Line Pipe Dimensional Tolerence

Line Pipe Dimensional Tolerence

Uploaded by

sudeep dsouzaCopyright:

Available Formats

Line Pipe Dimensional Tolerence

Line Pipe Dimensional Tolerence

Uploaded by

sudeep dsouzaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Line Pipe Dimensional Tolerence

Line Pipe Dimensional Tolerence

Uploaded by

sudeep dsouzaCopyright:

Available Formats

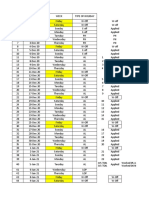

Tolerance Captured in Tolerance mentioned in API 5L Section 9, TABLE 10 &

Tolerances Mentioned in MR Tolerance mentioned in 01-SAMSS-35 Tolerance mentioned in API 5L Annex J

MR 11

-0% / +0.1% of the length in meters for Pipeline ‘Line

SUPPLY TOLERANCES Pipe items; The total length of pipe supplied per item on an order shall not

(Tolerances applicable to -0% of the length in meters / +1 joint for Risers/Spools’ be less than the amount ordered and shall not exceed the

whole Pipe Lot supplied) Line pipe items; amount ordered by more than three lengths, except by

agreement.

07-02-20 Confirmed

a) Unless otherwise agreed, random lengths shall be

delivered within the tolerances given in Table 12.

b) Approximate lengths shall be delivered within a tolerance J.6.3 Unless otherwise agreed, the minimum average length of

of ± 500 mm (20 in.). pipe shall be 12.1 m (39.7 ft). If

requested by the purchaser, the pipe manufacturer shall confirm

Pipe joint Length average: 12.2m, Max: 12.4m, Min: No pipe lengths less than 32.8 ft (9.99 m) will be accepted. the maximum average length of pipe to be supplied per order

12.0m, 98% Pipe supply shall be: within 12.1 - 12.3m Pipe lengths less than 38.1 ft (11.61 m) shall not exceed 2% of item. Unless otherwise agreed, the actual length of each pipe

Remaining: 2%. Shortest individual length allowed is the total line item quantity. Pipe intended for subsequent (end face to end face) shall lie within the range 11.70 m (38.4 ft)

Pipe joint Length 11.9m: 2% short pipe needs to be colour coded at Mill, internal coating shall have a maximum length of 42.0 ft (12.80) to 12.70 m (41.7 ft).

preferably for operations ease. for any individual length.

07-02-20 Confirmed Note:- it is, therefore, the responsibility of the purchaser to agree

with both the

manufacturer and the pipe-lay contractor on the length range to

be supplied.

9.12.6.3 The out-of-squareness, as shown in Figure 3, shall

be ≤ 1.6 mm (0.063 in.). The out-ofsquareness is measured

as the gap between the end of the pipe and the pipe end leg.

Max 1.6mm from true 90°.

Pipe End Squareness

07-02-20 Confirmed

1) The total deviation from a straight line, over the entire

pipe length, shall be ≤ 0.2 % of the pipe length, as shown in

Figure 1.

2)The local deviation from a straight line in the 1.5 m (5.0 ft)

portion at each pipe end shall be ≤ 3.2 mm (0.125 in.), as

Max 0.15% of pipe length shown in Figure 2. J.6.4 The total deviation from a straight line over the entire pipe

Pipe straightness 07-02-20 Confirmed length shall be ≤ 0.15 % of the pipe length.

Nominal OD ≤ 16” = ±0.5%ID but maximum ±1.0mm

(ID) Inside Diameter at

Pipe Ends

07-02-21- To proceed as of now.

Nominal OD ≤ 16” = 1.0% ID, but max. 2.0 mm

OOR Pipe Ends (ID)

07-02-21- To proceed as of now.

Tolerances for Wall Thickness (SMLS) Table 11

Tolerances for Wall Thickness (SMLS) Table J.4

t > 4.0 mm (0.157) to < 25.0 mm (0.984) = +0.150t –0.125t tickness - 10.0mm (0.394) to < 25.0mm (0.984) = +0.125t

10 ≤ WT ≤ 25.4 mm = -10%, + 12.5% −0.125t

Note-If the purchase order specifies a minus tolerance for

Wall Thickness wall thickness smaller than the applicable value given in this Note -If the purchase order specifies a minus tolerance for wall

07-02-21- To proceed as of now. table, the plus tolerance for wall thickness shall be increased thickness smaller than the applicable value given in this table, the

by an amount sufficient to maintain the applicable tolerance plus tolerance for wall thickness shall be increased by an amount

range. sufficient to maintain the applicable tolerance range.

Nominal OD ≤16” = ± 0,75% OD Diameter Tolerances -Pipe Except the End (SMLS) (Table 10) Diameter Tolerances-Pipe Except the End (SMLS) (Table J.3)

OD Tolerances at Pipe

Body 07-02-21- Below note to be added in MR OD > 168.3 (6.625) to 610 (24.000) = ±0.0075D OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = ± 0.5 (0.020) or ±

"To be measured through out the body of the pipe" 0.0075D, whichever is the greater

Nominal OD ≤16” = ± 1.5% OD Out-of-roundness Tolerances- Pipe Except the End (Table 10) Out-of-roundness Tolerances-Pipe Except the End (Table J.3)

OOR at Pipe Body (OD) 07-02-21- Below note to be added in MR

"To be measured through out the body of the pipe" OD> 168.3 (6.625) to 610 (24.000) = 0.020D OD ≥ 60.3mm (2.375) to 610mm (24.000) = 0.015D for D/t ≤ 75

07-02-21- This toleance not mentioned in MR.

"As per Annexure J" to be added in MR (Need to re Diameter Tolerances -Pipe End (SMLS) (Table 10) Diameter Tolerances-Pipe End (SMLS) (Table J.3)

OD Tolerances at confirm)

Pipe Ends 07-02-21- Below to be added in MR. OD> 168.3 (6.625) to 610 (24.000) = ±0.005D, but maximum OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = ± 0.5 (0.020) or ±

"OD Tolerances at Pipe Ends shall as per Annexure J" of ±1.6 (0.063) 0.005D, whichever is the greater, but max of ± 1.6 (0.063)

07-02-21- This toleance not mentioned in MR. Out-of-Roundness at the ends shall not exceed 1.0% of

" Nominal OD ≤16” = ± 0,75% OD " to be added in MR specified (nominal) O.D. For pipe with D/t < 75, the difference Out-of-roundness Tolerances-Pipe End (Table 10) Out-of-roundness Tolerances-Pipe End (Table J.3)

(Need to re confirm) between maximum diameter and minimum diameter shall

OOR at Pipe Ends (OD) OD ≥ 60.3 mm (2.375) to 610 mm (24.000) = 0.01D for D/t ≤ 75

meet the requirement of paragraph 9.11.3.1 [Table 10] of API OD> 168.3 (6.625) to 610 (24.000) = 0.015D

07-02-21- Below to be added in MR

" Nominal OD ≤16” = ± 0.75% OD " SPEC 5L subject to a maximum of 0.24 inch.

07-02-21- below SAMSS note to be added in MR

Pipe that is to be joined The difference in outside or inside diameter, at the ends,

using pipeline field "The difference in outside or inside diameter, at the between any two lengths of the same Line Item shall not

mechanized welding ends, between any two lengths of the same Line Item exceed 0.063 inch for 75% of the pipes produced.

systems: shall not exceed 0.063 inch for 75% of the pipes

produced"

You might also like

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDocument8 pagesDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNo ratings yet

- Steel Line Pipe, Black, Plain-End, Electric-Resistance-WeldedDocument6 pagesSteel Line Pipe, Black, Plain-End, Electric-Resistance-WeldedProduction DepartmentNo ratings yet

- BUTTING Clad Pipes PDFDocument12 pagesBUTTING Clad Pipes PDFsiswoutNo ratings yet

- C - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Document51 pagesC - Evaluation Selection of Directional Drill Pipe Coatings - 2023 - P9Pammy JainNo ratings yet

- Seat Material PDFDocument2 pagesSeat Material PDFkrisNo ratings yet

- 03 - Traffic and Equivalent Axle Loads (Updated)Document88 pages03 - Traffic and Equivalent Axle Loads (Updated)Besim QelajNo ratings yet

- Scope of Coating Requirements FOR Field Joints From External CorrosionDocument2 pagesScope of Coating Requirements FOR Field Joints From External CorrosionImalah UgoachanumNo ratings yet

- Meliadine Brine Project DescriptionDocument22 pagesMeliadine Brine Project DescriptionNunatsiaqNewsNo ratings yet

- 1997 GeoArabiaThamamaDocument25 pages1997 GeoArabiaThamamaCarlosNo ratings yet

- ERIKS - O-Ring Datasheet - FKM 75-Compound 514322 BlackDocument1 pageERIKS - O-Ring Datasheet - FKM 75-Compound 514322 Blackseeralan_1986No ratings yet

- Abu Dhabi FormationsDocument1 pageAbu Dhabi FormationsmdalgamouniNo ratings yet

- IPC2010-31273 IPC2010-: The Effect of Sample Flattening On Yield Strength Measurement in Line PipeDocument6 pagesIPC2010-31273 IPC2010-: The Effect of Sample Flattening On Yield Strength Measurement in Line PipeDhrumil ChauhanNo ratings yet

- Testing and Analysis of Pipeline Ball Valves Part 1 PDFDocument3 pagesTesting and Analysis of Pipeline Ball Valves Part 1 PDFNovianto Rachmad100% (1)

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNo ratings yet

- Squares and Square RootsDocument8 pagesSquares and Square RootsJessica RamerNo ratings yet

- Canusa Pipeline Repair Products Installation GuideDocument2 pagesCanusa Pipeline Repair Products Installation GuideLewoski100% (1)

- Dynamic Swing Trader Position Size CalculatorDocument3 pagesDynamic Swing Trader Position Size CalculatorHicham HasnaouiNo ratings yet

- Flange Basics: Rating FlangesDocument6 pagesFlange Basics: Rating FlangesBhavani PrasadNo ratings yet

- CorrosioncouponinstallationmethodDocument2 pagesCorrosioncouponinstallationmethodgunduboss1985No ratings yet

- NVI - Negative Volume IndexDocument9 pagesNVI - Negative Volume IndexDat TranNo ratings yet

- Stock Market IndicesDocument13 pagesStock Market IndicesilyasNo ratings yet

- Manuscript On TradingDocument25 pagesManuscript On TradingJack BagelzNo ratings yet

- Non-Intrusive Magnetic Pig SignallerDocument2 pagesNon-Intrusive Magnetic Pig SignallerAndresNo ratings yet

- Stock Exchange IndicesDocument19 pagesStock Exchange IndicesBunu MarianaNo ratings yet

- Bends - Offshore Line Pipe - Tenaris - Mother PipeDocument2 pagesBends - Offshore Line Pipe - Tenaris - Mother Pipemarjand66No ratings yet

- Maharashtra Seamless Limited: Location de Test SpecimensDocument3 pagesMaharashtra Seamless Limited: Location de Test SpecimensRavi TyagiNo ratings yet

- Blast Cleaning Technology HandbookDocument6 pagesBlast Cleaning Technology HandbookSarif IslamNo ratings yet

- DBB Gate Valve CatalogDocument11 pagesDBB Gate Valve CatalogVipul PanchalNo ratings yet

- BrederoShaw PDS FBE PDFDocument2 pagesBrederoShaw PDS FBE PDFJR RZNo ratings yet

- Capital Leverage Trading Budget % Trading Budget % Profit/LossDocument4 pagesCapital Leverage Trading Budget % Trading Budget % Profit/LossDamme LinkNo ratings yet

- Product Data Booklet Fibertec Ultimate HDD Coating SystemDocument8 pagesProduct Data Booklet Fibertec Ultimate HDD Coating Systemmkash028No ratings yet

- Cosasco Two-Inch System: CORROSION COUPONS (Alloy Specimens) & Coupon Holder AssembliesDocument17 pagesCosasco Two-Inch System: CORROSION COUPONS (Alloy Specimens) & Coupon Holder AssembliesArifinNo ratings yet

- CPF Upgrade - PFD: Pkg-01 - Inlet Manifold Skid Pkg-02 - Test Separator SkidDocument9 pagesCPF Upgrade - PFD: Pkg-01 - Inlet Manifold Skid Pkg-02 - Test Separator SkidIbrahim DewaliNo ratings yet

- DBB ValveDocument6 pagesDBB ValveshyamNo ratings yet

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Document6 pagesInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaNo ratings yet

- Ball ValvesDocument4 pagesBall ValvesJorge Arana YiNo ratings yet

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyNo ratings yet

- Attachment 7 - TRANSVERSE WELD TENSILE TESTDocument1 pageAttachment 7 - TRANSVERSE WELD TENSILE TESTkamikitaNo ratings yet

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocument1 pageFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Determining Average Grain Size: Standard Test Methods ForDocument28 pagesDetermining Average Grain Size: Standard Test Methods ForChristopherJohnGoodingNo ratings yet

- Heat TreatmentDocument4 pagesHeat TreatmentSomnath DeyNo ratings yet

- Datasheet Pigging Control Systems 0212 Rev1Document5 pagesDatasheet Pigging Control Systems 0212 Rev1Murli ramchandranNo ratings yet

- UCM Ball ValvesDocument22 pagesUCM Ball ValvesBalakrishna BisoyiNo ratings yet

- Pipe Hdpe Sdr11Document3 pagesPipe Hdpe Sdr11George_Wabag_20140% (1)

- Datasheet - Pig Signallers: Product Description and FunctionsDocument2 pagesDatasheet - Pig Signallers: Product Description and FunctionsMurli ramchandranNo ratings yet

- What Is Financial LeverageDocument2 pagesWhat Is Financial LeverageJORKOS1No ratings yet

- Alignment SheetDocument1 pageAlignment Sheetkhalid ahmedNo ratings yet

- API 5L 45-th Edition: Item No SawlDocument6 pagesAPI 5L 45-th Edition: Item No SawlRob WillestoneNo ratings yet

- Corrosion Coupon Rack: Installation & Operation ManualDocument7 pagesCorrosion Coupon Rack: Installation & Operation ManualVania Nicol Arapa YugarNo ratings yet

- GS 142-2Document31 pagesGS 142-2Serge RINAUDO0% (1)

- Criteria For The Selection of Metallic Pipelines CoatingsDocument10 pagesCriteria For The Selection of Metallic Pipelines CoatingsVinicius CarvalhoNo ratings yet

- MISC Materials ListDocument10 pagesMISC Materials ListWaqas WaqasNo ratings yet

- Position CalCulationDocument11 pagesPosition CalCulationChristian NicolausNo ratings yet

- Vibration Assessment of Barred TeeDocument1 pageVibration Assessment of Barred Teeข้าวเม่า ทอดNo ratings yet

- 05892e06 Pipes and Piping Components For PlantsDocument31 pages05892e06 Pipes and Piping Components For PlantsAhmed AbdulrazaqNo ratings yet

- Fracture Toughness and FatigueDocument10 pagesFracture Toughness and FatigueiamjemahNo ratings yet

- Tcst11105r0 - Limitation Tel CablesDocument10 pagesTcst11105r0 - Limitation Tel CablesengrandyNo ratings yet

- Dokumen - Tips - Simplified Reinforced Concrete Design 2010 NSCPDocument200 pagesDokumen - Tips - Simplified Reinforced Concrete Design 2010 NSCPmedel araoNo ratings yet

- Technical Specifications For 3.3kV Cables RemovedDocument4 pagesTechnical Specifications For 3.3kV Cables RemovedAshish bhattNo ratings yet

- Medical Centre SketchDocument9 pagesMedical Centre SketchkkkkNo ratings yet

- Leave PlanDocument3 pagesLeave Plansudeep dsouzaNo ratings yet

- List of Documents For Plates & TubularsDocument6 pagesList of Documents For Plates & Tubularssudeep dsouzaNo ratings yet

- NDT Technician ChecklistDocument1 pageNDT Technician Checklistsudeep dsouzaNo ratings yet

- Charpy Test - ShapesDocument1 pageCharpy Test - Shapessudeep dsouzaNo ratings yet

- Pmi Cost For J-Tube Scope: Machine Type Item 100% 25% Per HeatDocument2 pagesPmi Cost For J-Tube Scope: Machine Type Item 100% 25% Per Heatsudeep dsouzaNo ratings yet

- GAP Analysis DNVGL-B101 Vs EN 10025-4Document2 pagesGAP Analysis DNVGL-B101 Vs EN 10025-4sudeep dsouzaNo ratings yet

- Charpy TestDocument1 pageCharpy Testsudeep dsouzaNo ratings yet

- Hardness SymbolsDocument3 pagesHardness Symbolssudeep dsouzaNo ratings yet

- Technical ClarificationDocument2 pagesTechnical Clarificationsudeep dsouzaNo ratings yet

- Specification For Wrought Austenitic Stainless Steel Piping FittingsDocument11 pagesSpecification For Wrought Austenitic Stainless Steel Piping Fittingssudeep dsouzaNo ratings yet

- SF-467 13Document10 pagesSF-467 13sudeep dsouzaNo ratings yet

- Course Code Course Name Teaching Scheme (Contact Hours) Credits Assigned Theory Pract. Tut. Theory Tut. Pract. TotalDocument4 pagesCourse Code Course Name Teaching Scheme (Contact Hours) Credits Assigned Theory Pract. Tut. Theory Tut. Pract. TotalPabocNo ratings yet

- Electronics Transformer DesignDocument17 pagesElectronics Transformer DesignReziNo ratings yet

- SohcahtoaDocument18 pagesSohcahtoaASHWANI Raj100% (1)

- Engchem 111 Lesson 1Document33 pagesEngchem 111 Lesson 1FrancNo ratings yet

- Introduction To Food EngineeringDocument59 pagesIntroduction To Food EngineeringMaryam SarNo ratings yet

- Turning On A PivotDocument27 pagesTurning On A PivotEnola PearlNo ratings yet

- The Uni-Junction Transistors ExperimentDocument6 pagesThe Uni-Junction Transistors ExperimentCharles ObejeroNo ratings yet

- Surface Area of DuctsDocument6 pagesSurface Area of Ductsanwerquadri40% (5)

- S 704v2020 06 Supplementary Spec To IEC 60034 1 High Voltage Three Phase Cage Ind. MotorsDocument39 pagesS 704v2020 06 Supplementary Spec To IEC 60034 1 High Voltage Three Phase Cage Ind. MotorsEvangelos TsampourisNo ratings yet

- 10 Gravitation 40 MarksDocument2 pages10 Gravitation 40 Markskomal naxineNo ratings yet

- Ppoint-MotionSpeedVelocityAcceleration SUMMARY NOTES WORDDocument4 pagesPpoint-MotionSpeedVelocityAcceleration SUMMARY NOTES WORDIRFAN ZAIN ULABIDEENNo ratings yet

- WFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtDocument2 pagesWFT-0010 (2J9844L18) Jan 02 Ico-Corp-Mpt-5002 Mpi & UtApichai ZankerNo ratings yet

- WEEK 2 - Q2 - Math 7Document13 pagesWEEK 2 - Q2 - Math 7Jennilyn Salih AnogNo ratings yet

- Angles and DirectionsDocument25 pagesAngles and DirectionshabteNo ratings yet

- Icing On TransmissionDocument7 pagesIcing On Transmission1SI18EE012 HARSHDEEP SINGHNo ratings yet

- Basic Radiation Concepts Week 8Document36 pagesBasic Radiation Concepts Week 8melfordbatucanNo ratings yet

- MD 1Document145 pagesMD 1Orly SalvadorNo ratings yet

- Sheet 2Document5 pagesSheet 2Hmbs HrNo ratings yet

- Motion Multiple ChoiceDocument25 pagesMotion Multiple Choiceterrencendabambi100% (1)

- Industrial InstrumentationDocument24 pagesIndustrial InstrumentationNHIÊN CÙ VĂNNo ratings yet

- Ass 4Document3 pagesAss 4Syed Faras HaiderNo ratings yet

- Datasheet Hybrid H S2 Series 0722 Global en WebDocument2 pagesDatasheet Hybrid H S2 Series 0722 Global en WebhussamNo ratings yet

- OpenStax UniPhysVol2Chapter1Document61 pagesOpenStax UniPhysVol2Chapter1deltaruniaNo ratings yet

- Class Xi Physics CH - 7 - Gravitation (Competency - Based Test Items) Marks WiseDocument27 pagesClass Xi Physics CH - 7 - Gravitation (Competency - Based Test Items) Marks WiseunleashedtoxicityNo ratings yet

- WavesDocument27 pagesWavesBrianna MalcolmNo ratings yet

- Convert 1Document2 pagesConvert 1Tom VatNo ratings yet

- Rtech-Photometry Laboratory: 226-TEST NBN EN ISO/IEC 17025:2017Document8 pagesRtech-Photometry Laboratory: 226-TEST NBN EN ISO/IEC 17025:2017jhaan carlos garzon roblesNo ratings yet

- Ees Year 9 Revision Forces MomentsDocument32 pagesEes Year 9 Revision Forces MomentsJuan AnariNo ratings yet

- NLM-Constraint+ Equilibrium - KeysDocument2 pagesNLM-Constraint+ Equilibrium - Keysakankshachaubey732No ratings yet

- Linear Quartz ThermometersDocument28 pagesLinear Quartz ThermometersManu ChakkingalNo ratings yet