PDS Sikacrete 113 PP

PDS Sikacrete 113 PP

Uploaded by

Koh HanCopyright:

Available Formats

PDS Sikacrete 113 PP

PDS Sikacrete 113 PP

Uploaded by

Koh HanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

PDS Sikacrete 113 PP

PDS Sikacrete 113 PP

Uploaded by

Koh HanCopyright:

Available Formats

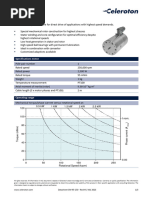

Product Data Sheet

Edition 03/07/2014

Identification no:

01 01 01 03 007 0 000014

Sikacrete 113 PP

Sikacrete -113 PP

®

Free flowing, shrinkage compensated microconcrete for grouting and repair

®

Product Sikacrete -113 PP one component, free-flowing, high strength, cement based

Description micro- concrete with a maximum aggregate size of 5 mm. Suitable for use in tropical

and hot climatic conditions.

®

Uses Sikacrete -113 PP used for the structural repair of deteriorated concrete.

It is ideal for casting sections or members where the volumes required are too

large for conventional grouts, and too small and inaccessible for normal

concreting applications.

A typical application is the re-profiling of damaged concrete members and

reprofiling of pile tops using formwork for both pouring and pumping

techniques.

Also suitable for base plate grouting where thickness exceeds 75 mm.

Characteristics / One component, requires the addition of water only

Advantages

Reduced waste and risk of mixing failures

Easy to mix, apply and finish

Economical Excellent adhesion Shrinkage compensated Rapid strength

development

Compatible with the properties of typical concrete

Vapour permeable High resistance to freeze/thaw cycling

Excellent flowability

Tests / Standards Complies to :

ASTM standards C157-99

BS1881 part 121: test for water absorption

Product Data

Mixture of Portland Cement and graded aggregates

Type

Grey powder

Form

Packaging 25 & 40 kg bag

Store in a dry area between 5ºC and 35ºC. Protect from direct sunlight

Storage

Storage Conditions / 12 months minimum from production date if stored properly in original unopened

Shelf-Life packaging

1 Sikacrete 113 PP 1/4

Technical Data

o

Density at 25 C Approx. 2.3±0.05 Kg/Lit

Mixing Ratio 3.0 – 3.50 liter potable water per 25kg bag or 12 -14% water by weight of powder.

Setting Time ~60 mins

Compressive Strength

(ASTM C 109) 1 day 7 days 28 days

(12% water)

2 2 2

25-35 N/mm 40-45 N/mm 60-65 N/mm

*Tested cubes (50x50x50 mm³) @ 25 °C

2

Flexural Strength 8-10 N/mm (BS 6319-P3)

2

Bond Strength ~ 1.5 N/mm

Thickness per pour Minimum 25 mm

Maximum 300 mm, for thicker layers contact our Technical Services Department

Length Change 28 Days 0.06059 % (ASTM C 157:93) (ASTM C 157:93)

Yield Approx. 12.20 Liter per 25 kg bag

Chloride Diffusion

=0.006% at 13-25mm depth (AASHTO T259:80 and ASSHTO T260:95)

Absorbed chloride ion

Resistivity Approximately 8-10 kΩ cm

Modulus of Elasticity Approximately 33,000 N/mm2 (BS 1881 Part 121)

2

Initial Surface 10 min =0.01 ml/(m .sec) (BS 1881 Part 5)

Absorption 30min= <0.01 ml/(m2.sec)

Coefficient of Thermal -6 ○

Expansion 11x10 m/m per C

System

Information

Application Details

Substrate Preparation

Concrete surfaces should be clean, sound and free from oil, grease, organic growth

& curing compounds.

Mechanically prepare concrete surfaces to remove laitance, curing compounds and

other loose materials back to sound concrete, to provide a mechanical key for the

subsequent product.

Repairs

For large volume repairs to columns, walls or soffits, mark the extremity of the

repair area and saw cut to a minimum depth of 10mm to define the area to be

removed.

Chip out the area within the saw cut back to sound concrete, to a minimum depth of

10 mm ensuring no feather edges and a good mechanical key for the Sika Crete

113 PP

If steel reinforcement is exposed, continue to break out the concrete to at least

15mm behind the bars, and mechanically prepare by grit blasting to remove rust,

contamination or other loose material.

2 Sikacrete 113 PP 2/4

Bonding Agent and Steel For standard concrete repair procedures:

Protection

Reinforcing should be treated with a suitable protective coating such as SikaTop

Armatec 110 EpoCem, SikaMonotop 610..

The concrete bond line should receive an application of a suitable bonding agent,

such as Sikadur-32, SikaMonotop 610 or SikaTop Armatec 110 EpoCem, will

improve adhesion on large areas or where particularly dense concrete substrates

are involved.

Surface Preparation for Cathodic Protection:

Apply cementitious slurry to the complete metal surface area.

All existing concrete surfaces should be pre soaked for an extended period

(minimum 1 hour) and dried out to a saturated surface dry condition immediately

prior to the repair application.

DO NOT use bonding resins or corrosion inhibitors for concrete or reinforcing

priming as it will restrict the performance of the Cathodic Protection systems

performance.

Application

Instructions

Mixing Accurately measure 3.0-3.50 litres (per 25kg pack powder) of drinking quality

water place 1.7 to 1.9 litres in a suitable empty container with sufficient volume to

accommodate the mixed material.

Slowly add the powder to the water and mix continuously for 2-3 minutes using a

slow speed drill and clean, rust free, mixing paddle or forced action mixer, until a

homogenous consistency is achieved.

Then add the remaining water and mix for an additional 2 minutes.

DO NOT MIX BY HAND OR PART MIX BAGS!

Application Before pouring, let the mixed mortar stand for 2 - 3 minutes after mixing to allow

entrapped air to escape.

Maintain sufficient hydrostatic head to keep the product flowing. Provide

channels for the air to escape while introducing the mortar.

After application of steel reinforcement protection and bonding agent, erect well

constructed, watertight formwork, which includes a breather pipe (to eliminate

trapped air) and a “letter box” opening in front to facilitate simple introduction of the

flowable mortar. Ensure the formwork is coated with a suitable release agent such

as Separol to facilitate easy de-moulding.

SikaCrete 113 PP may be introduced by tremie or 50mm diameter filling tube

installed into the bottom of the formwork. The flowable mortar is then fed by gravity

from an external reservoir through this filling pipe into the repair cavity, which is

sealed when repair void is filled completely

The application should be carried out in a continuous operation without breaks

therefore please ensure sufficient materials, equipment and labour are available to

achieve this. If the entire area cannot be finished in one go, we recommend

creating day joints to provide a neat edge to work to with the subsequent

application.

Protect from rain and curing liquids until initial set has been achieved.

Curing Treat exposed surfaces with Antisol-E Curing Compound or use other approved

Curing methods such as polyethylene sheeting or wet hessian. (Do not commence

Fogging until final set has been reached).

Cleaning Clean equipment and mixer after application with water. Hardened material can

only be removed mechanically.

Remarks Ensure formwork is secure and watertight to prevent movement and leaking

During placing and curing. At high temperatures use chilled water for mixing

to keep grout temperature below 30°C. In hot weather, base plates and

Foundations must be shaded from direct sunlight. Condition bags prior to

use.

For additional information on SikaCrete 113 PP or other repair materials

contact our Technical Services Department

Value Base All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Local Restrictions Please note that as a result of specific local regulations the performance of this

3 Sikacrete 113 PP 3/4

product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet containing

Information physical, ecological, toxicological and other safety-related data.

Do not dispose of into water or soil but according to local regulations.

Ecology

Toxicity

Non-toxic under the relevant Gulf health and safety codes

Transportation

Non-hazardous.

Legal Notes

The information, and, in particular, the recommendations relating to the application

and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sika’s recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the product’s suitability for the

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request

Sika UAE L.L.C

P.O. Box 126212

Dubai,

United Arab Emirates

Phone: +971 4 4398200

gcc.sika.com

4 Sikacrete 113 PP 4/4

You might also like

- DM 1Document5 pagesDM 1elsayedelgohary908No ratings yet

- Dubai Municipality Exam Solution g4Document9 pagesDubai Municipality Exam Solution g4santhi peddanna100% (1)

- Vessel Database: AIS Ship PositionsDocument3 pagesVessel Database: AIS Ship PositionsViraj SolankiNo ratings yet

- (Computer Science & Engineering) Name: Subject: DM Date: Marks: 20Document2 pages(Computer Science & Engineering) Name: Subject: DM Date: Marks: 20MeeraNo ratings yet

- Dubai Municipality Exam Updated-23Document1 pageDubai Municipality Exam Updated-23zash.in.akhterNo ratings yet

- Pad Footing BS8110Document1 pagePad Footing BS8110Asif BillalNo ratings yet

- Unlimited & G+12 DM Exam-Revision-03 - 230901 - 154530Document19 pagesUnlimited & G+12 DM Exam-Revision-03 - 230901 - 154530Ali403No ratings yet

- Unlimited & G+12 DM Exam-Revision-03Document19 pagesUnlimited & G+12 DM Exam-Revision-03Ali403No ratings yet

- ShoringDocument8 pagesShoringJeo LawrenceNo ratings yet

- Dubai Municipality Exam STEEL G+1 and G+4 UpdatedDocument20 pagesDubai Municipality Exam STEEL G+1 and G+4 UpdatedsfsghjshfdhhNo ratings yet

- Such A Scale Is Called AND That Ratio Is Called: Reducing Scale Representative FractionDocument21 pagesSuch A Scale Is Called AND That Ratio Is Called: Reducing Scale Representative FractionK S ChalapathiNo ratings yet

- PCI DWP Binder Ch6Document8 pagesPCI DWP Binder Ch6mrswcecivilNo ratings yet

- Concrete Technology: Civil EngineeringDocument24 pagesConcrete Technology: Civil EngineeringAkshay TangadiNo ratings yet

- TR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFDocument3 pagesTR 47-180 Floor Deck Profile Data Sheet 9-12-14 PDFAkhil VNNo ratings yet

- 03 30 00 Cast in Place Concrete ChristensonDocument9 pages03 30 00 Cast in Place Concrete ChristensonHendra Rikardo TobingNo ratings yet

- Staircase Design FinalDocument18 pagesStaircase Design FinalSiddiqui RanaNo ratings yet

- SpecificationDocument6 pagesSpecificationMOHAMAD AMIR BIN HALIDNo ratings yet

- Rev01 PDFDocument52 pagesRev01 PDFMohamed TahaNo ratings yet

- RCC95 Continuous Beams (Tables)Document7 pagesRCC95 Continuous Beams (Tables)Mohammad Twaha JaumbocusNo ratings yet

- A. General NotesDocument6 pagesA. General NotesNatalie WrightNo ratings yet

- Q2Document8 pagesQ2melvin lopenarioNo ratings yet

- A A 2886B PinturaDocument4 pagesA A 2886B PinturaFran GVNo ratings yet

- Earth Pit Maintenance Instructions MBCDocument2 pagesEarth Pit Maintenance Instructions MBCdilipgmNo ratings yet

- DM Contractor Activity EngDocument4 pagesDM Contractor Activity EngThasneem YaseenNo ratings yet

- Project: Villa (B+G+1+R) + Service Block Client: Mr. Essa Bin HadherDocument3 pagesProject: Villa (B+G+1+R) + Service Block Client: Mr. Essa Bin HadherSaahil KhaanNo ratings yet

- Dubai Municipality Exam UpdatedDocument49 pagesDubai Municipality Exam UpdatedSiddiqui RanaNo ratings yet

- GroutecDocument82 pagesGroutecThompson LaiNo ratings yet

- FountainDocument3 pagesFountainbonanzina8No ratings yet

- ASTM A490 Bolt Torque ChartDocument1 pageASTM A490 Bolt Torque ChartNeeraj VermaNo ratings yet

- CSSBI S15 12 How To Series Steel Roof Deck and Composite Floor DeckDocument13 pagesCSSBI S15 12 How To Series Steel Roof Deck and Composite Floor Deckrincivil2ry1232244No ratings yet

- Particular Specifications Frame & Shutters: 1.0 Indian StandardsDocument15 pagesParticular Specifications Frame & Shutters: 1.0 Indian StandardsSudip ShresthaNo ratings yet

- Letter of UndertakingDocument1 pageLetter of UndertakingAnonymous tBLJaNu100% (1)

- Chromadek PresentationDocument19 pagesChromadek PresentationArcelorMittalSANo ratings yet

- Ass. Sub Engineer 04 04Document3 pagesAss. Sub Engineer 04 04Bipul PoudelNo ratings yet

- Civil Engineering Question/Answer: Prepared By: Zia Ur RehmanDocument22 pagesCivil Engineering Question/Answer: Prepared By: Zia Ur RehmanRashid mahmoodNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- DSR PuneDocument17 pagesDSR Punedigvijayjagatap100% (1)

- Renderoc S2Document4 pagesRenderoc S2R.ThangarajNo ratings yet

- Technical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553Document31 pagesTechnical Data Sheet For HIT-HY 170 Injectable Mortar For Anchor in Concrete Technical Information ASSET DOC 4398553ing urban100% (2)

- Plywood SpecificationsDocument2 pagesPlywood Specificationsanuchn007100% (1)

- Modern Brick Construction Third Edition 3Document44 pagesModern Brick Construction Third Edition 3Boris MusungayiNo ratings yet

- (Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Document17 pages(Shima and Afshan, 3C) BMS Water-Proofing Market Survey (Group 4)Shima SharafNo ratings yet

- C-Purlin Data Sheet 3-3-2014Document3 pagesC-Purlin Data Sheet 3-3-2014Akhil VNNo ratings yet

- Full Mock Test Series 05Document10 pagesFull Mock Test Series 05Abhilasha CIVILNo ratings yet

- Chapter - 24: Fencing and Boundary MarksDocument5 pagesChapter - 24: Fencing and Boundary MarksRajesh BabuNo ratings yet

- Section - 08 11 16 - Aluminum Doors and FramesDocument2 pagesSection - 08 11 16 - Aluminum Doors and FramesEliseo LagmanNo ratings yet

- Anchor Bolt FAZ IIDocument4 pagesAnchor Bolt FAZ IImmaleniNo ratings yet

- General Catalogue VOL2Document296 pagesGeneral Catalogue VOL2Harish ManglaNo ratings yet

- Paving Type 13 - Section M Paving Type 14 - Section N: WaterfeaturesDocument1 pagePaving Type 13 - Section M Paving Type 14 - Section N: WaterfeaturesMohamed TahaNo ratings yet

- Ebcs-5 18Document4 pagesEbcs-5 18eyerusalemh100% (1)

- TDS - Rheofinish 288 FDDocument2 pagesTDS - Rheofinish 288 FDVenkata RaoNo ratings yet

- Ras Al Khaimah Structural Guidelines-2021-R4Document57 pagesRas Al Khaimah Structural Guidelines-2021-R4kveeraragavansafetyNo ratings yet

- Renderoc LAXtraDocument2 pagesRenderoc LAXtraMansoor Ali100% (1)

- GRC Panels With Recess 4mx2mSIZE: Structural Calculation ForDocument58 pagesGRC Panels With Recess 4mx2mSIZE: Structural Calculation ForvenkatNo ratings yet

- 0138 Corrugated Brochure 2019 LRDocument4 pages0138 Corrugated Brochure 2019 LRPieter SteenkampNo ratings yet

- Rc-Ductility Due To EQDocument303 pagesRc-Ductility Due To EQnfaayed100% (1)

- Midlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmDocument1 pageMidlanding: +2100 LVL 181716151413121110 R 150mm. T 300mmyash ayreNo ratings yet

- 7898 Limcon PDS Temp LTR 0714 LoRes FDocument2 pages7898 Limcon PDS Temp LTR 0714 LoRes FDaniyal AhmadNo ratings yet

- Sikacrete-114 SADocument46 pagesSikacrete-114 SAinfoNo ratings yet

- 2 Sikacrete-114 PDS GCC (06-2018) 1 1Document3 pages2 Sikacrete-114 PDS GCC (06-2018) 1 1Sri KanthNo ratings yet

- Sikagrout®-114 Ae: Product Data SheetDocument3 pagesSikagrout®-114 Ae: Product Data SheetAlexander Jonas Zach ValdrizNo ratings yet

- Certificate of Analysis 3 SPL Cv. Ilyas KaryaDocument6 pagesCertificate of Analysis 3 SPL Cv. Ilyas KaryaIrwan AdiNo ratings yet

- Reading Sketch Up 1 - 이램프 - Page 1 - 106 - Flip PDF Online - PubHTML5Document106 pagesReading Sketch Up 1 - 이램프 - Page 1 - 106 - Flip PDF Online - PubHTML5Maricel MaglahusNo ratings yet

- Datasheet CM 95 250Document3 pagesDatasheet CM 95 250earthwellnesNo ratings yet

- After Installing Homebrew, We Can Install LAMMPS On Your System With The Following CommandsDocument3 pagesAfter Installing Homebrew, We Can Install LAMMPS On Your System With The Following Commands17029 Ankon SahaNo ratings yet

- Maria Rahab January 2024Document1 pageMaria Rahab January 2024api-344367460No ratings yet

- Terastandard - Bsi Bs en 14019 819 1501652835Document12 pagesTerastandard - Bsi Bs en 14019 819 1501652835soheila ghaderi100% (1)

- Pending Punchlist To Be ClosedDocument12 pagesPending Punchlist To Be ClosedMudabbir HussainNo ratings yet

- 3.1 Lesson: Vector Attribute Data: ThreeDocument42 pages3.1 Lesson: Vector Attribute Data: Threeສີສຸວັນ ດວງມະນີNo ratings yet

- Kia Sportage Wheel Size and SpecsDocument1 pageKia Sportage Wheel Size and SpecsEs JunNo ratings yet

- Monthly Camp Inspection FormDocument22 pagesMonthly Camp Inspection FormvijithNo ratings yet

- TeSys Control Relays - CA3KN40BDDocument3 pagesTeSys Control Relays - CA3KN40BDElias Raimundo De OliveiraNo ratings yet

- Session - GuS - IIgs Emulator - KerwoodDocument7 pagesSession - GuS - IIgs Emulator - KerwoodAlex TirrellNo ratings yet

- Data Warehosing and Data MiningDocument15 pagesData Warehosing and Data Miningsourabhsaini121214No ratings yet

- Actual Purchases On Instagram Live Shopping The Influence of Live Shopping Engagement and Information Technology AffordanceDocument11 pagesActual Purchases On Instagram Live Shopping The Influence of Live Shopping Engagement and Information Technology AffordanceKristel Joy Eledia NietesNo ratings yet

- Inteligen 1000 3.0.2 DatasheetDocument6 pagesInteligen 1000 3.0.2 DatasheetjuadogonNo ratings yet

- Unit Iii Data Analysis and ReportingDocument14 pagesUnit Iii Data Analysis and Reportingjan100% (1)

- A Grammar of The Mahratta Language PDFDocument155 pagesA Grammar of The Mahratta Language PDFPratik MoreNo ratings yet

- Mobile App Banking T CsDocument8 pagesMobile App Banking T CsGhermand OrtizNo ratings yet

- BY: Technoaeronee Rs (Group 6)Document12 pagesBY: Technoaeronee Rs (Group 6)Jihan LuNo ratings yet

- Diploma 2nd Semester Course StructureDocument8 pagesDiploma 2nd Semester Course StructureMD AJMALNo ratings yet

- Balanced Scorecard: OM ER LA TI ON SH IPDocument5 pagesBalanced Scorecard: OM ER LA TI ON SH IPjpereztmpNo ratings yet

- Semantics Aware MalwareDocument15 pagesSemantics Aware MalwareDeepuNo ratings yet

- Humidification and DryingDocument2 pagesHumidification and DryingAstra Beckett0% (1)

- Seaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsDocument20 pagesSeaworthy.: A Selection of Lubricants For Marine and Offshore ApplicationsEduardo CastilloNo ratings yet

- The I Vors 2014 Rules and Guidelines For EntryDocument11 pagesThe I Vors 2014 Rules and Guidelines For EntryianmacmNo ratings yet

- Cisco UCS Central 2.0: About This DemonstrationDocument21 pagesCisco UCS Central 2.0: About This DemonstrationJosecriz DalmacioNo ratings yet

- Database Programming With SQL 4-1: Case and Character Manipulation Practice ActivitiesDocument3 pagesDatabase Programming With SQL 4-1: Case and Character Manipulation Practice ActivitiesFlorin Catalin0% (1)

- Appendix 2 - BD-PTP-GEN-PM-CP-00020-02.06 - Variation Proposal - De-Scope of Internal Floating RoofsDocument2 pagesAppendix 2 - BD-PTP-GEN-PM-CP-00020-02.06 - Variation Proposal - De-Scope of Internal Floating RoofsDanie SwanepoelNo ratings yet

- SECTION 2 Binary OperationsDocument8 pagesSECTION 2 Binary OperationsMELEE MARCONo ratings yet