Beam Design Detail Report: Material and Design Data

Beam Design Detail Report: Material and Design Data

Uploaded by

azwanCopyright:

Available Formats

Beam Design Detail Report: Material and Design Data

Beam Design Detail Report: Material and Design Data

Uploaded by

azwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Beam Design Detail Report: Material and Design Data

Beam Design Detail Report: Material and Design Data

Uploaded by

azwanCopyright:

Available Formats

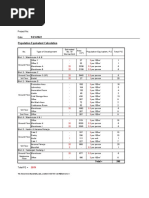

MATERIAL AND DESIGN DATA

Code of Practice fcu (N/mm²) Ec, (N/mm²) fy (N/mm²) fyv (N/mm²) γc γs

BS8110 : 1997 30 24597 460 460 1.5 1.05

Cover (mm) Side Cover (mm) Conc. Unit Weight (kN/m³) Steel Unit Weight (kg/m³)

25 25 24 7860

Beam Design Detail Report

DETAIL CALCULATION FOR BEAM GB9(225x450/600/450)

Beam Located along grid 1/D1-A2

Number of Span within beam = 8

Number of Section defined by user = 8

Number of Supports = 7

Beam Cantilever End = Both

Section Dimension Data

Length Width Begin Depth End Depth

Span Section

(mm) (mm) (mm) (mm)

1 1 1075 225 450 450

2 2 3100 225 450 450

3 3 2000 225 450 450

4 4 3500 225 600 600

5 5 3350 225 450 450

6 6 2300 225 450 450

7 7 4550 225 450 450

8 8 1563 225 450 450

MATERIAL PROPERTIES

Maximum Concrete Strain, Ecc = 0.0035

Average Concrete Stress above Neutral Axis, k1 = 12.12 N/mm²

Concrete Lever Arm Factor, k2 = 0.4518

Limiting Effective Depth Factor, cb = 0.50

k2 / k1 Factor, kkk = 0.0373

Limiting Concrete Moment Capacity Factor, kk1 = cb × k1 × (1 - cb * k2) = 0.50 × 12.12 × (1 - 0.50 × 0.4518) = 4.6911 N/mm²

BEAM GB9(225x450/600/450) SPAN NO. 1

FLEXURAL DESIGN CALCULATION

LOCATION : RIGHT SUPPORT

Design Bending Moment = 13.1 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 13.1 × 1000000 / (225.0 × 409.0²) = 0.349 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.349 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 11.946 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 11.946 / 1000 = 32.58 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 32.58 × 1000 / (460 / 1.05) = 75 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 32.58 × (409.0 - 0.4518 × 11.946) / 1000 = 13.1 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 6.9 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 6.9 × 1000000 / (225.0 × 409.0²) = 0.184 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.184 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 6.253 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 6.253 / 1000 = 17.05 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 17.05 × 1000 / (460 / 1.05) = 39 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 17.05 × (409.0 - 0.4518 × 6.253) / 1000 = 6.9 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 (B:-75 mm E:1000 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 16.4 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 16.4 × 1000 / (225.0 × 409.0) = 0.18 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.18 + 0.00 = 0.18 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 16.1 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 16.1 × 1000 / (225.0 × 409.0) = 0.17 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.175 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 7.0

Span Length, l = 1075.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 2.6

Ultimate Design Moment, Mu = 13.1 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 132 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 132) / (3 × 226)} × (1 / 1.00) = 178.5 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 178.5) / (120 × (0.9 + (13.1 × 1000000 / (225 × 409.0²)))}

= 2.54 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (225.0 × 409.0)) / (3 + (100 × 226 / (225.0 × 409.0)))}

= 1.08 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (7.0 × 2.00 × 1.08) / 2.6 = 5.73

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB9(225x450/600/450) SPAN NO. 2

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 1.4 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 1.4 × 1000000 / (225.0 × 409.0²) = 0.038 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.038 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.287 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.287 / 1000 = 3.51 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 3.51 × 1000 / (460 / 1.05) = 9 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 3.51 × (409.0 - 0.4518 × 1.287) / 1000 = 1.4 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 13.2 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 13.2 × 1000000 / (225.0 × 409.0²) = 0.351 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.351 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 11.998 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 11.998 / 1000 = 32.72 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 32.72 × 1000 / (460 / 1.05) = 75 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 32.72 × (409.0 - 0.4518 × 11.998) / 1000 = 13.2 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 0.8 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 0.8 × 1000000 / (225.0 × 409.0²) = 0.021 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.021 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 0.713 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 0.713 / 1000 = 1.94 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 1.94 × 1000 / (460 / 1.05) = 5 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 1.94 × (409.0 - 0.4518 × 0.713) / 1000 = 0.8 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

LOCATION : RIGHT SUPPORT SAGGING MOMENT

Design Bending Moment = 1.4 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 1.4 × 1000000 / (225.0 × 409.0²) = 0.038 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.038 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.287 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.287 / 1000 = 3.51 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 3.51 × 1000 / (460 / 1.05) = 9 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 3.51 × (409.0 - 0.4518 × 1.287) / 1000 = 1.4 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 6.3 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 6.3 × 1000000 / (225.0 × 409.0²) = 0.168 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.168 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 5.701 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 5.701 / 1000 = 15.55 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 15.55 × 1000 / (460 / 1.05) = 36 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 15.55 × (409.0 - 0.4518 × 5.701) / 1000 = 6.3 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:775 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 10.1 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 10.1 × 1000 / (225.0 × 409.0) = 0.11 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.11 + 0.00 = 0.11 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 9.7 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 9.7 × 1000 / (225.0 × 409.0) = 0.11 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.106 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:775 mm E:2325 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 6.5 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 6.5 × 1000 / (225.0 × 409.0) = 0.07 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.07 + 0.00 = 0.07 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 6.5 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 6.5 × 1000 / (225.0 × 409.0) = 0.07 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.071 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:2325 mm E:3100 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 2.6 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 2.6 × 1000 / (225.0 × 409.0) = 0.03 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.03 + 0.00 = 0.03 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 2.6 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 2.6 × 1000 / (225.0 × 409.0) = 0.03 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.028 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 3100.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 7.6

Ultimate Design Moment, Mu = 1.4 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 132 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 132) / (3 × 226)} × (1 / 1.00) = 178.5 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 178.5) / (120 × (0.9 + (1.4 × 1000000 / (225 × 409.0²)))}

= 3.20 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (225.0 × 409.0)) / (3 + (100 × 226 / (225.0 × 409.0)))}

= 1.08 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.08) / 7.6 = 7.38

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB9(225x450/600/450) SPAN NO. 3

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 1.7 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 1.7 × 1000000 / (225.0 × 409.0²) = 0.046 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.046 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.554 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.554 / 1000 = 4.24 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 4.24 × 1000 / (460 / 1.05) = 10 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 4.24 × (409.0 - 0.4518 × 1.554) / 1000 = 1.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 0.7 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 0.7 × 1000000 / (225.0 × 409.0²) = 0.020 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.020 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 0.672 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 0.672 / 1000 = 1.83 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 1.83 × 1000 / (460 / 1.05) = 5 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 1.83 × (409.0 - 0.4518 × 0.672) / 1000 = 0.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

LOCATION : LEFT SUPPORT SAGGING MOMENT

Design Bending Moment = 1.6 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 1.6 × 1000000 / (225.0 × 409.0²) = 0.043 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.043 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.443 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.443 / 1000 = 3.93 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 3.93 × 1000 / (460 / 1.05) = 9 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 3.93 × (409.0 - 0.4518 × 1.443) / 1000 = 1.6 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 3.1 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 3.1 × 1000000 / (225.0 × 409.0²) = 0.083 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.083 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 2.811 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 2.811 / 1000 = 7.67 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 7.67 × 1000 / (460 / 1.05) = 18 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 7.67 × (409.0 - 0.4518 × 2.811) / 1000 = 3.1 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 1.5 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 1.5 × 1000000 / (225.0 × 409.0²) = 0.039 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.039 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.322 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.322 / 1000 = 3.60 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 3.60 × 1000 / (460 / 1.05) = 9 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 3.60 × (409.0 - 0.4518 × 1.322) / 1000 = 1.5 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:500 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 3.3 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 3.3 × 1000 / (225.0 × 409.0) = 0.04 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.04 + 0.00 = 0.04 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 2.9 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 2.9 × 1000 / (225.0 × 409.0) = 0.03 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.032 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:500 mm E:1500 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 1.6 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 1.6 × 1000 / (225.0 × 409.0) = 0.02 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.02 + 0.00 = 0.02 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 4.1 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 4.1 × 1000 / (225.0 × 409.0) = 0.05 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.045 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:1500 mm E:2000 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 5.8 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 5.8 × 1000 / (225.0 × 409.0) = 0.06 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.06 + 0.00 = 0.06 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 5.5 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 5.5 × 1000 / (225.0 × 409.0) = 0.06 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.060 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 2000.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 4.9

Ultimate Design Moment, Mu = 1.7 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 132 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 132) / (3 × 226)} × (1 / 1.00) = 178.5 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 178.5) / (120 × (0.9 + (1.7 × 1000000 / (225 × 409.0²)))}

= 3.18 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (225.0 × 409.0)) / (3 + (100 × 226 / (225.0 × 409.0)))}

= 1.08 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.08) / 4.9 = 11.44

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB9(225x450/600/450) SPAN NO. 4

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 2.4 kNm Width, b = 225.0 mm Effective Depth, d = 559.0 mm

Mu / bd² = 2.4 × 1000000 / (225.0 × 559.0²) = 0.033 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.033 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 1.544 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 1.544 / 1000 = 4.21 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 4.21 × 1000 / (460 / 1.05) = 10 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 4.21 × (559.0 - 0.4518 × 1.544) / 1000 = 2.4 kNm

Maximum Depth of Section = 600.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 600.0 = 176 mm²

Top Compression Steel Area Required = 176 mm²

Bottom Tension Steel Area Required = 176 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 3.1 kNm Width, b = 225.0 mm Effective Depth, d = 559.0 mm

Mu / bd² = 3.1 × 1000000 / (225.0 × 559.0²) = 0.044 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.044 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 2.025 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 2.025 / 1000 = 5.52 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 5.52 × 1000 / (460 / 1.05) = 13 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 5.52 × (559.0 - 0.4518 × 2.025) / 1000 = 3.1 kNm

Maximum Depth of Section = 600.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 600.0 = 176 mm²

Top Tension Steel Area Required = 176 mm²

Bottom Compression Steel Area Required = 176 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 11.3 kNm Width, b = 225.0 mm Effective Depth, d = 559.0 mm

Mu / bd² = 11.3 × 1000000 / (225.0 × 559.0²) = 0.160 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.160 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 7.441 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 7.441 / 1000 = 20.29 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 20.29 × 1000 / (460 / 1.05) = 47 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 20.29 × (559.0 - 0.4518 × 7.441) / 1000 = 11.3 kNm

Maximum Depth of Section = 600.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 600.0 = 176 mm²

Top Tension Steel Area Required = 176 mm²

Bottom Compression Steel Area Required = 176 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 5.4 kNm Width, b = 225.0 mm Effective Depth, d = 559.0 mm

Mu / bd² = 5.4 × 1000000 / (225.0 × 559.0²) = 0.077 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.077 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 3.559 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 3.559 / 1000 = 9.71 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 9.71 × 1000 / (460 / 1.05) = 23 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 9.71 × (559.0 - 0.4518 × 3.559) / 1000 = 5.4 kNm

Maximum Depth of Section = 600.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 600.0 = 176 mm²

Top Tension Steel Area Required = 176 mm²

Bottom Compression Steel Area Required = 176 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:875 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 6.9 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 600 - 2 × 25 - 10 = 540 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 540 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 600.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 559.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 6.9 × 1000 / (225.0 × 559.0) = 0.05 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.05 + 0.00 = 0.05 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 540.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 540.0 / 550 = 4.30 N/mm²

νst = 0.00 N/mm² ≤ 4.30 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 6.4 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 6.4 × 1000 / (225.0 × 559.0) = 0.05 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.18 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 559.0 = 0.716

(400 / d)^ ¼ = 0.920 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.18}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.38 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.051 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:875 mm E:2625 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 2.9 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 600 - 2 × 25 - 10 = 540 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 540 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 600.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 559.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 2.9 × 1000 / (225.0 × 559.0) = 0.02 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.02 + 0.00 = 0.02 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 540.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 540.0 / 550 = 4.30 N/mm²

νst = 0.00 N/mm² ≤ 4.30 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 7.0 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 7.0 × 1000 / (225.0 × 559.0) = 0.06 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.18 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 559.0 = 0.716

(400 / d)^ ¼ = 0.920 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.18}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.38 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.056 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:2625 mm E:3500 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 11.0 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 600 - 2 × 25 - 10 = 540 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 540 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 600.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 559.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 11.0 × 1000 / (225.0 × 559.0) = 0.09 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.09 + 0.00 = 0.09 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 540.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 540.0 / 550 = 4.30 N/mm²

νst = 0.00 N/mm² ≤ 4.30 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 10.5 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 10.5 × 1000 / (225.0 × 559.0) = 0.08 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.18 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 559.0 = 0.716

(400 / d)^ ¼ = 0.920 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.18}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.38 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.084 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 3500.0 mm, Effective Depth, d = 559.0 mm

Actual Span / Effective Depth Ratio, Ar = 6.3

Ultimate Design Moment, Mu = 2.4 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 176 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 176) / (3 × 226)} × (1 / 1.00) = 237.9 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 237.9) / (120 × (0.9 + (2.4 × 1000000 / (225 × 559.0²)))}

= 2.68 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (225.0 × 559.0)) / (3 + (100 × 226 / (225.0 × 559.0)))}

= 1.06 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.06) / 6.3 = 8.77

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB9(225x450/600/450) SPAN NO. 5

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 12.1 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 12.1 × 1000000 / (225.0 × 409.0²) = 0.321 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.321 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 10.982 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 10.982 / 1000 = 29.95 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 29.95 × 1000 / (460 / 1.05) = 69 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 29.95 × (409.0 - 0.4518 × 10.982) / 1000 = 12.1 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 10.1 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 10.1 × 1000000 / (225.0 × 409.0²) = 0.269 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.269 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 9.170 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 9.170 / 1000 = 25.01 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 25.01 × 1000 / (460 / 1.05) = 58 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 25.01 × (409.0 - 0.4518 × 9.170) / 1000 = 10.1 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 10.6 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 10.6 × 1000000 / (225.0 × 409.0²) = 0.282 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.282 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 9.610 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 9.610 / 1000 = 26.21 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 26.21 × 1000 / (460 / 1.05) = 60 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 26.21 × (409.0 - 0.4518 × 9.610) / 1000 = 10.6 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 0.0 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 0.0 × 1000000 / (225.0 × 409.0²) = 0.000 N/mm²

Design to minimum steel percentage specified by code,

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:838 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 26.7 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 26.7 × 1000 / (225.0 × 409.0) = 0.29 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.29 + 0.00 = 0.29 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 25.3 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 25.3 × 1000 / (225.0 × 409.0) = 0.27 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.275 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:838 mm E:2513 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 9.8 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 9.8 × 1000 / (225.0 × 409.0) = 0.11 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.11 + 0.00 = 0.11 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 9.8 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 9.8 × 1000 / (225.0 × 409.0) = 0.11 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.107 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:2513 mm E:3350 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 27.9 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 27.9 × 1000 / (225.0 × 409.0) = 0.30 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.30 + 0.00 = 0.30 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 26.3 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 26.3 × 1000 / (225.0 × 409.0) = 0.29 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.286 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

Basic Span / Effective Depth Ratio, Br = 26.0

Span Length, l = 3350.0 mm, Effective Depth, d = 409.0 mm

Actual Span / Effective Depth Ratio, Ar = 8.2

Ultimate Design Moment, Mu = 12.1 kNm

Design Steel Strength, fy = 460.0 N/mm²

Tension Steel Area Required, AsReq = 132 mm²

Tension Steel Area Provided, AsProv = 226 mm²

Compression Steel Area Provided, AsProv (Comp.) = 226 mm²

- Checking for deflection is based on BS8110: 1997

- Table 3.9: Basic span / effective depth ratio for rectangular or flange beams

- Table 3.10: Modification factor for tension reinforcement

- Table 3.11: Modification factor for compression reinforcement

Design Service Stress in Tension Reinforcement, Equation 8

fs = {(2 × fy × AsReq) / (3 × AsProv)} × (1 / ßb)

= {(2 × 460.0 × 132) / (3 × 226)} × (1 / 1.00) = 178.5 N/mm²

Modification Factor for Tension Reinforcement, Equation 7

MFt = 0.55 + {(477 - fs) / (120 × (0.9 + (M/bd²)))}

= 0.55 + {(477 - 178.5) / (120 × (0.9 + (12.1 × 1000000 / (225 × 409.0²)))}

= 2.59 > 2.0

MFt taken as 2.0

New Modification Factor for Compression Reinforcement, Equation 9

MFc = 1 + {(100 × AsProv / (b × d)) / (3 + (100 × AsProv / (b × d)))}

= 1 + {(100 × 226 / (225.0 × 409.0)) / (3 + (100 × 226 / (225.0 × 409.0)))}

= 1.08 <= 1.5

New Deflection Ratio = (Br × MFt × MFc) / Ar = (26.0 × 2.00 × 1.08) / 8.2 = 6.83

Ratio >= 1.0 : Deflection Checked PASSED

BEAM GB9(225x450/600/450) SPAN NO. 6

FLEXURAL DESIGN CALCULATION

LOCATION : LEFT SUPPORT

Design Bending Moment = 11.5 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 11.5 × 1000000 / (225.0 × 409.0²) = 0.306 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.306 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 10.437 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 10.437 / 1000 = 28.46 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 28.46 × 1000 / (460 / 1.05) = 65 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 28.46 × (409.0 - 0.4518 × 10.437) / 1000 = 11.5 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 22.6 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 22.6 × 1000000 / (225.0 × 409.0²) = 0.602 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.602 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 20.782 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 20.782 / 1000 = 56.67 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 56.67 × 1000 / (460 / 1.05) = 130 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 56.67 × (409.0 - 0.4518 × 20.782) / 1000 = 22.6 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : 1/4 SPAN

Design Bending Moment = 14.2 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 14.2 × 1000000 / (225.0 × 409.0²) = 0.379 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.379 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 12.958 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 12.958 / 1000 = 35.34 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 35.34 × 1000 / (460 / 1.05) = 81 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 35.34 × (409.0 - 0.4518 × 12.958) / 1000 = 14.2 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

SHEAR & TORSION DESIGN CALCULATION

LOCATION : SECTION 1 LEFT SUPPORT

(B:0 mm E:575 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 17.0 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 17.0 × 1000 / (225.0 × 409.0) = 0.18 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.18 + 0.00 = 0.18 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 15.4 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 15.4 × 1000 / (225.0 × 409.0) = 0.17 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.167 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 MIDDLE ZONE

(B:575 mm E:1725 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 7.7 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 7.7 × 1000 / (225.0 × 409.0) = 0.08 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.08 + 0.00 = 0.08 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 16.5 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 16.5 × 1000 / (225.0 × 409.0) = 0.18 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.180 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

LOCATION : SECTION 1 RIGHT SUPPORT

(B:1725 mm E:2300 mm from left grid of span)

Maximum Torsion within Zone, T = 0.0 kNm

Shear at Location of Maximum Torsion, V = 25.9 kN

Link Horizontal Dimension, h1 = b - 2 × Side Cover - DiaLink = 225 - 2 × 25 - 10 = 165 mm

Link Vertical Dimension, v1 = h - 2 × Cover - DiaLink = 450 - 2 × 25 - 10 = 390 mm

Dimension x1 = Min (h1, v1) = 165 mm, y1 = Max (h1, v1) = 390 mm

Section Dimension: Dmin = 225.0 mm, Dmax = 450.0 mm

Torsion Stress, νst = 2 × T × 106 / (Dmin² × (Dmax - Dmin / 3)) = 0.00 N/mm²

Effective depth, d = 409.0 mm

Shear Stress, νss = V × 1000 / (b × d) = 25.9 × 1000 / (225.0 × 409.0) = 0.28 N/mm²

Part 2 : Clause 2.4.6 and Table 2.3

Maximum Combined Stress Allowed, νtu = Min (0.8 × √fcu, 5) = 4.38 N/mm²

Total Stress, νTot = νss + νst = 0.28 + 0.00 = 0.28 N/mm² ≤ νtu (4.38 N/mm²)

Checking for Combined Stress Allowed Pass

Part 2: Clause 2.4.5

Additional Checking While Small Cross Section (y1 < 550 mm)

Larger Link Dimension, y1 = 390.0 mm < 550 mm

νtu × y1 / 550 = 4.38 × 390.0 / 550 = 3.11 N/mm²

νst = 0.00 N/mm² ≤ 3.11 N/mm²

Checking for Torsion Stress Allowed Pass

Part 2 : Clause 2.4.6 Table 2.3

Torsion Strength contributed by concrete, νt,min = Min (0.067 × √fcu, 0.4) = 0.37 N/mm²

Torsion Stress, νst = 0.00 N/mm² < νt,min = 0.37 N/mm² -> No Torsion Reinforcement is needed

Maximum Shear within Zone, V = 24.2 kN

Maximum Shear Stress Allowed, νMax = Min (0.8 × √30, 5) = 4.38 N/mm² - Clause 3.4.5.2

Shear Stress, νss = V × 1000 / (b × d) = 24.2 × 1000 / (225.0 × 409.0) = 0.26 N/mm² ≤ νMax (4.38 N/mm²)

Checking for Maximum Shear Stress Allowed Pass

Tension Steel Area Provided, Ast = 226 mm²

- Table 3.8: Values of νc, design concrete shear stress

Steel Percentage, 100 × As / (bv × d) = 0.25 % ≤ 3.0 %

Effective Depth Ratio, edr = 400 / d = 400 / 409.0 = 0.978

(400 / d)^ ¼ = 0.994 < 1, (400 / d)^ ¼ taken as 1

Minimum fcu, fcuMin = 25 N/mm², Concrete Grade Ratio, Min(fcu, 40) / fcuMin = 30 / 25 = 1.200

Concrete Shear Capacity, νc = 0.79 {100 As / (bv d)}⅓ (400 / d)¼ (fcu / 25)⅓ / γm

= 0.79 × {0.25}⅓ × 1.000 × (1.200)⅓ / 1.25 = 0.42 N/mm²

Minimum Design Shear Stress, νMin = 0.40 N/mm²

νss = 0.263 < νc + 0.4, Provides only minimum link

Design for minimum Shear Stress, νd = νmin = 0.40 N/mm²

Shear Link Area / Spacing Ratio, SAsv_Sv = (vd × b) / (fyy × fy) = (0.40 × 225) / (0.95 × 460) = 0.205 mm²/mm

Shear Reinforcement Provided : T10-250 (Link spacing is governed by user setting)

Shear Link Area / Spacing Ratio Provided = 0.628 mm²/mm > 0.205 mm²/mm

DEFLECTION CHECKING FOR SPAN

No Sagging Moment on Span, No Deflection Check is Proceeded.

Deflection check is not required for this span due to reverse behaviour which may be caused by uplift effect or short span.

BEAM GB9(225x450/600/450) SPAN NO. 7

FLEXURAL DESIGN CALCULATION

LOCATION : SPAN

Design Bending Moment = 22.7 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 22.7 × 1000000 / (225.0 × 409.0²) = 0.602 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.602 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 20.799 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 20.799 / 1000 = 56.72 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 56.72 × 1000 / (460 / 1.05) = 130 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 56.72 × (409.0 - 0.4518 × 20.799) / 1000 = 22.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Compression Steel Area Required = 132 mm²

Bottom Tension Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : LEFT SUPPORT

Design Bending Moment = 21.7 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 21.7 × 1000000 / (225.0 × 409.0²) = 0.576 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.576 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 19.883 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 19.883 / 1000 = 54.22 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 54.22 × 1000 / (460 / 1.05) = 124 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 54.22 × (409.0 - 0.4518 × 19.883) / 1000 = 21.7 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)

Bottom Reinforcement Provided = 2T12 (226 mm²)

LOCATION : RIGHT SUPPORT

Design Bending Moment = 16.3 kNm Width, b = 225.0 mm Effective Depth, d = 409.0 mm

Mu / bd² = 16.3 × 1000000 / (225.0 × 409.0²) = 0.433 N/mm²

Singly Reinforced Design, limit Mu / bd² < kk1

Mu / bd² = 0.433 <= 4.691

Design as Singly Reinforced Rectangular Beam

Concrete Neutral Axis, x = 14.843 mm

Concrete Compression Force, Fc = k1 × b × x / 1000 = 12.12 × 225 × 14.843 / 1000 = 40.48 kN

Steel Area Required, AsReq = Fc × 1000 / (fy / γs) = 40.48 × 1000 / (460 / 1.05) = 93 mm²

Moment Capacity = Fc × (d - k2 × x) / 1000 = 40.48 × (409.0 - 0.4518 × 14.843) / 1000 = 16.3 kNm

Maximum Depth of Section = 450.0 mm

Minimum Tension Steel Area Required = 0.13% × 225.0 × 450.0 = 132 mm²

Top Tension Steel Area Required = 132 mm²

Bottom Compression Steel Area Required = 132 mm²

Top Reinforcement Provided = 2T12 (226 mm²)