Abacus

Abacus

Uploaded by

أنور مازوز أبو يوسفCopyright:

Available Formats

Abacus

Abacus

Uploaded by

أنور مازوز أبو يوسفCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Abacus

Abacus

Uploaded by

أنور مازوز أبو يوسفCopyright:

Available Formats

Abacus +

Hematology Analyzer

Service Manual

Release 1.09

DIATRON Messtechnik Ges.m.B.H.

A-1141 Wien, Ameisgasse 49-51/2.

AUSTRIA

Tel.: (431) 914-85-00, 911-38-48

Fax: 914-85-07-15

Web: www.diatron.com

DIATRON MI Ltd.

H-1038 Budapest, Papírgyár u. 58-59.

HUNGARY

Tel.: (361) 436-98-00

Fax: (361) 436-98-00

Web: www.diatron.com

E-mail: support@diatron.com

Downloaded from www.Manualslib.com manuals search engine

2 Diatron MI PLC

Revision history:

Revision Section Modification By At

1.00 All PRELIMINARY Support 10-11.2006

Team

1.09 All Updating tubing schematic Cust.Serv May 2007

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 3

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................................................................ 7

1.1. NAME AND SERIAL NUMBER.................................................................................................................... 7

1.2. INTENDED USE ........................................................................................................................................ 7

1.3. INTEGRATED SOFTWARE ......................................................................................................................... 8

2. FUNCTIONAL DESCRIPTION ................................................................................................................. 9

2.1. MAIN ELECTRONIC PARTS OF THE ANALYZER .......................................................................................... 9

2.1.1. Counting chambers with electrodes and measuring apertures ................................................... 10

2.1.2. HGB Head ................................................................................................................................... 10

2.1.3. Cell counter Amplifier Board ...................................................................................................... 11

2.1.4. Control and Measurement Board (COMB) with DIMM-PC core ............................................... 12

2.1.5. DIMM-PC* Module .................................................................................................................... 13

2.1.6. Configuration and ID E2PROM board (IDEPROM) .................................................................. 13

2.1.7. Pneumatic and Power Board (PPB) ........................................................................................... 14

2.1.8. Opto-boards for stepper motors .................................................................................................. 15

2.1.9. Valve boards ............................................................................................................................... 15

2.1.10. Pressure Sensor ........................................................................................................................... 16

2.1.11. Digital Reagent Sensor Board..................................................................................................... 16

2.1.12. LCD Display Module with High Voltage Board ......................................................................... 17

2.1.13. Keypad ........................................................................................................................................ 18

2.1.14. External Power Supply ................................................................................................................ 18

2.2. MAIN MECHANIC AND FLUIDIC PARTS OF THE ANALYZER ..................................................................... 19

2.2.1. Sampling needle .......................................................................................................................... 20

2.2.2. Washing head .............................................................................................................................. 20

2.2.3. H&V moving unit ........................................................................................................................ 21

2.2.4. Main Dilutor................................................................................................................................ 22

2.2.5. Micro Dilutor .............................................................................................................................. 23

2.2.6. Puffer reservoir ........................................................................................................................... 23

2.2.7. Pump ........................................................................................................................................... 23

2.3. ASSEMBLED ANALYZER ........................................................................................................................ 24

2.3.1. Abacus+ ...................................................................................................................................... 24

3. ADJUSTMENT ........................................................................................................................................... 27

3.1. MECHANICAL SETTINGS ........................................................................................................................ 27

3.1.1. Opto wheel setting ....................................................................................................................... 27

3.1.2. Sampling needle setting ............................................................................................................... 28

3.2. HARDWARE SETTINGS ........................................................................................................................... 28

3.2.1. Amplifier offset setting ................................................................................................................ 28

4. OPERATION OF THE FLUIDIC SYSTEM ........................................................................................... 29

4.1. BASIC PROCESSES ................................................................................................................................. 30

4.1.1. Sampling process ........................................................................................................................ 30

4.1.2. Needle washing process .............................................................................................................. 31

4.1.3. Diluting processes ....................................................................................................................... 32

4.1.4. Fluid transfer from MIX chamber to WBC chamber ................................................................... 33

4.1.5. Lysing process ............................................................................................................................. 34

4.1.6. Counting process ......................................................................................................................... 35

4.1.7. Aperture priming process ............................................................................................................ 36

4.1.8. WBC chamber draining process.................................................................................................. 37

4.1.9. RBC chamber draining process .................................................................................................. 38

4.1.10. Cleaner priming process ............................................................................................................. 39

4.2. MAIN FUNCTIONS OF FLUIDIC SYSTEM ................................................................................................... 40

4.2.1. Initialization ................................................................................................................................ 40

4.2.2. Wake up ....................................................................................................................................... 40

4.2.3. Measurement cycle ...................................................................................................................... 41

4.2.4. Standby ........................................................................................................................................ 47

4.2.5. Cleaning ...................................................................................................................................... 48

4.2.6. Hard cleaning ............................................................................................................................. 48

4.2.7. Shutdown ..................................................................................................................................... 48

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

4 Diatron MI PLC

5. CHECKING THE PROPER OPERATION ............................................................................................. 49

5.1. SELF TEST ............................................................................................................................................. 49

5.1.1. Self test Screens ........................................................................................................................... 49

5.1.2. Normal range of Self Test parameters ......................................................................................... 50

5.1.3. Troubleshooting Guide for Self test ............................................................................................. 50

5.2. SERVICE MENU ..................................................................................................................................... 51

5.2.1. Entering to Service Menu ............................................................................................................ 51

5.2.2. Main Service Menu ...................................................................................................................... 51

5.2.3. Edit service contact ..................................................................................................................... 51

5.2.4. Device Information ...................................................................................................................... 51

5.2.5. Service Calibration ...................................................................................................................... 52

5.2.6. Settings ........................................................................................................................................ 52

5.2.7. Service Testing Menu .................................................................................................................. 55

5.2.8. Valve Test Menu .......................................................................................................................... 55

5.2.9. Motor Test Menu ......................................................................................................................... 55

5.2.10. Display and Keyboard Test ......................................................................................................... 56

5.2.11. Stress Mode ................................................................................................................................. 56

5.2.12. Miscellaneous Settings ................................................................................................................ 57

5.2.13. Multi-user Rescue Code .............................................................................................................. 57

6. SERVICE OPERATION ............................................................................................................................ 58

6.1. OPENING THE INSTRUMENT ................................................................................................................... 58

6.2. MDA (MONOCHROME DISPLAY ADAPTER) EMULATION MODE ............................................................. 58

6.3. KEY BIOS SETTINGS FOR CORRECT OPERATION .................................................................................... 58

6.4. CHECKING THE BIOS SETUP.................................................................................................................. 60

6.5. BIOS-DESCRIPTION .............................................................................................................................. 60

6.6. DOS FUNCTIONS ON THE INSTRUMENT .................................................................................................. 62

7. TROUBLESHOOTING ............................................................................................................................. 63

7.1. ERROR CODES ....................................................................................................................................... 64

7.1.1. Software/system errors ................................................................................................................ 64

7.1.2. Pneumatic errors ......................................................................................................................... 64

7.1.3. Measure errors ............................................................................................................................ 65

7.1.4. Printing errors ............................................................................................................................. 66

7.1.5. Other errors ................................................................................................................................. 67

7.2. WARNING MESSAGES ............................................................................................................................ 68

7.2.1. Pneumatic warnings .................................................................................................................... 68

7.2.2. Database relating warnings ........................................................................................................ 69

7.2.3. Warnings relating to QC measure ............................................................................................... 69

7.2.4. Calibration relating warnings ..................................................................................................... 69

7.2.5. Hardware relating warnings ....................................................................................................... 70

7.2.6. Other warnings ............................................................................................................................ 70

7.3. POSSIBLE CAUSES OF NOISE .................................................................................................................. 71

7.3.1. Contaminated reagent ................................................................................................................. 71

7.3.2. Bad earth grounding ................................................................................................................... 71

7.3.3. External electrical noise .............................................................................................................. 72

7.3.4. Internal noise sources.................................................................................................................. 72

8. MAINTENANCE ........................................................................................................................................ 74

8.1. WEEKLY MAINTENANCE BY USER ........................................................................................................ 74

8.1.1. Cleaning the washing head ......................................................................................................... 74

8.2. PERIODIC MAINTENANCE BY SERVICE .................................................................................................. 74

8.2.1. Check Self test and Device statistics ............................................................................................ 74

8.2.2. Cleaning and Greasing Dilutor Block ......................................................................................... 74

8.2.3. Checking and Lubricating Dilutor Piston Tips ........................................................................... 74

8.2.4. Cleaning and Lubricating Needle Moving Mechanics ................................................................ 74

8.2.5. Checking and Replacing Washing Head ..................................................................................... 74

8.2.6. Checking and Replacing Peristaltic Pump Tube ......................................................................... 74

8.2.7. Checking condition of lyse tubing ............................................................................................... 75

8.2.8. Bleaching of Fluidic System ........................................................................................................ 75

9. SPARE PARTS ........................................................................................................................................... 76

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 5

10. APPENDICES ........................................................................................................................................ 80

10.1. WARNING FLAGS ................................................................................................................................... 80

10.2. SERIAL COMMUNICATION PROTOCOL ................................................................................................... 82

10.2.1. General Description .................................................................................................................... 82

10.2.2. Format of Packages Sent ............................................................................................................ 83

10.2.3. Format of Acknowledge of the Receiver...................................................................................... 83

10.2.4. Detailed Description of Packages ............................................................................................... 83

10.2.5. Serial Protocol 1.0 ...................................................................................................................... 88

10.2.6. Serial Protocol 1.7 ...................................................................................................................... 89

10.2.7. Serial Protocol 2.20, 2.23 ........................................................................................................... 90

10.2.8. Serial Protocol 3.0 ...................................................................................................................... 91

10.3. ABACUS+ CABLING DIAGRAM ............................................................................................................... 95

10.4. ABACUS+ TUBING SCHEMATICS ............................................................................................................ 96

10.5. RECOMMENDED KIT OF TOOLS .............................................................................................................. 97

10.6. ELECTRONIC SCHEMATICS .................................................................................................................... 97

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

6 Diatron MI PLC

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 7

1. INTRODUCTION

Although Abacus+ is a member of Diatron‟s Abacus junior instrument, it has special

and different characteristics compared to other junior family members. We issue a

dedicated Service Manual for this instrument; information herein applies for

Abacus+.

To be well up in the instruments, please read this manual carefully to have the

knowledge for servicing the instruments perfectly and avoid extra costs and wasting

precious time.

This Abacus+ Service Manual contains the functional descriptions of the analyzer,

operation of the fluidic systems, adjustments and settings, and very important information for

the Service Personnel about the service operations and possible problems.

1.1. Name and serial number

Name: Abacus+ Hematology Analyzer

Serial No.: Every instrument has its own serial number, which is printed on the rear panel

label and it can be read out from Device Information or from the self test

submenu. This identity number is write-protected by DIATRON.

1.2. Intended use

Abacus+ hematology analyzer is a fully automated cell counter for in vitro diagnostic use.

The compact instrument was developed for small clinics, point-of-cares and vet offices.

Abacus+ can process 60 samples per hour and is intended to determine the following 18

hematology parameters from a 25µl whole blood sample:

WBC - LYM# - MID# - GRA# - LYM% - MID% - GRA% (three-part WBC differential)

HGB - RBC - HCT - MCV - RDW - MCH - MCHC

PLT - MPV - PCT – PDW

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

8 Diatron MI PLC

1.3. Integrated software

The integrated software controls the instrument operations, displays, stores, recalls data,

and allows the user to perform QC and calibration procedures and modify the user settings.

The software version number can be read out from the Device Information or from the Self

test submenu.

Software is absolutely “Plug and Play”, it can read out and detect the type and the serial

number of the instrument, therefore it will run the correct program for the hardware, without

any user or service help. Every Abacus+ software version is upgradeable (using an USB

drive) by the latest program developed by DIATRON, and it can be downloaded from:

www.diatron.com

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 9

2. FUNCTIONAL DESCRIPTION

2.1. Main electronic parts of the analyzer

Abacus+ contains the following electronic parts:

1. Counting chambers with electrodes and measuring apertures

2. HGB Measuring Head

3. Cell Counter Amplifier Board (behind the chambers)

4. CPU Board with DIMM-PC and measurement processing unit (COMB Board)

5. Pneumatic and Power Board (PPB) with motor controllers, valve & pneumatic

controller, pump driver and power supply for internal printer (+8V) and digital circuitry

(+5V)

6. Safe configuration E2PROM board connecting CPU board and PPB

7. Motors with common opto-board of needle moving motors (H/V)

8. Main dilutor block with opto-board for diluent, lyse

9. Micro-dilutor block with opto-board for sampling

10. Valve boards (set of 5 and max. 7)

11. Peristaltic Pump

12. Pressure Sensor

13. Digital Reagent Sensor Board

14. Graphic LCD Display Module with High Voltage Board

15. LCD and Keyboard controller and Keyboard Panel

16. Internal Printer

Abacus+ Electronic Functional Block Diagram

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

10 Diatron MI PLC

2.1.1. Counting chambers with electrodes and measuring apertures

Impedance method is used for determination of volume and number of cells. In this method

a known volume of dilution is drawn through a small aperture. Constant current is passed

through the aperture from one side to the other. When a cell passes through the aperture, it

causes a change in resistance, which generates a voltage pulse.

The amplitude of the voltage pulse is proportional to the ratio of cell volume per aperture

volume. This is used to determine the volume of cells. The number of cells can be obtained

by counting the pulses.

In the instrument there are two Cellcounter Probes: WBC probe with 100 μm aperture, and

RBC probe with 80 μm aperture. Both have a ground electrode assembly and U-shaped

metal fixing as it is shown in the next figure.

Assembled Cell-counter Probe Measuring tubes

Red rings mark

measuring tubes:

One: RBC – 80 μm

Two: WBC – 100 μm

O-ring

U-shaped metal fixing

Measuring tube Reference electrode

The aperture is made of ruby and it is moulded into the measuring tube.

2.1.2. HGB Head

Hemoglobin head is placed on the two sides of the WBC chamber.

It contains: light source (LED) at 540 nm wavelength and Photo Detector (TSL235). The

Photo Detector converts the light to frequency. The HGB concentration is a logarithmic

function of this frequency measured by the FPGA circuit of the COMB card.

Connection to the amplifier

LED TSL235

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 11

The analyzer performs enhanced Hemoglobin measurement technology for HGB

measurement. The output of HGB head is frequency (TSL235 detector is light to frequency

converter). This signal is counted by a digital counter in the FPGA circuit/micro-controller.

This counter counts up while the LED is on and counts down while the LED is off, the LED

and the counter directions are switched with a 100 Hz signal. This method provides “real

time backlight correction”, which makes the HGB measurement more precise in changing

backlight environment situation as well.

There are two kinds of HGB measurements:

Sample measurement (before RBC counting)

Diluent measurement (in WBC washing phase)

The HGB result is calculated from these measurements by:

HGB log (CNTdiluent light / CNTsample light)

In spite of the fact that Abacus+ is less sensitive to incident light changes it is

recommended to keep side door closed during measurements.

2.1.3. Cell counter Amplifier Board

Amplifier board includes its own voltage regulator, the connection interfaces to HGB head, to

high voltage board and to COMB card. In this board there is the current generator circuit,

which works from 50 V measuring voltage (generated by High Voltage Board) and the probe

voltage (DC) is amplified with a voltage follower (output: ELV). Nominal measuring current is

870 µA.

Amplifier board includes two input connectors for the chambers (measuring electrodes).

There are two reed relays on the input side: IC10 can select between the two channels

(RBC, WBC) with RSW signal; IC11 connects high voltage to the selected probe with HSW

signal. Test circuit makes possible to generate test pulses (with TEST and PLS signals

through FETs) for checking the proper operation of the amplifier channel.

Connection to the HVB Reed relays Connection to COMB (AMP and DIGIO)

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

12 Diatron MI PLC

Amplifier board includes a 3-stage main amplifier channel, which gains to the input signal to

the 0...5 V range (this is the input range of the A/D converter, which is placed on the COMB

card). There is an offset potentiometer, P1 in the third amplifier stage, manufacturer sets the

correct offset voltage.

Adjust the offset voltage only in case it is out of the +/- 5mV range.

DHON signal (from the COMB card) switches on the LED in the HGB head via a transistor

(Q3), but the Photo Detector in the HGB head is working continuously.

The other side of the amplifier board contains special connectors for the chambers and the

HGB head.

2.1.4. Control and Measurement Board (COMB) with DIMM-PC core

The compact COMB incorporates a single PC and its environmental functions, as well as the

specific measurement processing functions in one board.

PS2 COM 1

USB B USB USB

keyboard

nnection

Speaker IDEPROM

connection

HVB

connection

Display

Amplifier

connection

connection

Floppy

connection

DIGIO IDE

connection

PC system of the COMB board is based on the DIMM-PC module, which is a credit card

size PC with AMD Elan SC520 133 MHz micro-controller. DIMM-PC itself contains 16 or

32Mbyte RAM and same size of FlashDisk that acts like a hard disk. DIMM-PC module is

easily replaceable as it has an open socket (it has also a screw for safe fixing). COMB card

contains single ICs and some drivers/protection-circuits for the interfaces such as COM1,

PS2, USB, IDE and Speaker.

Measurement processing is based on a FPGA circuit. After power on, the FPGA holds the

DIMM-PC in wait state (with –IOCHRDY signal) until the PIC configures the FPGA circuit from

the IDEPROM (status LED is red during configuration). After that the FPGA controls the

entire pneumatic system through the Pneumatic I2C bus, the Keyboard and Display module

with video RAM for MDA (Monochrome Display Adapter) emulation, and Start button &

status LED. FPGA circuit also performs measurement data acquisition by using the 10-bit

A/D chip. FPGA makes digital data processing and stores the results in the internal FIFO

memory. Cell parameters are sent to the DIMM-PC by single DMA cycles.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 13

2.1.5. DIMM-PC* Module

The MB4 board incorporates a credit-card sized PC, named DIMM-PC*. The processor on

the DIMM-PC is a 133MHz Pentium-class core, with 32Mbytes on-board RAM, and

32Mbytes on-board FlashDisk. This is the HDD (hard disk drive) of the analyzer, so

instrument software with all user settings, calibration, database, etc. is stored on the DIMM-

PC.

DIMMPC® is the Trade Mark of Kontron Embedded Modules GmbH

Hard Disk

Flash BIOS

(FlashDisk)

FlashDisk

32 Mbytes RAM

controller

Clock

generator

On-board SMPS

Super I/O

AMD Elan

Edge connector SC520 CPU

2.1.6. Configuration and ID E2PROM board (IDEPROM)

This board is the interconnection between COMB and PPB cards: Pneumatic I2C bus, power

lines and internal printer signals are connected through this card. The board also contains a

24FC256 serial E2PROM, which stores the FPGA‟s configuration data and identity

information of the instrument (Serial Number, OEM, model, etc.).

2

E PROM

Keeping the hardware identity information (write-protected), IDEPROM allows running the

correct software.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

14 Diatron MI PLC

2.1.7. Pneumatic and Power Board (PPB)

PPB card contains the main power regulator circuits, valve and motor driver circuits and

other connections for the fluidic and pneumatic system‟s parts.

PUMP MDIL X_Y_SR

Peristaltic pump Micro dilutor Horizontal, Vertical &

connection connection Sample rotor connection

PRESSURE

Pressure sensor

connection

REAGENT_SENSOR

Reagent sensor

connection

VALVES

Valve connections

+12V_IN

Power input

PRINTER

Internal

printer

connection

I_PCB_CONNID

board connection FLOPPY/CD

5V voltage

regulator Power to

Floppy/CD DIL_MDIL

(on chassis)

Main Dilutor

connection

PPB card contains the main power regulator circuits, valve and motor driver circuits and

other connections for the fluidic and pneumatic system‟s parts.

Power system generates +5V (Digital power), +8V (Printer power) and +12V (Motor and

valve power) from the single +12V DC input signal.

Motor driver part consists of six separated PIC micro-controllers with power drivers.

Horizontal, Vertical and Sample rotor motors have one combined ribbon cable connection.

Main Dilutor (with two motors) and Micro-dilutor have separated connectors.

Valve driver section is based on the valve driver PIC micro-controller and three 8-bit,

powered output shift registers (with built in protection diodes) and there are two common

ribbon cable connections for the 4 valve boards. The peristaltic pump has a separated

Darlington driver circuit for more reliable operation.

All the 7 (6 for motors, 1 for pneumatic) microcontroller have 2 LEDs: a yellow one and a

green one.

The yellow one indicates motor moving or holding and active valve or pump moving. (it

means current flows into motors, valves or pump)

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 15

The green one has 3 states:

dark: (after initialization phase) error state,

blinking: communication in progress - normal state

on(just lighting): OK - normal state

2.1.8. Opto-boards for stepper motors

There are five stepper motors in the system: Horizontal and Vertical motors, which make the

movements of the sampling needle; the main Dilutor motors (2), which move the syringes

and the micro Dilutor motor, which drives the sampling phase. The stepper motor opto

boards make the connections between the motor driver ICs and motors, and have opto

switches for the motor‟s home and end positions. The actual status of the stepper motor‟s

optos is indicated by two LEDs on each stepper motor opto boards.

Dilutor and Micro-dilutor have its own separated opto-board, located directly in the units.

Horizontal and Vertical motors have a common Opto-board, called XYopto Board:

Connections for Hoirizontal &

Vertical motors

Opto switches & LEDs for Horizontal motor Opto switches & LEDs

for Vertical motor

The other side of the board contains a ribbon cable connection to the COMB.

2.1.9. Valve boards

There are two kinds of valve boards: Valve board 0-5 and Valve board 6-12.

The valve boards are connected to controller and driver chips are located on the PPB.

Valves

Valve Board

Connection to PPB

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

16 Diatron MI PLC

2.1.10. Pressure Sensor

This is an MPX5100AP calibrated pressure sensor, which can measure the required air

pressure and vacuum. The Pressure Sensor is connected directly to the PPB card.

Connection to Puffer reservoir

Connection to:

PPB

The pressure sensor can operate from +5V only. It is a calibrated sensor with 0-1.1 Bar input

range. Do not apply more than 1.5 Bar to it, because it can ruin the pressure sensor.

2.1.11. Digital Reagent Sensor Board

This board contains four liquid detector opto-detectors (optos) and a reference opto for

automatic temperature and stray light compensation. The reference opto is located in the

middle and it has the same temperature and backlight conditions as the sensing ones.

Reference detector

Control LEDs Reagent detectors

The Reagent Sensor Board is connected to the PPB card, and the valve driver micro-

controller makes the sensing and compensating operations.

Instrument makes automatic initialization – called calibration – of reagent sensors during

priming phase of fluidics.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 17

2.1.12. LCD Display Module with High Voltage Board

LCD &

Keypad

controller

LCD module

Start key

connection and

status LED

LCD backlight

lamp

Keypad connector

Display assembly contains the 240x128 dots graphics LCD display and the high voltage

board. LCD has a high voltage backlight lamp (high voltage board generates the required

voltage).

There is a special temperature compensation circuit in the display module, which makes

possible to use the LCD module in wide temperature ranges with the adjusted contrast.

High Voltage Board (HVB) generates LCD backlight voltage (300V), aperture cleaning

voltage (150V), and measuring voltage (50V). The high voltage board is connected to the

system through the amplifier board and the COMB card. This unit contains INVC191

inverter, which is a high voltage, high frequency circuit producing suitable voltage for CCFL

(cold cathode fluorescent lamp) of the LCD.

The CFSW digital signal (from the COMB card) controls HVB: logical LOW turns inverter on.

The MVON digital signal (from the COMB card) switches the measuring voltage (50 V) on/off

by O1 opto switch.

Warning! Be careful with servicing this board in active state, because the high

voltage (300V) at LCD lamp connector can cause damages or electric shock.

Start key is a micro-switch, connected to the COMB card (through the Display ribbon cable).

The status LED indicates the actual status of the analyzer and it has two colors: red and blue

(See User‟s Manual). The LED has three pins and the actual color depends on the controlled

pins. Start key and status LED are controlled by COMB.

Connection to

COMB and

amplifier

Connection

to LCD lamp

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

18 Diatron MI PLC

2.1.13. Keypad

The analyzer has a 29-button foil keypad including numerical keypad (0-9, “.”), cursor

moving, OK and Del buttons, and 6-6 function buttons, above and under the LCD display as

it is shown in the picture below:

Function buttons Status LED Cursor buttons

2.1.14. External Power Supply

The analyzer works with an external power supply. The next figure shows the power supply

unit generating 12VDC.

115V or 230V

AC inlet

12V DC outlet

The power supply modules have an auto range input, which makes possible to use them

with 230V or 115V mains outlet and it has the CE and UL safety certification. The input

socket of the power supply is a standard 3-terminal plug, with power cable connection; the

output is a special, lockable socket as it is shown in the picture.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 19

2.2. Main mechanic and fluidic parts of the Analyzer

Abacus+ Hematology Analyzers consist of the following mechanic and fluidic parts:

1. Sampling needle

2. Washing head

3. H&V moving unit

4. Micro Dilutor

5. Dilutor

6. Chambers

7. Cell-counter probes

8. Puffer reservoir

9. Pump

10.Valves

11.Tubing

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

20 Diatron MI PLC

2.2.1. Sampling needle

Sampling needle is assembled in the H&V moving unit and it makes the sample aspirations.

Correct setting of sampling needle is necessary and very important (see Chapter

Adjustments).

2.2.2. Washing head

Washing head is located at the bottom of the H&V moving unit and it is for cleaning the outer

surface of the sampling needle. This washing process is made with diluent reagent and the

fluid is drained by the pump. The arrows on the picture show the direction of diluent flow

during sampling needle washing.

Clean diluent

Pump to waste

Clean or replace washing head yearly, or after 10 000 measurements.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 21

2.2.3. H&V moving unit

This unit contains slides to move the sample sampling needle in Horizontal and Vertical

directions, two stepper motors, XYR opto board, opto wheel, washing head and the sampling

needle. It moves the needle to the desired position: from sampling position, to washing head,

and to the measuring chamber.

Sampling needle

holder

Sampling needle XYR opto board Vertical opto wheel

Washing head

Vertical

motor

Horizontal

motor

Both stepper motors have optical end-switch sensors for detecting these positions. These

are required for correct initialization and error detection. All sensors have status LEDs to

show actual conditions.

The Vertical motor works with a special opto wheel for detecting home & end positions. See

the Adjustment section of this manual to place this wheel to the proper position.

Greasing of the horizontal/vertical guiding rods should be done regularly using

“Photolube” (A598), a PTFE-based thin lubricant.

It is recommended to check and repeat greasing of guiding rods every year, or after

10000 measurements.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

22 Diatron MI PLC

2.2.4. Main Dilutor

There are two stepper motors, a common motor opto board, four syringes and piston rods

with gear transmission.

Maintenance should be provided to the piston tips, by applying neutral silicon

grease to the cogged end of the Macro and Lyse pistons, between the syringe and

the tip itself. This will ensure optimum sealing and longer lifetime of piston tips.

Greasing of the cogged transmission parts (cogwheel and cogged bar) should be

done regularly using machine grease.

It is recommended to check and repeat greasing of piston tips, and transmission

gear every year, or after 10000 measurements.

Lyse syringe and

Diluent syringes

piston

Control

Control

LEDs

LEDs

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 23

2.2.5. Micro Dilutor

Micro dilutor is taking the precise sample (25 or 50μl) into the sampling needle. It includes a

stepper motor, a motor opto board and the micro syringe.

Connection to Valve

Connection to

sampling needle

Connection to PPB

Motor opto board

Flexible clutch

Stepper motor

2.2.6. Puffer reservoir

The glass puffer reservoir is directly connected to the pressure sensor.

During measurement, there is no pump activity, so the puffer reservoir maintains measuring

vacuum stable. The instrument measures atmospheric pressure and adjusts measuring

vacuum according to it.

2.2.7. Pump

Pump generates regulated vacuum and drains the fluidic system. It is connected to the PPB

and it has its own driver circuit (Darlington).

If the tube of the peristaltic pump becomes worn, it can be broken, causing Pressure error.

It is recommended to check the state of the tube, and replace it every 2 years, or

after 20 000 measurements. Always replace the peristaltic pump tube to the same

PharMed® type, with the same length.

For servicing the tube of the pump, open the peristaltic pump from its top (see picture) and

remove the tube together with the white plastic side wall (see picture):

In case of damaged tubes, it can be replaced by a new one by opening the two metal locks

located at the two ends of the tube (see picture).

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

24 Diatron MI PLC

2.3. Assembled Analyzer

2.3.1. Abacus+

Front Panel

Built-in thermal

printer (optional) 240x128 dots

Graphic LCD

Foil keypad

Function keys

START button

Rear panel:

Power switch

12V DC inlet

Warning labels

USB ports

Serial Port

USB slave port

Reagent inlets PS/2 external

keyboard port

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 25

Construction – front:

Valve block

Pressure

sensor

Electronic

block

H&V unit

Speaker

Valve block

Construction – right side

:

Valve block

Needle moving

mechanics

Reagent

sensor

Puffer reservior

Microdilutor

Measuring

chambers Pump

Valve block Dilutor block

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

26 Diatron MI PLC

Construction – left side:

Pneumatic and

Power Board

(PPB)

ID Eprom Board

(IDEPROM)

Control and Speaker

Measurement Board

(COMB)

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 27

3. ADJUSTMENT

Mechanical and hardware adjustments are described in this section. Software settings are

included in Section 5.2.

3.1. Mechanical settings

There are two important mechanical settings in the system:

Opto wheel setting (Vertical motor)

Sampling needle setting

The manufacturer adjusts the analyzer during production. However, in case of

repairs in the mechanical system, these adjustments should be checked. The

omission of these settings can cause malfunction or damages to the instrument.

3.1.1. Opto wheel setting

This setting is necessary for the vertical motor movements because this adjustment sets the

opto end-switches of the H&V moving unit. The top of this block is called HV head and it is

shown in the figure below.

Set the distance to 1-2 mm between the moving

carriage and the stable part of the head.

Loose „A” screws to allow free movement of the timing

belt. Screw „B”

Adjust the opto wheel to home position, i.e. home hole

must be in home sensor, and LED corresponding to Screw „A”

home opto sensor goes on.

Fasten „A” screws.

Opto wheel

End opto

End hole

Home opto

Home hole

Check the end position as well: move the needle down. Adjustment is successful if end LED

goes on before moving part reaches end of mechanical range.

Once this adjustment is necessary, never miss sampling needle setting described in the next

section.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

28 Diatron MI PLC

3.1.2. Sampling needle setting

This adjustment sets the sampling needle to the operational position.

In Service menu, in Miscellaneous submenu of AJ/AJvet and in Service menu of AJB select

Needle setting.

The software moves the needle back and up, and turns on horizontal and vertical motors

(AJ/AJvet) to keep needle in place. AJB holds only the vertical motor during needle setting.

Sampling needle

Bottom plane of

Teflon stuffing ring

washing head

Tubes to/from the

washing head

Check the setting of the needle. If end of the needle is at the bottom of the washing head,

needle is set correctly. If not, open screws “B” (see above), and adjust the needle to the

bottom of the washing head. Fasten “B” screws.

Set the end of the tip to the washing head’s bottom plane, while the carriage is held

by motors. (Needle setting menu). Fix the „B” screws.

Be careful with the bent upper end of the sampling needle, because if badly

aligned, during movement it can hit other mechanical components causing

mechanical jam, and therefore damages or error.

3.2. Hardware settings

3.2.1. Amplifier offset setting

Amplifier offset should be between ±5mV. Run self test to determine whether offset is within

this range. If it is out of range, it should be re-set, by the following way.

1. Locate the opening for offset setting potentiometer on the

measuring block (see enclosed picture).

2. In Service menu select Offset adjustment menu.

3. Adjust the potentiometer to reach 0 mV.

Opening for offset adjustment on measuring block

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 29

4. OPERATION OF THE FLUIDIC SYSTEM

This section describes the main steps of Abacus+ fluidic functions. The instrument‟s Fluidic

Schematics are shown in section 2.2 of this manual. The following figures show total

measurement flow diagram and detailed descriptions of basic processes for understanding

the fluidic system work.

The following steps are introduced in this section:

1. Basic processes

1.1. Sampling process

1.2. Needle washing process

1.3. Diluting process

1.4. Fluid transfer from MIX chamber to WBC chamber

1.5. Lysing process

1.6. Counting process

1.7. Aperture priming process

1.8. WBC chamber draining process

1.9. RBC chamber draining process

1.10. Cleaner priming process

2. Main functions of the fluidic system

2.1. Initialization

2.2. Wake up

2.3. Measurement cycle

2.4. Standby

2.5. Cleaning

2.6. Hard cleaning

2.7. Shutdown

In the detailed process description figures, the active tube is filled with black or gray color,

while an arrow ( ) shows the direction of the flow. Moving mechanic parts have another

arrow indicating direction of movement. In the section of the basic processes only relevant

valves are mentioned in this section (ON or OFF) while all the other valves are in either ON

or OFF state depending on the status of the instrument and other parallel running process.

Abacus+ employs a software waste full checking feature. Software integrates volume of the

reagents used.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

30 Diatron MI PLC

4.1. Basic processes

4.1.1. Sampling process

The aspirating needle aspirates 25 µl (50 µl in prediluted mode) of blood sample. The Micro-

dilutor syringe makes the aspirating while the M5 Micro-dilutor motor moves down.

There is another sampling process for the second (RBC) dilution, when 35 μl of primary

dilution is aspirated from the MIX by the aspirating needle. Both of the samples are

separated from the diluent with a small air bubble and there is another air bubble between

the sample and the end of the needle.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 31

4.1.2. Needle washing process

The instruments clean the sampling needle with diluent in the washing head after sampling.

It is important to clean the outer surface of the sampling needle to avoid inaccurate

sampling.

The Macro syringe doses and the pump drains the diluent from the washing head, while the

sampling needle moves upwards so that the total length of it is washed and cleaned. This

process is called total sampling needle washing, and it is mainly used after taking primary

sample from sample tube.

Another process, which is washing only a smaller part of the sampling needle, is the same

but the needle does not move in the total length. Some procedures perform this kind of

sampling needle washing.

The M3 Macro syringe pushes the diluent through V11 (Off), V12 (On). The Pump aspirates

the diluent from the washing head through V4 (On), while the M2 Vertical motor moves the

sampling needle up.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

32 Diatron MI PLC

4.1.3. Diluting processes

Before the dilutions the MIX and the RBC chambers are filled up with 1 ml of diluent. This

method prevents the chamber from dirt and makes the diluting process faster.

The sampling process has aspirated 25µl of sample (or 35µl of primary dilution), which is in

the sampling needle. In the first diluting step the sample is dispensed into the MIX chamber

with 3 ml of diluent (1.0 ml is waiting in the MIX chamber), which comes from the Macro

syringe through V11 (On) and Micro-dilutor, while the M3 Dilutor motor moves upwards. This

process makes the 1:160 first dilution rate in the MIX chamber.

The second sampling process aspirates 35 μl of primary dilution and then it is added with 4.0

ml of diluent (1.0 ml + 3.0 ml) into the RBC chamber. This process makes 1:18285 dilution

rate in the RBC chamber.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 33

4.1.4. Fluid transfer from MIX chamber to WBC chamber

In Abacus+, during this step the liquid remaining in the mixing chamber flows via the V0

(On) into the WBC chamber, because the vacuum – which is in the puffer reservoir and

maintenated by the pump – aspirates the fluid through V5 (On) and V3 (On), while V2 and V1

are Off. Simultaneously, the peristaltic pump supports this procedure via V4 (On).

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

34 Diatron MI PLC

4.1.5. Lysing process

During this step the primary dilution remaining in the mixing chamber flows into the WBC

chamber, like a simple MIX WBC transfer, but in this case simultaneously, 0.8 ml of lysing

reagent is added through V9 (On), while the Lyse syringe moves upwards. This process

makes the 1:192 dilution rate and good mixing with lyse.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 35

4.1.6. Counting process

The regulated vacuum (it is generated by the pump in the puffer reservoir) aspirates the

diluted sample (WBC and RBC) from the chamber through V2 (On) valve. The instrument

counts the cells for 5 seconds in both counting phases (at first WBC and after it the RBC).

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

36 Diatron MI PLC

4.1.7. Aperture priming process

In this process the aperture branch and backsides of the apertures are filled with diluent and

. After generating vacuum in the puffer reservoir the pump continues the drainig of the

aperture branch (V2 and V3 On, V1 and V5 Off) meanwhile the diluent syringe of M4 dilutor

unit pushes diluent through V10 (On), V6 (On) and V8 (On).

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 37

4.1.8. WBC chamber draining process

The WBC chamber draining is performed via V3 (On) and V4 (On) valves by the pump while

the V5 must be off. The WBC chamber draining is always executed without using the puffer

reservoir. So other tasks like RBC chamber draining can be performed parallel with this

operation.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

38 Diatron MI PLC

4.1.9. RBC chamber draining process

The RBC chamber is drained by the vacuum in the puffer reservoir through V1 (On) valve

(V2 must be off). This vacuum is made (and maintenated) by the peristaltic pump. During the

draining the pump can perform either other task like WBC chamber draining or needle wash,

or can help the draining of the RBC chamber.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 39

4.1.10.Cleaner priming process

The cleaner solution is primed by vacuum in the following way: V7 (On), Cleaner Detector,

V6 (On), back side of the RBC aperture, back side of the WBC aperture, V2 (On), V3 (On),

V4 (On) and the peristaltic pump. The V1 and V5 valves are off. The flow of the cleaner is

controlled by the vacuum, generated in the puffer reservoir before the start of the priming.

After the priming the remaining cleaner between the cleaner detector and V6 (approx. 1 ml)

can be dosed into the mix chamber.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

40 Diatron MI PLC

4.2. Main functions of fluidic system

4.2.1. Initialization

Fluidic initialization process performs the following steps:

Positioning all mechanical components (stepper motors) by scanning moving range

(with end-switches)

Checking the atmospheric pressure

Checking of pump and pressure sensor by generating measuring vacuum

Priming of reagents and calibrating reagent sensors

Fill the tubing with the reagents

Cleaning of tubing & measuring chamber

Cleaning of aperture with high-pressure back-flush, cleaner reagent & high-voltage

burning

4.2.2. Wake up

If the instrument is in standby state the wake up process is taken place in order to make the

instrument ready to measure. During this process the needle is go out and down to the

sampling position and the M1 and M2 stepper motor hold it until the start button pressed or

the instrument go into standby. While the needle is moving the microdilutor (M5) is aspirate

some air into the needle (this bubble is going to separate the dilent and the blood). After this

procedure the status LED is turned blue and measurement can be started.

Simultaneously the MIX and the WBC chamber is drained (WBC draining, MIX WBC, WBC

draining). During the last WBC chamber draining the MIX is filled with 5.0 ml diluent. Then

this volume is moved into the WBC chamber.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 41

4.2.3. Measurement cycle

Before the start of the measurement cycle the instrument is in ready state (status LED is

green). In this state the sampling needle is in the sampling position: out and down. The Mix

chamber is empty, the WBC chamber contains 5.0 ml of diluent (the wake up process or

previous measurement put it into the chamber and the blank HGB measured with this liquid

used). The RBC chamber contains the last rinsing amount of diluent of the previous

measurement cycle or the standby volume.

The following two flowcharts introduce the entire measurement cycle. One of these

flowcharts describes the fluidic transfers related the needle, the other one the chamber

related activities. The flowcharts has synchronization points where one of them waiting (W)

for the others signal (S).

Needle

process

Dilutor (M3)

moves down Sampling

(primes diluent)

Needle washnig, needle

positioning over the MIX

chamber

S1

Dilutor (M3)

moves down

(primes diluent)

W1

S2

Needle moves down

into the MIX

chamber

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

42 Diatron MI PLC

W2

First dilution

(MIX chamber)

S3

Dilutior (M3 )

moves down RBC sampling

W3

Needle (short)

washing

S4

Dilutior (M3) Needle positioning

moves down over the RBC

chamber

W4

Second dilution

(RBC chamber)

S5

Dilutior (M3)

moves down

Needle up

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 43

W5

Microdilutor

syncronization

Fill up the MIX

chamber with 2.5ml

of diluent

S6

W6

Fill the MIX chamber

with 2.5ml of diluent

S7

Dilutior (M3) moves

down

Perform wake up

process

END

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

44 Diatron MI PLC

Chamber process

HGB blank delay Dilutor (M4) moves

W1

down and primes

diluent

Measuring HGB

S1

blank

RBC chamber Fill up the MIX

draining chamber with 1 ml

of diluent

Dilutor (M4) moves

down and primes

diluent

Fill up the RBC

chamber with 1 ml

of diluent

WBC chamber

draining

S2

W2

S3

Lysing

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 45

Dilutor (M4) moves

W3

down and primes

diluent

Aperture priming

Generating

measuring vacuum

WBC counting

RBC counting HGB measurement

S4

RBC chamber WBC chamber

draining draining

Pull out 0.2 ml of

Lyse

W4

Yes Autoclean? No

Fill up the RBC Fill up the RBC

chamber with 0.8 ml chamber with 2.5 ml

of diluent of diluent

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

46 Diatron MI PLC

MIX WBC

Yes No

Autoclean?

Cleaner Priming

WBC chamber Fill up the MIX

draining chamber with 2.5 ml

of diluent and cleaner

Fill up the RBC

chamber with

diluent

Aperture Priming

MIX WBC

Dilutor (M4) moves High voltage cleaning

down and primes pulses; backflush

diluent

RBC chamber

draining

WBC chamber Fill up the MIX

S5

draining chamber with 2.5 ml

of diluent and cleaner

Dilutor (M4) moves

down and primes

diluent

W5

Fill up the RBC

chamber with 4.5 ml

of diluent

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 47

MIX WBC

Autoclean?

Yes

Dilutor (M4) moves

No

down and primes

High voltage diluent

cleaning pulses;

backflush

Aperture Priming

Dilutor (M4) moves

down and primes

diluent

END

4.2.4. Standby

Standby process is executed when the instrument is in ready state and the standby time

(see Service Settings) ellapsed

In the beginning of the standby process the needle goes up and is washed and the

chambers are drained. After this the 3.0 ml diluent is put into MIX (via needle) and the

RBC chamber (via V8), and the diluent from the MIX is transferred into the WBC

chamber and at last MIX chamber is filled with 1 ml of diluent and the back side of the

apertures are primed. The diluent in the chambers prevent the apertures and chambers

from dirt, drying out and salt build up.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

48 Diatron MI PLC

4.2.5. Cleaning

Cleaning function drains all of the chambers and fills the RBC chamber and the MIX

chamber with 2.5 ml of diluent. After moving content of the MIX chamber into the WBC

chamber the aperture branch is primed with cleaner (see 1.x). The remaining cleaner

between the cleaner detector and the V6 valve is pushed into the MIX chamber with

diluent. After this the WBC chamber is drained and the cleaner with diluent transferred

here from the MIX chamber. Then the apertures are cleaned with high voltage burn and

with backflush. The RBC chamber rinsed with 5.0 ml of diluent and the remaining cleaner

is pushed out with diluent from the aperture branch (and back side off the apertures). At

least the volumes of the standby state are dosed into the chambers.

4.2.6. Hard cleaning

Before the hard cleaning a wakeup procedure is executed. After pressing the start button

the M3 dilutor aspirates 0.2 ml from the hard cleaning solution. Half of this amount is

dosed into the MIX chamber (diluted with 5.0ml diluent coming from the other dilutor unit

M4 through V10, V8 , V6) and the remaining cleaning solution is pushed into the RBC

chamber with 5.0 ml diluent (see diluting process). Then the M4 dilutor unit pulls and

pushes the diluted cleaner solution via the aperture combined with high voltage burns.

After this the chambers are drained and rinsed with diluent.

4.2.7. Shutdown

The fluidic shutdown performs the following steps:

Drains chambers

Perform a cleaning cycle

Priming chamber with diluent to avoid drying out of aperture (MIX 2.0 ml, RBC 5.0 ml,

WBC 5.0 ml)

Sampling needle is positioned above MIX chamber, needle up

All of the syringes are positioned down

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 49

5. CHECKING THE PROPER OPERATION

There is a built-in Self test and Service menu in the analyzer.

5.1. Self test

5.1.1. Self test Screens

Self test can be used to check the operation of

the instrument.

The first panel shows general information about

the instrument. (See menu on the left.)

With the new COMB card, the PCPNIF firmware

version is empty, and the MPU firmware version

holds the COMB version number.

The second and third panel contains tested

parameters, as follow:

HGB light (LED is on).

Measuring Electrode voltage, current and

offset.

Amplifier Noise test during a 5-second period.

Amplifier transfer by generating 20000 test

pulses, incl. gain related peak value, noise

related deviation.

Atmospheric pressure stands for outer

pressure.

Vacuum reports pump operation (vacuum made

by the pump in a 10-second period of time).

Drift represents pressure loss of vacuum

measured in a 10-second period of time.

Power ±12V shows the amplifier voltage value.

Power Batt reports the voltage value of the

battery. If battery fails, system time will stop.

Core Temp shows CPU temperature of the

Control and Measurement Board (COMB).

Overall test result is displayed, which can be

Successful (in case of every test result is OK) or

Errors (if HIGH, LOW or ERROR).

At the end of a result line status message is displayed, which means that the actual test

result is at the normal range (OK), higher (HIGH), lower (LOW) than the pre-determined

limits, or the result is an error (ERROR).

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

50 Diatron MI PLC

5.1.2. Normal range of Self Test parameters

Parameter Unit Lower bound Upper bound

HGB light count 3000 60000

HGB dark Count 0 3000

Electrode voltage V 45 55

Current µA 830 930

Offset mV -5.0 5.0

Amplifier test count 19990 20005

Peak of test pulses mV 1500 1800

deviation (noise) mV 0 80

Noise test pls/5sec 0 5

Outer pressure mBar 500 1050

Vacuum mBar 125 420

Drift mBar/10sec 0 10

Power +12V V 11.0 12.5

Power –12V V -13.0 -11.0

Power Batt. V 1.8 4.5

Core Temp. °C - -

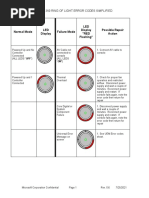

5.1.3. Troubleshooting Guide for Self test

Parameter Mark Possible reason Remedy

HGB dark HIGH Instrument door open Close instrument door

Check HGB head connections

HGB head not connected or

LOW check HGB LED during

HGB LED out of order

HGB light measurement

Instrument door open or Close door or replace HGB

HIGH

HGB LED too bright LED resistor on amplifier board

LOW Fault on High Voltage Check measuring voltage (50V) on

Electrode voltage or HIGH or Amplifier board High voltage and Amplifier boards

LOW Check current generator, and test

Current or HIGH Fault on Amplifier board generator FET on Amplifier board

LOW Check the offset potentiometer on

Offset Fault on Amplifier board

or HIGH Amplifier board

LOW Amplifier Boards is not Check cables and connectors

Amplifier test connected to main board coming from the Amplifier

HIGH Instrument not grounded Check mains ground lead

Peak of pulses LOW Check current generator, and test

or HIGH Fault on Amplifier board generator FET on Amplifier board

Dev. (noise) HIGH Instrument not grounded Check mains ground lead

Noise HIGH Instrument not grounded Check mains ground lead

LOW Pressure sensor, cable or Check pressure sensor, cable

Outer pressure or HIGH connector problem connections and controller board

pressure connector

Vacuum LOW Peristaltic pump failure Check peristaltic pump

Drift HIGH Leakage in pneumatics Check tubing in pneumatics

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 51

5.2. Service Menu

5.2.1. Entering to Service Menu

There is a Service menu for servicing and operation checking purposes. The entry point is in

the User‟s Service screen, where Service Information is displayed.

Enter the code to access Service menu: 6484

5.2.2. Main Service Menu

The Main Service menu provides access to submenus and service utilities.

5.2.3. Edit service contact

Here you can edit the Information card fields by

cursor keys, or by an external keyboard.

Press the OK button, if a field is completed.

This information will appear in the User Service

menu.

5.2.4. Device Information

In the Device Information menu the model name,

the serial number, the software version and

compilation date appear.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

52 Diatron MI PLC

5.2.5. Service Calibration

The analyzer provides a menu for Service calibration purposes.

In result calculations the service calibration factors are used as the user calibration factors,

so they are multiplied for each parameter: RBCDisp. = FactRBC User * FactRBC Serv. * RBCMeasured

If the user factor is near the bound (0.80 - 1.20), by setting the corresponding service factor,

the user factor can be adjusted to 1.00.

Example: Fact RBC User = 1.19 and Fact RBC Serv = 0.96, and

Fact RBC User = 1.00 and Fact RBC Serv = 1.14 gives the same result for RBC.

Apply user calibration factors function is used to combine user and service calibration

factors. The software will multiply the existing factors, and move them to the Service level to

set user factors to 1.00.

5.2.6. Settings

5.2.6.1. Pneumatic/Measurement options

Service Person can set the parameters of the automatic functions in this dialog menu.

Standby time: after how many minutes the

instrument goes to standby mode (default = 15

min).

Reblank time: after how many minutes the

instrument makes a blank measurement if it was

in standby mode (default = 1 hour). If it is set to

0, then no ReBlank is performed.

Rinse time: If this time is set, then the instrument will make an automatic, extended washing

procedure (with more diluent) of the chamber(s) to get wash dirt out of the chambers (dust).

If it is set to 0, then no Rinse is performed.

Autoclean cycle: after how many measurements the instrument makes an autocleaning.

Disable 3-part diff.: for using quick lyse (without 3-part differential) the errors and the bad

3-part parameters can be excluded from the results

Disable markers: setting this option to Yes will omit the vertical markers from printed

reports.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 53

Stretch histogram: setting this option to Yes

will modify the WBC histogram range from 0-

300 fl instead of 0-400 fl (this is recommended

for Veterinary mode).

Reagent code: This code can be used to

modify the offset of the HGB function. Enter a

value between 0 and 30 (default is 9).

Extended Probe Voltages: This option is ON by default. It makes the instrument accept the

physically highest probe voltages to allow operation at lower operating temperature range.

Maintenance day: You can select from week days. According to this setting, the instrument

will ask the user to do weekly maintenance during shut down.

Laboratory header lines: you can choose how many lines to contain the header of the

blood result.

Reagent pack: Using packed reagent in Reagent status menu system displays the reagent

pack installation day and the Reagent open stability period. User can change reagents only

together. In case of “No” reagents can be changed separately, the date of expiry is ignored.

Waste container capacity: it essential to set

the correct volume of the waste container for

proper usage of the software ”waste full” alert,

code: 5006. Set this value two liters less than

the total volume of waste container.

Lyse container capacity: Enter here volume of lyse container.

Cleaner container capacity: Enter here volume of cleaner container.

Rinse container capacity: For future development. Enter here 0.

It is possible, but not recommended ignoring the reagent volume check entering 0 as volume

of containers.

Clogging detections, bubble volumes for

development, do not touch them!

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

54 Diatron MI PLC

5.2.6.2. Operation Settings

LCD light off delay: LCD backlight switches

off after 4 hours, by pressing key switches

back. Still the light is off, the LED is flashing

yellow.

Disable multi-user mode: by this setting the

multi-user mode can be disabled

Instrument startup procedure: You can select to start the instrument with Database screen

(without any pneumatic initialization) or with Measurement screen (with pneumatic

initialization).

Database capacity: You can choose here the capacity of database at installation.

Changing later all measured data will be lost. Using larger database the instrument software

startup time can be increased.

Native keyboard: Setting it to Yes will utilize the external PC keyboard with the language

specific layout.

Calendar mode: You can select between the Gregorian and the Jalaali (Persian) calendar.

All dates will be converted accordingly.

Patient data: There are two options:

Birthdate and Age. According to this setting,

both in the sample information dialog and in

the database, the instrument will prompt for

the age or the date of birth. If age is

specified, it can be given in years or months.

5.2.6.3. Edit Service Code

You can change here the default (6484)

service code to a maximum 12 character

alphanumeric code. It is recommended not

to change the code, if it was changed, it is

hardly recommended to save the new code.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 55

5.2.7. Service Testing Menu

Service Testing menu provides tools for checking hardware.

5.2.8. Valve Test Menu

In the menu on the left you can see the

valve numbers and a number under each

that represents the actual state of the

valve. P means peristaltic pump.

Selected valve number is shown in

inverse. 0 is Off state, 1 is On state.

Use cursor keys for selecting and setting

valve state, or press OK to toggle state.

5.2.9. Motor Test Menu

Pressing numeric key on keyboard the

regarding motors start operation repeatedly,

until pressing „1„ , or another key. All motors

stop at initial positions.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

56 Diatron MI PLC

5.2.10. Display and Keyboard Test

Display and keyboard test is provided to

check keypad and LCD panel.

Press a key to test and the LCD will show the

code of the pressed key, and will be invert the

colors at each touch of a key for testing that

every LCD dot is functioning.

5.2.11. Stress Mode

In Stress mode, the instrument performs measuring cycles without sample (blank

measurements) continuously. This can be used for burn-in tests, or to check pneumatic

system after changing any main fluidic parts.

You can have information about stability, cleanliness, HGB operation, and counting time

stability. Results of the last 10 PLT and HGB blank is displayed as well.

You can detect any kind of noise, or bubbles in the system if the PLT is not stable low, or

HGB has big variation. To exit from this mode press the START button (at the end of a

normal cycle) until the Stress operation is finished.

rev 1.09

Downloaded from www.Manualslib.com manuals search engine

Abacus+ Service Manual 57

5.2.12. Miscellaneous Settings

In this menu, you can directly perform

Software upgrade (this will restart the

instrument).

Clear Device Statistics: Device statistics

(number of measurements, aperture-clogging

and other errors) can be cleared.

Clear Database: The whole Database

(measurement results including histograms)

can be cleared.

Offset adjustment: You can adjust the offset on the amplifier board.

Needle setting: By entering this menu the needle will go to the position you can adjust it.