JPAM Vol 12 No2 P 513-519

JPAM Vol 12 No2 P 513-519

Uploaded by

Anita HeraCopyright:

Available Formats

JPAM Vol 12 No2 P 513-519

JPAM Vol 12 No2 P 513-519

Uploaded by

Anita HeraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

JPAM Vol 12 No2 P 513-519

JPAM Vol 12 No2 P 513-519

Uploaded by

Anita HeraCopyright:

Available Formats

Journal of Pure and Applied Microbiology, June 2018.

Vol. 12(2), p. 513-519

The Effect of Different Matrix Bound on the

Transesterification Activity of Immobilized PPD2 Lipase

Anita Herawati Permana1,2, Fida Madayanti Warganegara1,

Deana Wahyuningrum3 and Akhmaloka1,4*

Biochemistry Research Group, Faculty of Mathematics and Natural Science,

1

Institut Teknologi Bandung, Indonesia.

2

Study Program of Quality Assurance of Food Industry, Politeknik AKA Bogor, Indonesia.

3

Organic Chemistry Research Group, Faculty of Mathematics and Natural Science,

Institut Teknologi Bandung, Indonesia.

4

Department of Chemistry, Faculty of Science and Computer,

Universitas Pertamina, Indonesia.

http://dx.doi.org/10.22207/JPAM.12.2.10

(Received: 06 April 2018; accepted: 25 May 2018)

Immobilization of thermostable lipase from Geobacillus thermoleovorans PPD2

(Lip-A) were carried out on Ni-NTA agarose and carboxymethyl chitosan. Free enzyme was

obtained by heterologous expression in Escherichia coli as a host cell. The enzyme showed

catalytic activity for transesterification reaction. Transesterification activity of immobilized

lipase on Ni-NTA agarose was increased by three fold (75.04% conversion) compared to that

the free enzyme (24.65%), while the activity of immobilized lipase on carboxymethyl chitosan

was slightly decreased (19.86%).

Keywords: Geobacillus thermoleovorans PPD2, thermostable lipase,

immobilization, Ni-NTA agarose, carboxmethyl chitosan, transesterification.

Transesterification of triglycerides with of Jatropha oil into ethyl ester6. Recombinant

short chain alcohols has an important role on lipase ITB1.1 from Geobacillus uzenensis local

industrial processes, such as biodiesel production strain, isolated from Manuk hot spring7, was also

or other chemical synthesis. Transesterification reported as catalyst for methylation of coconut

reaction is generally performed in non-aqueous oil. The product was identified as methyl laurate

media, catalyzed by chemicals or bio-catalyst1. (47.36%), methyl myristate (19.87%), and methyl

Chemical catalyst provides high transesterification caprate (15.96%)8. Lipase from other sources,

yield, however it has some disadvantages especially Pseudomonas fluorescens 26-2, showed 83.8%

on the downstream process: the complexity of side yield of soybean oil conversion into methyl

product removal and waste treatment. Biocatalyst ester. The enzyme also showed 80% yield

is preferable used since it offers clean process and conversion from rapeseed and cottonseed oil9.

highly specificity of substrates and products2. Transesterification assay catalyzed by organic

Lipases from different sources were soluble lipase from P. fluorescens AK was

reported as biocatalyst for esterification and reported10. Solubilized enzyme only convert 36%

transesterification reaction 3,4,5. Burkholderia yield of soybean oil conversion into methyl ester,

cepacia lipase showed high conversion yield (79%) while the native enzyme (insoluble in organic

solvent) did not produce the desired product.

* To whom all correspondence should be addressed. Organic solvents used in transesterification

Tel. : +62 22 2502103; Fax : +62 22 2504154; reaction show to strip water molecules from the

E-mail : loka@chem.itb.ac.id enzyme surface. It may leads to inactivation of

514 Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase

most enzymes, including lipases11. In order to kanamycin (Bio Basic) and IPTG (Thermo

overcome this limitation, immobilized enzyme Scientific) as marker and inducer. Chitosan

is employed to increase the enzyme stability powder (Acros Organics), sodium hydroxide

in organic solvent. Immobilized lipases from (Merck), and monochloroacetic acid were used

Chromobacterium viscosum was reported as for carboxymethyl chitosan synthesis. Ni-NTA

catalyst for transesterification reaction of Jatropha Agarose (Qiagen, Germany) and carboxymethyl

oil and ethanol12. The immobilized enzyme on chitosan were used as immobilization matrix.

Celite-545 enhanced the product yield to 71%, 2,4-nitrophenol (Sigma) was used as the standard

compared to the free enzyme (62%). Immobilized for the enzyme assay. 2,4-nitrophenol decanoate

lipase from Pseudomonas aeruginosa LX1 showed (Sigma), n-propanol (Merck), and acetonitrile were

80% conversion of soybean oil into methyl ester, used as the substrate for transesterification assay.

while the free enzyme showed 71.5% yield13. Heterologous Expression

Immobilized lipase from Mucor meihei on aminated Expression of lipase was carried out

polyethersulfone (PES-NH2) membrane cross- in Luria Bertani (LB) medium, containing

linked by glutaraldehyde, was reported as catalyst 0.1% kanamycin sulfate. Isopropyl â-D-1-

for methylation of sunflower oil. The product was thiogalactopyranoside (IPTG) was added when

identified as methyl palmitate (100%) and methyl optical density (OD600) of the medium reached

stearate (58%) with high quality for biodiesel, 0.60. Overexpression was conducted at 37 oC for

according to ASTM standard. Meanwhile, the 4 hours, with shaking at 200 rpm. Pellet cell was

reaction catalyzed by free lipase produced methyl collected by centrifugation and the overexpressed

palmitate (100%) and methyl stearate (45%)14. protein was obtained by two steps, pellet sonication

Several immobilization methods was used on followed by boiling lysis of the debris cell. The

lipase from Talaromyces thermophilus; such as supernatant from the second step was filtered by

adsorption (CaCO3), ionic binding (Amerlite, Amicon Ultra-4 Centrifugal Filters (10 kDa), then

Duolite, and DEAE-Sephadex), and covalent analyzed by SDS-PAGE on 10% running gel.

binding (chitin, chitosan, and gelatin). Optimum Freeze dried Lip-A was stored at 4 oC.

result for transesterification was observed from Immobilization on Ni-NTA agarose

immobilized lipase on chitosan (activated by Ni-NTA agarose matrix was pipetted

glutaraldehyde), with 76% yield conversion from into column, equilibrated by aqua miliQ and 50

oleic acid into butyl oleate15. mM K-phosphate buffer pH 8. Soluble protein

Lipase from local isolate, Geobacillus was then bound into matrix for 30 minutes. The

thermoleovorans PPD2, is potential as biocatalyst matrix was rinsed with K-phosphate buffer, and the

in transesterification reaction since it showed unbound protein was subjected to Bradford assay17.

tolerance towards short chain alcohols. The enzyme Immobilized Lip-A/Ni-NTA was submersed in

showed optimum temperature at 50 oC and high K-phosphate buffer and stored at 4 oC.

specificity towards pNP decanoate16. In this paper Carboxymethyl Chitosan Preparation

we described the effect of matrixs bound on the Carboxymethyl chitosan (CM-chitosan)

transesterification activity of immobilized lipase. was prepared using the method described by Chen

Two matrixs were used to bound the enzyme. One and Park18. A mixture of 2.0 g of chitosan, 2.7 g of

was based on covalent coordination bound at the sodium hydroxide, and 20 mL isopropanol:water

N-terminal, other based on covalent bound on the (4:1) were added into a ûask (100 mL). The

random surface of the enzyme. mixture was stirred at 50 oC until the polymer

swells. Monochloroacetic acid solution (3 g

MATERIALS AND METHODS solid dissolved in 4 mL isopropanol) was added

dropwise. The final mixture was allowed for 4

Chemical and Strains hours at 50 oC, then stopped by addition of 40 mL

E. coli BL21(DE3) carries pITBlip2.2 ethanol (70%) into the mixture. The solid product

plasmid inserted with PPD2 lipase gene was (Na salt of CM-chitosan) was ûltered and rinsed in

obtained from our collection. Luria Bertani medium ethanol, followed by air dried at room temperature.

was used for lipase expression, with antibiotic Na-salt CM-chitosan was then suspended in 100

J PURE APPL MICROBIOl, 12(2), June 2018.

Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase 515

mL ethanol (70%). Hydrochloric acid (37%) was solution (1 mg enzyme per mL buffer) was stirred

added until the pH reached 3, and the suspension at 20 oC for 12 hours. The mixture was centrifuged

was stirred for 30 min. The solid product (CM- (3800 g, 30 min), and the pellet was rinsed with

chitosan) was ûltered and rinsed in ethanol, then K-phosphate buffer. The unbound protein was

dried at room temperature. subjected to Bradford assay, while the freeze dried

Immobilization on Carboxymethyl chitosan pellet (immobilized Lip-A/CM-chitosan) was

A mixture of CM-chitosan (10 mg solid stored at 4 oC.

suspended in 2 mL isopropanol) and 1 mL enzyme Transesterification Assay

Transesterification assay was conducted

by spectrophotometry analysis 19 with some

modification. Substrates, p-nitrophenyl decanoate

(10 mM) and isopropanol (1 M), were mixed in

a total volume of 500 µL acetonitrile. Free and

immobilized Lip-A (equal to 1 mg protein) were

added into each tube to start the reaction. The

mixture was incubated at 50 oC with shaking

speed at 100 rpm for 2 min. After reaction, 30 µL

supernatant was pipetted into another tube and

immediately mixed with ethanol (total volume

1.5 mL). The control was carried out using the

same condition and protocols but without enzyme

addition. The mixture was measured at 315 nm,

and the conversion was calculated based on a

calibration curve of p-nitrophenol.

RESULT AND DISSCUSSION

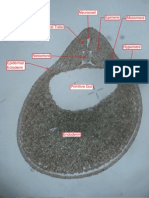

Fig. 1. SDS-PAGE Electrophoregram of PPD2 Lipase through

E.coli [M] protein marker; [1] Ultra-sonication lysate from

first step, [2] over expression protein from second step (boiling Expression and Purification of Lipase

treatment with addition of detergent), [3] Unbound protein after Recombinant lipase used for

immobilization process (fluthrough); ( ) overexpressed Lip A immobilization was obtained by two steps,

resulting in one dominant band on SDS-PAGE

electrophoregram (Fig 1). Most of the proteins

Fig. 2. Immobilization of Lip-A with various amount of protein loaded onto Ni-NTA agarose matrix. The steady

state of bound protein was showed at 4mg protein 10/ 4mL of resine

J PURE APPL MICROBIOl, 12(2), June 2018.

516 Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase

from host cell were separated in the first step matrix (data not shown). When fresh Lip-A was

(ultra-sonication lysis), since the heterologous reloaded into the previously used matrix, almost

expressed Lip-A formed insoluble and did not the same amount of protein was bound (data not

appear in the supernatant. The overexpressed lipase shown). Other paper also reported that immobilized

was obtained in the second step (boiling lysis) His-tagged Green Fluorescent Protein (GFP) on

with additional of detergent. Protein solubility Ni-NTA chitosan was specifically removed by

was increased by addition of detergent20. Isolation imidazole or EDTA23. Re-immobilization of His-

of insoluble thermostable protein by boiling lysis tagged GFP on the previously used matrix gave

was also reported21, resulting in high purity of the almost the same amount of immobilized GFP. This

recombinant protein. Detergent contamination on specific interaction may lead to the possibility of

the protein solution was later removed by filtration matrix to be reused for immobilization of fresh

using Amicon Ultra-4 Centrifugal Filters, and the enzyme.

post-treatment protein was used for immobilization. Immobilization on Carboxymethyl Chitosan

Immobilization on Ni-NTA Agarose Carboxymethyl chitosan (CM-chitosan)

Lip-A was successfully immobilized was prepared in two steps, synthesis of Na salt CM-

on Ni-NTA agarose after 30 min interaction. chitosan and acidification of the salt. FTIR analysis

Electrophoregram of the unbound protein showed

that the matrix showed high affinity towards

the enzyme (Fig 1). The interaction between the

Ni-NTA and histidine-tag at the N terminus was

occurred by covalent coordination bound between

the metal ion (Ni2+) and imidazole ring of histidine22.

The maximum capacity of matrix was observed at 4

mg protein per 0.4 mL matrix (Fig 2). Immobilized

Lip-A do not leach out by washing the matrix with

Triton-X (1%) or NaCl (100 mM), while imidazole

(100 mM) was effectively removed Lip-A from the

Fig. 3. FTIR spectra of chitosan, Na CM-chitosan,

CM-chitosan, and immobilized Lip-A on CM-chitosan

(Lip-A/CM-chitosan). Blue arrow showed peak of

carbonyl residue from CM-chitosan, meanwhile red Fig. 4. Transesterification activity and reusability

arrow showed carbonyl residue (-CONH-) of LipA- of free and immobilized Lip-A on Ni-NTA (A), and

CM-chitosan carboxymethyl chitosan (B)

J PURE APPL MICROBIOl, 12(2), June 2018.

Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase 517

19.86% conversion (Table 1), about 80% compared

Table 1. Transesterification activity of to that the free enzyme activity.

free and immobilized Lip-A

Reusability assay of Lip-A/Ni-NTA and

Sample Transesterification Activity Lip-A/CM-chitosan showed that the immobilized

(% conversion) enzyme reached half time after fourth usage (41%

remained, Fig 4, A) and third usage (30% remained,

Free Lip-A 24.65 Fig 4, B), respectively. Activity reduction of

Lip-A/Ni-NTA 75.04 immobilized Candida antartica lipase B on octyl

Lip-A/CM-chitosan 19.86 agarose was also reported 27. The enzyme was

catalyzed transesterification reaction between

of these three solids (chitosan, Na CM-chitosan, tributyrin and methanol, and the activity was

and CM-chitosan) showed that the CM-chitosan reduced about 10% after fifth usage.

was obtained (Fig 3). The FTIR spectra of chitosan Lip-A/Ni-NTA showed higher activity

shows the basic characteristic of chitosan at: 3353 and reusability compared to that Lip-A/CM-

cm-1 (O–H stretch), 2871 cm-1 (C–H stretch), 1589 chitosan. This probably due two reason, the first

cm-1 (N–H bend), and 1024 cm-1 (C–O stretch). one is interaction between the enzyme to Ni-

Meanwhile, spectra of CM-chitosan showed peaks NTA resulting on covalent coordination bound

at 1724 cm–1 (C=O stretch from –COOH), 1617 and meanwhile interaction of the enzyme to CM-

1520 cm–1 (N–H bend from –NH3+), and 1058 cm–1 chitosan resulted the covalent bound. The last

(C–O stretch), which fits the characteristic of CM- interaction is rather stronger compared to that

chitosan as described in previous studies [18,24]. covalent coordination bound. As consequence,

The –COOH peak (at 1724 cm-1) did not show in the 3D structure of the enzyme is easier to change

spectrum of chitosan and Na salt of CM-chitosan, and hence reducing the activity of the enzyme.

indicated that the carboxylate group was only The second possibility of loosing activity of

presented in the final product (Fig 3). Lip-A was the enzyme bound to CM-chitosan is due to the

successfully immobilized on CM-chitosan after 12 random interaction of the matrix into the surface

hour reaction. FTIR analysis of CM-chitosan and of the enzyme. There are many possibility that

complex Lip-A/CM-chitosan showed that the C=O the interaction occurred at the region close to

peak has shifted from 1724 cm-1 (–COOH) to 1651 the lid or catalytic site, hence the lid movement

cm-1 (–CONH–) (Fig 3). The result suggested that would be affected when the catalytic process

Lip-A was covalently attached to CM chitosan. The occured. Meanwhile using Ni-NTA matrix only

amide bond was formed from the carboxylate group the N-terminal on the enzyme was bound to the

in CM-chitosan and the amine group in Lip-A. matrix, so that the 3D structure of the enzyme was

Transesterification Activity of Immobilized not influenced by the above interaction resulting on

Lipase the increasing of the activity of the enzyme. These

Transesterification activity of immobilized result suggested that attachement of the enzyme

Lip-A on Ni-NTA agarose (Lip-A/Ni-NTA) was at specific binding and less tight interaction give

increased three fold (75.04% conversion) compared higher activity and reusability of immobilized of

to the free enzyme (24.65%). This supports the PPD2 lipase.

previews result that immobilized lipase from

Burkholderia sp. on alkyl-celite in a packed- CONCLUSION

bed reactor, also enhanced the activity to 85%

conversion, compared to the free enzyme (67%)25. Lipase of PPD2 was successfully

Immobilization of the whole cell of Aspergillus immobilized on Ni-NTA agarose and carboxymethyl

oryzae expressed Fusarium heterosporum lipase, chitosan. Enzyme-matrix interaction at specific

also enhanced the production by approximately location (Lip-A/Ni-NTA at the N-terminus) give

three fold26. Meanwhile, the activity of immobilized higher transesterification activity and reusability

Lip-A on CM-chitosan (Lip-A/CM-chitosan) was compared to that nonspecific residues on the

slightly decreased. Lip-A/CM-chitosan showed enzyme surface (Lip-A/CM-chitosan).

J PURE APPL MICROBIOl, 12(2), June 2018.

518 Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase

ACKNOWLEDGEMENT 10. Zhao, X., B. El-Zahab, R. Brosnahan, J. Perry,

and P. Wang. An organic soluble lipase for water-

We would like to thank P3MI research free synthesis of biodiesel. Applied Biochemistry

program of ITB and PDUPT program, Ministry and Biotechnology. 2007; 143(3): 236-243.

11. Yang, L., J. S. Dordick, and S. Garde. Hydration

of Research, Technology and Higher Education,

of enzyme in nonaqueous media is consistent with

Republic of Indonesia to make this research solvent dependence of its activity. Biophysical

possible to be carried out. journal. 2004; 87(2): 812-821.

12. Shah, S., S. Sharma, and M. N. Gupta. Biodiesel

REFERENCES preparation by lipase-catalyzed transesterification

of Jatropha oil. Energy and Fuels. 2004; 18(1):

1. Amini, Z., Z. Ilham, H. C. Ong, H. Mazaheri, and 154-159.

W. H. Chen. State of the art and prospective of 13. Ji, Q., S. Xiao, B. He, and X. Liu. Purification and

lipase-catalyzed transesterification reaction for characterization of an organic solvent-tolerant

biodiesel production. Energy Conversion and lipase from Pseudomonas aeruginosa LX1 and

Management. 2017; 141: 339-353. its application for biodiesel production. Journal

2. Bajaj, A., P. Lohan, P. N. Jha, and R. Mehrotra. of Molecular Catalysis B: Enzymatic. 2010;

Biodiesel production through lipase catalyzed 66(3): 264-269.

transesterification: an overview. Journal of 14. Handayani, N., D. Wahyuningrum, M. A.

Molecular Catalysis B: Enzymatic. 2010; 62(1): Zulfikar, S. Nurbaiti, and C. L. Radiman.The

9-14. synthesis of biodiesel catalyzed by Mucor

3. Nurhasanah, S. Nurbaiti, F. Madyanti, and miehei lipase immobilized onto aminated

Akhmaloka. Diversity of Gene Encoding polyethersulfone membranes. Bioresources and

Thermostable Lipase from Compost Based on Bioprocessing. 2016; 3(1): 22-26.

Metagenome Analysis. International Journal od 15. Romdhane, I. B. B., Z. B. Romdhane, A.

Integrative Biology. 2015; 16(1): 07-12. Gargouri, and H. Belghith. Esterification activity

4. Asy’ari, M., P. Aditiawati, R. Hertadi, and and stability of Talaromyces thermophilus lipase

Akhmaloka. Cloning and Squence Analysis of immobilized onto chitosan. Journal of Molecular

Lipase Gene of Halophilic Bacteria Isolated Catalysis B: Enzymatic. 2011; 68(3): 230-239.

from Mud Crater of Bledug Kuwu, Central Java, 16. Permana, A. H., F. M. Warganegara, D.

Indonesia. Bioscience, Biotechnology Research Wahyuningrum, M. P. Widhiastuty, and

Asia. 2015; 12(3): 1903-1912. Akhmaloka. Heterologous expression and

5. Kristia, Y. Y., S. F. Syihab, and Akhmaloka. characterization of thermostable lipase from

Cloning and Characterization of Lipase Gene Geobacillus thermoleovorans PPD2 through

from a Local Isolate of Psedoxanthomonas sp. Escherichia coli. Biosciences Biotechnology

Biosciences Biotechnology Research Asia. 2017; Research Asia. 2017; 14(3): 1081-1088.

14(2): 503-507. 17. Bradford, M.M. A rapid and sensitive method

6. Shah, S. and M. N. Gupta. The effect of ultrasonic for the quantitation of micrograms quantities

pre-treatment on the catalytic activity of lipases of protein utilizing the principle of protein-dye

in aqueous and non-aqueous media. Chemistry binding. Analytical Biochemistry. 1976; 72: 248-

Central Journal. 2008; 2(1): 1-8. 254.

7. Widhiastuty, M. P., Febriani, M. R. Moeis, 18. Chen, X. G., and H. J. Park. Chemical

Akhmaloka, and F. Madayanti. Cloning, characteristics of O-carboxymethyl chitosans

homological analysis and expression of Lipase related to the preparation conditions.

gene from hot spring isolate. International Carbohydrate Polymers. 2003; 53(4): 355-359.

Journal of Integrative Biology. 2011; 11(1): 8-13. 19. Fu, X., J. Zheng, X. Ying, H. Yan and Z.

8. Brilliantoro, R., R. Zidny, M. P. Widhiastuty, and Wang. Investigation of Lipozyme TL IM-

Akhmaloka. Hydrolytic and transesterification catalyzed transesterification using ultraviolet

activities of thermostable lipase ITB1.1. spectrophotometric assay. Chinese Journal of

Biosciences Biotechnology Research Asia. 2015; Catalysis. 2014; 35(4): 553-559.

12(1): 01-06. 20. Singh, A., V. Upadhyay, A. K. Upadhyay, S. M.

9. Yang, J., B. Zhang, and Y. Yan. Cloning and Singh, and A. K. Panda. Protein recovery from

expression of Pseudomonas fluorescens 26-2 inclusion bodies of Escherichia coli using mild

lipase gene in Pichia pastoris and characterizing solubilization process. Microbial cell factories.

for transesterification. Applied Biochemistry and 2015; 14(1): 41-46.

Biotechnology. 2009; 159(2): 355-365. 21. Livernois, A. M., D. J. Hnatchuk, E. E. Findlater,

J PURE APPL MICROBIOl, 12(2), June 2018.

Permana et al.: Transesterification Activity of Immobilized PPD2 Lipase 519

and S. P. Graether. Obtaining highly purified Continuous biodiesel conversion via enzymatic

intrinsically disordered protein by boiling transesterification catalyzed by immobilized

lysis and single step ion exchange. Analytical Burkholderia lipase in a packed-bed

Biochemistry. 2009; 392(1): 70-76. bioreactor. Applied Energy. 2016; 168: 340-350.

22. Wa r d , W. W. , & G . S w i a t e k . P r o t e i n 26. Amoah, J., S. H. Ho, S. Hama, A. Yoshida,

purification. Current Analytical Chemistry. A. Nakanishi, T. Hasunuma, C. Ogino, and A.

2009; 5(2): 85-105. Kondo. Converting oils high in phospholipids to

23. Oshige, M., K. Yumoto, H. Miyata, S. Takahashi, biodiesel using immobilized Aspergillus oryzae

M. Nakada, K. Ito, M. Tamegai, H. Kawaura, whole-cell biocatalysts expressing Fusarium

and S. Katsura, Immobilization of His-tagged heterosporum lipase. Biochemical engineering

proteins on various solid surfaces using NTA- journal. 2016; 105: 10-15.

modified chitosan. Open Journal of Polymer 27. Hirata, D. B., T. L. Albuquerque, N. Rueda, J.

Chemistry. 2013; 3(01): 6-11. J. Virgen-Ortíz, V. G. Tacias-Pascacio, and R.

24. Fei Liu, X., Y. Lin Guan, D. Zhi Yang, Z. Li, and Fernandez-Lafuente. Evaluation of different

K. De Yao. Antibacterial action of chitosan and immobilized lipases in transesterification

carboxymethylated chitosan. Journal of applied reactions using tributyrin: Advantages of the

polymer science. 2001; 79(7):1324-1335. heterofunctional octyl agarose beads. Journal of

25. Tran, D. T., C. L. Chen, and J. S. Chang. Molecular Catalysis B: Enzymatic. 2016; 133:

117-123.

J PURE APPL MICROBIOl, 12(2), June 2018.

You might also like

- Tableau: Classement Des BactériesDocument1 pageTableau: Classement Des BactériesCharlotte Taton100% (2)

- Enzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)Document6 pagesEnzyme Catalytic Promiscuity The Papain-Catalyzed Knoevenagel Reaction (Paper 2)thamtusieuquayNo ratings yet

- Organic Phase Synthesis of Ethyl Oleate Using Lipases Produced by Solid-State FermentationDocument9 pagesOrganic Phase Synthesis of Ethyl Oleate Using Lipases Produced by Solid-State FermentationROISYAHNo ratings yet

- Journal of Bacteriology-1991-Kordel-4836.fullDocument6 pagesJournal of Bacteriology-1991-Kordel-4836.fullMuhammad Abdullah HanifNo ratings yet

- 1application of Response Surface Design To Solvent, Temperature and Lipase Selection For Optimal Monoglyceride ProductionDocument7 pages1application of Response Surface Design To Solvent, Temperature and Lipase Selection For Optimal Monoglyceride ProductionKarliis MedinaNo ratings yet

- Aspergillus TerreusDocument6 pagesAspergillus Terreusgodfrey omariNo ratings yet

- 1 s2.0 S0021925818834779 MainDocument5 pages1 s2.0 S0021925818834779 MainOvwero EmmanuelNo ratings yet

- Purification and Identification of A Novel Leucine Aminopeptidase From Bacillus Thuringiensis IsraelensisDocument7 pagesPurification and Identification of A Novel Leucine Aminopeptidase From Bacillus Thuringiensis Israelensisavinash jNo ratings yet

- Purification of Papain From Carica Papay PDFDocument5 pagesPurification of Papain From Carica Papay PDFNiken SillVersNo ratings yet

- 2004 - Reverse Micelles ExtractionDocument6 pages2004 - Reverse Micelles ExtractionSebastian Gomez BetancourtNo ratings yet

- 53411844bp025508f20170606 26793 101qedw Libre - pdf1496797513 &response Content DispositioDocument5 pages53411844bp025508f20170606 26793 101qedw Libre - pdf1496797513 &response Content Dispositiodarireyess2020No ratings yet

- Esterification of Fatty Acids Using Partially Purified Dvl-2 LipaseDocument44 pagesEsterification of Fatty Acids Using Partially Purified Dvl-2 Lipaseakashgoyal1992100% (1)

- Torulaspora Delbrueckii and Conversion To Ephedrine byDocument4 pagesTorulaspora Delbrueckii and Conversion To Ephedrine bysalvia1025100% (1)

- Partial Characterization of Lipase From Cocoa BeanDocument6 pagesPartial Characterization of Lipase From Cocoa BeannubnubNo ratings yet

- Enzymatic Phenethyl Octanoate Synthesis: Lipase Selection and Reaction Optimization by Response Surface MethodologyDocument10 pagesEnzymatic Phenethyl Octanoate Synthesis: Lipase Selection and Reaction Optimization by Response Surface MethodologysreenathbtNo ratings yet

- Fermentum Aarnikunnas2003Document11 pagesFermentum Aarnikunnas2003Gabriel Márquez AravenaNo ratings yet

- Pnas 2013968117 SappDocument32 pagesPnas 2013968117 Sapplinawang567No ratings yet

- s002530051211Document7 pagess002530051211nehir KrtNo ratings yet

- SC 3000916Document6 pagesSC 3000916Jenny MarfàNo ratings yet

- 1 s2.0 S0141813016304871 MainDocument7 pages1 s2.0 S0141813016304871 MainMihaela DochiaNo ratings yet

- Sieval 1998Document9 pagesSieval 1998ArielDeCandiaNo ratings yet

- Rapid Regioselective Oligomerization of L Glutamic Acid Diethyl Ester Catalyzed by PapainDocument7 pagesRapid Regioselective Oligomerization of L Glutamic Acid Diethyl Ester Catalyzed by PapainIvan SuarezNo ratings yet

- Further Hnvestigation of The Biosynthesis of Caffeine in Tea Plants SinensisDocument4 pagesFurther Hnvestigation of The Biosynthesis of Caffeine in Tea Plants SinensisAndrew LiebermannNo ratings yet

- Protective Effect of Dietary Apricot Kernel Oil Supplementation On Cholesterol Levels and Antioxidant Status of Liver in Hypercholesteremic RatsDocument5 pagesProtective Effect of Dietary Apricot Kernel Oil Supplementation On Cholesterol Levels and Antioxidant Status of Liver in Hypercholesteremic RatsGÖKHAN DURMAZNo ratings yet

- Article 4 (Recovered)Document6 pagesArticle 4 (Recovered)adriannatsNo ratings yet

- Acid WashingDocument7 pagesAcid WashingArinaAdilaNo ratings yet

- Immobilization of Tomato (Lycopersicon Esculentum) Pectinmethylesterase in Calcium Alginate Beads and Its Application in Fruit Juice ClarificationDocument6 pagesImmobilization of Tomato (Lycopersicon Esculentum) Pectinmethylesterase in Calcium Alginate Beads and Its Application in Fruit Juice ClarificationcarolasbdNo ratings yet

- Moores New Esterase Inhibitor Pest Man Sci 2008Document5 pagesMoores New Esterase Inhibitor Pest Man Sci 2008Hanafy IsmailNo ratings yet

- Int J ChemTechDocument7 pagesInt J ChemTechIftiNo ratings yet

- 1,1-Diphenyl-2-Picrylhydrazyl (DPPH) Radical Scavenging by Protein Hydrolyzates From Tuna Cooking JuiceDocument6 pages1,1-Diphenyl-2-Picrylhydrazyl (DPPH) Radical Scavenging by Protein Hydrolyzates From Tuna Cooking JuiceDaniela UrreaNo ratings yet

- Fermentation and Recovery of L-Glutamic - Acid - FromDocument8 pagesFermentation and Recovery of L-Glutamic - Acid - FromPrachi Bhoir100% (1)

- 8 JulyDocument5 pages8 JulyFaisal AwanNo ratings yet

- Purification and Characterization From Stearothermophilus: BacillusDocument6 pagesPurification and Characterization From Stearothermophilus: BacillusAnindya Rahma O KNo ratings yet

- Benzaldehyde L-PacDocument8 pagesBenzaldehyde L-Pacjatzire50% (2)

- Acetaminophen Prodrugs: Synthesis, Physicochemical Properties, and Analgesic ActivityDocument7 pagesAcetaminophen Prodrugs: Synthesis, Physicochemical Properties, and Analgesic ActivityNguyễn HàNo ratings yet

- Create PDFDocument5 pagesCreate PDFexecNo ratings yet

- ajol-file-journals_82_articles_98632_submission_proof_98632-973-258910-1-10-20131212Document10 pagesajol-file-journals_82_articles_98632_submission_proof_98632-973-258910-1-10-20131212Prosie VNo ratings yet

- Topal 1993Document7 pagesTopal 1993IlijanaNo ratings yet

- Wang 2017Document9 pagesWang 2017Кирило КириченкоNo ratings yet

- C NPDFDocument4 pagesC NPDFharman_2389No ratings yet

- 3AsianJBiolLifeSci 6 3 408Document5 pages3AsianJBiolLifeSci 6 3 408AngelicGamer PlaysNo ratings yet

- Induction of An Extracellular Esterase From Candida Albicans and Some of Its PropertiesDocument5 pagesInduction of An Extracellular Esterase From Candida Albicans and Some of Its PropertiesasdasdasdkhkNo ratings yet

- Enzym ProteazaDocument16 pagesEnzym Proteazavithuat1No ratings yet

- The Use of Commercial Pectinase in Fruit Juice Industry. Part 3 (2001)Document6 pagesThe Use of Commercial Pectinase in Fruit Juice Industry. Part 3 (2001)Cris51No ratings yet

- Final MatterDocument119 pagesFinal MatterSonam ReddyNo ratings yet

- The Potential of Oil and Sago Palm Trunk Wastes As Carbohydrate ResourcesDocument7 pagesThe Potential of Oil and Sago Palm Trunk Wastes As Carbohydrate ResourcesMangasa SiregarNo ratings yet

- Nutritional Analyses For Proteins and Amino Acids in Beans (Phaseolus SP.)Document4 pagesNutritional Analyses For Proteins and Amino Acids in Beans (Phaseolus SP.)Tamara HamiltonNo ratings yet

- 04 Apr 2008Document3 pages04 Apr 2008santoshsharma024024No ratings yet

- Preparation of Fatty Acid Methyl EstersDocument9 pagesPreparation of Fatty Acid Methyl EstersSORIN AVRAMESCUNo ratings yet

- Sintesis de CineolDocument4 pagesSintesis de CineolNatalia RuizNo ratings yet

- GroundDocument9 pagesGroundgodfrey omariNo ratings yet

- Advanced Materials Obtained From LeatherDocument7 pagesAdvanced Materials Obtained From LeatherMohammed HussienNo ratings yet

- 1 s2.0 S1570023211007112 MainDocument6 pages1 s2.0 S1570023211007112 MainyasserNo ratings yet

- 2009 FTBDocument6 pages2009 FTBGarlapati Vijay KumarNo ratings yet

- Bred Dam 1991Document7 pagesBred Dam 1991Ruth Noemy Ruiz MangandiNo ratings yet

- Preparation of Chitooligosaccharides WitDocument8 pagesPreparation of Chitooligosaccharides WitKoreab KoeenNo ratings yet

- Production of Ethanol From The Hemicellulosic Fraction of Sunflower Meal BiomassDocument7 pagesProduction of Ethanol From The Hemicellulosic Fraction of Sunflower Meal BiomassJulio MoralesNo ratings yet

- Recent Advances in Polyphenol ResearchFrom EverandRecent Advances in Polyphenol ResearchHeidi HalbwirthNo ratings yet

- Practical Methods for Biocatalysis and Biotransformations 2From EverandPractical Methods for Biocatalysis and Biotransformations 2John WhittallNo ratings yet

- Practical Methods for Biocatalysis and Biotransformations 3From EverandPractical Methods for Biocatalysis and Biotransformations 3John WhittallNo ratings yet

- Akema Brochure 2011Document19 pagesAkema Brochure 2011J C Torres FormalabNo ratings yet

- APOE3 Christchurch Heterozygosity and Autosomal Dominant Alzheimer's DiseaseDocument9 pagesAPOE3 Christchurch Heterozygosity and Autosomal Dominant Alzheimer's Diseasecadence990No ratings yet

- ACE Group Patient Leaflet Dermal FillersDocument9 pagesACE Group Patient Leaflet Dermal FillersJim MackieNo ratings yet

- 5 Chapter Five Managing StressDocument52 pages5 Chapter Five Managing StressGirmaNo ratings yet

- Baobabs of The World Cover - For Print PDFDocument1 pageBaobabs of The World Cover - For Print PDFBelinda van der MerweNo ratings yet

- B UTS Bahasa Inggris Biologi 2020Document5 pagesB UTS Bahasa Inggris Biologi 2020kontol asuNo ratings yet

- Savage Worlds - Savage SpaceDocument47 pagesSavage Worlds - Savage SpaceShannon Russell (necron99)100% (2)

- Maths Science Talent Examination 2015-16 Class Ii Instructions To The Candidates (NO OMR Sheet, Please Answer On The Question Paper Itself)Document4 pagesMaths Science Talent Examination 2015-16 Class Ii Instructions To The Candidates (NO OMR Sheet, Please Answer On The Question Paper Itself)manijaiNo ratings yet

- Soil FertilityDocument5 pagesSoil FertilityAyu Ratna MutiaNo ratings yet

- Acute Respiratory Distress Syndrome: Jurnal RespirasiDocument11 pagesAcute Respiratory Distress Syndrome: Jurnal RespirasiArmia UsnihidayatiNo ratings yet

- Thyroid PathophysiologyDocument7 pagesThyroid PathophysiologyS RiarNo ratings yet

- 2nd English Sub Sum Pearson 22 (Class 6)Document2 pages2nd English Sub Sum Pearson 22 (Class 6)Emiya Arthuria TohsakaNo ratings yet

- Neural TubeDocument4 pagesNeural TubeRuth Danielle GasconNo ratings yet

- Natural and Synthetic Dyes in HistologyDocument4 pagesNatural and Synthetic Dyes in HistologyLavish ChauhanNo ratings yet

- Exercises in Nucleic AcidsDocument2 pagesExercises in Nucleic AcidsClowie Lyn CinconiegueNo ratings yet

- Determination of Heavy Metal in Marine Fish 2Document6 pagesDetermination of Heavy Metal in Marine Fish 2Muhammad Zainul Muttaqin0% (1)

- Thomas Stearns Eliot Knowledge and Experience in The Philosophy of F. H. Bradley 1964Document214 pagesThomas Stearns Eliot Knowledge and Experience in The Philosophy of F. H. Bradley 1964Carlos Wagner100% (3)

- Chapter 12 QuizDocument3 pagesChapter 12 Quizapi-203978737No ratings yet

- Earthworm Crayfish EssayDocument2 pagesEarthworm Crayfish EssayJohnNo ratings yet

- Grade 6 SCIENCE ST Q2 ST4Document4 pagesGrade 6 SCIENCE ST Q2 ST4blesilda corpinNo ratings yet

- Low Temperature Aged Garlic Extract Suppresses.7Document5 pagesLow Temperature Aged Garlic Extract Suppresses.7Tiara AmbarNo ratings yet

- Fluid Therapy (Ali Haedar)Document25 pagesFluid Therapy (Ali Haedar)Atika LuqyanaNo ratings yet

- 7-Vital Signs IDocument64 pages7-Vital Signs IVictim AljasrrNo ratings yet

- Nhls Handbook 2019Document337 pagesNhls Handbook 2019xhdrv7nvdrNo ratings yet

- Who Lives Here Quiz!: Click The Correct AnswerDocument13 pagesWho Lives Here Quiz!: Click The Correct AnsweraankleNo ratings yet

- Bleaching Literature ReviewDocument6 pagesBleaching Literature Reviewafdtlgezo100% (1)

- Micro PropagationDocument16 pagesMicro PropagationNasir Hussain Faraz100% (1)

- Invasive Species Scientific Poster TemplateDocument1 pageInvasive Species Scientific Poster Templatevilizsoph16No ratings yet

- 099 Vitamin B12-IFU-V3.06-en-EUDocument4 pages099 Vitamin B12-IFU-V3.06-en-EUMohamed BoulkadidNo ratings yet