Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Uploaded by

brilian pungkyCopyright:

Available Formats

Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Uploaded by

brilian pungkyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Avk Silent Check Valve, Pn25, Flanged 903/20-002: DN65-400, Epoxy Coated, Ductile Iron, Metal Seated

Uploaded by

brilian pungkyCopyright:

Available Formats

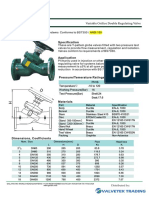

AVK SILENT CHECK VALVE, PN25, FLANGED 903/20-002

DN65-400, epoxy coated, ductile iron, metal seated

Series 903 metal seated silent check valves are designed to prevent back flow in high temperature range pumping

applications. The valve element movement is controlled via a central guide where a centrally mounted spring together with the

short movement aids the quick closing that is essential in reducing shock associated with valve closure. The pumped media

can be water, glycol or other clean, neutral liquids.

Product description:

Flanged silent check valve for water, and water with glycol from -10° C to 110° C

Standards:

· Designed according to EN 12334

· Face to face according to MSS SP-125 short globe

· Standard flange drilling to EN1092-2 (ISO 7005-2), PN 25

Test/Approvals:

· Experimental shell design strength according to EN12516-3

· Test according to EN12266

Features:

· The combination of light disc, short stroke distance and fast closing spring design is effectively mitigating slamming

· Streamlined contour for low head loss

· The special seat design ensures quick and easy trim replacement

· Fusion bonded epoxy coating on both external and internal surfaces

· Metal seat for durability and high temperature tolerance

· Up to and including DN200, the design makes it possible to mount a butterfly valve at the outlet side of the silent check

valve, without any additional adapters. This refers to the measure reference C

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

COPYRIGHT©AVK GROUP 2017 atao - 24-Nov-2017 14:22

1/3

AVK SILENT CHECK VALVE, PN25, FLANGED 903/20-002

DN65-400, epoxy coated, ductile iron, metal seated

Component list:

1 6

1. O-ring EPDM rubber 6. Bush Stainless steel 316

2 7

2. Body Ductile iron GJS-500-7 (GGG-50) 7. Bolt Stainless steel A2

3 8

3. Seat Stainless steel 1.4308 8. Retainer ball Stainless steel 304

4 9

4. Disc Stainless steel 1.4308 9. Bolt Stainless steel A2

5

5. Spring Stainless steel 1.4301

Components may be substituted with equivalent or higher class materials without prior notification.

* "Item 9" is available for DN250-DN400

Reference nos. and dimensions:

AVK ref. no. DN Flange L W C Net Weight

mm drilling mm mm mm Lbs

903-065-20-71000 65 PN25 140 185 27.5 18

903-080-20-71000 80 PN25 152 200 35.5 20

903-100-20-71000 100 PN25 184 235 46 33

903-125-20-71000 125 PN25 216 270 51 46

903-150-20-71000 150 PN25 248 300 61 71

903-200-20-71000 200 PN25 317 360 84 115

903-250-20-71000 250 PN25 394 440 118 187

903-300-20-71000 300 PN25 362 500 16 245

903-350-20-71000 350 PN25 400 580 35.5 348

903-400-20-71000 400 PN25 448 635 50 459

Row to make sure table is never blank

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

COPYRIGHT©AVK GROUP 2017 atao - 24-Nov-2017 14:22

2/3

AVK SILENT CHECK VALVE, PN25, FLANGED 903/20-002

DN65-400, epoxy coated, ductile iron, metal seated

The designs, materials and specifications shown are subject to change without notice due to the continuous development of our product range.

COPYRIGHT©AVK GROUP 2017 atao - 24-Nov-2017 14:22

3/3

You might also like

- IEC 62446 1 2016 AMD1 2018 CSV EN FR.1) B PDFDocument19 pagesIEC 62446 1 2016 AMD1 2018 CSV EN FR.1) B PDFDiego Vargas100% (2)

- FK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsDocument6 pagesFK 30.70 (3) GB NAF-Check Tilting Disc Check Valves: CharacteristicsNguyen KhaNo ratings yet

- Avk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument2 pagesAvk Centric U-Section Butterfly Valve, Pn10 820/20-028: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- 910 21 001 PDFDocument3 pages910 21 001 PDFMatt SterlingNo ratings yet

- Avk Dismantling Joint, Pn16 265/30-141: Reduced Tie Rods 25% of The Holes, A4 Stainless Steel Bolts, 300 M EP CoatingDocument2 pagesAvk Dismantling Joint, Pn16 265/30-141: Reduced Tie Rods 25% of The Holes, A4 Stainless Steel Bolts, 300 M EP CoatingFiroz HussainNo ratings yet

- Avk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric U-Section Butterfly Valve, PN 10 820/20-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDavidRNunesNo ratings yet

- 02 60 AVK Gate Valve F5 Long-BodyDocument3 pages02 60 AVK Gate Valve F5 Long-BodyArshad IqbalNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric ActuatorDocument2 pagesAvk Centric Wafer Butterfly Valve, Pn6/10/16 820/00-019: Loose EPDM Liner For Drinking Water, With Electric Actuatorbre brilianNo ratings yet

- 876-01-001 Avkcms enDocument3 pages876-01-001 Avkcms enbre brilianNo ratings yet

- Avk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare ShaftDocument3 pagesAvk Centric Wafer Butterfly Valve, Pn10/16 820/00-025: Loose EPDM Liner For Drinking Water, With Bare Shaftbre brilianNo ratings yet

- Avk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300kad-7No ratings yet

- Metallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelDocument3 pagesMetallic Sealing - Short Face-To-Face Length - Stainless Steel - With HandwheelJawad ChamsouNo ratings yet

- UL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510Document1 pageUL FM NRS Gate Valve, AWWA C515 - ANSI 250-300 Flanged Ends - Water Works - Fire Protection - Model 2510alanNo ratings yet

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Document2 pagesAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7No ratings yet

- Dismantling Joint - AVKDocument2 pagesDismantling Joint - AVKtecnoturbines ttNo ratings yet

- 3265-30-001 - Avk130 - en 2206 - 478770Document4 pages3265-30-001 - Avk130 - en 2206 - 478770Orbit 001No ratings yet

- Swing Check Valve - Flanged: Technical FeaturesDocument1 pageSwing Check Valve - Flanged: Technical FeaturesAhmed El MorsyNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve: Technical FeaturesMuhammad ElbarbaryNo ratings yet

- Avk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001Document3 pagesAvk Y-Strainer, PN 16 910/21: N50-300, A2 Plug and Fasteners 001AgieYogaswaraNo ratings yet

- Data Sheet For Metal Seated Gate Valves: ManufacturerDocument11 pagesData Sheet For Metal Seated Gate Valves: ManufacturerAHSAN GGCNo ratings yet

- EN - Needle ValveDocument8 pagesEN - Needle ValveManuel Alejandro ValenciaNo ratings yet

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- V5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Document2 pagesV5-Gan-Gp16 Series: Resilient Seated Gate Valve, Non Rising Stem (Hand Wheel)Em Es WeNo ratings yet

- 45-51 AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-51 AVK Gate Valve Non Rising Stem UL-FMImtiyaz KhanNo ratings yet

- 3.3 Valvula Os&y - SanfloDocument2 pages3.3 Valvula Os&y - SanfloYhonny ValenzuelaNo ratings yet

- Uni FlangeDocument4 pagesUni FlangeMOHAMEDNo ratings yet

- Avk Universal Under-Pressure Tee 257/30: With DN80 - 300 Flanged Branch 001Document3 pagesAvk Universal Under-Pressure Tee 257/30: With DN80 - 300 Flanged Branch 001tecnoturbines ttNo ratings yet

- 601-A-006 - Avk021 - en 2232 - 471287Document2 pages601-A-006 - Avk021 - en 2232 - 471287bre brilianNo ratings yet

- Avk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020Document2 pagesAvk Air & Vacuum Valve, PN 16 701/30: For Water, Ductile Iron, DN 100 and 200-300 020lan bautistaNo ratings yet

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Document1 pageOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNo ratings yet

- 1667026404butterfly Valve With Electrical Actiator 14 10 22Document6 pages1667026404butterfly Valve With Electrical Actiator 14 10 22nopriyanto.tpmsNo ratings yet

- Metallic Sealing - With Lever and Weight, Horizontal Type: PN 10/16 - DN 50... 800Document3 pagesMetallic Sealing - With Lever and Weight, Horizontal Type: PN 10/16 - DN 50... 800SathishkumarNo ratings yet

- Brochure Técnico - e-GS SeriesDocument12 pagesBrochure Técnico - e-GS SeriesAdrian CordovaNo ratings yet

- 33GS-80GS Submersible Pumps Tech BrochureDocument12 pages33GS-80GS Submersible Pumps Tech BrochureDecsih RuizNo ratings yet

- Avk Ball Float ValveDocument2 pagesAvk Ball Float ValveDota NgNo ratings yet

- Fig 907 Resilient Seated Gate Valve FlangedDocument1 pageFig 907 Resilient Seated Gate Valve FlangedSebastian Andres Quilodran BaquedanoNo ratings yet

- 621-41-001 - Avk130 - en 2206 - 478821Document2 pages621-41-001 - Avk130 - en 2206 - 478821bre brilianNo ratings yet

- Butterfly Valve: AL 42-G / AL 43-GDocument3 pagesButterfly Valve: AL 42-G / AL 43-GJohn DavidNo ratings yet

- TozenDocument2 pagesTozenAzwan SunlineNo ratings yet

- 2309+QT04 - Gala-Motorized Butterfly ValveDocument4 pages2309+QT04 - Gala-Motorized Butterfly ValveNam Đỗ100% (1)

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDocument8 pagesNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenNo ratings yet

- Osy 300fDocument4 pagesOsy 300fmaxgomotorNo ratings yet

- RPRRL21SPD500-Pressure Reducer and Flow Control Valve Type E2114-02Document13 pagesRPRRL21SPD500-Pressure Reducer and Flow Control Valve Type E2114-02Marinos GounaridisNo ratings yet

- 45-5D AVK Gate Valve Non Rising Stem UL-FMDocument2 pages45-5D AVK Gate Valve Non Rising Stem UL-FMumair186No ratings yet

- Amg RTJ Data PDFDocument8 pagesAmg RTJ Data PDFsiswoutNo ratings yet

- 76-71-012 Avkcms enDocument2 pages76-71-012 Avkcms enbre brilianNo ratings yet

- Monitored Butterfly Valve - GroovedDocument1 pageMonitored Butterfly Valve - GroovedAsly Siccha Santos100% (1)

- Page 31 34Document4 pagesPage 31 34ISHAN VERMANo ratings yet

- SY Rubber Disc Check ValveDocument2 pagesSY Rubber Disc Check ValvePhú Song LongNo ratings yet

- Ductile Iron Gate Valve Acc - To BS Flanged PN 16Document2 pagesDuctile Iron Gate Valve Acc - To BS Flanged PN 16khai ruleNo ratings yet

- En Ab STRDocument9 pagesEn Ab STRManuel Alejandro ValenciaNo ratings yet

- ORBINOX R6 CatalogueDocument2 pagesORBINOX R6 CatalogueBrian YangNo ratings yet

- 76-71-006 Avkcms enDocument2 pages76-71-006 Avkcms enbre brilianNo ratings yet

- 04-02 - AVK - SS 316 Rod - Extension - Spindle - Fixed - Gate - ValveDocument2 pages04-02 - AVK - SS 316 Rod - Extension - Spindle - Fixed - Gate - Valveminov minovitchNo ratings yet

- Valve and SupportsDocument3 pagesValve and SupportsMohamed ArafaNo ratings yet

- (S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Document3 pages(S-11.12-00) 2019 Gala Butterfly Valve Wafer Type 16 Bar SUS 304 Disc ANSI 150 Fig 2302Bernard Bonnin CervantesNo ratings yet

- Butterfly Valves EgeplastDocument4 pagesButterfly Valves EgeplastdsyashankaNo ratings yet

- Pipa/flangeDocument2 pagesPipa/flangeDimas Ageng PurnamaNo ratings yet

- 1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmDocument1 page1 Gala Balancing Valve Variable Orifice FT Fig DRVF 1210-Df Pn16 65mm To 450mmNon Etabas GadnatamNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- SVGW Certificate 2021 EnglishDocument2 pagesSVGW Certificate 2021 Englishbrilian pungkyNo ratings yet

- 21-36-002 Avkcms enDocument3 pages21-36-002 Avkcms enbrilian pungkyNo ratings yet

- Desponia Acs 20 Acc Ny 046 25 02 2025Document1 pageDesponia Acs 20 Acc Ny 046 25 02 2025brilian pungkyNo ratings yet

- Duo Check Valve Retainerless Execution Neptunia n1dr 1Document2 pagesDuo Check Valve Retainerless Execution Neptunia n1dr 1brilian pungkyNo ratings yet

- Bianca TUV-Certificate TA-Luft 2304enDocument1 pageBianca TUV-Certificate TA-Luft 2304enbrilian pungkyNo ratings yet

- DKM CP DN25-65 En1Document24 pagesDKM CP DN25-65 En1brilian pungkyNo ratings yet

- DK CP enDocument20 pagesDK CP enbrilian pungkyNo ratings yet

- Avk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRDocument2 pagesAvk Gate Valve, Flanged, Pn10/16 02/59-003: EN 558-2 S.15/DIN F5, Position Indicator, Replaceable Stem Sealing, NBRbrilian pungkyNo ratings yet

- Avk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400Document2 pagesAvk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400brilian pungkyNo ratings yet

- DS37500011503 enDocument2 pagesDS37500011503 enbrilian pungkyNo ratings yet

- FMB640 and Tacho Solution V1.0Document16 pagesFMB640 and Tacho Solution V1.0Дмитрий ДмитриевичNo ratings yet

- Owner'S Guide: More User Manuals OnDocument8 pagesOwner'S Guide: More User Manuals OnевгенийNo ratings yet

- Iii. Literature Review (Pressure Transducer)Document2 pagesIii. Literature Review (Pressure Transducer)kathirRavanNo ratings yet

- Mark Driscoll - On Who Is GodDocument90 pagesMark Driscoll - On Who Is GodFabiano Silveira MedeirosNo ratings yet

- Prestige Private LimitedDocument28 pagesPrestige Private Limitedlery.aryNo ratings yet

- Graphic Organizer NotesDocument2 pagesGraphic Organizer Notestownsenr94No ratings yet

- Fortinet Security Fabric ClickThru MGDocument1 pageFortinet Security Fabric ClickThru MGHector VelazquezNo ratings yet

- A SavannaDocument24 pagesA SavannaAnjum Ansh KhanNo ratings yet

- Types of Speech According To PurposeDocument3 pagesTypes of Speech According To PurposeTrixieNo ratings yet

- Harvard Ukrainian Studies. Volume III-IV. Part 1. 1979 - 1980 PDFDocument507 pagesHarvard Ukrainian Studies. Volume III-IV. Part 1. 1979 - 1980 PDFandreusDADA67% (3)

- Standard Operating ProcedureDocument39 pagesStandard Operating ProcedureAndrew Charles0% (1)

- English For Vocational School: Passive VoiceDocument9 pagesEnglish For Vocational School: Passive VoiceFebria RusdhyaniNo ratings yet

- Datum Transformation PDFDocument165 pagesDatum Transformation PDFfreddy ramdin100% (1)

- InvestingDocument2 pagesInvestingDonnie PutinyNo ratings yet

- NALCO 73500: Safety Data SheetDocument13 pagesNALCO 73500: Safety Data SheetJHUPEL ABARIAL100% (1)

- Sally R. Sommer "Mary Overlie: I Was A Wild Indian Who Happened To Dance"Document15 pagesSally R. Sommer "Mary Overlie: I Was A Wild Indian Who Happened To Dance"thoushaltnotNo ratings yet

- Bonsai: Edith L. TiempoDocument21 pagesBonsai: Edith L. TiempoMariella MallariNo ratings yet

- Lec 1Document59 pagesLec 1Asvk VinayakNo ratings yet

- Design Condition For Earthing SystemDocument4 pagesDesign Condition For Earthing SystemRashad SarwarNo ratings yet

- Brochure Management Manual - EN PDFDocument45 pagesBrochure Management Manual - EN PDFbudiaeroNo ratings yet

- Session One British Literary HistoryDocument9 pagesSession One British Literary HistoryVollkommen UnmoeglichNo ratings yet

- IEEE 802.20: See AlsoDocument2 pagesIEEE 802.20: See Alsomau_mmx5738No ratings yet

- (Thermal Conductivity of Liquid and Gases) EXPERIMENTAL MANUALDocument33 pages(Thermal Conductivity of Liquid and Gases) EXPERIMENTAL MANUALGracylla RoseNo ratings yet

- Chemola Desco TFE Versi-PakDocument1 pageChemola Desco TFE Versi-PakMiguel BetancourtNo ratings yet

- Department of Mechanical and Production Engineering (MPE) : Islamic University of Technology (IUT)Document28 pagesDepartment of Mechanical and Production Engineering (MPE) : Islamic University of Technology (IUT)maruf morshedNo ratings yet

- Villanueva MDocument6 pagesVillanueva MDrakie SumanilNo ratings yet

- 1ET400A - Product Brief (1.01)Document8 pages1ET400A - Product Brief (1.01)SakulaNo ratings yet

- Söderdagen Helsingborg CityDocument2 pagesSöderdagen Helsingborg CityAniesha G. HawaningrumNo ratings yet

- ORR Chennai SchedulesDocument178 pagesORR Chennai SchedulesDharmesh SharmaNo ratings yet