1441 MOTOR SPEED PRODUCT LINE:

Page 1441.14 CAST IRON PUMPS

Issue B SERIES 495, 4195

NPSH REQUIRED

Printed performance curves are not available.

Performance curves can be electronically generated with the Viking Pump Selector Program on vikingpump.com.

NPSHR data is not available on the pump selector.

Increasing the operating speed of positive displacement pumps increases the NPSHR (Net Positive Suction Head – Required by

pump) and sound levels. These are two factors that should be considered when selecting the correct pump for the application.

Below are charts for the NPSHR and sound levels of the Motor Speed Series pumps.

NPSH (Net Positive Suction Head): The NPSHR (Net Positive Suction Head Required by the pump) is given in the table below

and applies for viscosities through 750 SSU. NPSHA (Net Positive Suction Head – Available in the system) must be greater than

the NPSHR. For a complete explanation of NPSH, see Application Data Sheet AD-19.

FOR VISCOSITIES UP TO 750 SSU – See NPSHR table below.

NPSHR for high viscosities can be estimated using the following method:

1. Calculate line loss for a 1 foot long pipe of a diameter matching the pump inlet port size. Use your flow rate and max viscosity.

2. Convert this value into Feet of Liquid (S.G. 1.0)

3. Add this value to the NPSHR value in the chart below.

PUMPS SPEED, RPM

PUMP SIZE

520 640 780 950 1150 1450 1750

G, GG 1.6 2.2 2.6 3.1 3.9 5.6 7.6

H, HJ, HL 2 2.8 3.4 4.5 6.2 9.5 13.5

AS, AK, AL 2.8 3.9 5.5 7.7 11.2 16.8 23.3

① KE, KKE 4.4 4.9 5.7 7 8.9 12.8 17.9

① LQE, LSE 7.3 9.3 10.9 13.1 16.1 — —

① Q, QS 6.8 9 ② 12.2 — — — —

Note: NPSHR – FEET OF LIQUID (Specific Gravity 1.0), Viscosities up to 750 SSU

① These pumps utilize a directional design.

② Applies to Q pump only. QS pump max speed is 640 RPM.

EXPECTED NOMINAL SOUND LEVELS FOR MOTOR SPEED PUMPS

The sound pressure level, measured in dB(A), is a measurement of the deviation in the atmospheric pressure caused by a sound

wave. The measurement is taken at a distance of approximately 1 meter from the sound source. The sound pressure levels are

for the pump only using a 100 SSU liquid, at 100 PSI discharge pressure, at the speeds indicated. Background noise and ancillary

equipment, such as drives and motors, in the operating environment will likely cause the actual sound pressure level to deviate

from the information in the table below.

Local national laws and regulations on noise exposure in the workplace should be observed during operation.

PUMPS SPEED, RPM

PUMP SIZE

520 640 780 950 1150 1450 1750

G, GG — — — 62 63 63 63

H, HJ, HL — — — 68 70 75 80

AS, AK, AL — — — 82 84 86 88

① KE, KKE — — — 84 86 87 89

① LQE, LSE — 88 89 91 93 — —

① Q, QS 91 93 ② 94 — — — —

Note: NPSHR – FEET OF LIQUID (Specific Gravity 1.0), Viscosities up to 750 SSU

① These pumps utilize a directional design.

② Applies to Q pump only. QS pump max speed is 640 RPM.

• A Unit of IDEX Corporation • Cedar Falls, IA ©2018

You might also like

- Modern Digital and Analog Communications Systems - B P Lathi Solutions ManualDocument155 pagesModern Digital and Analog Communications Systems - B P Lathi Solutions Manualsandy_00991% (89)

- F6198 CMM 011Document218 pagesF6198 CMM 011airbusa420No ratings yet

- Product Information.: Technical Training. N47TU EngineDocument66 pagesProduct Information.: Technical Training. N47TU EngineAndreAPL100% (2)

- FPD 1034 e PDFDocument923 pagesFPD 1034 e PDFBenicio Joaquín Ferrero Brebes75% (4)

- Safety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20Document9 pagesSafety Data Sheet MSDS - Vanadium-Electrolyt-Lösung2014-10-20XaviAlonsoNo ratings yet

- Force Feed Lubricator Pump: PrimingDocument2 pagesForce Feed Lubricator Pump: Priminggustavofx21No ratings yet

- Grid Method Earthwork Calculation PDFDocument4 pagesGrid Method Earthwork Calculation PDFarbiNo ratings yet

- Software Optimization For High-Performance ComputingDocument409 pagesSoftware Optimization For High-Performance Computingapi-3714165100% (3)

- Clash DetectionDocument9 pagesClash DetectionprinccharlesNo ratings yet

- Lane Width PDFDocument4 pagesLane Width PDFtanieNo ratings yet

- 4127qviking UmpDocument12 pages4127qviking UmpkishorsinghNo ratings yet

- Technical Service Manual: Heavy-Duty Stainless Steel Pumps SERIES 4197 Sizes GG, HJ, HL, As, Ak, AlDocument10 pagesTechnical Service Manual: Heavy-Duty Stainless Steel Pumps SERIES 4197 Sizes GG, HJ, HL, As, Ak, AlMartín TeranNo ratings yet

- Sec - 1701 - Non-Jacketed 4127 Q Viking PumpDocument13 pagesSec - 1701 - Non-Jacketed 4127 Q Viking Pumpkishorsingh100% (1)

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Bombas Contra Incendio PattersonDocument9 pagesBombas Contra Incendio PattersonLENINROMEROH4168No ratings yet

- M7..dw.. en PDFDocument25 pagesM7..dw.. en PDFkiranNo ratings yet

- XMZ 210Document3 pagesXMZ 210Carlos GutierrezNo ratings yet

- MCPK 100-065-125 CCX Andalan 316Document5 pagesMCPK 100-065-125 CCX Andalan 316Efril dilen franciscoNo ratings yet

- Bomba Goulds 3X4 - E213h513 PDFDocument18 pagesBomba Goulds 3X4 - E213h513 PDFRoger Chavez100% (1)

- 8.data Sheet 150 DL 57.5Document4 pages8.data Sheet 150 DL 57.5Gokula Krishnan CNo ratings yet

- REICH ARCUSAFLEX Rubber Disc CouplingsDocument20 pagesREICH ARCUSAFLEX Rubber Disc Couplingsfernandoalvesvnb100% (1)

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- 905 Series Liquid Ring Vacuum Pumps & CompressorsDocument4 pages905 Series Liquid Ring Vacuum Pumps & CompressorscarlosNo ratings yet

- Pump ZM B PDFDocument12 pagesPump ZM B PDFRamon Pacheco100% (1)

- TECHNICAL VOGEL L Series - English Only ITT 1 PDFDocument94 pagesTECHNICAL VOGEL L Series - English Only ITT 1 PDFadamNo ratings yet

- KSB - Catálogo Completo - 2008Document32 pagesKSB - Catálogo Completo - 2008Deyvith RiosNo ratings yet

- Brochure Flowserve FRBH Worthington® Heavy Duty Paper Stock and Process PumpDocument8 pagesBrochure Flowserve FRBH Worthington® Heavy Duty Paper Stock and Process PumpCarlos Daniel Michel Leyton100% (1)

- Viking 4324A Oandm TSM6303 PDFDocument11 pagesViking 4324A Oandm TSM6303 PDFQOBITNo ratings yet

- RW PDFDocument6 pagesRW PDFnbharath1988100% (1)

- Data Sheet - GBL Tag No. P-772P-ADocument9 pagesData Sheet - GBL Tag No. P-772P-ARajendra GuptaNo ratings yet

- Rego Multiport A8574AGDocument2 pagesRego Multiport A8574AGCristobal CherigoNo ratings yet

- Manual T8A3 BDocument37 pagesManual T8A3 BHéctor José Muñoz Roca100% (1)

- Product Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304Document16 pagesProduct Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304josecordova2014100% (1)

- Engineering DataDocument26 pagesEngineering DataadcaNo ratings yet

- Positive Displacement Dosing Pump: The Right Dosing ChoiceDocument12 pagesPositive Displacement Dosing Pump: The Right Dosing ChoiceTrungGVNo ratings yet

- User Instructions: Installation Operation MaintenanceDocument60 pagesUser Instructions: Installation Operation MaintenanceYaku YokuNo ratings yet

- 195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0Document8 pages195363-EBA-02-DS-0001 - PUMP DATA SHEET - Rev.0leejo100% (1)

- 16 RR NOV 165T-5 Technical Data SheetsDocument2 pages16 RR NOV 165T-5 Technical Data SheetsJunior Francisco QuijanoNo ratings yet

- Morin Actuator-79S 79B 79C HPDocument8 pagesMorin Actuator-79S 79B 79C HPInamex-fpVeracruzNo ratings yet

- PumpDocument4 pagesPumpMario AvilesNo ratings yet

- Comparison SICcast Metales RaaDocument1 pageComparison SICcast Metales RaaDonald Cuadros CondoriNo ratings yet

- 5Document6 pages5Rizal100% (1)

- GILKESDocument25 pagesGILKESJohnny CcanchiNo ratings yet

- Angus Hose Product GuideDocument16 pagesAngus Hose Product GuidevamsixNo ratings yet

- Datasheet BombaDocument4 pagesDatasheet BombasaculNo ratings yet

- Product Catalogue SomefluDocument20 pagesProduct Catalogue SomefluIlkuNo ratings yet

- Horizontal Multi-Stage Centrifugal Pumps Vertical Multi-Stage Centrifugal PumpsDocument36 pagesHorizontal Multi-Stage Centrifugal Pumps Vertical Multi-Stage Centrifugal PumpsTushig AriunboldNo ratings yet

- Catalogo S20Document25 pagesCatalogo S20Jaime Zzaa100% (1)

- Malmedi 50HZ 14-09-04Document538 pagesMalmedi 50HZ 14-09-04rhusseinpos4765No ratings yet

- ISO Pump 50Hz Technical Data Metric UnitsDocument29 pagesISO Pump 50Hz Technical Data Metric UnitsTimothy PopeNo ratings yet

- Instructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Document50 pagesInstructions On Installation, Operation and Maintenance Manual For Syncroflo Non-Clog Submersible Series (Ie2)Denar PurnamaNo ratings yet

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Document29 pagesHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanNo ratings yet

- Noruegan StandardDocument152 pagesNoruegan StandarderikohNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- PX-260 Performance CurveDocument1 pagePX-260 Performance CurveRoberto Leon MendezNo ratings yet

- KSB Etanorm LDocument40 pagesKSB Etanorm LhaseitoNo ratings yet

- Data Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorDocument1 pageData Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorkayakurbanoNo ratings yet

- Omega Rdlo Presentation en V20220519Document30 pagesOmega Rdlo Presentation en V20220519InácioMendalaNo ratings yet

- QL Series: Vertical, Double-Suction Twin-Volute Turbine PumpsDocument8 pagesQL Series: Vertical, Double-Suction Twin-Volute Turbine PumpstangouzeNo ratings yet

- Colfax Product CatalogDocument36 pagesColfax Product CatalogPrasanna BalrajNo ratings yet

- MANUAL PACIFIC E27 - EG27 Rev 01-17 ENGDocument94 pagesMANUAL PACIFIC E27 - EG27 Rev 01-17 ENGArtur100% (2)

- API Vertical FlowayDocument8 pagesAPI Vertical FlowayRaja RamachandranNo ratings yet

- Lavalin Bomba SumergibleDocument3 pagesLavalin Bomba SumergibleEyffer Cabrera PalominoNo ratings yet

- 4 - 3D Ah-5vcmDocument1 page4 - 3D Ah-5vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- SP ManualDocument16 pagesSP ManualJOSE BARONNo ratings yet

- Manual Book Pompa 104G5Document7 pagesManual Book Pompa 104G5Ardi 4791No ratings yet

- Sec 1743Document12 pagesSec 1743JOSE INESNo ratings yet

- Brosur Hdpe 1Document2 pagesBrosur Hdpe 1arbiNo ratings yet

- Diagram-Rute-Jarak-Stasiun-2015-KRL-Commuter-Line-Jabodetabek-TransportUmum - JPG (1500×2121)Document2 pagesDiagram-Rute-Jarak-Stasiun-2015-KRL-Commuter-Line-Jabodetabek-TransportUmum - JPG (1500×2121)arbiNo ratings yet

- Fence Metal Sheet: Patimban Port Development Project (I) Package 1 - Terminal ConstructionDocument1 pageFence Metal Sheet: Patimban Port Development Project (I) Package 1 - Terminal ConstructionarbiNo ratings yet

- Data FLY OverDocument1 pageData FLY OverarbiNo ratings yet

- Temporary Office 16.5 8Document3 pagesTemporary Office 16.5 8arbiNo ratings yet

- Analisa Struktur Baja Temporary Office 16.5 M: AttachmentDocument1 pageAnalisa Struktur Baja Temporary Office 16.5 M: AttachmentarbiNo ratings yet

- Toko Bahan Bangunan SintangDocument4 pagesToko Bahan Bangunan SintangarbiNo ratings yet

- Erection PCI GirderDocument1 pageErection PCI GirderarbiNo ratings yet

- Temporary Office 16.5 9Document4 pagesTemporary Office 16.5 9arbiNo ratings yet

- Design of A Reinforced Concrete Deck-Girder Bridge To AASHTO & ACI CodesDocument1 pageDesign of A Reinforced Concrete Deck-Girder Bridge To AASHTO & ACI CodesarbiNo ratings yet

- General Bridge Design ManualDocument3 pagesGeneral Bridge Design ManualarbiNo ratings yet

- Britool Torque Wrench PDFDocument2 pagesBritool Torque Wrench PDFarbiNo ratings yet

- Catalog Spun Pile WIKA BEtonDocument1 pageCatalog Spun Pile WIKA BEtonarbiNo ratings yet

- 1J10NJ541H .0 6 %0 & + . .0 6 &0 ' + . ¿ÀáâããàäåæçáèéêëæìDocument1 page1J10NJ541H .0 6 %0 & + . .0 6 &0 ' + . ¿ÀáâããàäåæçáèéêëæìarbiNo ratings yet

- Composite Design Criteria SUBDocument1 pageComposite Design Criteria SUBarbiNo ratings yet

- Britool Torque WrenchDocument5 pagesBritool Torque WrencharbiNo ratings yet

- Turnbuckle AssembliesDocument4 pagesTurnbuckle AssembliesarbiNo ratings yet

- SAR Remote Sensing (Microwave Remote Sensing) Shared by Eugène Dongmo A.Document65 pagesSAR Remote Sensing (Microwave Remote Sensing) Shared by Eugène Dongmo A.Eugene DongmoNo ratings yet

- 15 - 2013-09-16 Apex 10 15 20 2nd Round TrainingDocument33 pages15 - 2013-09-16 Apex 10 15 20 2nd Round TrainingAlejandro OdioNo ratings yet

- Beam Web Connections With Coped Top FlangesDocument115 pagesBeam Web Connections With Coped Top Flangeshusna shaikhNo ratings yet

- Ve Diy StrobeDocument5 pagesVe Diy Strobeasa2034No ratings yet

- Lightning M Queen Hawk: Nose Dive! Back Flip!Document1 pageLightning M Queen Hawk: Nose Dive! Back Flip!Etienne Poy PoeymirouNo ratings yet

- Advanced CNC Programming & Code PDFDocument38 pagesAdvanced CNC Programming & Code PDFAswath Sridhar100% (1)

- Pidicrete CF 204Document3 pagesPidicrete CF 204Casey BallNo ratings yet

- Installation Materials - Valve SpecificationsDocument2 pagesInstallation Materials - Valve SpecificationsKasarachi AmadiNo ratings yet

- Instruction Manual: Rotary Lobe Pumps - SRU RangeDocument58 pagesInstruction Manual: Rotary Lobe Pumps - SRU RangeramiressNo ratings yet

- 003 Questions CommunicationsDocument19 pages003 Questions CommunicationsR D SandeepNo ratings yet

- Business Intelligence Data Warehouse Project PlanDocument39 pagesBusiness Intelligence Data Warehouse Project PlanJackson WanjohiNo ratings yet

- Seneca Lake Hydrology ReportDocument70 pagesSeneca Lake Hydrology ReportWashington BureauNo ratings yet

- Melc Science 5Document1 pageMelc Science 5Mariene Patrisabel Ungriano - AndaluzNo ratings yet

- Anna University Exams Nov/Dec 201 9 - Regulation 2017 CE8392 Engineering Geology PART B & PART C Questions For All 5 UnitsDocument2 pagesAnna University Exams Nov/Dec 201 9 - Regulation 2017 CE8392 Engineering Geology PART B & PART C Questions For All 5 UnitsVishnuNo ratings yet

- Nitobond PVA : Multipurpose PVA Adhesive, Sealer and Cement AdmixtureDocument4 pagesNitobond PVA : Multipurpose PVA Adhesive, Sealer and Cement AdmixturemilanbrasinaNo ratings yet

- Geobag River DibangDocument6 pagesGeobag River DibangPalak ShivhareNo ratings yet

- X Icse Physics Practicals 2021-2022Document32 pagesX Icse Physics Practicals 2021-2022Andhra Pros GamingNo ratings yet

- Engineering Mathematics by GillesaniaDocument237 pagesEngineering Mathematics by GillesaniaAmie Malobago93% (41)

- Atlantic Supplies Company Profile 2023Document74 pagesAtlantic Supplies Company Profile 2023vlinemubeenNo ratings yet

- ER-Relational Mapping From VITDocument27 pagesER-Relational Mapping From VITNavya VermaNo ratings yet

- MIS PackagesDocument21 pagesMIS PackagesRajMalhotra100% (1)

- Receiving Receipts FAQSDocument13 pagesReceiving Receipts FAQSBrandon AustinNo ratings yet

- Javamagazine20120102 DLDocument70 pagesJavamagazine20120102 DLjavadev_ruNo ratings yet

- 2015 JBLPRO Components CatalogDocument13 pages2015 JBLPRO Components CatalogGastón SañudoNo ratings yet