Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Uploaded by

Rakesh BobongaCopyright:

Available Formats

Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Uploaded by

Rakesh BobongaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Nxco Rock Breaking Cartridges (Nxco RBC'S) : Energy

Uploaded by

Rakesh BobongaCopyright:

Available Formats

Nxco Rock Breaking Cartridges (Nxco RBC’s)

I would like to use this opportunity to present you with more information about our company and products.

1. Introduction

Nxco Mining Technologies (Pty) Ltd is a Level 2 BBBEE South African based company that manufactures and

distributes non-detonating cartridges throughout the world.

Our cartridges have been tested by UN accredited testing company – TEN E Packaging, NRCan, Bureau Veritas in

France, BAM in Germany for CE accreditation and these tests have been accepted by every country that we sell

our cartridges in.

2. Comparison

The most significant difference between Nxco RBC’s and explosives are the following:

• Nonex cartridges deflagrate, unlike conventional explosives that detonate.

• They also break rock on tensile strength rather than compressive strength.

These 2 fundamental differences offer significant advantages when using our cartridges. In sensitive blasting

environments where the use of High Explosives is restricted or prohibited.

3. The advantages of Nxco RBC’s

3.1 Energy

Nxco RBC’s have low energy when compared to high explosives. This is because the speed of deflagration is

significantly lower than the velocity of detonation (VOD) typically associated with conventional explosives that

exceed 3500m/s.

Due to the above, there is minimal vibration when using our products (this has been tested and proven on many

occasions) and it allows our product to be used close to green cement, busy roads, personnel, expensive

equipment and sensitive structures/facilities.

For the reasons stated above, Fly-rock is therefore 100% controllable.

3.2 Environmental Impact and Sensitivity

Dust and Noise levels are significantly lower than conventional explosives.

When breaking rock towards a free face, the back break or damage to adjacent rock is non-existent.

3.3 Flexibility

Rock Breaking Cartridges only break the rock according to the designed drill and blast pattern.

• It also allows you to plan the breaking in stages if necessary.

Directors: MJ Durie, GJS Paterson, NN Macamo, JA Groenewald (Managing), GHC Barnard, AJ Kruger

www.nxco.co.za www.nonex.com www.nxburst.com

2

• The Nonex RBC solution is effective and safe.

3.4 Safety Distances

One of the major advantages of Nonex RBC’s is that your safety distances for personnel and equipment are

approximately 50 metres if no coverage are used. This means that personnel and equipment only require local

clearance instead of complete site evacuation. The benefit of this is that rocks and boulders can be broken in shift

and close to working operations.

3.5 Training and Accreditation

To become an accredited Nonex blaster one needs to undergo our training course which includes a theoretical and

practical aspect followed by a written exam.

Following the successful completion of the training course, the trainee will be issued a Nxco competency

certificate.

More detail on training will be provided closer to the start of the project. (this is dependent on the type of

operation and regulators involved with the project, as well as previous experience and certification of the blasters

recruited for the project).

3.6 Safety

Inherent safety characteristics are:

1. Minimal fly rock.

2. Absence of detonation eliminates ultra-fine particles from being produced thus less dust is generated and

the dust settles fast.

3. The product produces low noise levels and most of the noise is generated when the rock fractures.

Measured levels are about 116dB compared to explosives above 154dB at 30m.

4. Vibrations are very dependent on soil conditions and rock strata. As a rule, Nxco RBC’s generate around

1,3 – 5,9mm/s at 10m compared to explosives that frequently exceed 30mm/s. With our sequential timing

system, Nxco can meet all international vibration standards.

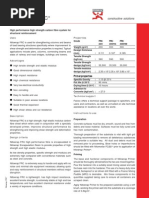

4. Product range

Stemmed cartridges Self stemming cartridges

13mm (5-10 grams) Concentric case 43mm (140-220grams)

28mm (20 - 120grams) Axial Piston 43mm (80 – 240grams)

34mm (40 – 250grams)

42mm (60 – 650grams)

60mm (200 – 500grams)

90mm (2000 – 4000grams)

This range allows the contractor to tackle virtually any rock or concrete breaking project/application

5. Various Applications

The applications of RBC’s include:

3

1. Any sensitive in-situ rock (found in gardens, commercial & industrial areas and environmentally sensitive

situations).

2. Mass excavations – any mass rock excavation project that is sensitive in any way or is near busy roads,

structures, gas or water pipelines or in a built-up area.

3. Oversize boulders (above and underground – with Nxco RBC’s, these can always be broken in shift).

4. Breaking down or demolition of concrete and reinforced concrete structures (i.e. concrete bases,

harbour coping, thick reinforced walls. etc).

5. Trenching applications:

• Pipelines,

• Harbour deepening projects,

• Tunnelling (almost all secondary work should be carried out by Nxco RBC’s as it can be done

during shift and it leaves a more competent finish), and

• Pipe jacking.

6. References

Nonex cartridges have been used for various important projects around the world.

Some of these include:

1. Removal of a pier in Galveston, Texas, for the national railway corporation.

2. Removal of rocks displaced by the earthquake in Christchurch, New Zealand.

3. General rock removal is done of the underground railway service in Singapore.

4. Removal of a harbour quay in Durban, South Africa.

5. Mass excavation of rock at Kusile Power Station in South Africa.

6. Creation of the box cuts for the Gautrain underground high-speed train service in Johannesburg, South

Africa

7. Parliament building tunnel Ontario Canada

8. West Wits mining of gold

9. Sogima Mine 11m bench in Chrome ore

10. In shift oversize blasting at Tharisa Mine

You might also like

- People and Performance by Peter Drucker_previewpdfDocument21 pagesPeople and Performance by Peter Drucker_previewpdfAvia MariaNo ratings yet

- Schedules A - RDocument146 pagesSchedules A - Rabhijeet kumarNo ratings yet

- Drill BlastDocument8 pagesDrill Blastgzapas100% (4)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Joyce Grant Award Letter 041609Document6 pagesJoyce Grant Award Letter 041609Sweet WaterNo ratings yet

- Soft Eye ApplicationsDocument8 pagesSoft Eye ApplicationsGustavo MariduenaNo ratings yet

- Rock BlastingDocument22 pagesRock BlastingSheruth KuanNo ratings yet

- Non Explosive Rock Breaking TechniquesDocument7 pagesNon Explosive Rock Breaking Techniquescontenido100% (2)

- Dual Rotary Drilling BenefitsDocument20 pagesDual Rotary Drilling Benefitsjlhunter70No ratings yet

- Cabiting Act 9Document19 pagesCabiting Act 9Norjhon BruzonNo ratings yet

- Blasting Theory: Underground Mining and Planning MethodsDocument30 pagesBlasting Theory: Underground Mining and Planning MethodsManinder Singh Bagga100% (1)

- Introduction To Rock ExcavationDocument2 pagesIntroduction To Rock ExcavationAdrian DueroNo ratings yet

- Murfor vs Conventional RCC Band WorkabilityDocument2 pagesMurfor vs Conventional RCC Band WorkabilityVirendra NegiNo ratings yet

- drilling assDocument11 pagesdrilling assprominancemaate08No ratings yet

- Blasting Plan TrenchDocument16 pagesBlasting Plan TrenchVelina Mileva100% (2)

- Development of A Remote Control Rock Bolting System For n18 - O'ConnorDocument14 pagesDevelopment of A Remote Control Rock Bolting System For n18 - O'Connorersi4dNo ratings yet

- Presplitting Techniques and Design Open Pit MineDocument7 pagesPresplitting Techniques and Design Open Pit MinechistejoNo ratings yet

- Metodos de Lavra SubterraneaDocument4 pagesMetodos de Lavra SubterraneaAmilton filhoNo ratings yet

- Corrosion RingsDocument1 pageCorrosion RingsRichard More LeonNo ratings yet

- 1 - Specialized en InglesDocument0 pages1 - Specialized en InglesJoao Cristofer Tarqui FloresNo ratings yet

- Facts & Myths of HardbandingDocument3 pagesFacts & Myths of Hardbandingsdb158No ratings yet

- Drilling & BlastingDocument7 pagesDrilling & BlastingVikram Sharma100% (1)

- Drilling and Blasting As A Tunnel Excavation MethodDocument26 pagesDrilling and Blasting As A Tunnel Excavation MethodMIGUEL FERNANDO AGUIRRE QUISPE100% (1)

- Unit No. Topics To Be Covered Hours: Ground Breaking OperationDocument32 pagesUnit No. Topics To Be Covered Hours: Ground Breaking OperationmushagraNo ratings yet

- AnchoringDocument20 pagesAnchoringjack21abNo ratings yet

- Demolination Method & Techniques: PG. Student, Civil Engineering, SNPIT & RC, Umrakh, Gujarat, IndiaDocument5 pagesDemolination Method & Techniques: PG. Student, Civil Engineering, SNPIT & RC, Umrakh, Gujarat, IndiaVasava MehulNo ratings yet

- Anchor SoilDocument20 pagesAnchor Soilenowenoh182No ratings yet

- Nitowrap FRC BaruDocument2 pagesNitowrap FRC BaruZax SantanaNo ratings yet

- Decommissioning of Offshore PlatformsDocument21 pagesDecommissioning of Offshore PlatformsChandra HaasNo ratings yet

- LM Bend Restrictors FLDRDocument4 pagesLM Bend Restrictors FLDRFan RapidNo ratings yet

- Rock AnchoringDocument15 pagesRock AnchoringPrasanjit RoyNo ratings yet

- Soil Nail Launcher PaperDocument12 pagesSoil Nail Launcher PaperbufaloteNo ratings yet

- The Latest Developments in Laser Profiling, Borehole Deviation and Laser Enhanced VideometryDocument15 pagesThe Latest Developments in Laser Profiling, Borehole Deviation and Laser Enhanced VideometryeduardoNo ratings yet

- Engineering Encyclopedia: Underwater NDTDocument9 pagesEngineering Encyclopedia: Underwater NDTabyNo ratings yet

- NOTA BAB 5-Ujian BataDocument8 pagesNOTA BAB 5-Ujian BataNorsuzilawate Binti Zulkapli0% (1)

- A Review Paper On Shotcrete TechnologyDocument5 pagesA Review Paper On Shotcrete TechnologyDarshan mNo ratings yet

- 4th Sem - Mining Engg - Th-01Document19 pages4th Sem - Mining Engg - Th-01Satyajeet ParidaNo ratings yet

- Demolition of StructuresDocument28 pagesDemolition of StructuresSharath WankdothNo ratings yet

- Demolition Materials 2017Document54 pagesDemolition Materials 2017grenzoNo ratings yet

- Tendon Grouting - VSLDocument46 pagesTendon Grouting - VSLIrshadYasinNo ratings yet

- Anchoring ArticleDocument4 pagesAnchoring ArticleVan LLiNo ratings yet

- Anclajes Al Terreno DELFTDocument46 pagesAnclajes Al Terreno DELFTRankineNo ratings yet

- Method-Statement-for-Blasting PifoneerDocument11 pagesMethod-Statement-for-Blasting PifoneerJohn MwauraNo ratings yet

- Efficient and Adaptable New Anchoring System For Floating WindDocument16 pagesEfficient and Adaptable New Anchoring System For Floating WindBenoit BriereNo ratings yet

- CI1 - Element 4 (1)Document68 pagesCI1 - Element 4 (1)Sana NajeemNo ratings yet

- Decommissioning of Offshore Platforms PDFDocument45 pagesDecommissioning of Offshore Platforms PDFWildan MessiNo ratings yet

- RockFrag 070716Document169 pagesRockFrag 070716vongai chimbundeNo ratings yet

- Erich NeugebauerDocument18 pagesErich NeugebauerrannscribdNo ratings yet

- For Excavation Sierra 11022025Document6 pagesFor Excavation Sierra 11022025Anil TiwariNo ratings yet

- Case Studies - Coastal Pathways 9-12-19Document1 pageCase Studies - Coastal Pathways 9-12-19Zara DesignNo ratings yet

- Conventional Tunneling: Drill and Blast MethodDocument6 pagesConventional Tunneling: Drill and Blast MethodGodfrey EmilioNo ratings yet

- Selective Blast in Gold MinesDocument4 pagesSelective Blast in Gold Minespleasure masango100% (1)

- TunnelingDocument15 pagesTunnelingalfanfazaNo ratings yet

- Duckbill Ground Anchor Systems - Helical Anchors & Anchor Bolts (Feb 2010)Document12 pagesDuckbill Ground Anchor Systems - Helical Anchors & Anchor Bolts (Feb 2010)sandycastleNo ratings yet

- Blasting Design For TunnelsDocument51 pagesBlasting Design For TunnelsEdisonNo ratings yet

- Close in BlastingDocument9 pagesClose in BlastingrakoNo ratings yet

- Drill & Blast MethodDocument11 pagesDrill & Blast MethodHarsha Vardhan MeduriNo ratings yet

- Improved Safety and Efficiency With Ground Support and Rehabilitation Practices at The X41 Copper Mine, Mount Isa MinesDocument9 pagesImproved Safety and Efficiency With Ground Support and Rehabilitation Practices at The X41 Copper Mine, Mount Isa Minesjulio1051No ratings yet

- Methods of QuarryingDocument7 pagesMethods of Quarryingmosesbala078No ratings yet

- Is 14593 1998Document15 pagesIs 14593 1998rbs_75100% (1)

- 08 PrimingDocument6 pages08 PrimingJose RojasNo ratings yet

- India China RelationshipDocument7 pagesIndia China RelationshipAthena MagistrateNo ratings yet

- Liebert PDX Liebert PCW System Design Manual - 2017Document140 pagesLiebert PDX Liebert PCW System Design Manual - 2017JeffNo ratings yet

- 9 Health EconomicsDocument42 pages9 Health EconomicsShivangi SharmaNo ratings yet

- Assets Uploads Unifiedsolutions Invoice Invoice 546341 Unified Solutions Corp.Document1 pageAssets Uploads Unifiedsolutions Invoice Invoice 546341 Unified Solutions Corp.anitamares81No ratings yet

- Adobe Scan 29 Aug 2022Document9 pagesAdobe Scan 29 Aug 2022kumardeepak5242No ratings yet

- Taking Alarm Management From Concept To Reality: A Step by Step GuideDocument16 pagesTaking Alarm Management From Concept To Reality: A Step by Step GuideJennyNo ratings yet

- Nitocote EpsDocument4 pagesNitocote EpsmangjitNo ratings yet

- Konga Mall New Merchant OrientationDocument54 pagesKonga Mall New Merchant OrientationJubril AkinwandeNo ratings yet

- University of Central Punjab: Department of Electrical EngineeringDocument3 pagesUniversity of Central Punjab: Department of Electrical EngineeringKainat YousafNo ratings yet

- Peranan Infrastruktur Jalan Terhadap Perekonomian Regional Di IndonesiaDocument21 pagesPeranan Infrastruktur Jalan Terhadap Perekonomian Regional Di IndonesiaFrankincense AveroesNo ratings yet

- Srashti Brizawar STPRDocument64 pagesSrashti Brizawar STPRSrashti BrizawarNo ratings yet

- Easy Arduino Sentry GunDocument4 pagesEasy Arduino Sentry GunMatheus SilvaNo ratings yet

- HCIE-Routing & Switching V3.0 Lab GuideDocument420 pagesHCIE-Routing & Switching V3.0 Lab GuideSisay50% (2)

- Gbss Kpi Reference (v900r013c00 04) (PDF) enDocument86 pagesGbss Kpi Reference (v900r013c00 04) (PDF) enabdelrhmanahmedsayedNo ratings yet

- Omn PQD-1Document2 pagesOmn PQD-1lakax76026No ratings yet

- Research Methodology Code: PROJ-CS601 Term Paper: 1. Tell About The Final Year Project That You Are Parsing.Document7 pagesResearch Methodology Code: PROJ-CS601 Term Paper: 1. Tell About The Final Year Project That You Are Parsing.nitish kumarNo ratings yet

- SG Airlines V Pano DigestDocument2 pagesSG Airlines V Pano DigestShaneBeriñaImperialNo ratings yet

- NiedeckerDocument1 pageNiedeckerduckythiefNo ratings yet

- Quarterwatch: Anticoagulants The Leading Reported Drug Risk in 2011Document25 pagesQuarterwatch: Anticoagulants The Leading Reported Drug Risk in 2011Laney SommerNo ratings yet

- Leroy Somer R450 ManualDocument20 pagesLeroy Somer R450 ManualFreddy AmadoNo ratings yet

- Remedial Law I Utopia LMT 2022Document13 pagesRemedial Law I Utopia LMT 2022Christian TajarrosNo ratings yet

- ACET Topper Interview PDFDocument1 pageACET Topper Interview PDFVijayaNo ratings yet

- Chapter 1-3 1Document49 pagesChapter 1-3 1michaelandanarNo ratings yet

- Social Media Scavenger Hunt (London)Document4 pagesSocial Media Scavenger Hunt (London)Damian RadcliffeNo ratings yet

- Inverter Installation and Inverter DB Wiring With RCCBDocument3 pagesInverter Installation and Inverter DB Wiring With RCCBP.Rajan Guru100% (1)

- XS4921 2300XPC DC BroDocument8 pagesXS4921 2300XPC DC BroRaul Mendoza Subia100% (1)