Vehicle Identification: Technical Bulletin # 1259

Vehicle Identification: Technical Bulletin # 1259

Uploaded by

Jovan MitrevskiCopyright:

Available Formats

Vehicle Identification: Technical Bulletin # 1259

Vehicle Identification: Technical Bulletin # 1259

Uploaded by

Jovan MitrevskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Vehicle Identification: Technical Bulletin # 1259

Vehicle Identification: Technical Bulletin # 1259

Uploaded by

Jovan MitrevskiCopyright:

Available Formats

Technical Bulletin # 1259

Transmission: 722.6

Subject: Introduction

Application: Mercedes, Chrysler

Issue Date: June, 2009

722.6

Introduction

288 MERCEDES

722.6/NAG 1

In 1997, Mercedes installed in the E-class its electronically-controlled model 722.6 5-speed auto-

matic transmission that first saw duty in 1996 in the V8-powered W140 S-class models. The 722.6

transmission is now used in a number of Daimler-Chrysler vehicles.

Vehicle Identification

Copyright © 2009 ATRA. All Rights Reserved. JR> Page 1 of 11

Transmission Ranges and Operation

Technical Bulletin # 1259

“Touch” Shifter Transmission Ranges

Shift Gear Description

Lever Selection

Position

P Parking and starting position

R Reverse Reverse gear, Standard mode, Winter mode, and

default reverse

N Neutral and starting position. No transmission of

power. The vehicle can be moved freely. Allows

starting engine with the vehicle in motion.

D D Shifts 1,2,3,4,5. TCC is available in 3 rd, 4th, and 5 th

gear.

D – (1 time) 4 Shifts 1,2,3,4, engine braking available

D – (2 times) 3 Shifts 1,2,3, engine braking available

D – (3 times) 2 Shifts 1,2, engine braking available

D – (4 times) 1 First gear only, maximum engine braking

© 2006 ATRA, All Rights Reserved

JR> Page 2 of 11 Copyright © 2009 ATRA. All Rights Reserved.

Transmission Ranges and Operation

Technical Bulletin # 1259

(continued)

Daimler-Chrysler has many different shifter part numbers but there are only two

basic types that a driver would notice. One is a common shifter like all other cars

and the second one is the “Touch” shifter as shown. When the shifter is in the D

range the shifter will also move side to side. If you push the shifter handle side-

ways toward the driver, or to the Minus sign, ( - ) for a moment the transmission

will down shift to the next lowest range. If you push the shifter side ways away

from the driver, or to the Plus sign, ( + ) it will up shift to the next highest gear.

The shifter can be used this way for sporty manual shifting. If you want it to go

back to full automatic shifting, push the shifter sideways away from the driver and

hold it for at least one second.

On most Daimler-Chrysler vehicles the Transmission Control Module will not let

the engine RPM exceed a safe operating speed so it may up shift to a higher gear

than the driver has selected. Also it may prevent or delay a down shift that has

been requested by the driver if a safe engine RPM will be exceeded.

The shifter shown on the opposite page has a Standard Mode/Winter Mode switch.

(Not all shifters will have a mode switch). In the Standard Mode all shifts will be

normal. The Winter Mode is for better traction on slippery roads in both forward

and reverse, it will take off in second gear and will shift earlier. It will also take off

in a higher ratio reverse than in the Standard Mode.

Ratio

W5A580 Ratio

Gear Range

W5J400 W5A330

W5A380

First 3.59 3.95

Second 2.19 2.423

Third 1.41 1.486

Fourth 1 1

Fifth 0.83 0.833

Reverse 3.16 3.147

Reverse 1.93 1.93

4X4 low or Winter

mode

© 2006 ATRA, All Rights Reserved

JR > Page 3 of 11 Copyright © 2009 ATRA. All Rights Reserved.

Component A pplication Chart

Technical

Power FlowBulletin # 1259

Component Application

The Mercedes 722.6 uses six multi-plate clutches and two sprags (freewheels) to

achieve its five forward and two reverse ranges (standard and winter modes). The

following chart shows which elements are used for each gear.

Gear B1 F1 K1 K2 F2 B3 K3 B2

1 X(1) X X X(1) X

2(2) X X X(1) X

3 X X X

4 X X X

5 X X(1) X X

N X X

R X(1) X X X

R(2) X X X

(1) For engine braking

(2) When in 4X4 low (if equipped) or Winter mode (if

equipped)

© 2006 ATRA, All Rights Reserved

JR > Page 4 of 11 Copyright © 2009 ATRA. All Rights Reserved.

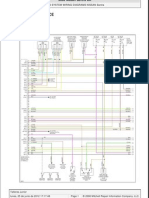

Solenoid Operation

Technical Bulletin # 1259

Solenoid Overview

The Mercedes 722.6 transmission uses six solenoids on the valve body to control

transmission operation; three shift solenoids, a converter clutch solenoid, a pres-

sure control solenoid, and a shift pressure control solenoid. Mercedes uses terms

for their solenoids that may not relate to an obvious function. The three shift

solenoids: the 1-2/4-5 shift, 2-3 shift, and 3-4 shift solenoids are obvious. How-

ever, the lock up solenoid is referred to as a PWM solenoid, the pressure control

solenoid is referred to as the modulating pressure regulator solenoid. The shift

pressure control solenoid is somewhat unique and we’ll cover its function later.

Solenoid Operation

The modulating pressure regulating solenoid controls line rise by raising pres-

sure to the spring side of the pressure regulator. This is a standard function like

most all computer-controlled transmissions. It also controls oil to three other

valves.

The PWM solenoid is also a fairly standard solenoid in that it controls converter

clutch operation.

Where the Mercedes transmission is radically different in solenoid operation is

with the shift solenoids. Because each shift releases one clutch while applying

another, timing is very important so you don’t get a flare or bind-up during the

shift “transition”. Each shift solenoid uses a bank of four valves to control the shift

transitions. These valves are called:

1. Command Valve

2. Holding Pressure Shift Valve

3. Shift Pressure Shift Valve

4. Pressure Overlap Control Valve

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR > Page 5 of 11

Solenoid Operation (continued)

Technical Bulletin # 1259

Keep in mind that each shift solenoid uses four of these valves, so in total there

are 12 valves that control all of the shift transitions.

The basic operation of these four valves is the same for each shift. To initiate a

shift transition the computer turns on one of the shift solenoids. For example, for

a 1-2 shift the computer turns on the 1-2/4-5 shift solenoid. This strokes the

command valve and initiates a shift “transition”. The other three valve control the

release rate of the B1 brake and the apply rate of the K1 clutch. Once the transi-

tion is complete, the 1-2/4-5 shift solenoid is turned off. To make a 2-1 down shift

the computer again turns on the 1-2/4-5 shift solenoid to initiate a transition. In

this case, since the transmission is in second gear the transmission transitions

back to first gear.

For a shift from second to third the 2-3 shift solenoid is energized to initiate the

transition. And just like to 1-2 shift, once the transition is complete the solenoid

is turned off. For a 3-2 downshift, the 2-3 shift solenoid goes through this cycle

again. Each shift works in this fashion.

During each transition apply pressure is controlled by the shifting pressure con-

trol solenoid. The release rate is controlled, in part, by the modulating pressure

regulator solenoid. These two solenoids work together to control the overlap for

each shift transition.

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR> Page 6 of 11

MERCEDES 301

722.6/NAG 1 Technical Bulletin # 1259

Solenoid Application Chart

Gear 1-2 /4-5 2-3 3-4 Modulating Shift TCC

Shift Shift Shift Pressure Pressure Pressure

Solenoid Solenoid Solenoid Control Control Control

Solenoid Solenoid Solenoid

Park Modulate Regulate Regulate

P-to-R Modulate Modulate Modulate

Reverse Regulate On

R-to-N Modulate Regulate Modulate

Neutral Modulate Regulate Regulate

st Modulate Regulate Modulate

N-to-D (1 )

1st Modulate On

1st to 2nd Modulate Modulate Modulate

nd Modulate On

2

2nd to 3rd Modulate Modulate Modulate

3rd Modulate On Modulate

rd th Modulate Modulate Modulate Modulate

3 to 4

4th Modulate On Modulate

4th to 5th Modulate Modulate Modulate Modulate

5th Modulate On Modulate

5th to 4th Modulate Modulate Modulate

4th Modulate On

4th to 3rd Modulate Modulate Modulate

rd Modulate On

3

3rd to 2nd Modulate Modulate Modulate

2nd Modulate On

2nd to 1st Modulate Modulate Modulate

1st Modulate On

st Modulate Regulate Regulate

1 to N

Neutral Modulate Regulate Regulate

N to R Modulate Regulate Modulate

Reverse Modulate On

R to P Modulate Regulate Regulate

Park Modulate Regulate Regulate

The shift solenoids are off electrically when the transmission is in any gear.

The shift solenoid is on for 1.5 seconds when shifting.

ON =Regulated line pressure

Regulate = Constant Pressure

Modulate = Pulse Width Modulated (PWM)

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR> Page 7 of 11

722.6/NAG 1

Technical Bulletin # 1259

Torque Converter Operation

The Torque Converter Clutch (TCC) is hydraulically operated and electronically

controlled. The TCC consists of a piston and friction discs that provide a mechani-

cal link between the impeller and turbine. When pressure is applied to the rear of

the TCC piston, TCC engagement is obtained. The torque converter clutch is never

fully engaged. The TCC when engaged, is always slipping at a rate of somewhere

between 5% and 95%. This reduces excess heat build-up, engine vibration and

pulse transmission through the torque converter and improves fuel economy.

TCC operation can be activated in 3rd, 4th or 5th gear ranges, depending on

transmission model, application, shift lever position, transmission temperature

and other factors.

The hub of the torque converter housing drives the transmission oil pump at

engine speed.

NOTE: Don’t be fooled by the dis-coloration of the torque

converter, a blueish tint color is normal. When the factory

furnace brazes the fins in the torque converter, the color of the

metal takes on the look of a failed or burnt converter. Do NOT

replace the converter on its look alone without a proper test to

verify a failure.

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR > Page 8 of 11

Transmission Fluid Technical Bulletin # 1259

Transmission fluid serves a number of purposes including application of hydrau-

lics, lubrication, cooling, cleaning and seal conditioning. Transmission shift qual-

ity, heat dissipation and Transmission Control Module (TCM) calibration all dictate

the type of transmission fluid that is used. Transmission fluids are similar but

have different characteristics such as viscosity and the additives in the fluid,

which is why there will be different fluids used in Crossfire, Sprinter and 300C.

Drain and refill the transmission fluid at the recommended service interval of

80,000 miles. Most other models are life time fill.

The transmission has varying capacities depending on vehicle application. Trans-

mission fluid capacity includes the transmission, the torque converter and the

transmission fluid cooler.

The fill tube in Sprinter, Crossfire, Jaguar, and Mercedes vehicles is sealed from

the factory and requires a special service dipstick tool (#8863A) to check the fluid

level. A special cap is used for sealing the transmission dipstick tube. When the

locking pin is removed it will break off. The locking pin part number is A 140 991

00 55 when ordered from a Mercedes dealer. The 300C (LX) requires a special

service dipstick tool (9336). Grand Cherokee (WJ) comes equipped with a dipstick.

Dipstick tools are availible from miller tools for Chrysler vehicles.

Dipsticks are also availible

from Mercedes under part

number 140 589 15 21 00

1. Locking Pin

2. Fill Tube Cap

3. Fill Tube

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR > Page 9 of 11

Transmission FluidTechnical Bulletin # 1259

When checking the fluid level, always check it in the Park position.

Full

77°F (25°C)

Full

176°F (80°C)

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR > Page 10 of 11

Transmission Fluid

Technical Bulletin # 1259

For ALL Mercedes and For ALL Jeep and other

Chrysler Sprinter and Crysler applications

Crossfire applications (EXCEPT Sprinter and

Crossfire)

Part# Chrysler Part#

A 001 989 07 03 05013457AA

Meets Spec 236.10 (Type 9602)

© 2006 ATRA, All Rights Reserved

Copyright © 2009 ATRA. All Rights Reserved. JR > Page 11 of 11

You might also like

- Wiring Diagram Nissan 2002 1.8 2.5Document14 pagesWiring Diagram Nissan 2002 1.8 2.5Herbert Giovanni60% (10)

- Jeep XJ Cherokee 1998 System Wiring DiagramsDocument582 pagesJeep XJ Cherokee 1998 System Wiring DiagramsRafael Pertile Carneiro71% (7)

- 20r-22-68 GM 9t50 Non-Etrs Models Preliminary InformationDocument37 pages20r-22-68 GM 9t50 Non-Etrs Models Preliminary InformationVIDAL ALEJANDRO GARCIAVARGAS100% (6)

- Basic Vacuum PracticeDocument324 pagesBasic Vacuum PracticeJovan MitrevskiNo ratings yet

- 6r80 Shift SolenoidDocument5 pages6r80 Shift SolenoidBAO ANH LÊ100% (1)

- 722.6 Adaptation ProcedureDocument3 pages722.6 Adaptation ProcedureBartłomiej Kilian83% (6)

- 722.6 Solenoid Truth TableDocument4 pages722.6 Solenoid Truth TableJack Carl100% (2)

- Catalogue Driveline Solutions SPIDANDocument821 pagesCatalogue Driveline Solutions SPIDANMihai Octavian100% (4)

- 5eat HD 2 Transgo InstructionsDocument6 pages5eat HD 2 Transgo InstructionsStephane Glaude100% (1)

- Manual 722.6 PDFDocument6 pagesManual 722.6 PDFAndy Paez100% (3)

- 722.6 Shift PointsDocument4 pages722.6 Shift PointsAmy CoxNo ratings yet

- SAP ATRA Webinar RE5RO5ADocument66 pagesSAP ATRA Webinar RE5RO5ACarlos Pereira86% (7)

- Seminar 1Document61 pagesSeminar 1AdamCzulewicz60% (5)

- Btra 4 Auto Transmission RextonDocument218 pagesBtra 4 Auto Transmission RextonСергей Есипов80% (5)

- Festo Electrical, Pneumatic and Logic SymbolsDocument1 pageFesto Electrical, Pneumatic and Logic SymbolsAvtomatika Kole Nehtenin50% (4)

- Lista de Cabos, Ligações e Aplicações para Digiprop3Document2 pagesLista de Cabos, Ligações e Aplicações para Digiprop3helderNo ratings yet

- The Mercedes 722.6 Not Just Another 5-SpeedDocument10 pagesThe Mercedes 722.6 Not Just Another 5-Speedkalico67100% (1)

- The Upshift Delay DilemmaDocument5 pagesThe Upshift Delay DilemmaAlin Nita100% (1)

- 722.6 ETC TroubleshootingDocument9 pages722.6 ETC TroubleshootingAnonymous wZDruUu100% (1)

- 722.6 Failure To UpshiftDocument3 pages722.6 Failure To UpshiftJack CarlNo ratings yet

- 722 3Document12 pages722 3Daniel AlvaradoNo ratings yet

- 722 5infoDocument34 pages722 5infoGypsyR75% (4)

- 722 6Document2 pages722 6slick0012100% (3)

- Technical Service Information 12-59Document8 pagesTechnical Service Information 12-59Planta Damiana2100% (1)

- Imported Checkball2Document112 pagesImported Checkball2waggcas100% (1)

- 2008 7 8Document8 pages2008 7 8Peps Ren100% (3)

- 722.6 TruthTable 2Document2 pages722.6 TruthTable 2Jack CarlNo ratings yet

- Transmision A5hf Hyundai PDFDocument152 pagesTransmision A5hf Hyundai PDFIongornistuNo ratings yet

- Transmission NoteDocument6 pagesTransmission Notesyariza ismailNo ratings yet

- Mercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDDocument6 pagesMercedes 722.0 To 722.6 5 Speed Chassis Ending 177-123 - 4 Bolt Pan Chassis Ending 123-126 - 6 Bolt Pan 3-4 SPEEDTransmisiones Automáticas Chepe50% (2)

- Technical Service Information: Automatic Transmission Service GroupDocument6 pagesTechnical Service Information: Automatic Transmission Service GroupPlanta Damiana2No ratings yet

- Technical Service Information: BMW ZF-5HP-18Document2 pagesTechnical Service Information: BMW ZF-5HP-18Alejandro RoldanNo ratings yet

- VBL Mercedes 722 6Document1 pageVBL Mercedes 722 6a1416194No ratings yet

- 5R55N Seminar InfoDocument18 pages5R55N Seminar InfocarlosNo ratings yet

- 307-01 Automatic Transmission 10 Speed - Description and Operation - D ClutchDocument6 pages307-01 Automatic Transmission 10 Speed - Description and Operation - D ClutchCARLOS LIMADA100% (1)

- TF 60 SNDocument5 pagesTF 60 SNyermain100% (2)

- 722.6 Automatic Transmission - Oil and Filter ChangeDocument2 pages722.6 Automatic Transmission - Oil and Filter Changedollabillz100% (2)

- 722.6 ATF FlushDocument4 pages722.6 ATF FlushalintrigitalNo ratings yet

- 4HP20 Bodyvalve Explode ViewDocument5 pages4HP20 Bodyvalve Explode ViewCarlota SilvaNo ratings yet

- Quick Reference: 722.6 Component Location and I.DDocument7 pagesQuick Reference: 722.6 Component Location and I.DAyhan Ümit100% (1)

- 41TE Accumulator PositionDocument10 pages41TE Accumulator PositionLula MarquesNo ratings yet

- 2005-2007 5EAT ManualDocument2 pages2005-2007 5EAT ManualGiorgi Avetisov100% (1)

- Sonnax VW Audi Ag4Document1 pageSonnax VW Audi Ag4vaskaservNo ratings yet

- VBL ZF6HP19 26 32Document1 pageVBL ZF6HP19 26 32PedroMecanico100% (1)

- ZF6 GEN2 Vac LocationsDocument4 pagesZF6 GEN2 Vac LocationsDavid LacunesNo ratings yet

- Engine - Repair - 1997-2000 EV Repair ManualDocument327 pagesEngine - Repair - 1997-2000 EV Repair ManualJorge Sepulveda100% (1)

- 62TEDocument2 pages62TEAnonymous eExWojLxNo ratings yet

- 2006 Seminar Sonnax PDFDocument18 pages2006 Seminar Sonnax PDFHumberto Lojan100% (1)

- Tools 5l40eDocument4 pagesTools 5l40eRichard Andrianjaka Lucky100% (2)

- Mercedes 722.6 Failure To UpshiftDocument3 pagesMercedes 722.6 Failure To Upshiftirc100% (2)

- 2008 - 7 - 4 4L30E PumpDocument4 pages2008 - 7 - 4 4L30E PumpJon Rodriguez100% (2)

- 4HP20 Repair ManualDocument140 pages4HP20 Repair Manualautomaticosbrasil100% (1)

- Lube Gard AtfDocument249 pagesLube Gard Atfjuan garcia guerra100% (1)

- 5HP18Document39 pages5HP18Leonard67% (3)

- 722 6 VacTestDocument4 pages722 6 VacTestMauricio Exequiel Chavez100% (2)

- MB 722.9 7GDocument18 pagesMB 722.9 7GSam Park100% (6)

- Service Training Manual: AutolearnDocument33 pagesService Training Manual: AutolearnBasukiNo ratings yet

- Procedure To Complete Iavl When Idle Speed Needs To Be ReducedDocument5 pagesProcedure To Complete Iavl When Idle Speed Needs To Be ReducedZNN9002No ratings yet

- DRBIII Release Notes - 56.0Document5 pagesDRBIII Release Notes - 56.0MarioNo ratings yet

- Transmission atDocument31 pagesTransmission atScribdTranslationsNo ratings yet

- 5hp20 AtsgDocument16 pages5hp20 AtsgmarcusNo ratings yet

- 2005 FocusDocument8 pages2005 FocusRudi DCNo ratings yet

- Technical Bulletin #195: General InformationDocument4 pagesTechnical Bulletin #195: General InformationCatalin IordacheNo ratings yet

- Deutsche GROVE Kessler Power Train: General Description: Transfer CaseDocument7 pagesDeutsche GROVE Kessler Power Train: General Description: Transfer CaseВиталий РогожинскийNo ratings yet

- Welcome To Today's Presentation Sponsored byDocument26 pagesWelcome To Today's Presentation Sponsored byDavid LacunesNo ratings yet

- Asian Warner 55-50SN Seminar General DescriptionDocument15 pagesAsian Warner 55-50SN Seminar General DescriptionTawatchai BoonpermNo ratings yet

- Unit 15 Balneotherapy: 1. Warm-UpDocument8 pagesUnit 15 Balneotherapy: 1. Warm-UpJovan MitrevskiNo ratings yet

- Health Building Note 00-08: Addendum 2 - A Guide To Town Planning For Health OrganisationsDocument18 pagesHealth Building Note 00-08: Addendum 2 - A Guide To Town Planning For Health OrganisationsJovan MitrevskiNo ratings yet

- RWD 5 Speed: Europeantransmissions 2430 Oak Street East Cumming, GA 30041 Tel: 770 888 1499Document10 pagesRWD 5 Speed: Europeantransmissions 2430 Oak Street East Cumming, GA 30041 Tel: 770 888 1499Jovan MitrevskiNo ratings yet

- United States Courthouse Annex, Wheeling WV Architect: Goody, Clancy & AssociatesDocument4 pagesUnited States Courthouse Annex, Wheeling WV Architect: Goody, Clancy & AssociatesJovan MitrevskiNo ratings yet

- KataloziDocument2 pagesKataloziJovan MitrevskiNo ratings yet

- BiggerBook PDFDocument146 pagesBiggerBook PDFJovan MitrevskiNo ratings yet

- Solar PV Technology: Use This Worksheet To Help You Design Your Own Off-Grid Solar Power SystemDocument2 pagesSolar PV Technology: Use This Worksheet To Help You Design Your Own Off-Grid Solar Power Systemg_junk5213No ratings yet

- Jetfoil - Tunnel Fans PDFDocument16 pagesJetfoil - Tunnel Fans PDFJovan MitrevskiNo ratings yet

- Testing and Certification Regulations (Pzo) of Tüv Rheinland Lga Products GMBH (TRLP)Document7 pagesTesting and Certification Regulations (Pzo) of Tüv Rheinland Lga Products GMBH (TRLP)Jovan MitrevskiNo ratings yet

- Functional Recovery Following Pertrochanteric Hip Fractures Fixated With The Dynamic Hip Screw vs. The Percutaneous Compression PlateDocument10 pagesFunctional Recovery Following Pertrochanteric Hip Fractures Fixated With The Dynamic Hip Screw vs. The Percutaneous Compression PlateJovan MitrevskiNo ratings yet

- ControlDocument17 pagesControlHalil İbrahim KüplüNo ratings yet

- AISIN Fully Synthetic AFW VI Product DatasheetDocument2 pagesAISIN Fully Synthetic AFW VI Product DatasheetAmr El-FekkyNo ratings yet

- dp4 - Packages 2015 Price List - End User - Eng PDFDocument4 pagesdp4 - Packages 2015 Price List - End User - Eng PDFCALEBE LEANDRONo ratings yet

- Transmeta CatalogoDocument6 pagesTransmeta CatalogoJacky Ibañez50% (2)

- Catálogo Clio PDFDocument44 pagesCatálogo Clio PDFValentín Castañón RodríguezNo ratings yet

- SSP 344 Audi A6 Avant 2005 PDFDocument40 pagesSSP 344 Audi A6 Avant 2005 PDFFabian Henao Calle100% (2)

- PI ForeignDocument108 pagesPI ForeignMiguel Eduardo Castillo Blanco100% (1)

- 3 GAIKINDO Wholesales Data Jan2024Document3 pages3 GAIKINDO Wholesales Data Jan2024Trick UnikNo ratings yet

- Mercedes Clase C 2023 UKDocument29 pagesMercedes Clase C 2023 UKzxzxzxzx1978No ratings yet

- (1878) The World On Wheels: Or, Carriages With Their Historical Associations From The Earliest To The Present TimeDocument514 pages(1878) The World On Wheels: Or, Carriages With Their Historical Associations From The Earliest To The Present TimeHerbert Hillary Booker 2nd100% (2)

- Volgren Audace Brochure Final 291116 WEBDocument2 pagesVolgren Audace Brochure Final 291116 WEBPangeran LarmothaNo ratings yet

- Brochure SpecDocument2 pagesBrochure Specyeahyea.kabirNo ratings yet

- Autoboss V30 CapabilitiesDocument16 pagesAutoboss V30 CapabilitiesPaing Min KoNo ratings yet

- BM34 Engine Slave Unit 34 Fuse(s) - CIRCUTDocument3 pagesBM34 Engine Slave Unit 34 Fuse(s) - CIRCUTMohd Ropi AbdullahNo ratings yet

- Ev2.8Torsion Bar AdjustmentDocument8 pagesEv2.8Torsion Bar Adjustmentqvalff80% (1)

- Session5 Automotive PackagingDocument72 pagesSession5 Automotive PackagingShivprasad Savadatti100% (1)

- Volvo TowingDocument11 pagesVolvo Towing250gtoNo ratings yet

- Toyota Noah L AT 2Document4 pagesToyota Noah L AT 2Anonymous I5hdhuCxNo ratings yet

- Ignition CoilsDocument8 pagesIgnition CoilsHassan askarNo ratings yet

- Fabrika PricelistDocument1 pageFabrika PricelistAwad SalibNo ratings yet

- 096 - Lighting - Schematic Wiring DiagramDocument21 pages096 - Lighting - Schematic Wiring DiagramGedas GvildysNo ratings yet

- Researching Primarily Frontal Impact Tests Part 4Document33 pagesResearching Primarily Frontal Impact Tests Part 4samotquinielaNo ratings yet

- Brochure - I30 Fastback NDocument13 pagesBrochure - I30 Fastback NRyan ChanNo ratings yet

- Peugeot 3008 Prices and Specifications B PDFDocument13 pagesPeugeot 3008 Prices and Specifications B PDFMiroslav UrosevicNo ratings yet

- MT Land Cruiser S 7 Troopy PDFDocument1 pageMT Land Cruiser S 7 Troopy PDFIlir DalipiNo ratings yet

- GM Body CodesDocument5 pagesGM Body CodesFred RuizNo ratings yet

- Volvo 9400 6X2 MULTI-AXLE Coach: When The Best GetsDocument8 pagesVolvo 9400 6X2 MULTI-AXLE Coach: When The Best GetsNiraj SinghNo ratings yet