Fibeair Ip-20S: Installation and User Guide

Fibeair Ip-20S: Installation and User Guide

Uploaded by

Matheus Gomes VieiraCopyright:

Available Formats

Fibeair Ip-20S: Installation and User Guide

Fibeair Ip-20S: Installation and User Guide

Uploaded by

Matheus Gomes VieiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fibeair Ip-20S: Installation and User Guide

Fibeair Ip-20S: Installation and User Guide

Uploaded by

Matheus Gomes VieiraCopyright:

Available Formats

Installation and User Guide

FibeAir® IP-20S

Part ID: BM-0280-0 | Doc ID: DOC-00038494 Rev F.10

February 2018

© Copyright 2018 by Ceragon Networks Ltd. All rights reserved.

Installation and User Guide for FibeAir IP-20S

Notice

This document contains information that is proprietary to Ceragon Networks Ltd. No part of this publication

may be reproduced, modified, or distributed without prior written authorization of Ceragon Networks Ltd.

This document is provided as is, without warranty of any kind.

Trademarks

Ceragon Networks®, FibeAir® and CeraView® are trademarks of Ceragon Networks Ltd., registered in the

United States and other countries.

Ceragon® is a trademark of Ceragon Networks Ltd., registered in various countries.

CeraMap™, PolyView™, EncryptAir™, ConfigAir™, CeraMon™, EtherAir™, CeraBuild™, CeraWeb™, and

QuickAir™, are trademarks of Ceragon Networks Ltd.

Other names mentioned in this publication are owned by their respective holders.

Statement of Conditions

The information contained in this document is subject to change without notice. Ceragon Networks Ltd. shall

not be liable for errors contained herein or for incidental or consequential damage in connection with the

furnishing, performance, or use of this document or equipment supplied with it.

Open Source Statement

The Product may use open source software, among them O/S software released under the GPL or GPL alike

license ("Open Source License"). Inasmuch that such software is being used, it is released under the Open

Source License, accordingly. The complete list of the software being used in this product including their

respective license and the aforementioned public available changes is accessible at:

Network element site: ftp://ne-open-source.license-system.com

NMS site: ftp://nms-open-source.license-system.com/

Information to User

Any changes or modifications of equipment not expressly approved by the manufacturer could void the

user’s authority to operate the equipment and the warranty for such equipment.

Intended Use/Limitation

Fixed point-to-point radio links for private networks.

Authorized to Use

Only entities with individual authorization from the National Regulator to operate the mentioned radio

equipment.

The equipment can be used in the following EU countries:

Austria (AT) - Belgium (BE) - Bulgaria (BG) - Switzerland/Liechtenstein (CH) - Cyprus (CY) - Czech Republic (CZ)

- Germany (DE) – Denmark (DK) - Estonia (EE) - Finland (FI) - France (FR) -Greece (GR) - Hungary (HU) -

Ireland (IE) – Iceland (IS) – Italy (IT) – Lithuania (LT) - Luxembourg (LU) – Latvia (LV) - Malta (MT) -

Netherlands (NL) - Norway (NO) - Portugal (PT) - Romania (RO) - Sweden (SE) - Slovenia (SI) - Slovak Republic

(SK) – United Kingdom (UK) – Spain (SP) – Poland (PL)

Page 2 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Table of Contents

1. Before You Start........................................................................................................ 8

1.1 Important Notes........................................................................................................................... 8

1.2 Safety Precautions & Declared Material ...................................................................................... 9

1.2.1 General Equipment Precautions .................................................................................................. 9

1.2.2 Précautions générales relatives à l'équipement ........................................................................ 10

1.2.3 Allgemeine Vorsichtsmaßnahmen für die Anlage ...................................................................... 10

1.3 Pre-Installation Instructions ....................................................................................................... 10

1.3.1 Packing ....................................................................................................................................... 10

1.3.2 Transportation and Storage ....................................................................................................... 11

1.3.3 Unpacking .................................................................................................................................. 11

1.3.4 Inspection .................................................................................................................................. 11

2. Product Hardware Description ................................................................................ 12

2.1 IP-20S Hardware Overview ........................................................................................................ 12

2.1.1 IP-20S Interfaces ........................................................................................................................ 13

2.2 PoE Injector ................................................................................................................................ 14

2.2.1 PoE Injector Interfaces ............................................................................................................... 14

2.3 System Components .................................................................................................................. 15

2.4 Antenna Connection .................................................................................................................. 16

2.4.1 Antenna Specifications for 1 ft Antennas .................................................................................. 16

2.4.2 Antenna Specifications for 2 ft Antennas .................................................................................. 17

2.5 Power Specifications .................................................................................................................. 20

2.5.1 Electrical Requirements ............................................................................................................. 20

2.5.2 Important Notes! ....................................................................................................................... 20

2.6 Environmental Specifications ..................................................................................................... 20

3. Cable Installation and Grounding............................................................................. 21

3.1 Minimum and Maximum Cable Diameter ................................................................................. 21

3.2 Cable Grounding ........................................................................................................................ 21

3.2.1 Grounding Procedure ................................................................................................................. 22

3.3 Power Source ............................................................................................................................. 23

3.4 Surge Protection ........................................................................................................................ 23

3.5 Available Cable Options ............................................................................................................. 24

3.5.1 Fiber Optic Cables - Single Mode ............................................................................................... 24

3.5.2 Fiber Optic Cables - Multi Mode ................................................................................................ 25

3.5.3 DC Cable and Connector ............................................................................................................ 25

3.5.4 Ethernet Cable and Specifications ............................................................................................. 26

3.5.5 Outdoor Ethernet Cable Specifications ...................................................................................... 27

3.5.6 Outdoor DC Cable Specifications ............................................................................................... 28

3.6 Securing the Cables .................................................................................................................... 28

3.7 Special Instructions for use of Glands ........................................................................................ 29

Page 3 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.8 Connecting an Optical Fiber Cable and SFP ............................................................................... 30

3.8.1 General Installation Procedure .................................................................................................. 35

3.9 Connecting a DC Power Cable .................................................................................................... 39

3.10 Connecting the Ethernet Cable .................................................................................................. 43

3.10.1 Preparing the Ethernet Cable and Plug-in Field ......................................................................... 43

3.10.2 Preparing the Ethernet Cable Already Assembled ..................................................................... 45

3.10.3 Connection of Ethernet Cable to IP-20S .................................................................................... 46

4. PoE Injector Installation and Connection ................................................................. 48

4.1 PoE Injector Cable Connection ................................................................................................... 48

4.2 PoE Injector Grounding .............................................................................................................. 49

4.3 PoE Injector Wall Mount Installation ......................................................................................... 49

4.4 PoE Injector Pole Mount Installation ......................................................................................... 51

4.5 PoE Injector 19” Rack Installation .............................................................................................. 52

4.6 PoE Injector ETSI Rack Installation ............................................................................................. 53

5. Generic Installation Procedures and Notes .............................................................. 55

5.1 Torque Requirements ................................................................................................................ 55

5.2 Pole Mount Installation ............................................................................................................. 55

5.2.1 IP-20S DC Pole Mount Procedure .............................................................................................. 55

6. IP-20S Detailed Configurations Description .............................................................. 57

6.1 1+0 Direct Mount Installation .................................................................................................... 57

7. Antenna Installation Instructions............................................................................. 61

7.1 Installation Instructions for 1 ft Antenna ................................................................................... 61

7.2 Antenna Assembly Procedure .................................................................................................... 63

7.3 Antenna Installation Procedure ................................................................................................. 68

7.4 Antenna Alignment Procedure .................................................................................................. 70

7.4.1 Elevation Adjustment ................................................................................................................. 70

7.4.2 Azimuth Adjustment .................................................................................................................. 70

7.5 Installation Instructions for 2 ft Antenna ................................................................................... 71

7.6 Antenna Assembly Procedure .................................................................................................... 74

7.7 Antenna Installation Procedure ................................................................................................. 81

7.8 Antenna Alignment Procedure .................................................................................................. 83

7.8.1 Elevation Adjustment ................................................................................................................. 83

7.8.2 Azimuth Adjustment .................................................................................................................. 83

Page 4 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

List of Figures

Figure 1: IP-20S Rear View (Left) and Front View (Right) ....................................................... 12

Figure 2: Cable Gland Construction ........................................................................................ 12

Figure 3: IP-20S Interfaces ...................................................................................................... 13

Figure 4: PoE Injector .............................................................................................................. 14

Figure 5: PoE Injector Ports ..................................................................................................... 14

Figure 6: IP-20S........................................................................................................................ 15

Figure 7: Twist ......................................................................................................................... 15

Figure 8: PoE Injector .............................................................................................................. 15

Figure 9: Tightening the Front Portion of the Gland .............................................................. 39

Figure 10: Tightening the Rear Portion of the Gland ............................................................. 39

Figure 11: Mount IP-20S DC Pole Mount to Pole .................................................................... 56

Figure 12: Horizontal / Vertical Pole ....................................................................................... 58

Figure 13: Twist Orientation ................................................................................................... 58

Figure 14: Right Side Antenna Installation .............................................................................. 64

Figure 15: Left Side Antenna Installation ................................................................................ 64

Figure 16: Clamp orientation for pipes Ø50-66mm (32Nm) ................................................... 69

Figure 17: Clamp orientation for pipes Ø66-120mm (24Nm) ................................................. 69

Figure 18: Right Side Antenna Installation .............................................................................. 75

Figure 19: Left Side Antenna Installation ................................................................................ 75

Figure 20: Clamp orientation for pipes Ø50-66mm (32Nm) ................................................... 82

Figure 21: Clamp orientation for pipes Ø66-120mm (24Nm) ................................................. 82

Page 5 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

List of Tables

Table 1: Ethernet Cable Color Code ........................................................................................ 27

Table 2: Ethernet Cable Electrical Requirements.................................................................... 27

Table 3: Ethernet Cable Mechanical/Environmental Requirements ...................................... 27

Table 4: Outdoor DC Cable Electrical Requirements............................................................... 28

Table 5: Outdoor DC Cable Mechanical/Environmental Requirements ................................. 28

Table 6: Cable Clamps ............................................................................................................. 29

Table 7: Glands Kit................................................................................................................... 29

Table 8: Gland Cap .................................................................................................................. 29

Page 6 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

About This Guide

This guide describes the FibeAir IP-20S installation procedures and provides additional

information concerning system parts and frequency bands.

What You Should Know

For the warranty to be honored, install the unit in accordance with the instructions in this

manual.

Target Audience

This guide contains technical information about IP-20S installation, and is intended for use

by qualified Ceragon technical personnel at all levels.

Page 7 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

1. Before You Start

1.1 Important Notes

• For the warranty to be honored, install the unit in accordance with the

instructions in this manual.

• Any changes or modifications of equipment not expressly approved by the

manufacturer could void the user’s authority to operate the equipment and

the warranty for such equipment.

• IP-20S is intended for installation in a restricted access location.

• IP-20S must be installed and permanently connected to protective earth by

qualified service personnel in accordance with applicable national electrical

codes.

• This device complies with FCC Rules Part 15. Operation is subject to two

conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference that may be received or that may cause

undesired operation.

• This device complies with Industry Canada’s RSS-310. Operation is subject to

the condition that this device must not cause harmful interference and must

accept any interference, including interference that may cause undesired

operation of the device.

• Changes or modifications to this equipment not expressly approved by the

party responsible for compliance (Ceragon Networks Ltd.) could void the

user’s authority to operate the equipment.

• NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

◦ Reorient or relocate the receiving antenna.

◦ Increase the separation between the equipment and receiver.

◦ Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

◦ Consult the dealer or an experienced radio/TV technician for help.

• Cet appareil est conforme au CNR-310 d’Industrie Canada. Son exploitation

est autorisée à condition que l’appareil ne produise pas de brouillage

préjudiciable et qu’il accepte tout brouillage, même celui susceptible d’en

compromettre le fonctionnement

Page 8 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

1.2 Safety Precautions & Declared Material

1.2.1 General Equipment Precautions

To avoid malfunctioning or personnel injuries, equipment or

accessories/kits/plug-in unit installation, requires qualified and trained

personnel. Changes or modifications not expressly approved by Ceragon

Networks could void the user's authority to operate the equipment.

Where special cables, shields, adapters and grounding kits are supplied

or described in this manual, these items must be used, to comply with

the FCC regulations.

Use of controls, adjustments, or performing procedures other than

those specified herein, may result in hazardous radiation exposure.

When working with an IP-20S, note the following risk of electric shock

and energy hazard:

Disconnecting one power supply disconnects only one power supply

module. To isolate the unit completely, disconnect all power supplies.

Machine noise information order - 3. GPSGV, the highest sound pressure

level amounts to 70 dB (A) or less, in accordance with ISO EN 7779.

Static electricity may cause body harm, as well as harm to electronic

components inside the device. Anyone responsible for the installation or

maintenance of the IP-20S must use an ESD Wrist Strap. ESD protection

measures must be observed when touching the unit. To prevent

damage, before touching components inside the device, all electrostatic

must be discharged from both personnel and tools.

In Norway and Sweden:

Equipment connected to the protective earthing of the building

installation through the mains connection or through other equipment

with a connection to protective earthing – and to a cable distribution

system using coaxial cable, may in some circumstances create a fire

hazard. Connection to a cable distribution system has therefore to be

provided through a device providing electrical isolation below a certain

frequency range (galvanic isolator, see EN 60728-11).

Utstyr som er koplet til beskyttelsesjord via nettplugg og/eller via annet

jordtilkoplet utstyr – og er tilkoplet et kabel-TV nett, kan forårsake

brannfare. For å unngå dette skal det ved tilkopling av utstyret til kabel-

TV nettet installeres en galvanisk isolator mellom utstyret og kabel- TV

nettet.

Page 9 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Utrustning som är kopplad till skyddsjord via jordat vägguttag och/eller

via annan utrustning och samtidigt är kopplad till kabel-TV nät kan i vissa

fall medfőra risk főr brand. Főr att undvika detta skall vid anslutning av

utrustningen till kabel-TV nät galvanisk isolator finnas mellan

utrustningen och kabel-TV nätet.

1.2.2 Précautions générales relatives à l'équipement

L’utilisation de commandes ou de réglages ou l'exécution de procédures

autres que celles spécifiées dans les présentes peut engendrer une

exposition dangereuse aux rayonnements.

L’usage de IP-20S s’accompagne du risque suivant d'électrocution et de

danger électrique : le débranchement d'une alimentation électrique ne

déconnecte qu'un module d'alimentation électrique. Pour isoler

complètement l'unité, il faut débrancher toutes les alimentations

électriques.

Bruit de machine d’ordre - 3. GPSGV, le plus haut niveau de pression

sonore s'élève à 70 dB (A) au maximum, dans le respect de la norme ISO

EN 7779.

1.2.3 Allgemeine Vorsichtsmaßnahmen für die Anlage

Wenn andere Steuerelemente verwendet, Einstellungen vorgenommen

oder Verfahren durchgeführt werden als die hier angegebenen, kann

dies gefährliche Strahlung verursachen.

Beachten Sie beim Arbeiten mit IP-20S das folgende Stromschlag- und

Gefahrenrisiko: Durch Abtrennen einer Stromquelle wird nur ein

Stromversorgungsmodul abgetrennt. Um die Einheit vollständig zu

isolieren, trennen Sie alle Stromversorgungen ab.

Maschinenlärminformations-Verordnung - 3. GPSGV, der höchste

Schalldruckpegel beträgt 70 dB(A) oder weniger gemäß EN ISO 7779.

1.3 Pre-Installation Instructions

1.3.1 Packing

The equipment should be packed and sealed in moisture absorbing bags.

Page 10 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

1.3.2 Transportation and Storage

The equipment cases are prepared for shipment by air, truck, railway and sea,

suitable for handling by forklift trucks and slings. The cargo must be kept dry

during transportation, in accordance with ETS 300 019-1-2, Class 2.3. For sea-

transport, deck-side shipment is not permitted. Carrier-owned cargo containers

should be used.

It is recommended that the equipment be transported to the installation site in its

original packing case.

If intermediate storage is required, the packed equipment must be stored in a dry

and cool environment, and out of direct sunlight, in accordance with ETS 300 019-

1-1, Class 1.2.

1.3.3 Unpacking

The equipment is packed in sealed plastic bags and moisture absorbing bags are

inserted. Any separate sensitive product, i.e. printed boards, are packed in anti-

static handling bags. The equipment is further packed in special designed cases.

Marking is done according to standard practice unless otherwise specified by

customers. The following details should be marked:

• Customers address

• Contract No

• Site name (if known)

• Case No

1.3.4 Inspection

Check the packing lists and ensure that correct parts numbers quantities of goods

have arrived. Inspect for any damage on the cases and equipment. Report any

damage or discrepancy to a Ceragon representative, by e-mail or fax.

Page 11 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2. Product Hardware Description

2.1 IP-20S Hardware Overview

FibeAir IP-20S features an all-outdoor architecture consisting of a single unit

directly mounted on the antenna.

Figure 1: IP-20S Rear View (Left) and Front View (Right)

Figure 2: Cable Gland Construction

Page 12 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2.1.1 IP-20S Interfaces

Figure 3: IP-20S Interfaces

• Data Port 1 for GbE traffic:

◦ Electric: 10/100/1000Base-T. Supports PoE.

◦ Optical: 1000Base-X (optional)

• Data Port 2 for GbE traffic:

◦ Electric10/100/1000Base-T

◦ Optical: 1000Base-X (optional)

• Data Port 3 for GbE traffic

◦ Electric: 10/100/1000Base-T

◦ Optical: 1000Base-X (optional)

• Power interface (-48VDC)

• Management Port: 10/100Base-T

• 1 RF Interface – Standard interface per frequency band

• RSL interface: BNC connector

• Grounding screw

Page 13 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2.2 PoE Injector

The PoE injector is an outdoor unit which can be mounted on a wall, pole, or

indoor rack.

Each PoE Injector kit includes the following items:

• PoE injector

• 2 DC power connectors

Figure 4: PoE Injector

Two models of the PoE Injector are available:

• PoE_Inj_AO_2DC_24V_48V – Includes two DC power ports with power input

ranges of ±(18-60)V each.

• PoE_Inj_AO – Includes one DC power port (DC Power Port #1), with a power

input range of ±(40-60)V.

2.2.1 PoE Injector Interfaces

• Power-Over-Ethernet (PoE) Port

• GbE Data Port supporting 10/100/1000Base-T

• DC Power Port 1 ±(18-60)V or ±(40-60)V

• DC Power Port 2 ±(18-60)V (Optional)

• Grounding screw

Figure 5: PoE Injector Ports

Page 14 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2.3 System Components

The following figures show the main components used in the IP-20S installation

procedures.

Figure 6: IP-20S Figure 7: Twist Figure 8: PoE Injector

Page 15 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2.4 Antenna Connection

FibeAir iP-20S can be ordered with any of the following antennas:

• 1 ft antennas:

AN-3501-1

AN-2505-0

• 2 ft antennas:

AN-3315-1

AN-2517-1

2.4.1 Antenna Specifications for 1 ft Antennas

The following table lists the specifications for each available 1 ft antenna.

AN-2505-0 AN-3501-1

Antenna Marketing Model Am-1-26-CR1 Am-1-26-CR

General Specifications

Nominal diameter 0.3m (1ft) 0.3m (1ft)

Polarization Single, Vertical or Horizontal Single, Vertical or Horizontal

Radio interface Direct Mount for RFU-C type ODU Direct Mount for RFU-C type ODU

Antenna color NCS S 2502 R Grey Gray (Pantone 1C)

Radome color NCS S 2502 R Grey Gray (Pantone 1C)

Radome type UV Stabilized PC Hard Cover

Packing type Carton Carton

Gross weight, kg 6.9 – 8.8 12±2

Packed dimensions, mm 395 (L) X 395 (W) X 285 (H) 500 (L) X 450 (W) X 320 (H)

Packing Volume, m3 0.044 0.072

Electrical Specifications

Frequency Band (GHz) 24.000 – 26.500 24.000 – 26.500

Waveguide Interface UBR220 UBR220

Gain (dBi) Low 36.9 36.4

Gain (dBi) Mid 37.0 36.8

Gain (dBi) High 36.5 37.1

3 dB BW (°) 2.3 2.4

VSWR 1.30 1.30

F/B Ratio (dB) 71 63

XPD (dB) 30 30

Page 16 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

AN-2505-0 AN-3501-1

RPE Number 906-HAE2603 BL 10587

Mechanical Specifications

Wind Velocity Operational, km/h 180 200

Wind Velocity Survival Rating, km/h 250 250

Ice Load, mm 25 25

Azimuth Adjustment, Degrees ±15 ±15

Elevation Adjustment, Degrees ±15 ±15

Mounting Pipe Diameter, mm 50 to 120 51 to 114

Net weight, kg 5.2 kg 8.5±1

Feed horn, Operational Pressure, KPa 40 50

Operational Temperature, °C -45 to +55 -45 to +60

Storage Temperature, °C -55 to +85 -55 to +70

Adjustment Struts None None

Fixed Support Struts None None

Humidity 100% 100%

Rain Intensity, mm/min 15 15

Solar Radiation, W/m2 1120 1120

Electrical Properties ETSI EN 302 217-4-2 ETSI EN 302 217-4-2

Vibration ETSI 300 019-2-4 V2.2.2 (2003-04) ETSI 300 019-2-4 V2.2.2 (2003-04)

T4.1E. 4M5 T4.1E.

RoHS 2002/95/EC Compliant Compliant

2.4.2 Antenna Specifications for 2 ft Antennas

The following table lists the specifications for each available 2 ft antenna.

AN-2517-0 AN-3315-1

Antenna Marketing Model Am-2-26-CR1 Am-2-26-CR

General Specifications

Nominal diameter 0.6m (2ft) 0.6m (2ft)

Polarization Single, Vertical or Horizontal Single, Vertical or Horizontal

Radio interface Direct Mount for RFU-C type ODU Direct Mount for RFU-C type ODU

Antenna color NCS S 2502 R Grey Gray (Pantone 1C)

Radome color NCS S 2502 R Grey Gray (Pantone 1C)

Page 17 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

AN-2517-0 AN-3315-1

Radome type UV Stabilized PC Hard Cover

Packing type Carton Carton

Gross weight, kg 11.2 – 12.4 18±2

Packed dimensions, mm 720/480 (L) X 790 (W) X 320 (H) 750 (L) X 750 (W) X 440 (H)

Packing Volume, m3 0.144 0.248

Electrical Specifications

Frequency Band (GHz) 24.000 – 26.500 24.000 – 26.500

Waveguide Interface UBR220 UBR220

Gain (dBi) Low 42.0 41.1

Gain (dBi) Mid 42.4 41.5

Gain (dBi) High 42.3 41.8

3 dB BW (°) 1.4 1.4

VSWR 1.30 1.30

F/B Ratio (dB) 68 67

XPD (dB) 30 30

RPE Number 906-HAE2606 BL 10594

Mechanical Specifications

Wind Velocity Operational, km/h 180 200

Wind Velocity Survival Rating, km/h 250 250

Ice Load, mm 25 25

Azimuth Adjustment, Degrees ±15 ±15

Elevation Adjustment, Degrees ±15 ±15

Mounting Pipe Diameter, mm 50 to 120 51 to 114

Net weight, kg 8.2 kg 11±1

Feed horn, Operational Pressure, KPa 40 50

Operational Temperature, °C -45 to +55 -45 to +60

Storage Temperature, °C -55 to +85 -55 to +70

Adjustment Struts None None

Fixed Support Struts None None

Humidity 100% 100%

Rain Intensity, mm/min 15 15

Solar Radiation, W/m2 1120 1120

Electrical Properties ETSI EN 302 217-4-2 ETSI EN 302 217-4-2

Page 18 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

AN-2517-0 AN-3315-1

Vibration ETSI 300 019-2-4 V2.2.2 (2003-04) ETSI 300 019-2-4 V2.2.2 (2003-04)

T4.1E. 4M5 T4.1E.

RoHS 2002/95/EC Compliant Compliant

Page 19 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2.5 Power Specifications

2.5.1 Electrical Requirements

• -48V DC Nominal

• Maximum current rating 1.5 A

• Maximum Cable length 300 meter

• Maximum cable size for PoE cable is 24 AWG, with maximum current up to 2A

from the power source.

2.5.2 Important Notes!

• The unit must only be installed by service personnel.

• The unit must have a permanent connection to protective grounding.

• Data port 2, Data port 3, the Management port, and the TNC connector do not

provide protection from over-voltages on telecommunication networks for

host equipment users.

• The RSL interface connector is intended for technician use only.

• Disconnect device (circuit breaker) in the building installation:

• Shall be readily accessible and incorporated external to the equipment.

• The maximum rating of the overcurrent protection shall be up to 6 Amp.

2.6 Environmental Specifications

Operating: ETSI EN 300 019-1-4 Class 4.1

Temperature range for continuous operating temperature with high reliability:

-33°C (-27°F) to +55°C (131°F)

Temperature range for exceptional temperatures; tested successfully, with limited

margins:

-45°C (-49°F) to +60°C (140°F)

Humidity: 5%RH to 100%RH

IEC529 IP66

Storage: ETSI EN 300 019-1-1 Class 1.2

Transportation: ETSI EN 300 019-1-2 Class 2.3

Page 20 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3. Cable Installation and Grounding

3.1 Minimum and Maximum Cable Diameter

To fit the gland, the outer cable diameter should be between 6-10 mm. This

applies to all glands on both the IP-20S unit and the PoE Injector.

To fit the grounding clamp, the outer diameter of CAT5E Ethernet cables must be

between 6-7.1mm.

3.2 Cable Grounding

Cables must be grounded as follows:

• For fiber cables (see Connecting an Optical Fiber Cable and SFP on page 30),

no grounding is required.

• For DC power cables (see Connecting a DC Power Cable on page 39), no

grounding is required.

• For Ethernet cables, the shielded Ethernet cable (SF/UTP construction) should

be grounded to the antenna tower at the top (next to the IP-20 unit), the

entry to the indoor cabinet, and every 50m, using the kit CAT5E_gnd_kit.

Page 21 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.2.1 Grounding Procedure

Required Tools

• Metric offset wrench key wrench #3

• Metric wrench 10mm

Procedure

1 On the front of each IP-20S unit, loosen the nut, plain washer, and serrated

washer from the GND stud, using the metric offset hexagon key and the

wrench.

2 Place the cable lug (supplied with the IP-20S grounding kit) in place on the

screw.

3 Secure the cable lug.

4 The second side of the GND cable should be connected to the main ground

bar or terminal ground bar of the site.

5 Perform a resistance test between the 2 lugs of the GND cable. Verify that the

result is 0-2 ohms.

Notes: The unit’s earthing screw terminal shall be permanently connected to

protective earth in a building installation in accordance with applicable

national code and regulations by a service person.

A 2-pole circuit breaker, a branch circuit protector, suitably certified in

accordance with applicable national code and regulations, rated

maximum 20A, shall be installed for full power disconnection in a

building installation.

Any outdoor antenna cable shield shall be permanently connected to

protective earth in a building installation.

Page 22 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.3 Power Source

The power cable must be plugged into the unit before turning on the external

power.

When selecting a power source, the following must be considered:

DC power can be from -40 VDC to -60 VDC.

Recommended: Availability of a UPS (Uninterrupted Power Source), battery

backup, and emergency power generator.

The power supply must have grounding points on the AC and DC sides.

Caution! The user power supply GND must be connected to the positive

pole in the IP-20S power supply.

Any other connection may cause damage to the system!

Note! For the warranty to be honored, you must install the IP-20S in

accordance with the instructions above.

3.4 Surge Protection

IP-20S includes built-in surge protection for its Ethernet and power interfaces. IP-

20S’s surge protection implementation complies with surge immunity standard

IEC 61000-4-5, level 4, provided the Ethernet cables were prepared according to

the instructions in Preparing the Ethernet Cable and Plug-in Field on page 43.

In areas in which severe lighting conditions are likely to occur, it is strongly

recommended to add additional protection by placing lightning protectors on all

electrical Ethernet cables, near the connection points with the IP-20S unit.

Page 23 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.5 Available Cable Options

3.5.1 Fiber Optic Cables - Single Mode

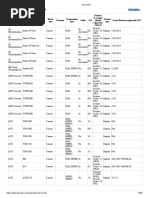

Marketing P/N Description

IP-20_FO_SM_LC2LC_ARM_7m CABLE,FO,DUAL LC/LC,7M,SM,55mm OPEN END,M28

GLAND,ARMORED,OU

IP-20_FO_SM_LC2LC_ARM_15m CABLE,FO,DUAL LC/LC,15M,SM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_SM_LC2LC_ARM_30m CABLE,FO,DUAL LC/LC,30M,SM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_SM_LC2LC_ARM_50m CABLE,FO,DUAL LC/LC,50M,SM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_SM_LC2LC_ARM_70m CABLE,FO,DUAL LC/LC,70M,SM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_SM_LC2LC_ARM_80m CABLE,FO,DUAL LC/LC,80M,SM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_SM_LC2LC_ARM_100m CABLE,FO,DUAL LC/LC,100M,SM,55mm OPEN END,M28

GLAND,ARMORED

IP-20_FO_SM_LC2LC_ARM_150m CABLE,FO,DUAL LC/LC,150M,SM,55mm OPEN END,M28

GLAND,ARMORED

Page 24 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.5.2 Fiber Optic Cables - Multi Mode

Marketing P/N Description

IP-20_FO_MM_LC2LC_ARM_7m CABLE,FO,DUAL LC/LC,7M,MM,55mm OPEN END,M28

GLAND,ARMORED,OU

IP-20_FO_MM_LC2LC_ARM_15m CABLE,FO,DUAL LC/LC,15M,MM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_MM_LC2LC_ARM_20m CABLE,FO,DUAL LC/LC,20M,MM,55mm OPEN END,M28

GLAND,ARMORED

IP-20_FO_MM_LC2LC_ARM_30m CABLE,FO,DUAL LC/LC,30M,MM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_MM_LC2LC_ARM_50m CABLE,FO,DUAL LC/LC,50M,MM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_MM_LC2LC_ARM_80m CABLE,FO,DUAL LC/LC,80M,MM,55mm OPEN END,M28

GLAND,ARMORED,O

IP-20_FO_MM_LC2LC_ARM_100m CABLE,FO,DUAL LC/LC,100M,MM,55mm OPEN END,M28

GLAND,ARMORED

IP-20_FO_MM_LC2LC_ARM_150m CABLE,FO,DUAL LC/LC,150M,MM,55mm OPEN END,M28

GLAND,ARMORED

IP-20_FO_MM_LC2LC_ARM_200m CABLE,FO,DUAL LC/LC,200M,MM,55mm OPEN END,M28

GLAND,ARMORED

3.5.3 DC Cable and Connector

Marketing P/N Description

Outdoor_DC_cbl_2x18AWG_drum CABLE,305M,OUTDOOR_DC_CBL_2X18AWG_DRUM

IP-20C_DC_Conn IP-20C_DC_Conn

Page 25 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.5.4 Ethernet Cable and Specifications

Marketing P/N Description

CAT5E_SFUTP_Outdoor_50m CABLE,RJ45 TO RJ45 STR 50M,CAT-5E,ETHER,UV

RES

CAT5E_SFUTP_Outdoor_75m CABLE,RJ45 TO RJ45 STR 75M,CAT-5E,ETHER,UV

RES

CAT5E_SFUTP_Outdoor_305m_drum CABLE,MATERIAL,CAT-5E,SFUTP,4X2X24AWG,UV

RESISTANCE,305M

CAT5E_Arm_50m CABLE,RJ45 TO RJ45 STR,50M,CAT-5E,M28

GLAN,ARM,UV RESISTANCE

CAT5E_Arm_70m CAT5E_Arm_75mCABLE,RJ45 TO RJ45

STR,70M,CAT-5E,M28 GLAN,ARM,UV RESISTANCE

CAT5E_Arm_305m_drum CABLE,MATERIAL,CAT-

5E,FTP,4X2X24AWG,ARMORED,UV RESIST,305M

This cable has the following specifications:

• Suitable for:

◦ Fast Ethernet

◦ Gigabit Ethernet

◦ PoE

Cable Design – The numbers in the figure below refer to the items listed beneath

the figure.

• [1]Conductor

• [2]Insulation

• [3]Screen: Alu/Pet foil. Alu outside

• [4]Tinned copper braid

• [5]Jacket

Page 26 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Table 1: Ethernet Cable Color Code

Pair Wire A Wire B

1 WHITE-blue BLUE

2 WHITE-orange ORANGE

3 WHITE-green GREEN

4 WHITE-brown BROWN

3.5.5 Outdoor Ethernet Cable Specifications

Table 2: Ethernet Cable Electrical Requirements

Cable type CAT-5e SFUTP, 4 pairs, according to ANSI/TIA/EIA-568-B-

2

Wire gage 24 AWG

Stranding Solid

Voltage rating 70V

Shielding Braid + Foil

Pinout

Table 3: Ethernet Cable Mechanical/Environmental Requirements

Jacket UV resistant

Outer diameter 6-7.1 mm (in order to be compatible with the

grounding clamp, CAT5E_gnd_kit)

Operating and Storage -40°C - 85°C

temperature range

Flammability rating According to UL-1581 VW1, IEC 60332-1

RoHS According to Directive/2002/95/EC

Page 27 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.5.6 Outdoor DC Cable Specifications

Table 4: Outdoor DC Cable Electrical Requirements

Cable type 2 tinned copper wires

Wire gage 18 AWG (for <100m installations)

12 AWG (for >100m installations)

Stranding stranded

Voltage rating 600V

Spark test 4KV

Dielectric strength 2KV AC min

Mechanical/ Environmental Requirements

Jacket PVC, double, UV resistant

Outer diameter 7-10 mm

Operating & Storage temperature range -40°C - 85°C

Flammability rating According to UL-1581 VW1, IEC

60332-1

RoHS According to Directive/2002/95/EC

Table 5: Outdoor DC Cable Mechanical/Environmental Requirements

Jacket UV resistant

Outer diameter 7-10 mm

Operating & Storage temperature range -40°C - 85°C

Flammability rating According to UL-1581 VW1, IEC

60332-1

RoHS According to Directive/2002/95/EC

3.6 Securing the Cables

All cables should be secured at every meter on-site using either a T-Rups kit, P/N

Outdoor Ties (SI-0027-0) or cable clamps. When using the T-Rups kit, take special

care to apply the proper amount of force in order to avoid damage to the cable.

This is especially important for optical (SFP) cables.

The following cable clamps are available:

Page 28 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Table 6: Cable Clamps

Part Number Marketing Model Item Description

SI-1229-0 Fiber_clamp_2cbl_4.0-7.0mm DUAL FEADER CLAMP FOR 4.0-7.0mm CABLE 2 WAY.

SI-1230-0 Fiber_clamp_4cbl_4.0-7.0mm DUAL FEADER CLAMP FOR 4.0-7.0mm CABLE 4 WAY.

SI-1231-0 Fiber_clamp_6cbl_4.0-7.0mm DUAL FEADER CLAMP FOR 4.0-7.0mm CABLE 6 WAY.

3.7 Special Instructions for use of Glands

Note: Each IP-20S unit is supplied with two glands. If additional glands are

required, they must be ordered separately, in kits of five glands each.

Table 7: Glands Kit

Marketing Model Marketing Description

IP-20_Glands_kit IP-20_Glands_x5_kit

In addition, gland caps can be ordered to protect the cable and connector from

damage when elevating the cable and gland to the radio unit. See Step 5 in

Section 3.8.1, General Installation Procedure. Gland caps are ordered separately,

in kits of 10 caps each.

Table 8: Gland Cap

Marketing Model Marketing Description

Cable_Prot_10Caps_kit Cable protective caps kit 10 pcs, IP-20C/S/E

Page 29 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

In order to remove the plastic plugs for the unit, you can use the flange of

supplied glands to disconnect them. See below pictures

3.8 Connecting an Optical Fiber Cable and SFP

To connect an optical fiber cable and the SFP transceiver:

1 Use a pre-assembled cable.

Page 30 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

2 Split the connector into two separate LC connectors (one for each fiber).

3 Remove the gland cap and rubber from the gland body.

4 Slide the gland cap into the cable.

5 Slide the rubber into the cable.

Page 31 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

6 Insert the wires with the connectors one by one into the cable gland.

7 Secure the cable to the lip of the gland using a tie wrap.

Important Note: If you are raising the cable to a radio unit on a tower, this step

is crucial to prevent the cable from slipping from the gland, which

could damage the connector.

Page 32 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

8 Connect the fibers to the SFP transceiver. Listen for the “click” to ensure that

it is fully inserted.

9 Remove the tie wrap securing the cable to the gland.

Note: A new tie wrap must be used to secure the cable to the gland at the

end of the procedure, as described in Step 13.

10 Connect the connector into the IP-20S LC connector.

11 Tighten the gland to the radio unit until there is full contact between the gland

and the radio unit.

Page 33 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

12 Tighten the gland cap.

Important Note! Before tightening the gland, make sure the gland is aligned

with the tapped hole in the unit.

Tightening the gland at an angle can ruin the thread on the gland and

prevent proper sealing of the interface Tighten the gland gently and

make sure there is no resistance. If there is resistance, stop

immediately, thread out the gland, and verify that the gland threads

are not damaged. Then, tighten the gland again.

If the gland thread is damaged do not use it!

13 Secure the cable to the gland using a tie wrap.

Page 34 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.8.1 General Installation Procedure

This procedure applies to all cable types, and explains how to install the cables

using long glands. The gland is supplied assembled.

1 Before inserting a cable, you must disassemble the gland cap and gland rubber

from the gland body.

2 Slide the gland cap into the cable.

3 Slide the gland rubber into the cable.

Page 35 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4 Slide the cable into the body of the gland. If you are using a gland cap (see

Step 5), make sure to leave enough space for the gland cap to fit into the

gland without disturbing the cable.

5 Optionally, after securing the cable into the body of the gland, you can close

the other side of the gland with an M28 gland cap. The gland cap protects the

cable and connector from damage when elevating the cable and gland to the

radio unit.

Page 36 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

6 The M28 gland cap has hook on top. After attaching the gland cap to the

gland, you can connect a rope to the hook and use this to lift the gland and

cable up to the radio unit. Before screwing the gland into the radio unit, you

must remove the gland cap.

7 If you used an M28 gland cap to close the gland when raising the gland and

cable to the radio unit, remove the gland cap from the gland at this point by

unscrewing the cap.

8 Connect the cable to the port.

Page 37 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

9 Screw the gland into the radio unit until there is full contact between the

gland and the radio unit.

Important Note! Before tightening the gland, make sure the gland is aligned

with the tapped hole in the unit. Tightening the gland at an angle can

ruin the thread on the gland and prevent proper sealing of the

interface.

10 Insert the main part of the gland into the thread in the radio body and tighten

until there is full contact and the gasket is fully contained between the gland

and the radio and cannot be seen. Tighten the gland gently and make sure

there is no resistance. If there is resistance, stop immediately, and thread out

the gland. Verify that the gland thread is not damaged and tighten the gland

again.

Important Note! Pay attention that the gland rubber is properly located and

not damaged during the tightening of the gland cap.

If the gland thread is damaged do not use it!

11 Tighten the rear portion of the gland onto the main part of the gland and

make sure that the main part of the gland does not have an additional swivel

after the rear portion is secured.

Note: If the main portion of the gland is rotated while the rear portion is

seizing the cable, this may ruin the cable connector.

Page 38 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Figure 9: Tightening the Front Portion Figure 10: Tightening the Rear Portion

of the Gland of the Gland

12 Secure the cable to the lip of the gland using a tie wrap.

3.9 Connecting a DC Power Cable

Note: The DC power cable and connector must be ordered separately. See

DC Cable and Connector on page 25.

To connect a DC power cable:

1 Strip off 45 mm from the cable jacket.

2 Expose 10 mm at the edge of each of the two wires.

3 Insert the power cable into the gland.

Page 39 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4 Insert the power cable wires into the power connector.

5 Insert the power cable wires into the power connector. Match “+” to the 0V

wire and “-“ to the -48V wire.

6 Tighten the two top screws.

7 Plug the power cable with connector into the IP-20S power connector.

Page 40 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

8 Tighten the two front screws.

Page 41 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

9 Screw the gland into the radio unit

Important Note! Before tightening the gland, make sure the gland is even with

the cover. Tighten the gland gently and make sure there is no

resistance. If there is resistance, stop immediately and verify that the

gland is not being inserted at an angle. Tightening the gland at an

angle can ruin the thread on the gland and prevent proper sealing of

the interface.

10 Tighten the gland cap.

11 Secure the cable to the gland with a tie wrap.

Page 42 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.10 Connecting the Ethernet Cable

If you need to assemble the Ethernet cable, follow the instructions in section

3.10.1, Preparing the Ethernet Cable and Plug-in Field, then proceed to section

3.10.3, Connection of Ethernet Cable to IP-20S.

If you using a pre-assembled Ethernet cable, follow the instructions in section

3.10.2, Preparing the Ethernet Cable Already Assembled, then proceed to section

3.10.3, Connection of Ethernet Cable to IP-20S.

Note: To ensure proper grounding and connectivity, it is recommended to

use pre-assembled Ethernet cables.

3.10.1 Preparing the Ethernet Cable and Plug-in Field

Important Note: To ensure proper grounding, the RJ-45 plug must be shielded,

with a crimping tail.

To prepare the Ethernet cable and plug-in field:

1 Prepare the gland and insert the cable, as described in General Installation

Procedure on page 35.

2 Strip off approximately 45 mm of the outer insulation jacket from the CAT5E

cable.

3 Do not strip off the end of the cable shield, but rather, twist the shield to form

a braid.

4 Roll back the foil shield insulation and wrap the drain wire around the foil. Do

not remove any insulation from the conductors.

5 Align the colored wires.

Page 43 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Note: Cord colors should be matched to the same pins on both ends of the

cable.

6 Trim all wires to the same length. About 12 mm on the left should be exposed

from the inner sheath.

7 Separate the wires and place the twisted braid between the separated wires.

8 Insert the wires into the RJ45 plug. Verify that each wire is fully inserted into

the front of the RJ45 plug and in the correct order, according to the pinouts

shown in Section 3.5.5, Outdoor Ethernet Cable Specifications. The sheath of

the Ethernet cable should extend into the plug by about 13 mm and held in

place by the crimp.

9 Extend the cable jacket with the shield into the connector about 5 mm for

strain relief and shielding connection.

10 Wrap the twisted braid firmly around the cable jacket and let the crimping tail

of the RJ45 plug envelop it.

Important Note! To ensure proper grounding, it is essential that the twisted

braid be firmly connected to the RJ45 plug.

Page 44 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

11 Crimp the RJ45 plug with the crimp tool. Make sure the twisted braid is

crimped firmly to the RJ45 plug.

12 Verify that the wires ended up the correct order and that the wires extend to

the front of the RJ45 plug and make good contact with the metal contacts in

the RJ45 plug.

13 Push back the CAT5E plug cover on the connector plug.

Note: It is recommended that the newly prepared cable be tested with a

Cable Analyzer such as the FLUKE DTX-1800 (or the equivalent), to

make sure the cable complies with ANSI/TIA/EIA-568-B-2. Make sure

to verify both connectivity and grounding continuity at both ends of

the cable.

3.10.2 Preparing the Ethernet Cable Already Assembled

To prepare the Ethernet cable already assembled:

1 Release the gland cap and the gland rubber slightly.

2 Insert the CAT5E cable into the gland cap and into the rubber gland.

3 Insert the CAT5E cable into the gland body.

Page 45 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3.10.3 Connection of Ethernet Cable to IP-20S

To connect the Ethernet cable to the IP-20S:

1 Remove the relevant cap from the IP-20S radio. You can use the side of the

gland to unscrew the cap.

2 Connect the CAT5E cable to the IP-20S.

Page 46 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3 Screw the gland into the radio unit.

Important Note! Before tightening the gland, make sure the gland is even with

the cover. Tighten the gland gently and make sure there is no

resistance. If there is resistance, stop immediately and verify that the

gland is not being inserted at an angle. Tightening the gland at an

angle can ruin the thread on the gland and prevent proper sealing of

the interface.

4 Tighten the gland cap.

5 Secure the cable to the gland using a tie wrap.

Page 47 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4. PoE Injector Installation and Connection

4.1 PoE Injector Cable Connection

The PoE Injector cables are connected similar to the IP-20S.

• To connect the Ethernet (CAT5E) cable to the PoE or Data port, refer to

Connection of Ethernet Cable to IP-20S on page 46.

• To connect the DC power cable to the power port or dual feed port, refer to

Connecting a DC Power Cable on page 39. This cable is not supplied with the

PoE Injector.

• The total length of the cable between the IP-20S port and the Switch/Router

the device is connected to should not exceed 100m/328ft. This length includes

the connection between the IP-20S and the PoE Injector (X1 + X2 ≤

100m/328ft in the figure below).

Note: The length of the cable connecting the customer equipment to the PoE

injector should not be longer than 10m (according to ANSI/TIA-568

standard).

IP-20S

X2

DC

X1

CSR

Note! For the warranty to be honored, the connection must be through the

glands only. Do not open the PoE injector box cover.

Page 48 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4.2 PoE Injector Grounding

To ground the PoE Injector:

1 On the right side of each PoE Injector, loosen the screw, plain washer, and

serrated washer.

2 Place the cable lug (supplied with the PoE injector kit) between the plain and

serrated washer.

3 Tighten the screw.

4 Perform a resistance test between the 2 lugs of the GND cable. Verify that the

result is 0-2 ohms.

4.3 PoE Injector Wall Mount Installation

List of Items

Item Description Quantity Remarks

1 PoE Injector 1

1 Glands Kit 1 For outdoor installations.

Note: Glands are required for outdoor installations. The glands kit (three or

five glands) is not supplied with the PoE Injector, and must be ordered

separately.

Glands Kit

Marketing Model Marketing Description

IP-20_3xGlands_kit IP-20_3xGlands_kit

IP-20_Glands_kit IP-20_Glands_x5_kit

Required Tools

• Metric offset wrench key wrench set

• Hammer

• Drilling Machine

Procedure

1 Mount and tighten the PoE Injector to a wall using two M6 bolts and anchors.

The M6 bolts and anchors must be purchased separately.

Note: Use Anchor Stainless Steel with flanged Hexagonal nut M6X70.

2 Drill two 6mm diameter holes with 100mm distance between the center of

the holes.

3 Insert the anchors with the bolts.

Page 49 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4 Place the washers on the bolt.

5 Tighten the nuts.

Page 50 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4.4 PoE Injector Pole Mount Installation

List of Items

Item Description Quantity Remarks

1 PoE Injector 1

Required Tools

• Slot Screwdriver

Procedure

To mount the PoE Injector on a pole:

1 Mount and tighten the PoE Injector to a pole with a diameter of 114 mm using

a stainless steel hose clamp.

2 Pass the hose clamp through the pole mount slots.

Note! The Hose Clamp is not supplied with PoE injector kit.

3 Attach the PoE injector to the pole.

4 Connect the ends of the hose clamp.

5 Tighten the hose clamp using the captive screw.

Page 51 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4.5 PoE Injector 19” Rack Installation

List of Items

Item Description Quantity Remarks

1 PoE Injector 1

2 PoE Injector 19” Rack Mount 1

Kit

Required Tools

• Philips Screwdriver

To mount the PoE Injector on a rack:

1 Mount the PoE Injector to a 19” rack using a 19” rack adaptor.

2 Mount the PoE Injector on the 19” adaptor through the wall mounting holes,

using M6 screws and washers.

3 Mount the 19” rack adaptor to a 19” rack using four M6 screws and cage nuts.

Page 52 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

4.6 PoE Injector ETSI Rack Installation

List of Items

Item Description Quantity Remarks

1 PoE Injector 1

2 PoE Injector ETSI Rack 1

Mount Kit

Required Tools

• Philips Screwdriver

To mount the PoE Injector to an ETSI rack:

1 Mount the PoE Injector to an ETSI rack using a 19” rack adaptor and ETSI

adapting ears.

2 Connect the ETSI adapting ears to a 19” rack adaptor using four M6 screws.

Page 53 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

3 Mount the PoE Injector on the adaptor through the wall mounting holes using

M6 screws and washers.

4 Mount the 19” rack adaptor with the ETSI ears on the ETSI rack using four M6

screws and cage nuts.

Note: For this type of installation, a 2RU space is required.

Page 54 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

5. Generic Installation Procedures and Notes

5.1 Torque Requirements

When tightening the captive screws, use 20 Nm torque for radio-antenna, radio-

mediation device, and mediation device-antenna connections. In order to avoid

misalignment, screws should be tightened progressively.

When fastening a waveguide to the radio or mediation device, use the following

torque, according to frequency and screw type:

• 6 GHz: M5/#10-32: 3.5 Nm

• 7/8-15 GHz: M4/#8-32: 2.5 Nm

• 18-42 GHz: M3/#4-40: 1Nm

5.2 Pole Mount Installation

The pole diameter range for pole mount installations is 8.89 cm – 11.43 cm (3.5

inches – 4.5 inches).

5.2.1 IP-20S DC Pole Mount Procedure

List of Items

Item Description Quantity Remarks

1 IP-20S DC POLE MOUNT KIT 1

Required Tools

• Metric offset wrench key wrench set

Procedure

1 Mount and tighten the IP-20S DC pole mount to a pole with a diameter of 114

mm using the four washers and screws supplied with the IP-20S DC pole

mount kit.

Page 55 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Figure 11: Mount IP-20S DC Pole Mount to Pole

Page 56 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

6. IP-20S Detailed Configurations Description

6.1 1+0 Direct Mount Installation

List of Items

Item Description Quantity Remarks

1 IP-20S RADIO 1

Required Tools

The following tools are required for the IP-20S installation:

• Metric offset hexagon key wrench #6

• Phillips #2 screwdriver

Procedure

To install the IP-20S in a direct mount 1+0 configuration:

Important! Do not remove the transparent pressure window located on the

antenna interface.

Note: If necessary, change the antenna polarization by rotating the unit in

accordance with the relevant antenna installation guide.

Page 57 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Figure 12: Horizontal / Vertical Pole

Figure 13: Twist Orientation

Page 58 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

◦ For horizontal polarization, locate the twist with the letter “H” vertical to

the hook cover and fasten the two screws.

◦ For vertical polarization,

locate the twist with the

letter “V” vertical to the

hook cover and fasten

the two screws.

1 Mount the IP-20S on the antenna using the four M8 captive screws and

washers that are supplied, assembled, in the IP-20S, and tighten the screws.

Page 59 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Note: Make sure the polarization mounting direction of the IP-20S is correct.

Page 60 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

7. Antenna Installation Instructions

Note: Appropriate lubricant or grease can be applied to the screws that

connect the IP-20S to the antenna interface.

7.1 Installation Instructions for 1 ft Antenna

List of Items

Item Description Quantity Remarks

A Antenna (with preassembled feeder) 1

B Antenna support (Box) (not preassembled) 1

Pipe attachment bracket 1

Clamp bracket 1

Pivot bracket 1

M8 link screw (and M8 nut) 1

M8x100 screw 3

M8x35 screw 1

M8x25 screw 3

Washer M8 9

M8 nut 6

C Radio interface (not preassembled) 1

Interface plate 1

Adapter plate 1

Securing hook 1

M10x25 screw 4

M6x18 screw (countersunk) 2

M4x10 screw 1

Washer M10 4

D Grease (not preassembled) 1

Page 61 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Page 62 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Required Tools

Required Tool Head Size Thread Size Torque Nm

Allen Key 3 mm M4 2.6

Allen Key 4 mm M6 9.1

Allen Key 8 mm M10 33

Combination Wrench (ring/open jaw) 13 mm M8 24/32

Socket wrench and sockets 13 mm M8 24/32

Tool for torque levels 2.6 Nm – 33 Nm

Unpacking

Before starting with the installation, make sure to remove any protection tapes

covering the waveguide openings.

Please the antenna on a flat, clean surface, such as the top of the packing

material.

Handle the Feeder carefully at all times.

7.2 Antenna Assembly Procedure

Step 1 – Left or right side installation

Before proceeding with the installation, you must determine whether a left or

right side installation is required.

For a right side installation, see Step 2.1 – Antenna support (right side

installation).

For a left side installation, see Step 2.2 – Antenna support (left side installation).

Page 63 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Figure 14: Right Side Antenna Installation Figure 15: Left Side Antenna Installation

Step 2.1 – Antenna support (right side installation).

a) Mount the pivot bracket (1) to the antenna (2) using 1 M8x35 screw and 1 M8

washer (3) and 2 M8x25 screws with 2 M8 washers (4). Fit the screws finger tight.

b) Mount 1 M8 link screw (5) to the pivot bracket (1) using 1 M8x25 screw with 1

M8 washer (6). Fit the screw loosely.

c) Mount 2 M8x100 screws (7) to the pipe attachment bracket (8) using 2 M8 nuts

(9). Tighten the nuts finger tight.

d) Mount the pipe attachment bracket (8) to the pivot bracket (1) using 1 M8x100

screw (10) and 2 M8 nuts with 3 M8 washers (11). Fit the screw and nuts loosely.

Page 64 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Step 2.2 – Antenna support (left side installation).

a) Mount the pivot bracket (1) to the antenna (2) using 1 M8x35 screw with 1 M8

washer (3) and 2 M8x25 screws with 2 M8 washers (4). Fit the screws finger tight.

b) Mount 1 M8 link screw (5) to a pivot bracket (1) using 1 M8x25 screw with 1

M8 washer (6). Fit the screw loosely.

c) Mount 2 M8x100 screws (7) to the pipe attachment bracket (8) using 2 M8 nuts

(9). Tighten the nuts finger tight.

d) Mount the pipe attachment bracket (8) to the pivot bracket (1) using 1 M8x100

screw (10) and 2 M8 nuts with 3 M8 washers (11). Fit the screw and nuts loosely.

Page 65 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Step 3 – Adapter Plate.

If the adapter plate (2) is already mounted, skip Step 3 and go directly to Step 4.

a) Mount the adapter plate (2) onto the antenna (1) using 4 M10x25 screws with 4

M10 washers (3). First make sure that the adapter plate guide pins are properly

inserted into the feeder (4), then tighten the screws with torque of 33Nm ± 5%.

b) Mount the securing hook (5) to the adapter plate (2) using 1 M4x10 screw (6).

The securing hook can be mounted in two positions. Choose the position that will

be pointing upward when the antenna installation has been completed. Tighten

the screw with torque of 2.6Nm ± 5%.

Page 66 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Step 4 – Interface Plate.

If the Interface plate (1) is already mounted, skip Step 4 and go directly to Step 5.

a) Mount the interface plate (1) to the adapter plate (2) using 2 M6x18 screws (3).

Tighten the screws with torque of 9.1Nm ± 5%.

Step 5 – Selecting Polarization.

Single Polarization: For interface plates (1) with a rectangular interface, it is

possible to choose between vertical polarization (“V”) and Horizontal polarization

(“H”), see Step 5a-5b.

Dual Polarization: For interface plates (1) with a circular interface there is no need

to adjust polarization on the antenna, skip Step 5 and go directly to Step 6.

a) If the required polarization is not correct after step 4, loosen 2 M6x18 screws

(3) and adjust the polarization by lifting and rotating the interface plate (1) 90°.

Align the mark on the interface plate (1) with the required polarization mark (“V”

or “H”) on the adapter plate (2).

b) After adjusting the polarization, reassemble and tighten the screws with torque

of 9.1 Nm ± 5%.

Page 67 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Step 6 – Apply Extra Grease.

For heavier radio equipment it is recommended to add extra grease to the

antenna support, to reduce friction.

a) Apply a layer of grease onto surfaces A and B on Pivot bracket (1).

b) Apply grease onto the thread of the elevation screw (2).

7.3 Antenna Installation Procedure

Tower pipe compatibility: Ø50- Ø120.

The following steps and figures describe a right side installation. See “Assembly:

Step 1 – Left or right side installation”.

a) Hoist and secure the antenna to the pipe using 1 clamp bracket (1) and 2 M8

nuts and 2 M8 washers (2). Rotate the clamp bracket depending on the pipe’s

diameter.

b) Position the antenna so it will point along the radio link path and then tighten

the nuts (3) with torque of 24 Nm ± 5% and nuts (2) with torque of either 24 Nm ±

5% if the pipe is ø66-120mm or 32Nm ± 5% if the pipe is ø50-66mm.

Page 68 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Figure 16: Clamp orientation for pipes Ø50-66mm (32Nm)

Figure 17: Clamp orientation for pipes Ø66-120mm (24Nm)

Page 69 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

7.4 Antenna Alignment Procedure

7.4.1 Elevation Adjustment

a) Ensure that the 3 M8 screws (1) are slightly loose.

b) Rotate the elevation screw to adjust the direction ± 15°.

c) On completion, tighten the screws (1) with torque of 24 Nm ± 5%.

7.4.2 Azimuth Adjustment

a) Ensure that the 3 M8 nuts (2) (3) and 1 M8 screw (4) are slightly loose.

b) Move the M8 nuts (2) along the Azimuth screw to adjust the direction ± 15°.

c) On completion, tighten the nuts (2) (3) and screw (4) with torque of 24 Nm ± 5%.

Page 70 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

7.5 Installation Instructions for 2 ft Antenna

List of Items

Item Description Quantity Remarks

A Antenna 1

B Antenna support (Box) (not preassembled) 1

Pipe attachment bracket 1

Clamp bracket 1

Pivot bracket 1

M8 link screw (and M8 nut) 1

M8x100 screw 3

M8x35 screw 1

M8x25 screw 3

Washer M8 9

M8 nut 6

C Feeder kit 1

Feeder 1

M4x10 screw 4

D Radio interface (not preassembled) 1

Interface plate 1

Adapter plate 1

Securing hook 1

M10x25 screw 4

M6x18 screw (countersunk) 2

M4x10 screw 1

Washer M10 4

E Grease (not preassembled) 1

Page 71 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Page 72 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Required Tools

Required Tool Head Size Thread Size Torque Nm

Allen Key 3 mm M4 2.6

Allen Key 4 mm M6 9.1

Allen Key 8 mm M10 33

Combination Wrench (ring/open jaw) 13 mm M8 24/32

Socket wrench and sockets 13 mm M8 24/32

Tool for torque levels 2.6 Nm – 33 Nm

Unpacking

If the feeder is not pre-installed, remove it from its packaging carefully. Avoid any

contact with the top of the feeder. Before starting with the installation, make sure

to remove any protection tapes covering the waveguide openings.

Please the antenna on a flat, clean surface, such as the top of the packing

material.

Handle the Feeder carefully at all times.

Page 73 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

7.6 Antenna Assembly Procedure

Step 1 – Radome

a) Detach the spherical radome (1) from the reflector (2) by unscrewing 1 M4

screw and 1 square nut (3).

b) Dismount the edge ring (4) and turn the spherical radome (1) 180°.

c) Reattach the spherical radome (1) and edge ring (4) to the reflector (2) using

the same M4 screw and square nut (3).

d) Align the opening of the edge ring (5) to one of the two drain holes in the

reflector (6), depending on whether a left or right side installation is required. The

opening of the edge ring (5) should be facing downward after installation has

been completed. (See “Assembly: Step 2 - Left or right side installation”).

e) Tighten the screw with torque of 2.6Nm ± 5%.

Page 74 of 83

Ceragon Proprietary and Confidential

Installation and User Guide for FibeAir IP-20S

Step 2 – Left or right side installation

Before proceeding with the installation, you must determine whether a left or

right side installation is required.

For a right side installation, see Step 3.1 – Antenna support (right side

installation).

For a left side installation, see Step 3.2 – Antenna support (left side installation).

Figure 18: Right Side Antenna Installation Figure 19: Left Side Antenna Installation

Step 3.1 – Antenna support (right side installation).

a) Mount the pivot bracket (1) to the antenna (2) using 1 M8x35 screw and 1 M8

washer (3) and 2 M8x25 screws with 2 M8 washers (4). Fit the screws finger tight.