Job Hazard Analysis: Rohan Builders (I) PVT LTD

Job Hazard Analysis: Rohan Builders (I) PVT LTD

Uploaded by

soubhagyaCopyright:

Available Formats

Job Hazard Analysis: Rohan Builders (I) PVT LTD

Job Hazard Analysis: Rohan Builders (I) PVT LTD

Uploaded by

soubhagyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Job Hazard Analysis: Rohan Builders (I) PVT LTD

Job Hazard Analysis: Rohan Builders (I) PVT LTD

Uploaded by

soubhagyaCopyright:

Available Formats

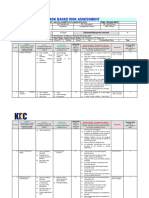

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

DSM Engineering - MIDC Ranjangaon

PROJECT / TASK : Construction water tank at site CONTRACTOR: Rohan Builders JOB No.:

SUPERVISOR : Rana LOCATION : Process Plant area DATE:

JOB STEP HAZARDS Control Measure ACTION

Break the job into steps. List the hazard or type of harm List the necessary control measures to be followed to Person who will ensure

Listing work which may be hazardous. identified with each step eliminate the identified hazards this happens

Sanjeev Pandiya

Excavation Mobileplants/Vehicle Movement Access to be cleared from all unwanted materiels

or traffic to enter the work area.

Hit hazard

Documents of the mobile plant/vehicle to be

cleared before entering the site.

Valid licence to be checked for the operator

Helper to be provided for controlling the traffic by

signal.

Swing area of the machine wil be controlled with

the help of supervisor.

Continuous supervision to be provided.

Fall Hazard Tape barricading will be done as soon as the

excavation completes to indicate the excavated

area.

Continuous supervision to be provided.

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

Illumination to be provided from both sides while

working at night.

Earth collapse

Excavated Materials to be put 2mtr away from the

excavated pit. If required excavated material to be

shifted from excavated area to the designated

Trip hazard place.

PPE’s to be provided (Safety Shoes, Helmet, Hand

gloves, Goggles, If required dust mask will also be

provided.

House keeping will be done to avoid unsafe

condition.

Stacking of excavated material at the work area will

not be more than 2mtrs height.

Continuous supervision will be provided.

Daily tool box talks will be followed.

Dressing, levelling & Compaction Hit Hazard PPE’s (Safety Helmet, Shoes, Goggles, Reflective

vest, handgloves to be provided. (if required Dust

Mask also.

Daily tool box to be conducted and explained the

hazard of using “Dhurmuz” while doing

Compaction.

If road roller to be used after completing all the

entry formalities roller should be allowed to enter

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

the work area through proper access provided after

physical inspection.

Area will be isolated from all other activities &

continuous supervision to be provided for the

same.

PCC Fall Hazard Access towards cement Gordon from Mixer

machine will be cleared from all unwanted

Shifting of material

materials.

PPE’s (Safety Helmet, shoes, goggles,

handgloves, Dust mask to be provided.

Dust Hazard Dust mask to be provided those who are engaged

in cement shifting work.

Mixer machine operation Trip Hazard All rotating parts to be guarded before starting.

Mixer machine should be physically inspected and

to put Safe to Use board before starting.

Experinced and trained operator to be provided.

No loose clothing allowed near the mixer machine.

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

Fire extinguisher to be placed at work area.

Fire Hazard

Nobody is allowed to stand near loader while in

Hit Hazard

operation to avoid hit hazard.

Only operator is authorised to lift the loader.

Material Shifting

Fall hazard

PPE’s Safety Helmet, Shoes, goggles &

handgloves to be provided.

Proper access to be provided from the storage

area to the work area.

All unwanted materials to be cleared out from the

access to avoid fall hazard.

Material fall hazard

Do not overload. Proper stacking to be maintained.

Do not stack materials above 2mtr.

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

PCC & Brick Masonry Work Cut Hazard Mason working on PCC & Brick work to wear

Rubber Hand gloves while working. If the area is

wet, will provide with gumboot.

Area will be cleared out from all type of sharp edge

materials before starting the work.

Proper Platform/ ladders to be used for working

below 2 mtrs and the platform/ladder to be properly

secured before using the platform/ladder.

Fall protection like Safety harness to be used for

working at a height above 2mtrs and should be

properly secured above shoulder level.

Daily tool box to be given to all those who are

engaged on the work.

Job Hazard Analysis Attendees:

Name Signature Date

Written by:

Reviewed by:

ROHAN BUILDERS (I) PVT LTD

Job Hazard Analysis

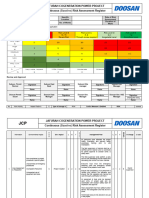

Score TABLE OF CONSEQUENCE Score LIKELIHOOD

People Plant Environment

5 – Very High/ Multiple Fatalities Greater than Catastrophe, destruction of sensitive environment, worldwide 5 – Almost The event is expected to occur in most

Catastrophic $10Million Loss attention. Likely EPA prosecution. More than 30 days delay. certain circumstances. Likely to occur frequently-

More than 1 per year

4 – High/ Major Fatality or Permanent Disabilities $1Million to Disaster, high levels of media attention, high cost of clean 4 – likely/ The event will probably occur in most

$10Million Loss up. Offsite environmental harm, more than 10 days delay. probable circumstances. Likely to occur several tines. 1

per year

3 – Moderate Major Injuries - Incapacitations or $100Thousand to Major spills, onsite release, substantial environmental 3– The event should occur at some time. Likely to

requiring time of work $1Million Loss nuisance, more than 1day delay. (Leads to an additional moderate/ occur some time. 1 per 5 years

resources call out i.e. SES) occasional

2 – Low/ Minor Significant Injuries – Medical $10Thousand to Significant spills (leads to a call out of Site Emergency 2 – remote/ The event could occur at some time. Unlikely

Treatments, non-permanent injury $100Thousand Loss Response Group) unlikely but possible. 1 per 10 years

1 – Very Low/ Minor Injuries – First Aid Treatments Less than Low environmental impact. Minor Spills less than 80 Litres. 1 – rare/ The event may occur only in exceptional

Insignificant (cuts/bruises) $10Thousand Loss very circumstances. Assumed it may not be

unlikely experienced. 1 per 100 years

Action Required

Intolerable Task not to start till the risk is eliminated or reduced. Bring to the immediate attention of

5 6 7 8 9 10 8 - 10

management. Formal assessment required. MUST reduce the risk as a matter of priority.

High Bring to the immediate attention of management. Task not to start till the risk is eliminated or

4 5 6 7 8 9 7

reduced. Further Assessment required. MUST reduce the risk as a matter of priority.

Significant Risk Bring to the attention of supervision. Review risks and ensure that they are reduced to as low as

3 4 5 6 7 8 6 reasonably practicable. To be dealt with as soon as possible, preferably before the task

commences. Introduce some form of hardware to control risk.

Moderate Risk Needs to be controlled but not necessarily immediately, an action plan to control the risk should be

2 3 4 5 6 7 5 drawn up. Review effectiveness of controls. Ensure responsibilities for control are specified.

Low Risk If practical reduce the risk. Ensure personnel are competent to do the task. Manage by routing

1 2 3 4 5 6 2-4

procedure. Monitor for change

1 2 3 4 5 A JHA considers a variety of activities/tasks involved in a job scope and analyses the key hazards (sources of harm) and their

consequences (types of harm) eg. Sources of harm – lifting a heavy pipe, which is manual handling. Types of harm – Back strain.

Main Points – On how to write a JHA. Hierarchy of Hazard Management – Control Measures

1. Define the task – what is to be done. These steps outline what should be planned for when deciding what control measures are to be put in

2. Review previous JHA if any – have we done it before? place. Whenever possible the highest step should be used first and then progress down the list.

3. Identify the steps – what is to be done. 1. Eliminate the hazard.

4. Identify the hazards of each step. 2. Substitution.

5. Identify who or what could be harmed. 3. Reducing the frequency of a hazardous task.

6. Give the task a risk rating – Consequence + Frequency 4. Enclosing the hazard.

7. Develop solutions to eliminate or control hazards in each step. 5. Additional procedures.

8. Review the risk rating after the control system has been implemented. 6. Additional supervision.

9. If risk rating unacceptable review the solutions till risk rating acceptable. 7. Additional training.

10. Agree who will implement the control system. 8. Instructions / information.

11. Document the JHA and discuss with the relevant personnel. 9. Some personal protective equipment.

You might also like

- Hirarc For Culvert Construction WorksDocument2 pagesHirarc For Culvert Construction Worksdahlanconstruction66No ratings yet

- Concrete Breakina Jsa by Breaker MachineDocument2 pagesConcrete Breakina Jsa by Breaker MachineAKBAR ALI100% (1)

- Plastering Works JSA HSE ProfessionalsDocument1 pagePlastering Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Jsa For Excavation and BackfillingDocument5 pagesJsa For Excavation and Backfillingshaibaz chafekarNo ratings yet

- JHA For Plumbing and Piping TradesDocument84 pagesJHA For Plumbing and Piping TradesKhurram Iqbal100% (2)

- JHA Soil InvestigationDocument7 pagesJHA Soil InvestigationRyan50% (2)

- jesa-INSTALLATION OF Toilet Cubicle PartitionDocument5 pagesjesa-INSTALLATION OF Toilet Cubicle PartitionLeo PascualNo ratings yet

- JSA For Dewatering PumpDocument1 pageJSA For Dewatering Pumpwahyu nugroho100% (3)

- JHA Pump CreteDocument2 pagesJHA Pump CretePopo EaldamaNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya60% (5)

- Equilibrium.2 ExampleDocument14 pagesEquilibrium.2 Examplekindenew50% (2)

- Jsa For Inst. of TSF & Laydown AreaDocument23 pagesJsa For Inst. of TSF & Laydown AreaAshir RIZNo ratings yet

- Project JHA For Grading Compacting WorksDocument27 pagesProject JHA For Grading Compacting WorksBasker Balu100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 pagesNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebNo ratings yet

- Job Safety Analysis (JSA) : Description Hazard ControlDocument3 pagesJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNo ratings yet

- Demolition: Hazards & Control MeasuresDocument9 pagesDemolition: Hazards & Control MeasuresSAMUEL POBRENo ratings yet

- Jsa For Tie in of Fuel Gas LineDocument3 pagesJsa For Tie in of Fuel Gas LineMohammed Minhaj100% (2)

- Risk Assessment For Rectification of AwlDocument4 pagesRisk Assessment For Rectification of AwlAnonymous ExWAN2xjFJNo ratings yet

- Job Steps Potential Hazards Recommended Safe Job ProceduresDocument3 pagesJob Steps Potential Hazards Recommended Safe Job ProceduresDJadee Anuppur AmlaiNo ratings yet

- Taking Bunkers: Job Safety AnalysisDocument4 pagesTaking Bunkers: Job Safety AnalysisOgunwa EmmanuelNo ratings yet

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 pagesJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalNo ratings yet

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisDocument3 pagesSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- Jsa - Duck Bank InstallationDocument10 pagesJsa - Duck Bank InstallationAmadeo Sabanal100% (1)

- Boring & Cone Penetration test-JSA-01Document3 pagesBoring & Cone Penetration test-JSA-01Akash Shukla67% (3)

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSNo ratings yet

- Method Statement - Panel ErectionDocument2 pagesMethod Statement - Panel ErectionsoubhagyaNo ratings yet

- Method Statement: Errection of Canopy Shed. PurposeDocument1 pageMethod Statement: Errection of Canopy Shed. Purposesoubhagya100% (2)

- Finn Power Catalog Finn PowerDocument44 pagesFinn Power Catalog Finn PowerAlexandru Ionut TomaNo ratings yet

- JSA - Civil Compaction WorkDocument4 pagesJSA - Civil Compaction WorkRajuNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocument2 pagesRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (2)

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdf100% (1)

- Jsa Road BlockingDocument3 pagesJsa Road BlockingRam Krishna100% (1)

- Job Hazard Analysis - Granite Surface PlateDocument2 pagesJob Hazard Analysis - Granite Surface PlateRaziellia Nor SaafriNo ratings yet

- JSA For Bobcat OperationDocument2 pagesJSA For Bobcat Operationwahyu nugrohoNo ratings yet

- JHA - Plumbing WorksDocument1 pageJHA - Plumbing WorksBilly Joe BreakfastNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet

- JHA For Installation and Demolition of Moisture Analyzer at RG PlantDocument11 pagesJHA For Installation and Demolition of Moisture Analyzer at RG PlantFrancis Enriquez Tan0% (1)

- JSA FOR Dismantel of StructureDocument3 pagesJSA FOR Dismantel of Structurem.rehanhseNo ratings yet

- 004 Piling JSADocument5 pages004 Piling JSAmidozoty100% (1)

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment For Installation of PipeDocument38 pagesRisk Assessment For Installation of Pipesana ullahNo ratings yet

- JHA - To Carry Out Reinstate of Interlock StonesDocument7 pagesJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- JSA 01-1 Right of Way Cinstruction at CorridorDocument3 pagesJSA 01-1 Right of Way Cinstruction at CorridorHaleemUrRashidBangashNo ratings yet

- Risk Assessment Welding Grinding Cutting WorksDocument5 pagesRisk Assessment Welding Grinding Cutting Worksdebruynbeer100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pages2020 06 17 JSA For AC Servicing-Server RoomDarren Oscar100% (1)

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 pagesHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashNo ratings yet

- Rafter, Beam, Column Assembly and Erection JsaDocument19 pagesRafter, Beam, Column Assembly and Erection JsavenkatNo ratings yet

- JHA For Excavation Backfilling and Compaction R 01Document6 pagesJHA For Excavation Backfilling and Compaction R 01Sreekumar100% (3)

- JSA. CompactorDocument3 pagesJSA. CompactorSajid Hussain100% (1)

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- JSA FOR Concerate PlacementDocument1 pageJSA FOR Concerate Placementwahyu nugrohoNo ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- Plumbing Sewerage - Drainage Swms 10Document26 pagesPlumbing Sewerage - Drainage Swms 10Shahrin KamaruzamanNo ratings yet

- Exavation Works PipercksDocument4 pagesExavation Works PipercksHRTYR100% (1)

- Risk Assessment For Demolition of Slab - Book Store-HCNSDocument4 pagesRisk Assessment For Demolition of Slab - Book Store-HCNSappu pocom3No ratings yet

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 pagesSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabNo ratings yet

- RA 13 (Water Proofing Membrane Application)Document4 pagesRA 13 (Water Proofing Membrane Application)abdulthahseen007No ratings yet

- JSA Ladders Working at Heights 001Document2 pagesJSA Ladders Working at Heights 001Anonymous voA5Tb0No ratings yet

- JSA For Earth Work & ExcavationDocument4 pagesJSA For Earth Work & ExcavationMuthu AlaguRajNo ratings yet

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanNo ratings yet

- Door Installation JsaDocument2 pagesDoor Installation Jsauz9143895No ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- JSA Gypsom WorkDocument5 pagesJSA Gypsom WorksoubhagyaNo ratings yet

- JSA Bore We Jabil SiteDocument3 pagesJSA Bore We Jabil SitesoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Jha Batching Plant PlatformDocument5 pagesJha Batching Plant PlatformsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- Electrical Safety Do - S - Dont - SDocument2 pagesElectrical Safety Do - S - Dont - SsoubhagyaNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaNo ratings yet

- ELCB Checklist PDFDocument1 pageELCB Checklist PDFsoubhagyaNo ratings yet

- Jha RWFW Raft Cocrete JobDocument3 pagesJha RWFW Raft Cocrete JobsoubhagyaNo ratings yet

- Method Statement For Horizontal Tray Erection.Document5 pagesMethod Statement For Horizontal Tray Erection.soubhagyaNo ratings yet

- Method Statement - Bus DuctDocument2 pagesMethod Statement - Bus Ductsoubhagya100% (1)

- CONCRETING OF BOLERO SHEDDocument1 pageCONCRETING OF BOLERO SHEDsoubhagyaNo ratings yet

- Cuplocks Scaffolding JSA UtilityDocument4 pagesCuplocks Scaffolding JSA UtilitysoubhagyaNo ratings yet

- Method Statement: Erection, Shuttering & Casting of ColumnDocument2 pagesMethod Statement: Erection, Shuttering & Casting of Columnsoubhagya67% (3)

- Method Statement - Tower ErectionDocument2 pagesMethod Statement - Tower ErectionsoubhagyaNo ratings yet

- Method Statement - Bus BarDocument2 pagesMethod Statement - Bus Barsoubhagya100% (1)

- METHOD STATMENT FORFIRE DETECTOR INSTALATIONDocument2 pagesMETHOD STATMENT FORFIRE DETECTOR INSTALATIONsoubhagyaNo ratings yet

- Method Statement Bolero Shed: Purpose: Scope of WorkDocument2 pagesMethod Statement Bolero Shed: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement - Cable LayingDocument5 pagesMethod Statement - Cable Layingsoubhagya100% (3)

- Safe Work Method Statement For Erection of All Works:: Client ConsultantDocument4 pagesSafe Work Method Statement For Erection of All Works:: Client ConsultantsoubhagyaNo ratings yet

- Method Statement Mrs Building: Purpose: Scope of WorkDocument1 pageMethod Statement Mrs Building: Purpose: Scope of WorksoubhagyaNo ratings yet

- Method Statement Staircase (Process Plant) LocationDocument4 pagesMethod Statement Staircase (Process Plant) LocationsoubhagyaNo ratings yet

- Method Statement: Purpose: Scope of WorkDocument1 pageMethod Statement: Purpose: Scope of WorksoubhagyaNo ratings yet

- METHOD STATEMENT FORVacuum PipingDocument2 pagesMETHOD STATEMENT FORVacuum PipingsoubhagyaNo ratings yet

- METHOD STATEMENt FabricationDocument2 pagesMETHOD STATEMENt FabricationsoubhagyaNo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (3)

- JSA FOR Using The Hand and Power Tools - 2Document2 pagesJSA FOR Using The Hand and Power Tools - 2soubhagya100% (2)

- PBC-TENDER-NO.-R7-597-2024-Meru-MikinduriDocument302 pagesPBC-TENDER-NO.-R7-597-2024-Meru-MikinduriBander Al–kouhlaniNo ratings yet

- Siriusxm For 3 Mos. For $1: America'S Environmental SchoolDocument5 pagesSiriusxm For 3 Mos. For $1: America'S Environmental SchoolOo PasNo ratings yet

- MDA Session 4Document5 pagesMDA Session 4Mahendra AkkapatruniNo ratings yet

- Embedded Linux Kernel Make With Compressed Boot PDFDocument12 pagesEmbedded Linux Kernel Make With Compressed Boot PDFMochamad Rizal JauhariNo ratings yet

- Restaurant Monthly Profit and Loss StatementDocument17 pagesRestaurant Monthly Profit and Loss StatementMozitom100% (1)

- Richeson Impossible CylinderDocument2 pagesRicheson Impossible CylinderDave DaveNo ratings yet

- Structure of Ethics ManagementDocument5 pagesStructure of Ethics ManagementIulia T Popa100% (1)

- Asian Paints Expansion Strategy in South PacificDocument5 pagesAsian Paints Expansion Strategy in South PacificKshitij JindalNo ratings yet

- Meo Assignment 1: Application On The Boat Project: Parcours Ouvert O2025 Year: O1Document4 pagesMeo Assignment 1: Application On The Boat Project: Parcours Ouvert O2025 Year: O1Dony Emmanuel NGASSANo ratings yet

- Sampling Theorem: Principle of Communication Lab ManualDocument12 pagesSampling Theorem: Principle of Communication Lab Manualعمیر بن اصغرNo ratings yet

- Robert Martinez Stock GuidDocument6 pagesRobert Martinez Stock Guidkuwar.shubham18No ratings yet

- 9 Speed TransmissionDocument9 pages9 Speed TransmissioniwearnexusNo ratings yet

- Arabia FinalsDocument11 pagesArabia FinalsAlexis CarbonNo ratings yet

- Culture and SubcultureDocument17 pagesCulture and SubcultureRekkles TedNo ratings yet

- Assignment 1-SolutionDocument4 pagesAssignment 1-SolutionAsad RehanNo ratings yet

- Dual Axis Solar Activity Tracker For Solar Panels: Department of Engineering, Sciences and Humanities (DESH)Document5 pagesDual Axis Solar Activity Tracker For Solar Panels: Department of Engineering, Sciences and Humanities (DESH)sujay patilNo ratings yet

- An Analytical Framework For The Cross-Country Comparison of Higher Education GovernanceDocument19 pagesAn Analytical Framework For The Cross-Country Comparison of Higher Education GovernanceHeba NoiemNo ratings yet

- The New Auditor's Report: Overview of The New and Revised Auditor Reporting Standards and Related Conforming AmendmentsDocument26 pagesThe New Auditor's Report: Overview of The New and Revised Auditor Reporting Standards and Related Conforming AmendmentsAndhika Suhud Meliora SitumorangNo ratings yet

- Eir August2016Document131 pagesEir August2016Nazim KhanNo ratings yet

- Tutorial Pipeline SystemsDocument48 pagesTutorial Pipeline SystemsHarry PiyoNo ratings yet

- A Fine Placement TestDocument6 pagesA Fine Placement TestNesrinnil100% (1)

- UFED Extraction Flows: A Step-By-Step Guide For Recommended Extraction Flows On Android DevicesDocument7 pagesUFED Extraction Flows: A Step-By-Step Guide For Recommended Extraction Flows On Android DevicesbrunopjNo ratings yet

- IREEED RE PolicyDocument155 pagesIREEED RE PolicybismuthsunilNo ratings yet

- TwitterDocument2 pagesTwitterAbhijeet SingareNo ratings yet

- Appointment Letter - DraftDocument5 pagesAppointment Letter - DraftKarishma ParekhNo ratings yet

- Metro Notes Mrs 2Document49 pagesMetro Notes Mrs 2azmityNo ratings yet

- General Purpose Butterfly ValvesDocument2 pagesGeneral Purpose Butterfly Valvesphe zenNo ratings yet

- Manual Makita 9562CVRDocument72 pagesManual Makita 9562CVRyvlvifjpmcylaykgtqNo ratings yet