Manual STC 9200

Uploaded by

DIEGO SEGUELManual STC 9200

Uploaded by

DIEGO SEGUELSTC-9200 INSTRUCTIONS Parameters items:

Main functions and features: Menu items (character

Parameter range Default

Menu level type) (optional) Remark

1、Multi-control mode among refrigeration,defrost,fan,etc.

SEt Temp. min. set value ~ Temp. min. set value -5℃ Tem. Set parameter

2、User menu and administrator menu can be set separately. Not only convenient for user operation, User menu

HY 1℃~25℃ 2℃ Return difference setting

but also left enough space for the adjustment of high-level management. US SEt~50℃ +20 Max.temp. set value

3、Differential control mode, and the resolution of temperature display is 0.1 LS -50℃~SEt -20 Min. temp. set value

AC 0~50 min 3 Compressor protection delay

4、Multi-protection and alarm mode optional

IdF 0~120 Hr. 6 Defrost cycle

5、COPYKEY function. MdF 0~255 min 30 Defrost time

Administrator

Main technical parameters: dtE -50℃~50℃ 10℃ Defrost termination temp.

1、Temperature measuring and controlling range:-50~50℃ Fdt 0~100min 2 Water-dripping time after defrost

tdF EL: Electric-heating defrost HtG: Thermal EL Defrost mode

2、Power supply:220VAC

Rt: the interval of defrosting actually

3、Relay capacity of Compressor :8A/220VAC dct Rt Count mode of defrost cycle

COH: the accumulated time of compressor operation

menu

4、Relay capacity of fan and defrost : 8A/220VAC dFd Rt: normal temp. displayIt: defrost start-up temp. Rt Display mode when defrost

5、Digital display : Three-digit LED + Minus digit + Status indicator light Ctr: to be controlled O-N: continuous operation, OFF when Ctr Fan operation mode

FnC

(set; refrigeration; defrost; fan) defrost C-N: start/stop with compressor, ON when defrost

FOT -50℃~fan termination temp. -10℃ Fan start-up temp.

Indicator light: 60S

FOd -255S~255S Fan start-up delay

FST Fan start-up temp.~50℃ -5℃ Fan's termination temp.

Indicator light Status Function

ALU ALL ~50℃ 50℃ Alarm value of exceed upper limit

OFF Compressor stop

ALL -50℃~ALU -50℃ Alarm value of exceed lower limit

FLASH Compressor delay 15

Refrigeration ALd 0~99min Temp. alarm delay

ON Compressor work 0℃ Temp. calibration

ot -10℃~+10.0℃

QUICK FLASH Enforced refrigeration

OFF Defrost stop

FLASH Defrost draining Function description:

Defrost

ON Defrost work

1、Compressor

QUICK FLASH Enforced to defrost

OFF Fan stop A、under electric-heating defrost, the set values of fan are positive:

Fan FLASH Fan delay

Activation condition: Relay of the compressor connects when it meets both a)、b) or both a)、c).

ON Fan work

Set

OFF Normal work mode a) compressor delay time exceeds the set delay time

ON Under setting mode

b) the storage temperature is above the set temperature, and the forcible refrigeration has begun.

c) Under the non-defrost status , the storage temperature is above the sum of the set temperature and

Keystroke function and set mode: differential set value.

Function 1(normal status) Function 2 Function 3 (when the fan's delay time is minus, the compressor relay connects if it meets other start-up conditions

Remark

Keystroke operation (menu status) (parameters setting status)

SET Enter into parameters set Save the parameters and return to set interface and the fan has operated the absolute value of the delay numerical value.)

SET……3S Enter into user set Quit from set mode Quit from set mode

Stop condition: Relay of compressor disconnects when meet any of the ff. conditions.

SET+ ………10S Enter into administrator set Press SET and hold on ,then press key

Check the defrost temperature Check the menu items Modify the parameters a) Storage temperature is lower than the set temperature.

……3S Check the defrost temperature Promptly go forward the menu items Modify the parameters promptly

Check the menu items Modify the parameters b) At start-up of defrost.

……3S Enter into forcible refrigeration Promptly go backward the menu items Modify the parameters promptly

c) Forcible refrigeration stops.

……3S Enter into forcible defrost

+ ………10S Switch keyboard-lock status

2、Defrost function 6、Keyboard lock function:Under normal mode, press ▲ and ▼ for 10s to open or close the keyboard

Relay of defrost connects when meets all of the ff. conditions: lock, and display the status of button switch. Loosen the keystroke to display the normal temperature.

a) Defrost delay time meets the set time of the defrost delay Under the keyboard lock mode, the parameter can be checked but cannot be modified.

b) Defrost temperature is lower than the termination temperature of defrost 7、The modification of part parameters may take into effectiveness during the next working cycle. If it is

c) Defrost cycle is over or forcible defrost is beginning necessary operating currently, turn of the controller and then restart.

Relay of defrost disconnects when meet any of the ff. conditions:

a) Defrost operation time is over.

b) Defrost temperature is higher than the termination temperature of defrost

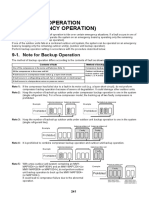

3、Fan function Indicator light: Wiring diagram:

When the delay time of fan start-up is minus, and need the compressor to start, compressor starts up until

SET LIGHT FAN LIGHT

the fan starts firstly and runs out of the set delay time completely. The compressor stops, and the fan also

Ref. Indicator Light

stops simultaneously. Minus

When the delay time of fan start-up is nonnegative, and fan's operation is under "Continuous operation, Def.

OFF when defrost" mode, the fan starts up under defrost-OFF status, and stops when defrost starts up. Decimal

When the delay time of fan start-up is nonnegative, and fan's operation is under "start/stop with

compressor, OFF when defrost" mode, the fan starts up after compressor starting up for the delay time of

fan, and stops when compressor stops or defrost begins.

Front panel:

4、Alarm function

LED blinkingly displays and buzzer alarms when storage temperature exceeds the temperature upper limit

or lower limit and it runs out of the set delay time.

LED blinkingly displays "HHH" and buzzer alarms when storage temperature exceeds the measuring

temperature upper limit or the sensor short-circuit. LED blinkingly displays "LLL" and buzzer alarms when

storage temperature exceeds the measuring temperature lower limit or the sensor open-circuit.

SENSOR'S TERMINAL

DEFROSTING

SENSOR'S TERMINAL

STORAGE TEMP.

COPY CARD

Press any key can cancel the buzzer's alarm but can't change the display status. DEFROST

CO-POINT

COMPRESSOR FAN

5、Operation of COPYKEY

The controller must be under operating status when it needs to upload the parameters to COPYKEY in NOTE:

★ Strictly distinguish the connections interfaces of relay,sensor and power from

order to saving them. Plug into COPYKEY and press ▲ key to display "UPL", at this time, press SET key one another.

★ Sensor connections and power wires should be kept for a proper distance.

to upload the parameters to COPYKEY. And it is over when LED displays "END" , then turn off the

controller and take away the COPYKEY.LED will blinkingly display "err" if there is error during uploading.

Under the controller's power-off mode, plug into the COPYKEY and turn on the controller, at this time, the

COPYKEY will automatically detect the COPYKEY and download parameters from it, then LED displays

"DOL" and start normal operation after downloading. At the moment, turn off the controller and take away

the COPYKEY. Next, restart the controller. The machine displays "err" if parameter error or controller

model error.

You might also like

- Manual de Termostato Hisense Modelo Hyxe-Va01a100% (1)Manual de Termostato Hisense Modelo Hyxe-Va01a36 pages

- Wiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480No ratings yetWiring Diagram Schema Electrique: 30RA 100 B0921 PEE 000026948013 pages

- 285.004-F Quantum Operating Instructions ENNo ratings yet285.004-F Quantum Operating Instructions EN53 pages

- TL-330 Micro Computor Thermostat For Freezer (User Instructions)No ratings yetTL-330 Micro Computor Thermostat For Freezer (User Instructions)3 pages

- Midea Modularni Cilleri MGB-service ManualNo ratings yetMidea Modularni Cilleri MGB-service Manual119 pages

- Critical Spares: Suppliers To The Air-Conditioning, Heating and Refrigeration Trade100% (1)Critical Spares: Suppliers To The Air-Conditioning, Heating and Refrigeration Trade24 pages

- Model: SF-104S-2 Digital Temperature Controller: Features of FunctionNo ratings yetModel: SF-104S-2 Digital Temperature Controller: Features of Function2 pages

- User Manual of STC-9200 Thermostat: 1. Package 2. SpecificationNo ratings yetUser Manual of STC-9200 Thermostat: 1. Package 2. Specification2 pages

- D A T A S H E E T: TX6 Thermo Expansion Valves Alco ControlsNo ratings yetD A T A S H E E T: TX6 Thermo Expansion Valves Alco Controls12 pages

- T6800 Series Large LCD Digital Thermostat 110/220 VAC 2-Pipe Fan Coil ControlNo ratings yetT6800 Series Large LCD Digital Thermostat 110/220 VAC 2-Pipe Fan Coil Control7 pages

- Thermostatic Expansion Valves - Alco: Operating Principles ProcedureNo ratings yetThermostatic Expansion Valves - Alco: Operating Principles Procedure34 pages

- Operating Instructions SZ-2711: General Description Operating Messages and Icon StatusNo ratings yetOperating Instructions SZ-2711: General Description Operating Messages and Icon Status2 pages

- 【Final】Service News (DIT-S-19012) Simple remote control BRC2E61 cannot s PDFNo ratings yet【Final】Service News (DIT-S-19012) Simple remote control BRC2E61 cannot s PDF1 page

- Owner'S Manual: Full DC Inverter Xpower VRF Outdoor UnitNo ratings yetOwner'S Manual: Full DC Inverter Xpower VRF Outdoor Unit11 pages

- Manual de Serviços VRF Toshiba SMMSi - Inibir Condensadora RevNo ratings yetManual de Serviços VRF Toshiba SMMSi - Inibir Condensadora Rev16 pages

- 05T / 06T Screw Compressor Application GuideNo ratings yet05T / 06T Screw Compressor Application Guide20 pages

- Temperature Controller HK 02 Refrigerated Instruction Manual en 200608No ratings yetTemperature Controller HK 02 Refrigerated Instruction Manual en 2006089 pages

- The Ultimate GP Referral Script Final - CompressedNo ratings yetThe Ultimate GP Referral Script Final - Compressed12 pages

- Joining The Ties of Kinship - Islamic NetworkNo ratings yetJoining The Ties of Kinship - Islamic Network4 pages

- Module 2 - Handout 2.0 - Demand Theory, Analysis and EstimationNo ratings yetModule 2 - Handout 2.0 - Demand Theory, Analysis and Estimation4 pages

- Mechanical Liquid Flow Switch: Penn Commercial RefrigerationNo ratings yetMechanical Liquid Flow Switch: Penn Commercial Refrigeration2 pages

- 8130.1 Application For Export Certificate of AirworthinessNo ratings yet8130.1 Application For Export Certificate of Airworthiness2 pages

- Download Principles of Population Genetics 4th Edition Daniel L. Hartl ebook file with all chapters100% (1)Download Principles of Population Genetics 4th Edition Daniel L. Hartl ebook file with all chapters37 pages

- Saint Mary's University - Criminology Review Center: Subject: Traffic Management & Accident InvestigationNo ratings yetSaint Mary's University - Criminology Review Center: Subject: Traffic Management & Accident Investigation7 pages

- Bleaching Our Roots: Race and Culture in American Popular MusicNo ratings yetBleaching Our Roots: Race and Culture in American Popular Music258 pages

- [Ebooks PDF] download The Event Manager s Bible How to Plan and Deliver an Event 2nd Edition Des Conway full chapters100% (8)[Ebooks PDF] download The Event Manager s Bible How to Plan and Deliver an Event 2nd Edition Des Conway full chapters85 pages

- AC500 High Availability Library For CM574-RSNo ratings yetAC500 High Availability Library For CM574-RS2 pages

- Yu Hua - On Brothers and Chaotic Aesthetics, (Chinese Literature Today, Spring 2011)No ratings yetYu Hua - On Brothers and Chaotic Aesthetics, (Chinese Literature Today, Spring 2011)6 pages

- ALMCO Risk Assessment Kitchen & Dinning Area-JAN 2021No ratings yetALMCO Risk Assessment Kitchen & Dinning Area-JAN 202110 pages

- Million-Day Gregorian-Julian Calendar - Notes100% (1)Million-Day Gregorian-Julian Calendar - Notes10 pages