Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Uploaded by

Li LiuCopyright:

Available Formats

Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Uploaded by

Li LiuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Central Business District CBD EAST - Phase 1 of The New Administrative Capital

Uploaded by

Li LiuCopyright:

Available Formats

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

SECTION 232113 - HYDRONIC PIPING

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. This Section includes piping, special-duty valves, and hydronic specialties for hot-water

heating, chilled-water cooling, and condenser water systems; makeup water for these

systems; blowdown drain lines; and condensate drain piping.

B. Related Sections:

1. Section 230719 "HVAC Piping Insulation."

1.3 STANDARDS

A. The following standards are referred to in this section as alternative equivalent standards to

those specified in this section:

1. BS 10 Flanges for bolting pipes, valves and fittings.

2. BS 21 Pipe threads for tubes and fittings where pressure-type joints are made on

threads (metric dimensions).

3. BS EN 10255 Non-alloy steel tubes suitable for welding and threading. Technical

delivery conditions.

4. BS EN 1044 Filler metals for brazing.

5. BS EN 10253-1 Butt-welding pipe fittings. Wrought carbon steel for general use and

without specific inspection requirements.

6. BS EN 10253-2 Butt-welding pipe fittings. Non alloy and ferritic alloy steels with

specific inspection requirements.

7. BS EN 1092-1 Flanges and their joints. Circular flanges for pipes, valves, fittings

and accessories, PN designated. Steel flanges.

8. API American Petroleum Institute.

9. Or other equivalent relevant EN standards.

1.4 [DEFINITIONS

A. Welding inspector: Mechanical Engineer, Certified Welding Inspector (CWI) or

(CSWIP3.1) and shall have minimum 10 years’ experience.

B. Painting inspector: BSC chemical, certified painting inspector (BGAS CSWIP) or (NACE)

level II and shall have minimum 10 years’ experience.

C. NDT inspector: NDT personal certified as level II minimum in the NDE methods utilized.

HYDRONIC PIPING 232113 - Page 1 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

D. Third Party : International inspection company ( GL,LG,BV,TUV,…etc)]

1.5 SUBMITTALS

A. Quality Manual and Quality plan for Contractor and its related Sub Contractors including:

1. Inspection Test Plan (ITP) for Manufacturing , Fabrication and installation

2. NDT procedures and shall be prepared by certified ASNT NDE Level III and

approved & stamped by 3rd Party Level III.

3. Organization Chart, CV’s and certificates for each personal including NDT Company

and Third Party Company; Third party Engineers shall have minimum 10 years’

experience.

4. Product Data: For each type of special-duty valve indicated. Include flow and

pressure drop curves based on manufacturer's testing for diverting fittings, calibrated

balancing valves and automatic flow-control valves.

B. Shop Drawings: Detail fabrication of piping Isometric & spools, pipe anchors, hangers,

special pipe support assemblies, alignment guides, expansion joints and loops, and their

attachment to the building structure. Detail location of anchors, alignment guides, welding

map and expansion joints and loops.

C. Proposal Welding Procedure Specification (PWPS).

D. Welding Procedure Specification (WPS) supported by Procedure Qualification Record

(PQR).

E. Welder Qualification Certificates.

F. Original Mill Certificates for piping, fitting, filler metal,…etc.

G. Release for shipment for ERW, Seam weld & spiral weld pipe and Equipment.

H. Calibration Certificate for Equipment and Gauges.

I. Surface preparation, Insulation and protection Coating procedures

J. Handling and storage procedures

K. Field Test Reports: Written reports of tests specified in Part 3 of this Section. Include the

following:

1. Test procedures used.( NDT Procedures, Hydrostatic& leak test procedures,…etc)

2. Test results that comply with standards and specifications requirements.

3. Failed test results and corrective action taken to achieve requirements.

L. Maintenance Data: For hydronic specialties and special-duty valves to include in

maintenance manuals specified in Division 1.

1.6 QUALITY ASSURANCE

A. Retain option below if section 1.4 is retained or if required for special projects Surface

preparation for all steel pipes: Shot blasting to SA 2.5 and then immediate application of 150

µm polyamide epoxy paint to be confirmed for proper bonding with pre-insulated pipes

HYDRONIC PIPING 232113 - Page 2 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

manufacturer , and the contractor shall employ a certified painting inspector to be

responsible.

B. Welding: Qualify processes and operators according to the ASME Boiler and Pressure

Vessel Code: Section IX, "Welding and Brazing Qualifications" and ASME B31.1 or

ASME B31.9 as applicable. Welders shall be certified for the type of pipe material specified,

welding process and position of welds required during fabrication of the piping. Welder’s

Qualification Test to be performed on site and attended by Contractor Welding Inspectors,

Third Party and Engineer prior to commencing piping fabrication.

C. Non destructive examination shall be performed to all pipe welds in accordance to ASME

B31.1 or ASTM B31.9 as applicable. A Non destructive test shall perform the tests and

submit the related reports after getting the approval and stamping of third party inspection

company, prior prequalification approval should be obtained from Engineer on NDT &

Third Party Inspection both companies.

D. All welds shall be identified by the welder’s mark and a sequence number. The Contractor

shall employ a Certified Welding Inspector (CWI) or CSWIP 3.1, NDT personal certified as

Level 2 minimum in the NDE methods utilized (independent of the contractor fabricating or

installing the piping) to visually examine all welds in accordance with inspection and

examination requirements of ASME B31.1 or ASME B31.9 as applicable. Any welds

failing the visual or NDE inspection shall be ground out or cutout, re-welded and radio

graphed at the expense of the Contractor. The CWI shall submit a written report signed and

stamped from the approved third party for each weld to the Engineer.

E. Additionally, 5% of all fitting, flange and Butt joint welds shop or field or as per ASME

requirements, minimum of 5% of Butt Joints welds, randomly selected by the Engineer,

shall be radio graphed at the expense of the contractor. The certified welding inspector shall

examine the films and provide a written report to the Engineer. All welds not meeting the

requirements of ASME B31.1 or ASME B31.9 latest edition as applicable will be ground

out, re-welded and re-radio graphed at the expense of the Contractor. If any 10% of the

randomly selected radio graphed welds fail, all welds in the piping will be radio graphed and

repaired at the expense of the contractor.

F. High rejection rate welders (with rejection rate of 25%or more) will be revoked from the

project

G. 10 % of Fillet Joints shall be tested by Dye Pentrent Test Or Magnetic Test

H. ASME Compliance: Comply with ASME B31.1 and ASME B31.9 as applicable for

materials, products, and installation. Safety valves and pressure vessels shall bear the

appropriate ASME label. Fabricate and stamp air separators and expansion tanks to comply

with the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1.

I. All pre-insulated piping systems shall be completely sealed and waterproof, and they shall

be capable of allowing sufficient movement for thermal expansion and contraction. Each

assembly shall be factory-designed for the specific service medium, temperature, and

pressure. Expansion loops, expansion joints, anchors, and guides shall be furnished and

installed to provide a trouble-free system and avoid stress on any equipment.100% Welding

joints of Pre-insulated piping spools shall be tested by RT , RT films shall interpretation by

approved 3rd party

J. The pre-insulated pipe manufacturer shall comply with the inspection requirements of BS

EN 253 or approved equal.

HYDRONIC PIPING 232113 - Page 3 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

K. On Site Supervision of Underground Pre-insulated Chilled Water Piping Installation:

1. The pre-insulated pipe manufacturer shall have a determined quality assurance

program to ensure compliance with specifications.

2. All inner insulation to be visually inspected to ensure absence of any void prior to the

application of jacket.

3. The following tests shall be performed on daily basis to ensure quality of installation:

a. Density (greater or equal to 60 Kg/m3)

b. Thermal conductivity (smaller or equal to 0.023 W/m°C)

c. Compressive strength (greater or equal to 300 KPa)

d. Closed cell content (greater or equal to 88%)

4. Full Time Factory trained field technical assistance & supervision shall be provided

by pre-insulated manufacturer during installation.

5. Representative's daily written reports to the Resident Engineer: Present the original of

each report on the day it is prepared. The report shall be signed by the manufacturer's

representative. The report shall state whether or not the condition and quality of the

materials used and the installation of the system is in accordance with the plans,

specifications, and published standards of the manufacturer, and is satisfactory in all

respects. If anything connected with the installation is unsatisfactory, the report shall

state that corrective action has been taken or shall contain the manufacturer's

recommendations for corrective action. The report shall cover any condition that

could result in an unsatisfactory installation. The representative shall take prompt

action to return to the factory all damaged and defective material, and shall order

prompt replacement of such material.

6. On completion of the installation, the Contractor shall deliver to the Resident

Engineer a certificate from the manufacturer that the installation is in compliance

with all installation recommendations and warranty requirements of the manufacturer.

1.7 COORDINATION

A. Coordinate layout and installation of hydronic piping and suspension system components

with other construction, including light fixtures, HVAC equipment, fire-suppression-system

components, and partition assemblies.

B. Coordinate pipe sleeve installations for foundation wall penetrations.

C. Coordinate piping installation with roof curbs, equipment supports, and roof penetrations.

D. Coordinate pipe fitting pressure classes with products specified in related Sections.

E. Coordinate size and location of concrete bases. Cast anchor-bolt inserts into base..

F. Coordinate installation of pipe sleeves for penetrations through exterior walls and floor

assemblies. Coordinate with requirements for firestopping specified in Section "Penetration

Firestopping" for fire and smoke wall and floor assemblies.

1.8 DELIVERY, STORAGE and HANDLING

A. Products shall be delivered in original, unbroken packages, containers, or bundles bearing

the name of the manufacture.

HYDRONIC PIPING 232113 - Page 4 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

B. Products shall be carefully stored in a manner that will prevent damage and in an area that is

protected from the elements.

C. End caps weather supplied by the piping manufacturer or fabricated by the contractor are to

be placed at the ends of the piping sections to keep debris and reptiles from entering inside

the pipe while it is placed in storage.

D. Prefabricated sections of the pre-insulated pipe are to be handled per the manufacturer’s

recommendations or instructions.

E. All pre-insulated pipes shall be protected from direct sunlight while transported or stored.

1.9 EXTRA MATERIALS

A. Water Treatment Chemicals: Furnish sufficient chemicals for initial system startup and for

preventive maintenance for one year from date of Substantial Completion.

1.10 WARRANTY

A. Manufacturer's warranty form in which manufacturer agrees to repair or replace components

that fails in materials or workmanship within specified warranty period.

PART 2 - PRODUCTS

2.1 PIPING MATERIALS

A. General: Refer to Part 3 "Piping Applications" Article for applications of pipe and fitting

materials.

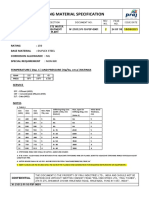

2.2 PIPE AND TUBING

A. Minimum steel pipe size recommended for hydronic piping is NPS 3/4 (DN 20).

B. Chilled Water (above ground), Heating Water (above ground), Condenser Water (above

ground), and Vent Piping:

1. Steel pipes DN 50 and smaller: ASTM A53/A53M Grade B, ERW, Schedule 40 with

threaded ends.

2. Steel pipes DN 50 and up to DN 250: ASTM A53/A53M Grade B or ASTM

A106/A106M Grade B, ERW, Schedule 40 with beveled ends for butt welding

downstream the heat exchanger and could be accepted as roll Grooved ends for

Coupled Joints.

3. Steel pipes DN 300 to DN 600: ASTM A53/A53M Grade B, or ASTM A106/A106M

Grade B, ERW, and beveled ends for butt welding downstream the heat exchanger

and could be accepted as roll Grooved ends for Coupled Joints.

4. Pipes above DN 600: API 5L Grade B, SAW at both sides with helical seam and

beveled ends for butt welding downstream the heat exchanger and could be accepted

as roll Grooved ends for Coupled Joints.

5. Minimum wall thickness shall be in accordance with the calculation based on ASME

B31.1 to verify that wall thickness is adequate enough as per actual system pressure:

HYDRONIC PIPING 232113 - Page 5 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

C. Extension of Domestic Water Make-up Piping: as specified for Domestic water piping.

Refer to section 221116 “Domestic Water Piping”.

D. Cooling Coil Condensate Drain Piping:

1. From air handling units: Schedule 40, PVC Pipe with solvent-welded joints.

2. From fan coil or other terminal units: Schedule 40, PVC Pipe with solvent-welded

joints.

2.3 FIELD APPLIED INSULATION:

A. Insulation for valves, fittings, field casing closures, as required, and other piping system

accessories shall be cellular glass conforming to ASTM C552, calcium silicate conforming

to ASTM C533 or polyurethane matching the pipe insulation. Insulation shall be pre-

molded, precut or job fabricated to fit and shall be removable and reusable. Thickness shall

match adjacent piping.

B. Metal jackets shall be provided for all pipe insulation in manholes. Insulation bands shall be

19 mm wide 0.13 mm stainless steel.

C. Buried fittings and accessories shall be factory fabricated and may have field foamed

polyurethane insulation to match adjacent piping and shall be protected with a covering

matching the pipe casing. Shrink sleeves shall be provided over casing connection joints.

2.4 END SEALS:

A. General: Each pre-insulated section of piping shall have a complete sealing of the insulation

to provide permanent water and vapor seal at each end of the pre-insulated section of piping.

Pre-insulated sections of piping modified in the field shall be provided with an end seal

which is equivalent to the end seals furnished with the pre-insulated section of piping.

Provide complete sealing of the insulation at each end of each pre-insulated conduit section

by one of the following methods:

1. Carrying the outer casing over tapered pipe insulation ends and extending it to the

carrier pipe. Provide sufficient surface bonding area between the casing and the

carrier pipe to ensure a permanent water and vapor resistant seal.

2. Using specially designed prefabricated caps made of the same material and not less

than the same thickness as the casing. Provide sufficient surface bonding area

between the cap, and both the casing and carrier pipe, to ensure permanent water and

vapor resistant seal.

B. Factory casing and end seal testing and certification:

1. Testing and certification procedures by an independent testing laboratory shall

demonstrate that casings and end seals are capable of resisting penetration of water

into the casing and insulation at 60 kPa of head pressure, measured above the highest

point of the test sample, subjected over the entire surface of an 2.5 m test sample of

prefabricated pipe for not less than 48 hours. Test shall use 24 degrees C water for

chilled water service, while the sample is either buried or encased in dry bedding sand

with a minimum of 305 mm of sand all around sample. The carrier pipe size in the

test section shall be 75 mm in diameter and shall be restrained during the test period.

The insulation thickness shall not exceed the maximum thickness provided for the

piping in the project.

HYDRONIC PIPING 232113 - Page 6 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

2.5 JOINTS:

A. Welded joints: Welded joints between sections of pipe and between pipe and fittings shall

be provided where specified or indicated. Branch connections shall be made with either

welding tees or forged branch outlet fittings attached to the main and reinforced against

external strains.

B. Flanged joints: Flanged joints shall be provided with gaskets and made perfectly square and

tight. Full-faced gaskets shall be used with cast-iron flanges and all gaskets shall be as thin

as the finish of the flange face permits. Gaskets shall be 5 mm (3/16-inch) thick for 25

through 300 mm (1 through 12 inch) flanges and 6 mm (1/4-inch) thick for flanges 350 mm

(14 inches) and larger.

C. Threaded joints: Joints shall be made tight with polytetrafluoroethylene tape applied to the

male threads only. Not more than three threads shall show after the joint is made up.

D. Solder Filler Metals: ASTM B 32, lead-free alloys. Include water-flushable flux according

to ASTM B 813.

E. Brazing Filler Metals: AWS A5.8/A5.8M, BCuP Series, copper-phosphorus alloys for

joining copper with copper; or BAg-1, silver alloy for joining copper with bronze or steel.

F. Mechanical joints: Sleeve and grooved pipe couplings shall be installed and protected

against corrosion as recommended by the coupling manufacturer. Joints between

nonmetallic and metallic carrier pipe shall be designed and furnished by the piping system

manufacturer. The transition pieces shall be factory fabricated and shall be designed so that

no field chemical welding of the carrier pipe will be required. Transitional joint connections

to manhole steel piping shall be made inside the manhole except for prefabricated, pre-piped

manholes where joints shall be outside the manhole wall.

G. Insulating joints and dielectric fittings: Shall be installed where shown.

H. Nonmetallic pipe joints: Nonmetallic pipe joints shall be installed in accordance with the

written instructions of the manufacturer.

2.6 FITTINGS FOR STEEL PIPE

A. General

1. The pipes fittings shall be to ASTM A234/A234M WPB, ASTM A105/A105M or

ASTM A53/A53M Grade B, suitable for butt welding, seamless or ERW and

thickness as per matching pipe.

2. All Butt welded fittings shall be in accordance with ASME B16.9, socket welded

fittings shall be to ASME B16.11.

3. Mechanical coupled joints are allowed as alternative in mechanical rooms and chiller

house but not in pre-insulated pipes running in culverts or tunnels.

4. Manufacture trade name to be marked on pipes and fitting

B. 50 mm and Smaller: Screwed. Mechanical couplings are optional for water piping only.

1. Fitting shall have same wall thickness as pipes.

2. Pipes 50 mm and smaller shall have threaded ends.

3. Forged steel, socket welding or threaded: ASME B16.11.

HYDRONIC PIPING 232113 - Page 7 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

4. Screwed: 150 pound malleable iron, ASME B16.3. 125 pound cast iron, ASME

B16.4, may be used in lieu of malleable iron. Bushing reduction of a single pipe size,

or use of close nipples, is not acceptable.

5. Unions: ASME B16.39.

6. Water hose connection adapter: Brass, pipe thread to 20 mm garden hose thread, with

hose cap nut.

C. 65 mm and Larger: Welded or flanged joints. Mechanical couplings and fittings are optional

for water piping only.

1. Pipe fitting material shall be to ASTM A 234/A 234M WPB, ASTM A105/A105M or

ASTM A53/A53M Grade B ERW.

2. Butt welding fittings: ASME B16.9 with same wall thickness as connecting piping.

Elbows shall be long radius type, unless otherwise noted.

3. Socket welded fittings shall be in accordance with ASME B16.11.

4. Welding flanges and bolting: ASME B16.5:

a. Water service: Weld neck or slip-on, plain face, with 6 mm (1/8 inch) thick full

face neoprene gasket suitable for 104 degrees C (220 degrees F).

1) Contractor's option: Convoluted, cold formed 150 pound steel flanges,

with Teflon gaskets, may be used for water service.

b. Flange bolting: Carbon steel machine bolts or studs and nuts, ASTM A307,

Grade B.

D. Welded Branch and Tap Connections: Forged steel weldolets, or branchlets and threadolets

may be used for branch connections up to one pipe size smaller than the main. Forged steel

half-couplings, ASME B16.11 may be used for drain, vent and gage connections.

E. Mechanical Pipe Couplings and Fittings: If used and accepted by The Engineer shall be used

with roll grooved pipe, in water service up to 110 degrees C (230 degrees F).

1. Grooved mechanical couplings: Malleable iron, ASTM A47/A47M or ductile iron,

ASTM A536, fabricated in two or more parts, securely held together by two or more

track-head, square, or oval-neck bolts, ASTM A183.

2. Gaskets: Rubber product recommended by the coupling manufacturer for the

intended service.

3. Grooved end fittings: Malleable iron, ASTM A47/A47M; ductile iron, ASTM A536;

or steel, ASTM A53/A53M or ASTM A106/A106M, designed to accept grooved

mechanical couplings. Tap-in type branch connections are acceptable.

2.7 FITTINGS FOR COPPER TUBING

A. Solder Joint:

1. Joints shall be made up in accordance with recommended practices of the materials

applied. Apply 95/5 tin and antimony on all copper piping.

2. Mechanically formed tee connection in water and drain piping: Form mechanically

extracted collars in a continuous operation by drilling pilot hole and drawing out tube

surface to form collar, having a height of not less than three times the thickness of

tube wall. Adjustable collaring device shall insure proper tolerance and complete

uniformity of the joint. Notch and dimple joining branch tube in a single process to

provide free flow where the branch tube penetrates the fitting.

HYDRONIC PIPING 232113 - Page 8 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

B. Bronze Flanges and Flanged Fittings: ASME B16.24.

2.8 FITTINGS FOR PLASTIC PIPING

A. PVC Plastic Pipe fittings socket-type, schedule 40, ASTM D2466.

1. PVC Solvent Cement: ASTM D2564-04el.

B. Chemical feed piping for condenser water treatment: Chlorinated polyvinyl chloride

(CPVC), Schedule 80, ASTM F439.

2.9 DIELECTRIC FITTINGS

A. Provide where copper tubing and ferrous metal pipe are joined.

B. 50 mm and Smaller: Threaded dielectric union, ASME B16.39.

C. 65 mm and Larger: Flange union with dielectric gasket and bolt sleeves, ASME B16.42.

D. Temperature Rating, 99 degrees C.

2.10 SCREWED JOINTS

A. Pipe Thread: ANSI B1.20.1.

B. Lubricant or Sealant: Oil and graphite or other compound approved for the intended service.

C. Grooved Mechanical-Joint Fittings: ASTM A 536, Grade 65-45-12 ductile iron;

ASTM A 47/A 47M, Grade 32510 malleable iron; ASTM A 53/A 53M, Type F, E, or S,

Grade B fabricated steel; or ASTM A 106/A 106M, Grade B steel fittings with grooves or

shoulders designed to accept grooved end couplings.

D. Grooved Mechanical-Joint Couplings: Ductile- or malleable-iron housing and synthetic

rubber gasket of central cavity pressure-responsive design; with nuts, bolts, locking pin,

locking toggle, or lugs to secure grooved pipe and fittings.

E. Welding Materials: Comply with Section II, Part C, of the ASME Boiler and Pressure

Vessel Code for welding materials appropriate for wall thickness and for chemical analysis

of pipe being welded.

F. Gasket Material: Thickness, material, and type suitable for fluid to be handled; and design

temperatures and pressures.

2.11 VALVES

A. Gate, globe, check, ball, butterfly valves and motorized valves are specified in Section

"General-Duty Valves for HVAC Piping."

B. Asbestos packing is not acceptable.

C. All valves of the same type shall be products of a single manufacturer. Provide gate and

globe valves with packing that can be replaced with the valve under full working pressure.

HYDRONIC PIPING 232113 - Page 9 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

D. Provide chain operators for valves 100 mm (4 inches) and larger when the centerline is

located 2400 mm (8 feet) or more above the floor or operating platform.

E. Refer to Part 3 "Valve Applications" Article for applications of each valve.

F. Dynamic Water Flow Balancing Valves, used for balancing, shut off and measuring of

pressure drop. Balancing valves shall be provided with two measuring nipples to have the

possibility to measure the differential pressure (water flow indirectly) through the balancing

valve and a tight shut off function with a hidden memory of the setting. Each valve shall be

provided with a label including at least the valve reference number, valve’s diameter, design

flow, setting after balancing and pressure drop in setting and design position. All valves

shall be supplied with Prefab insulation material sourced from the valve manufacturer, made

of Polyurethane, volume weight 50-60 Kg/cubic m.

G. Dynamic Water Flow Balancing Valves, DN 50 (NPS 2) and Smaller: bronze body, fitted

with a red nylon hand-wheel and a protection cap, 1035-kPa (150 psig) working pressure,

107 deg C (225 deg F) maximum operating temperature, and having threaded end

connections.

H. Dynamic Water Flow Balancing Valves, DN 65 (NPS 2-1/2) and Larger: Y-pattern globe

valve style, Cast-iron or steel body, fitted with seat seal cone, bonnet bolts chromed steel

and digital hand wheel, 1035-kPa (150 psig) working pressure, 107 deg C (225 deg F)

maximum operating temperature, and having flanged or grooved connections.

I. Pressure-Reducing Valves: Diaphragm-operated, bronze or brass body with low inlet

pressure check valve, inlet strainer removable without system shutdown, and noncorrosive

valve seat and stem. Select valve size, capacity, and operating pressure to suit system.

Valve shall be factory set at operating pressure and have capability for field adjustment.

J. Safety Valves: Diaphragm-operated, bronze or brass body with brass and rubber, wetted,

internal working parts; shall suit system pressure and heat capacity and shall comply with

the ASME Boiler and Pressure Vessel Code, Section IV: Heating Boilers, Bear ASME

stamp

K. Pressure Relief Valve: Bronze or iron body and bronze or stainless steel trim, with testing

lever. Comply with ASME Code for Pressure Vessels, Section 8; bear ASME stamp.

L. Automatic Dynamic Flow-Control Valves: Gray-iron body, factory set to maintain constant

flow with plus or minus 5 percent over system pressure fluctuations, and equipped with a

readout kit including flow meter, probes, hoses, flow charts, and carrying case. Each valve

shall have an identification tag attached by chain, and be factory marked with the zone

identification, valve number, and flow rate. Valve shall be line size and one of the following

designs:

1. Gray-iron or brass body, designed for 1206 kPa (175 psig) at 93 deg C (200 deg F)

with stainless-steel piston and spring.

2. Brass or ferrous-metal body, designed for 2068 kPa (300 psig) at 121 deg C (250

deg F) with corrosion-resistant, tamperproof, self-cleaning, piston-spring assembly

easily removable for inspection or replacement.

3. Combination assemblies, including bronze ball valve and brass alloy control valve,

with stainless-steel piston and spring, fitted with pressure and temperature test valves,

and designed for 2067 kPa (300 psig) at 121 deg C (250 deg F).

M. Triple Duty Valve: Contractors option for use at pump discharge in lieu of check valve and

balancing/shut-off valve. Triple duty valve is a non-slam check valve with spring-loaded

HYDRONIC PIPING 232113 - Page 10 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

weighted disc and a calibrated adjustment feature permitting regulation of pump discharge

flow and shut-off. Valves shall be designed to permit repacking under full line pressure.

Unit shall be installed on discharge side of pump in a horizontal or vertical position with the

stem up. Unit shall be cast iron body construction suitable for maximum working pressure

of 1205 kPa (175 PSI) and maximum operating temperature of 149 C (300 F), bronze disc

and seat, stainless steel stem and spring.

N. Drain Valves: Valves shall be the gate valve types which are in accordance with MSS SP-

80. Valve shall be manually operated, 20 mm pipe size and above with a threaded end

connection. Valve shall be provided with a water hose nipple adapter.

O. Drain Cocks: MSS SP-110, DN20 (3/4-inch NPS) ball valve, rated for 2760 kPa (400-psig)

minimum CWP. Include 2-piece, bronze body with standard port, chrome-plated brass ball,

replaceable seats and seals, blowout-proof stem, and vinyl-covered steel handle.

1. Inlet: Threaded or solder joint.

2. Outlet: Short-threaded nipple with ANSI/ASME B1.20.7 garden-hose thread and

cap.

2.12 HYDRONIC SPECIALTIES

A. Air Vents

1. Manual Air Vent: Bronze body and nonferrous internal parts; 1035-kPa (150-psig)

working pressure; 107 deg C (225 deg F) operating temperature; manually operated

with screwdriver or thumbscrew; with DN 6 (NPS 1/8) discharge connection and

DN 15 (NPS 1/2) inlet connection.

2. Automatic Air Vent: Designed to vent automatically with float principle; bronze

body and nonferrous internal parts; 1035-kPa (150-psig) working pressure; 116 deg C

(240 deg F) operating temperature; with DN 8 (NPS 1/4) discharge connection and

DN 15 (NPS 1/2) inlet connection.

3. Air vents on water coils shall have not less than 3 mm threaded end connections.

4. Air vents on water mains shall have not less than 20 mm threaded end connections.

5. Air vents on all other applications shall have not less than 15 mm threaded end

connections

B. Closed Expansion Tanks: Welded carbon steel, rated for 1206-kPa (175-psig) working

pressure and 121 deg C (250 deg F) maximum operating temperature. Separate air charge

from system water to maintain design expansion capacity by a flexible bladder securely

sealed into tank. Provide sight glass and include drain fitting and taps for pressure gage and

air-charging fitting. Support vertical tanks with steel legs or base; support horizontal tanks

with steel saddles. Factory fabricate and test tank with taps and supports installed and

labeled according to the ASME Boiler & Pressure Vessel Code - Section VIII - Pressure

Vessels, Division 1.

C. Tangential-Type Air Separators: Welded black steel; ASME constructed and labeled for

1206-kPa (175-psig) minimum working pressure and 191 deg C (375 deg F) maximum

operating temperature; perforated stainless-steel air collector tube designed to direct released

air into expansion tank; tangential inlet and outlet connections; threaded connections for

DN 50 (NPS 2) and smaller; flanged connections for DN 65 (NPS 2-1/2) and larger;

threaded blowdown connection. Provide units in sizes for full-system flow capacity.

Applicable to central plants.

HYDRONIC PIPING 232113 - Page 11 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

D. Y-Pattern Strainers: 1035-kPa (150-psig) working pressure; cast-iron body (ASTM A126-

04, Class B), flanged ends for DN 65 (NPS 2-1/2) and larger, threaded connections for

DN 50 (NPS 2) and smaller, bolted cover, perforated stainless-steel basket, and bottom drain

connection.

E. Basket Strainers: 1035-kPa (150-psig) working pressure; high-tensile cast-iron body

(ASTM A126-04, Class B), flanged-end connections, bolted cover, perforated stainless-steel

basket, and bottom drain connection.

F. Flexible Connectors: Stainless-steel bellows with woven, flexible, bronze, wire-reinforcing

protective jacket; 1035-kPa (150-psig) minimum working pressure and 121 deg C (250

deg F) maximum operating temperature. Connectors shall have flanged- or threaded-end

connections to match equipment connected and shall be capable of 20-mm (3/4-inch)

misalignment.

G. Spherical, Rubber, Flexible Connectors: Fiber-reinforced rubber body with steel flanges

drilled to align with Classes 150 and 300 steel flanges; operating temperatures up to 121

deg C (250 deg F) and pressures up to 1035 kPa (150 psig).

H. Packed, Slip, Expansion Joints: 1035-kPa (150-psig) minimum working pressure, steel pipe

fitting consisting of telescoping body and slip-pipe sections, packing ring, packing, limit

rods, flanged ends, and chrome-plated finish on slip-pipe telescoping section.

2.13 WATER FLOW MEASURING DEVICES

A. Minimum overall accuracy plus or minus three percent over a range of 70 to 110 percent of

design flow. Select devices for not less than 110 percent of design flow rate.

B. Venturi Type: Bronze, steel, or cast iron with bronze throat, with valved pressure sensing

taps upstream and at the throat.

C. Wafer Type Circuit Sensor: Cast iron wafer-type flow meter equipped with readout valves

to facilitate the connecting of a differential pressure meter. Each readout valve shall be fitted

with an integral check valve designed to minimize system fluid loss during the monitoring

process.

D. Self-Averaging Annular Sensor Type: Brass or stainless steel metering tube, shutoff valves

and quick-coupling pressure connections. Metering tube shall be rotatable so all sensing

ports may be pointed down-stream when unit is not in use.

E. Flow Measurement/Balance Valves: A system comprised of two valves of bronze and

stainless steel metallurgy designed for 1205 kPa pressure at 121 degrees C, with thermal

insulation sleeve.

F. Measurement and shut-off valve: An on/off ball valve with integral high regain venturi and

dual quick connect valves with integral check valves and color coded safety caps for

pressure/temperature readout.

G. A butterfly balancing valve as specified herein, with memory stop and quick connect valve

for pressure/temperature readout.

H. Flow Measuring Device Identification:

1. Metal tag attached by chain to the device.

HYDRONIC PIPING 232113 - Page 12 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

2. Include meter or equipment number, manufacturer's name, meter model, flow rate

factor and design flow rate in l/m (gpm).

I. Vent and drain hose and two 3000 mm (10 feet) lengths of hose with quick disconnect

connections.

J. Factory fabricated carrying case with hose compartment and a bound set of capacity curves

showing flow rate versus pressure differential.

K. Provide one portable meter for each range of differential pressure required for the installed

flow devices.

L. Permanently Mounted Water Flow Indicating Meters: Minimum 150 mm diameter, or 450

mm long scale, for 120 percent of design flow rate, direct reading in lps with three valve

manifold and two shut-off valves.

2.14 EXPANSION JOINTS

A. Factory built devices, inserted in the pipe lines, designed to absorb axial cyclical pipe

movement which results from thermal expansion and contraction. This includes factory-built

or field-fabricated guides located along the pipe lines to restrain lateral pipe motion and

direct the axial pipe movement into the expansion joints.

B. Manufacturing Quality Assurance: Conform to Expansion Joints Manufacturers Association

Standards.

C. Bellows - Internally Pressurized Type:

1. Multiple corrugations of Type 304 or Type A240-321 stainless steel.

2. Internal stainless steel sleeve entire length of bellows.

3. External cast iron equalizing rings for services exceeding 340 kPa (50 psig).

4. Welded ends.

5. Design shall conform to standards of EJMA and ASME B31.1.

6. External tie rods designed to withstand pressure thrust force upon anchor failure if

one or both anchors for the joint are at change in direction of pipeline.

7. Integral external cover.

D. Bellows - Externally Pressurized Type:

1. Multiple corrugations of Type 304 stainless steel.

2. Internal and external guide integral with joint.

3. Design for external pressurization of bellows to eliminate squirm.

4. Welded ends.

5. Conform to the standards of EJMA and ASME B31.1.

6. Threaded connection at bottom, 25 mm (one inch) minimum, for drain or drip point.

7. Integral external cover and internal sleeve.

E. Expansion Compensators:

1. Corrugated bellows, externally pressurized, stainless steel or bronze.

2. Internal guides and anti-torque devices.

3. Threaded ends.

4. External shroud.

5. Conform to standards of EJMA.

HYDRONIC PIPING 232113 - Page 13 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

F. Expansion Joint Identification: Provide stamped brass or stainless steel nameplate on each

expansion joint listing the manufacturer, the allowable movement, flow direction, design

pressure and temperature, date of manufacture, and identifying the expansion joint by the

identification number on the contract drawings.

G. Guides: Provide factory-built guides along the pipe line to permit axial movement only and

to restrain lateral and angular movement. Guides must be designed to withstand a minimum

of 15 percent of the axial force which will be imposed on the expansion joints and anchors.

Field-built guides may be used if detailed on the contract drawings.

2.15 GAGES, PRESSURE AND COMPOUND

A. ASME B40.100, Accuracy Grade 1A, (pressure, vacuum, or compound for air, oil or water),

initial mid-scale accuracy 1 percent of scale (Qualify grade), metal or phenolic case, 115

mm (4-1/2 inches) in diameter, 6 mm (1/4 inch) NPT bottom connection, white dial with

black graduations and pointer, clear glass or acrylic plastic window, suitable for board

mounting. Provide red "set hand" to indicate normal working pressure.

B. Provide brass lever handle union cock. Provide brass/bronze pressure snubber for gages in

water service.

C. Range of Gages: Provide range equal to at least 130 percent of normal operating range.

1. For condenser water suction (compound): Minus 100 kPa (30 inches Hg) to plus 700

kPa (100 psig).

2.16 PRESSURE/TEMPERATURE TEST PROVISIONS

A. Pete's Plug: 6 mm (1/4 inch) MPT by 75 mm (3 inches) long, brass body and cap, with

retained safety cap, nordel self-closing valve cores, permanently installed in piping where

shown, or in lieu of pressure gage test connections shown on the drawings.

B. Provide one each of the following test items to the Resident Engineer:

1. 6 mm (1/4 inch) FPT by 3 mm (1/8 inch) diameter stainless steel pressure gage

adapter probe for extra long test plug. PETE'S 500 XL is an example.

2. 90 mm (3-1/2 inch) diameter, one percent accuracy, compound gage, , –—100 kPa

(30 inches) Hg to 700 kPa (100 psig) range.

3. 0 - 104 degrees C (220 degrees F) pocket thermometer one-half degree accuracy, 25

mm (one inch) dial, 125 mm (5 inch) long stainless steel stem, plastic case.

2.17 THERMOMETERS

A. Mercury or organic liquid filled type, red or blue column, clear plastic window, with 150

mm (6 inch) brass stem, straight, fixed or adjustable angle as required for each in reading.

B. Case: Chrome plated brass or aluminum with enamel finish.

C. Scale: Not less than 225 mm (9 inches), range as described below, two degree graduations.

D. Separable Socket (Well): Brass, extension neck type to clear pipe insulation.

HYDRONIC PIPING 232113 - Page 14 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

E. Scale ranges may be slightly greater than shown to meet manufacturer's standard. Required

ranges in degrees C (F):

1. Chilled Water 0 to 38 degrees C (32-100 degrees F)

PART 3 - EXECUTION

3.1 PIPING APPLICATIONS

A. External chilled water/ heating water pipes and chilled water/ heating water pipes inside

utility culverts or directly buried: Pre-insulated piping. Chilled water/ heating water pipes

inside building: Black steel pipes.

B. Condensate drain pipes: uPVC pipes.

C. Chilled water/ heating water pipes above ground and exposed to outdoors: Black steel pipes.

3.2 VALVE APPLICATIONS

A. General-Duty Valve Applications: Unless otherwise indicated, use the following valve

types:

1. Shutoff Duty: Gate, ball, and butterfly valves.

2. Throttling Duty: Globe and ball valves.

B. Install shutoff duty valves at each branch connection to supply mains, at supply connection

to each piece of equipment, unless only one piece of equipment is connected in the branch

line. Install throttling duty valves at each branch connection to return mains, at return

connections to each piece of equipment, and elsewhere as indicated.

C. Install calibrated balancing valves in the return water line of each heating or cooling element

and elsewhere as required to facilitate system balancing.

D. Install silent type check valves at each pump discharge and elsewhere as required to control

flow direction.

E. Install safety valves as required by the ASME Boiler and Pressure Vessel Code. Install

safety-valve discharge piping, without valves, to floor. Comply with the ASME Boiler &

Pressure Vessel Code - Section VIII - Pressure Vessels, Division 1, for installation

requirements.

F. Install pressure-reducing valves on hot-water generators and elsewhere as required to

regulate system pressure.

3.3 PIPING INSTALLATIONS

A. Install groups of pipes parallel to each other, spaced to permit applying insulation and

servicing of valves.

B. Install drains, consisting of a tee fitting, DN 20 (NPS 3/4) ball valve, and short DN 20

(NPS 3/4) threaded nipple with cap, at low points in piping system mains and risers, and

elsewhere as required for system drainage.

HYDRONIC PIPING 232113 - Page 15 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

C. Install piping at a uniform grade of 0.2 percent upward in direction of flow.

D. Reduce pipe sizes using eccentric reducer fitting installed with level side up.

E. Unless otherwise indicated, install branch connections to mains using tee fittings in main

pipe, with the takeoff coming out the bottom of the main pipe. For up-feed risers, install the

takeoff coming out the top of the main pipe.

F. Install strainers on supply side of each control valve, pressure-reducing valve, solenoid

valve, in-line pump, and elsewhere as indicated. Install DN 20 (NPS 3/4) nipple and ball

valve in blowdown connection of strainers DN 50 (NPS 2) and larger. Match size of strainer

blowoff connection for strainers smaller than DN 50 (NPS 2).

G. Anchors shall be provided wherever necessary or indicated to localize expansion or to

prevent undue strain on piping. Anchors shall consist of heavy steel collars with lugs and

bolts for clamping and attaching anchor braces, unless otherwise indicated. Anchor braces

shall be installed in the most effective manner to secure the desired results using turnbuckles

where required. Supports, anchors, or stays shall not be attached where they will injure the

structure or adjacent construction during installation or by the weight of expansion of the

pipeline. Where pipe and conduit penetrations of vapor barrier sealed surfaces occur, these

items shall be anchored immediately adjacent to each penetrated surface, to provide

essentially zero movement within penetration seal. Detailed drawings of pipe anchors shall

be submitted for approval before installation.

3.4 HANGERS AND SUPPORTS

A. Hanger, support, and anchor devices are specified in Section "Hangers and Supports for

HVAC Piping and Equipment." Comply with requirements below for maximum spacing of

supports.

B. Install the following pipe attachments:

1. Adjustable steel clevis hangers for individual horizontal piping less than 6 m long.

2. Adjustable roller hangers and spring hangers for individual horizontal piping 6 m or

longer.

3. Pipe Roller: MSS SP-58 for multiple horizontal piping 6 m or longer, supported on a

trapeze.

4. Spring hangers to support vertical runs.

5. On plastic pipe, install rubber pads or cushions on bearing surfaces to prevent hanger

from scratching pipe.

C. Install hangers for steel piping with the following maximum spacing and minimum rod

sizes:

1. DN 20 (NPS 3/4): Maximum span, 2.1 m; minimum rod size, 10 mm.

2. DN 25 (NPS 1): Maximum span, 2.1 m; minimum rod size, 10 mm.

3. DN 40 (NPS 1-1/2): Maximum span, 2.7 m; minimum rod size, 10 mm.

4. DN 50 (NPS 2): Maximum span, 3 m; minimum rod size, 10 mm.

5. DN 65 (NPS 2-1/2): Maximum span, 3.4 m; minimum rod size, 10 mm.

6. DN 80 (NPS 3): Maximum span, 3.7 m; minimum rod size, 10 mm.

7. DN 100 (NPS 4): Maximum span, 4.3 m; minimum rod size, 13 mm.

8. DN 150 (NPS 6): Maximum span, 5.2 m; minimum rod size, 13 mm.

9. DN 200 (NPS 8): Maximum span, 5.8 m; minimum rod size, 16 mm.

10. DN 250 (NPS 10): Maximum span, 6.1 m; minimum rod size, 19 mm.

HYDRONIC PIPING 232113 - Page 16 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

11. DN 300 (NPS 12): Maximum span, 7 m; minimum rod size, 22 mm.

12. DN 350 (NPS 14): Maximum span, 7.6 m; minimum rod size, 25 mm.

13. DN 400 (NPS 16): Maximum span, 8.2 m; minimum rod size, 25 mm.

14. DN 450 (NPS 18): Maximum span, 8.5 m; minimum rod size, 32 mm.

15. DN 500 (NPS 20): Maximum span, 9.1 m; minimum rod size, 32 mm.

D. Install hangers for drawn-temper copper piping with the following maximum spacing and

minimum rod sizes:

1. DN 20 (NPS 3/4): Maximum span, 1.5 m; minimum rod size, 10 mm.

2. DN 25 (NPS 1): Maximum span, 1.8 m; minimum rod size, 10 mm.

3. DN 40 (NPS 1-1/2): Maximum span, 2.4 m; minimum rod size, 10 mm.

4. DN 50 (NPS 2): Maximum span, 2.4 m; minimum rod size, 10 mm.

5. DN 65 (NPS 2-1/2): Maximum span, 2.7 m; minimum rod size, 10 mm.

6. DN 80 (NPS 3): Maximum span, 3 m; minimum rod size, 10 mm.

E. PVC Piping Hanger Spacing: Space hangers according to pipe manufacturer's written

instructions for service conditions. Avoid point loading. Space and install hangers with the

fewest practical rigid anchor points.

F. Support vertical runs at roof, at each floor, and at 3-m intervals between floors.

3.5 PIPE JOINT CONSTRUCTION

A. Ream ends of pipes and tubes and remove burrs. Bevel plain ends of steel pipe.

B. Remove scale, slag, dirt, and debris from inside and outside of pipe and fittings before

assembly.

C. Soldered Joints: Apply ASTM B 813, water-flushable flux, unless otherwise indicated, to

tube end. Construct joints according to ASTM B 828 or CDA's "Copper Tube Handbook,"

using lead-free solder alloy complying with ASTM B 32.

D. Brazed Joints: Construct joints according to AWS's "Brazing Handbook," "Pipe and Tube"

Chapter, using copper-phosphorus brazing filler metal complying with AWS A5.8/A5.8M.

E. Threaded Joints: Thread pipe with tapered pipe threads according to ASME B1.20.1. Cut

threads full and clean using sharp dies. Ream threaded pipe ends to remove burrs and restore

full ID. Join pipe fittings and valves as follows:

1. Apply appropriate tape or thread compound to external pipe threads unless dry seal

threading is specified.

2. Damaged Threads: Do not use pipe or pipe fittings with threads that are corroded or

damaged. Do not use pipe sections that have cracked or open welds.

F. Welded Joints: Construct joints according to AWS D10.12M/D10.12, using qualified

processes and welding operators according to "Quality Assurance" Article.

G. Flanged Joints: Select appropriate gasket material, size, type, and thickness for service

application. Install gasket concentrically positioned. Use suitable lubricants on bolt threads.

H. Plastic Piping Solvent-Cemented Joints: Clean and dry joining surfaces. Join pipe and

fittings according to the following:

HYDRONIC PIPING 232113 - Page 17 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

1. Comply with ASTM F 402 for safe-handling practice of cleaners, primers, and

solvent cements.

2. CPVC Piping: Join according to ASTM D 2846/D 2846M Appendix.

3. PVC Pressure Piping: Join ASTM D 1785 schedule number, PVC pipe and PVC

socket fittings according to ASTM D 2672. Join other-than-schedule number PVC

pipe and socket fittings according to ASTM D 2855.

4. PVC Nonpressure Piping: Join according to ASTM D 2855.

I. Grooved Joints: Assemble joints with coupling and gasket, lubricant, and bolts. Cut or roll

grooves in ends of pipe based on pipe and coupling manufacturer's written instructions for

pipe wall thickness. Use grooved-end fittings and rigid, grooved-end-pipe couplings.

J. Mechanically Formed, Copper-Tube-Outlet Joints: Use manufacturer-recommended tool

and procedure, and brazed joints.

K. Pressure-Sealed Joints: Use manufacturer-recommended tool and procedure. Leave insertion

marks on pipe after assembly.

L. Mechanical and Heat Fusion Joints: Assemble joints according to fitting manufacturer’s

written instructions.

3.6 HYDRONIC SPECIALTIES INSTALLATION

A. Install manual air vents at top of risers and high points in piping, at heat-transfer coils, and

elsewhere as required for system air venting.

B. Install automatic air vents in mechanical equipment rooms only at high points of system

piping, at heat-transfer coils, and elsewhere as required for system air venting.

C. Install combination air separator and strainer in pump suction lines. Install piping to

compression tank with a 2 percent upward slope toward tank. Install blowdown piping with

gate valve; extend to nearest drain.

D. Install expansion tanks on floor. Vent and purge air from hydronic system, and ensure tank

is properly charged with air to suit system design requirements.

3.7 TERMINAL EQUIPMENT CONNECTIONS

A. Size for supply and return piping connections shall be same as for equipment connections.

B. Install control valves in accessible locations close to connected equipment.

C. Install bypass piping with globe valve around control valve. If multiple, parallel control

valves are installed, only one bypass is required.

D. Install ports for pressure and temperature gages at coil inlet connections.

3.8 FIELD QUALITY CONTROL

A. Prepare hydronic piping according to ANSI/ASME B31.9 and as follows:

1. Leave joints, including welds, uninsulated and exposed for examination during test.

HYDRONIC PIPING 232113 - Page 18 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

2. Provide temporary restraints for expansion joints that cannot sustain reactions due to

test pressure. If temporary restraints are impractical, isolate expansion joints from

testing.

3. Flush system with clean water. Clean strainers.

4. Isolate equipment from piping. If a valve is used to isolate equipment, its closure

shall be capable of sealing against test pressure without damage to valve. Install

blinds in flanged joints to isolate equipment.

5. Install safety valve, set at a pressure no more than one-third higher than test pressure,

to protect against damage by expanding liquid or other source of overpressure during

test.

B. Perform the following tests on hydronic piping:

1. Use ambient temperature water as a testing medium unless there is risk of damage

due to freezing. Another liquid that is safe for workers and compatible with piping

may be used.

2. While filling system, use vents installed at high points of system to release trapped

air. Use drains installed at low points for complete draining of liquid.

3. Check expansion tanks to determine that they are not air bound and that system is full

of water.

4. Subject piping system to hydrostatic test pressure that is not less than 1.5 times the

design pressure. Test pressure shall not exceed maximum pressure for any vessel,

pump, valve, or other component in system under test. Verify that stress due to

pressure at bottom of vertical runs does not exceed either 90 percent of specified

minimum yield strength or 1.7 times "SE" value in Appendix A of ANSI/ASME

B31.9, "Building Services Piping."

5. After hydrostatic test pressure has been applied for at least 10 minutes, examine

piping, joints, and connections for leakage. Eliminate leaks by tightening, repairing,

or replacing components, and repeat hydrostatic test until there are no leaks.

6. Prepare written report of testing.

C. In addition to mentioned code requirements, ensure the following further specific

requirements for welding joints in hydronic piping:

a. Primary welding procedure specification to be submitted for review and

approval by welding engineer.

b. Procedure qualification to be done prior to any welding activity on site.

c. Welder qualification test to be done prior to any welding activity on site.

d. Mill certificate for consumable material “Electrode, flux,..etc” to be submitted

for review and approval and the mechanical test for electrode material may be

required.

e. Heat input during welding is important value so the visual inspection for

welding activity “before, during and after” welding is required.

3.9 ADJUSTING

A. Mark calibrated nameplates of pump discharge valves after hydronic system balancing has

been completed, to permanently indicate final balanced position.

B. Perform these adjustments before operating the system:

HYDRONIC PIPING 232113 - Page 19 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

Central Business District CBD EAST – Phase 1

Of the New Administrative Capital

1. Open valves to fully open position. Close coil bypass valves.

2. Check pump for proper direction of rotation.

3. Set automatic fill valves for required system pressure.

4. Check air vents at high points of system and determine if all are installed and

operating freely (automatic type), or bleed air completely (manual type).

5. Set temperature controls so all coils are calling for full flow.

6. Check operation of automatic bypass valves.

7. Check and set operating temperatures of boilers, chillers, and cooling towers to

design requirements.

8. Lubricate motors and bearings.

3.10 PAINTING

A. All exposed surfaces of ferrous and non-ferrous piping outdoors or indoors in equipment

rooms and exposed to view in occupied spaces shall be cleaned, primed and painted.

B. Refer to Sections "Interior Painting" and "Exterior Painting" for painting requirement.

3.11 CLEANING

A. Flush hydronic piping systems with clean water. Remove and clean or replace strainer

screens. After cleaning and flushing hydronic piping systems, but before balancing, remove

disposable fine-mesh strainers in pump suction diffusers.

B. Coordinate with HVAC water treatment Sub-Contractor for flushing requirement to ensure

adequacy of flushing prior to Chemical Treatment.

C. Submit cleaning and flushing method statements for Engineer approval.

END OF SECTION 232113

HYDRONIC PIPING 232113 - Page 20 of 20

E18066-0105D-FD-18-G00-SPC-ME-01 REV 0

You might also like

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- QYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementDocument6 pagesQYD-QCP-MS-001 Tank Shell Weld Repair Procedure-Method StatementAbdul Khaleem KhanNo ratings yet

- AWWA C 204 Mortar Lined MS PipeDocument19 pagesAWWA C 204 Mortar Lined MS PipeAnonymous D66WHl100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- compliance sheet of euroclima加承包商Document9 pagescompliance sheet of euroclima加承包商Li Liu100% (1)

- FM IS Standard 3615Document33 pagesFM IS Standard 3615SureshNo ratings yet

- Oce Som S4 03 007 Ocz ZZ SP XX 232113Document14 pagesOce Som S4 03 007 Ocz ZZ SP XX 232113Arafa SalemNo ratings yet

- 232113-Hydronic PipingDocument39 pages232113-Hydronic PipingMohamed SokarNo ratings yet

- SPCC PTM P Ts 001 Rev BDocument27 pagesSPCC PTM P Ts 001 Rev BDan MorganNo ratings yet

- AnnexuresDocument29 pagesAnnexuresammarashraf91No ratings yet

- (0018) 2.3 - SteelWaterPipe - Aug2011Document14 pages(0018) 2.3 - SteelWaterPipe - Aug2011Sixto GerardoNo ratings yet

- Mechanical SpecificationsDocument83 pagesMechanical SpecificationsMohamed EidNo ratings yet

- Technical Specifications For Reduction Retort Bottom SectionDocument5 pagesTechnical Specifications For Reduction Retort Bottom SectionSharat ChandraNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam Prabhakaran100% (1)

- Rubber Gasket TypesDocument92 pagesRubber Gasket Typessushant_moreyNo ratings yet

- SECTION 15061 Steel Pipe Specification - Transmission MainDocument9 pagesSECTION 15061 Steel Pipe Specification - Transmission MainMohammad AlizadehNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- Steel Pipe, CMLC - Rev 3-17Document18 pagesSteel Pipe, CMLC - Rev 3-17A T AlhershNo ratings yet

- Spec 2Document637 pagesSpec 2Waqar KhanNo ratings yet

- C.1 Method Statement For Fabrication of Pipe and FittingsDocument23 pagesC.1 Method Statement For Fabrication of Pipe and Fittingsagbon johnNo ratings yet

- 23.6.10Document3 pages23.6.10Emad GanebNo ratings yet

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocument15 pagesAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENo ratings yet

- Facility Sanitary SewersDocument14 pagesFacility Sanitary SewerssamNo ratings yet

- Hamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPDocument29 pagesHamad International Airport Jet Fuel System Expansion: 00 31/01/2019 Issued For Construction Ms LW LW DPsrp. mohammedNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- Welding Inspection ProcedureDocument5 pagesWelding Inspection ProcedurePugalNo ratings yet

- Steel WaterPipeDocument14 pagesSteel WaterPipesofianina05No ratings yet

- T-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentDocument59 pagesT-MCE-STD-001 Rev 0 - Welding and Inspection of Process and Utility Pipework Vessels and EquipmentMichael CovillNo ratings yet

- CCCC Et Ha Spec ST 649 00 Reply BDocument14 pagesCCCC Et Ha Spec ST 649 00 Reply B黄赛赛No ratings yet

- P 1-11 Storm Drainage PDFDocument11 pagesP 1-11 Storm Drainage PDFMahmoud GwailyNo ratings yet

- Inspection and Test ProcedureDocument8 pagesInspection and Test Proceduregaehdd1100% (1)

- SPC 332530 UDocument12 pagesSPC 332530 UkkkhattabbbNo ratings yet

- Specification 001 - Welding and Fabrication of Structural SteelDocument19 pagesSpecification 001 - Welding and Fabrication of Structural SteelMario JacobsonNo ratings yet

- Drainage & Sump Pumps Specs PDFDocument25 pagesDrainage & Sump Pumps Specs PDFWalid El Ghonamy100% (1)

- 3LPE Coating SpecsDocument36 pages3LPE Coating SpecsRudra Pandit100% (1)

- Piping SpecDocument355 pagesPiping Speclcaron44100% (1)

- 23 21 13 Hydronic PipingDocument15 pages23 21 13 Hydronic PipingSoumojit SamantaNo ratings yet

- Project Standard Specification: Fuel Gas Piping 15194 - Page 1/17Document17 pagesProject Standard Specification: Fuel Gas Piping 15194 - Page 1/17adel rihanaNo ratings yet

- 06 PIPING Design Basis PDFDocument8 pages06 PIPING Design Basis PDFKatamaneni Koteswararao100% (3)

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- Specification Plumbing SystemDocument16 pagesSpecification Plumbing SystemGhiovani DayananNo ratings yet

- Welding SpecsDocument22 pagesWelding Specsazhart0425No ratings yet

- STD Spec For Piping WeldingDocument14 pagesSTD Spec For Piping WeldingknsaravanaNo ratings yet

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDocument8 pages44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNo ratings yet

- MSC RD 19440 PDFDocument13 pagesMSC RD 19440 PDFJairo WilchesNo ratings yet

- Split Tee Specifications and DrawingsDocument7 pagesSplit Tee Specifications and DrawingsFareha AbdelkaderNo ratings yet

- Piping Chevron OffDocument44 pagesPiping Chevron OffdfdflkNo ratings yet

- Enbridge Pipeline Repair Workplan Welding PDFDocument23 pagesEnbridge Pipeline Repair Workplan Welding PDFquiron2014No ratings yet

- Asme VDocument1 pageAsme VMohd AnsariNo ratings yet

- 24 Steel PipesDocument11 pages24 Steel Pipeselynah mistiolaNo ratings yet

- General Specification For Welding and Weld Inspection (EIL)Document19 pagesGeneral Specification For Welding and Weld Inspection (EIL)Mitchel Fernandes100% (6)

- Ecfn Aus Ci 0100 Spe 01007 (C PDF)Document9 pagesEcfn Aus Ci 0100 Spe 01007 (C PDF)Janeth MeraNo ratings yet

- Welding Inspection Ass 1Document7 pagesWelding Inspection Ass 1mohd as shahiddin jafri100% (1)

- (Expansion Fittings and Loops For Hvac Piping)Document2 pages(Expansion Fittings and Loops For Hvac Piping)Mostafa SalemNo ratings yet

- KBR Piping Stress SpecificationDocument23 pagesKBR Piping Stress Specificationsamprof4vw86% (7)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Estimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesFrom EverandEstimator's Piping Man-hours Tool: Estimating Man-hours for Carbon Steel Process Piping Projects. Manual of Man-hours, ExamplesNo ratings yet

- ISA Certified Control Systems Technician (CCST): Certification Exam Prep: 500 Practice Exam Questions and ExplanationsFrom EverandISA Certified Control Systems Technician (CCST): Certification Exam Prep: 500 Practice Exam Questions and ExplanationsNo ratings yet

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Compliance Statement R1 Add CSCEC PartsDocument39 pagesCompliance Statement R1 Add CSCEC PartsLi LiuNo ratings yet

- 1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkDocument5 pages1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkLi LiuNo ratings yet

- AHU Selection Reply - CUCDocument1 pageAHU Selection Reply - CUCLi LiuNo ratings yet

- Psychrometric Analyzer Version 6.8 by Mcquay InternationalDocument1 pagePsychrometric Analyzer Version 6.8 by Mcquay InternationalLi LiuNo ratings yet

- Ultrasonic Examination Procedure (Issue 2)Document14 pagesUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- Magnetic Particle Examination Report: Project: .........................................Document1 pageMagnetic Particle Examination Report: Project: .........................................Li LiuNo ratings yet

- Annex 5 API 650 Storage Tanks Certificate of Compliance SampleDocument3 pagesAnnex 5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuNo ratings yet

- Annex 4.5 API 650 Storage Tanks Certificate of Compliance SampleDocument1 pageAnnex 4.5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuNo ratings yet

- Tank Data Sheet Rev CCDocument2 pagesTank Data Sheet Rev CCLi LiuNo ratings yet

- TS Vacumm FormDocument1 pageTS Vacumm FormLi LiuNo ratings yet

- Comply: The Comply Provided Co Ordination With Other Systems SuppliersDocument46 pagesComply: The Comply Provided Co Ordination With Other Systems SuppliersLi LiuNo ratings yet

- Hydrostatic Test FormDocument1 pageHydrostatic Test FormLi LiuNo ratings yet

- Response To SCG Comment-29June2020Document1 pageResponse To SCG Comment-29June2020Li LiuNo ratings yet

- Ifc Check & Revise Record - Cbd-Cuc-E01-Ar-001Document57 pagesIfc Check & Revise Record - Cbd-Cuc-E01-Ar-001Li LiuNo ratings yet

- Mat Cscec 00 Me PL 0110 01Document2 pagesMat Cscec 00 Me PL 0110 01Li LiuNo ratings yet

- Ifc Check & Revise Record - Cbd-Cuc - E06-Ar-001Document4 pagesIfc Check & Revise Record - Cbd-Cuc - E06-Ar-001Li LiuNo ratings yet

- Pipe Schedule Chart - USA Industries, IncDocument6 pagesPipe Schedule Chart - USA Industries, IncMykmen SánchezNo ratings yet

- Kilo-W-Cal-0104 1Document19 pagesKilo-W-Cal-0104 1maniacs14No ratings yet

- QC TolaranceDocument35 pagesQC TolaranceRajkumar A100% (1)

- 1CS101 IBR 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube IBR L P Steam, M P SteamDocument9 pages1CS101 IBR 150#RF Optional Comments: Non-Lethal A106 GR B Seamless Pipe or Tube IBR L P Steam, M P SteamAshish ShahNo ratings yet

- Hazen William Formula PDFDocument4 pagesHazen William Formula PDFMac ShaikNo ratings yet

- Pipe Size DesignationsDocument1 pagePipe Size DesignationsleoscbdNo ratings yet

- Table U-3 Year of Acceptable Edition of Referenced Standards in This DivisionDocument1 pageTable U-3 Year of Acceptable Edition of Referenced Standards in This DivisionSilvana MendesNo ratings yet

- BS en Iso 17292 - 3Document5 pagesBS en Iso 17292 - 3pvsreddy2002No ratings yet

- PT 3Document1 pagePT 3vietsdsNo ratings yet

- Asme Q&aDocument57 pagesAsme Q&amsraja7767% (3)

- Technical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions NetworksDocument91 pagesTechnical Standards & Specifications Including Safety Standards For City or Local Natural Gas Distributions Networkspravesh sharma80% (5)

- KL UHP Catalog 2011-02 PDFDocument30 pagesKL UHP Catalog 2011-02 PDFaconibet9040No ratings yet

- Pipe Data 85x11Document7 pagesPipe Data 85x11RSGatesNo ratings yet

- Sa 135Document10 pagesSa 135Girish RajNo ratings yet

- Cálculo y Catálogo de Conexiones de PVC+GF+Document108 pagesCálculo y Catálogo de Conexiones de PVC+GF+Jesus ANo ratings yet

- B36.19M 1985 Stainless Steel Pipe PDFDocument13 pagesB36.19M 1985 Stainless Steel Pipe PDFMadidj_2014No ratings yet

- Pressure Vessel RadiographyDocument12 pagesPressure Vessel RadiographyPratik WalheNo ratings yet

- Mesc Specification SPE 77/166: NormativeDocument16 pagesMesc Specification SPE 77/166: Normative윤규섭No ratings yet

- FINAL EXAMINATION API 570 Close BookDocument6 pagesFINAL EXAMINATION API 570 Close BookdenarlijeronNo ratings yet

- Full Vacuum Vs Half Vacuum - Chemical Plant Design & Operations - Eng-TipsDocument5 pagesFull Vacuum Vs Half Vacuum - Chemical Plant Design & Operations - Eng-TipsShantanuNo ratings yet

- VTCH en 2017Document32 pagesVTCH en 2017no TengoNo ratings yet

- Solidworks PipingDocument1 pageSolidworks Pipingabhi_mohit2005No ratings yet

- Weco Wing UnionsDocument15 pagesWeco Wing Unionsturend50% (2)

- WeldBend CatalogDocument186 pagesWeldBend CatalogJaime I. de la RosaNo ratings yet

- 2 Peso de Bridas Por Cedula o LBSDocument1 page2 Peso de Bridas Por Cedula o LBSjulio cesar arroyoNo ratings yet

- PIPING PIPING PIPING - Piping-Components-Guide-for-Oil-and-Gas-EngineerDocument92 pagesPIPING PIPING PIPING - Piping-Components-Guide-for-Oil-and-Gas-EngineerIsaac Africana100% (2)

- Piping Material SpecificationDocument6 pagesPiping Material SpecificationyutkaNo ratings yet

- Iso 7005-1-2011Document18 pagesIso 7005-1-2011piprdNo ratings yet

- CPE PACIFIC PRESSURESEAL TD EN LT 2018 - 10 - 03 WebDocument34 pagesCPE PACIFIC PRESSURESEAL TD EN LT 2018 - 10 - 03 Webpm-kcpNo ratings yet