0 ratings0% found this document useful (0 votes)

165 views3.5 Drill Pipe W Nc38 Connections

3.5 Drill Pipe W Nc38 Connections

Uploaded by

Mohamed FikryThis document provides specifications for 3-1/2" 13.30# S-135 drill pipe with 3-1/2" IF connections including:

- Nominal pipe dimensions such as outer diameter of 3.5" and inner diameter of 2.764"

- Material properties including grade of S-135, wall thickness of 0.368", and tensile strength of 381,900 lbs

- Connection details including outer diameter of 4.875" and recommended make up torque of 12,100 ft-lbs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

3.5 Drill Pipe W Nc38 Connections

3.5 Drill Pipe W Nc38 Connections

Uploaded by

Mohamed Fikry0 ratings0% found this document useful (0 votes)

165 views1 pageThis document provides specifications for 3-1/2" 13.30# S-135 drill pipe with 3-1/2" IF connections including:

- Nominal pipe dimensions such as outer diameter of 3.5" and inner diameter of 2.764"

- Material properties including grade of S-135, wall thickness of 0.368", and tensile strength of 381,900 lbs

- Connection details including outer diameter of 4.875" and recommended make up torque of 12,100 ft-lbs

Original Title

3.5 Drill Pipe w Nc38 Connections

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides specifications for 3-1/2" 13.30# S-135 drill pipe with 3-1/2" IF connections including:

- Nominal pipe dimensions such as outer diameter of 3.5" and inner diameter of 2.764"

- Material properties including grade of S-135, wall thickness of 0.368", and tensile strength of 381,900 lbs

- Connection details including outer diameter of 4.875" and recommended make up torque of 12,100 ft-lbs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

165 views1 page3.5 Drill Pipe W Nc38 Connections

3.5 Drill Pipe W Nc38 Connections

Uploaded by

Mohamed FikryThis document provides specifications for 3-1/2" 13.30# S-135 drill pipe with 3-1/2" IF connections including:

- Nominal pipe dimensions such as outer diameter of 3.5" and inner diameter of 2.764"

- Material properties including grade of S-135, wall thickness of 0.368", and tensile strength of 381,900 lbs

- Connection details including outer diameter of 4.875" and recommended make up torque of 12,100 ft-lbs

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

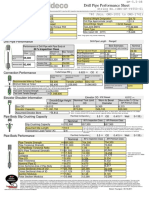

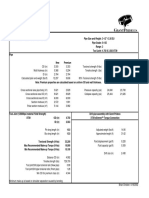

DRILL PIPE SPECIFICATION DATA

3-1/2" 13.30# S-135 DRILL PIPE WITH 3-1/2" IF CONNECTIONS

Pipe Body O.D. (in) 3.500

Nominal Pipe I.D. (in) 2.764

Nominal Weight Designation 13.30

Drill Pipe Adjusted Weight (lbs./ft.) 15.53

Pipe Body Grade S-135

Pipe Body Wall Thickness (in) 0.368

API Class - Tube Premium

Pipe Body Tensile (lbs.) 381,900

Pipe Body Torsional (ft./ lbs.) 25,900

Pipe Body Collapse (psi) 21,626

Pipe Body Internal Yield / Burst (psi) 22,711

Pipe Body Displacement (bbls/ft.) 0.0057

Pipe Body Capacity (bbls/ft.) 0.0070

Connection Type NC38 / 3-1/2" IF

Connection O.D. (in) 4.875

Connection I.D. (in) 2.563

Tool Joint Drift (in) 2.438

Recommended Make Up Torque (ft./ lbs.) 12,100

Minimum Make Up Torque (ft./ lbs.) 10,000

Tool Joint Torsional Strength (ft./ lbs.) 20,100

Tool Joint Tensile Strength (At Rec. MUT) (lbs.) 543,000

The technical information contained herein, including the product performance/spec sheets and other attached documents, have been generated from material provided by the

manufacturer. It is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and suitablility of use of all technical

information. Platinum Pipe Rentals, LLC cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended.

Assembly properties are based on uniform OD and wall thickness. No safety factor is applied. The information provided for various wear conditions (remaining body wall) is for

information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and/or end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. The user should consider all field

conditions along with combined factors which may affect the final string design used in the field, Per the IADC drilling manual, it is recommended that drilling torque should not

exceed 80% of MUT.

You might also like

- Kansas City Zephyrs Baseball ClubDocument3 pagesKansas City Zephyrs Baseball Clubbinzidd007100% (1)

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Drill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFDocument1 pageDrill Collar, 6.625 API Reg (8.000 X 2.813) 100,000 (Psi PDFИнженер Луис А. ГарсиаNo ratings yet

- Graphical Method Exercises Solved in Linear Programming1Document4 pagesGraphical Method Exercises Solved in Linear Programming1MKogiNo ratings yet

- 4.0 Drill Pipe W XT39 ConnectionsDocument1 page4.0 Drill Pipe W XT39 ConnectionsDugas DeivyNo ratings yet

- 5.5 Drill Pipe W Cet54 ConnectionsDocument1 page5.5 Drill Pipe W Cet54 Connectionsfarhad iqbalNo ratings yet

- 4.0 S-135 Drill Pipe W Xt39Document1 page4.0 S-135 Drill Pipe W Xt39rdos14No ratings yet

- 3.5 Eue 9.3 L80 TubingDocument1 page3.5 Eue 9.3 L80 TubingGeorge IkpeNo ratings yet

- 2.875 Eue 6.50 L80 TubingDocument1 page2.875 Eue 6.50 L80 TubingALEX MAKANGANo ratings yet

- Tubing Specification DataDocument1 pageTubing Specification DataAadil HaroonNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- 3.500 P110 12.95ppf TSHDDocument1 page3.500 P110 12.95ppf TSHDDeepak RanaNo ratings yet

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38 PDFDocument3 pagesHeavyWeight 3.5 25.58lbs NC-38 PDFHomero NavarroNo ratings yet

- 4in DP 14# IU S135T XTF39 (5.00 x2.5625)Document7 pages4in DP 14# IU S135T XTF39 (5.00 x2.5625)Pavin PiromNo ratings yet

- 2.875 N80 6.51ppf EUEDocument1 page2.875 N80 6.51ppf EUEHanyNo ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- Drillpipe 3.500 G 105 2.438 ID 15.5ppf NC38Document1 pageDrillpipe 3.500 G 105 2.438 ID 15.5ppf NC38german131418No ratings yet

- Spiral Drill Collars 9.500Document1 pageSpiral Drill Collars 9.500muhammad shoaibNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- Spiral Drill Collars 4.750Document1 pageSpiral Drill Collars 4.750Robert TirtaNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- DrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Document3 pagesDrillPipe, 80%, 2.875 OD, 0.362 Wall, EU, G-105.. XT26 (3.375 X 1.750)Luis Alberto García CórdovaNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- For Reference Only: Drill Pipe Performance Characteristics ©Document3 pagesFor Reference Only: Drill Pipe Performance Characteristics ©alekz89100% (1)

- 5 5PDSDocument1 page5 5PDSMAICOLNo ratings yet

- Datasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1Document2 pagesDatasheet - 5 IEU X 1950 X S135 X R2 31.5 FT - 658 X 312 X TSDS50 X 135 Ksi SMYS - 14 Box 11 Pin - HB Box - 60 70 MUT - 1.0 FF and 1.15 FF - TSC DP Web Site 1oscar0% (1)

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- Drill Pipe Data & Performance Sheet: 5" 19.50# S-135 R2 NC50 (4-1/2 IF)Document2 pagesDrill Pipe Data & Performance Sheet: 5" 19.50# S-135 R2 NC50 (4-1/2 IF)Valee kienNo ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) Spiralfaishal hafizhNo ratings yet

- 4英寸短钻杆 HT40质量文件包裹模板Document17 pages4英寸短钻杆 HT40质量文件包裹模板zhaibo666No ratings yet

- 7.13.1.4 DP 2 7,8 10,4ppfDocument1 page7.13.1.4 DP 2 7,8 10,4ppfkbgwseNo ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- Heavy Weight Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint SpecificationDocument2 pagesHeavy Weight Drill Pipe Performance Sheet: Pipe Body Specification Tool Joint SpecificationLenin Merchán MartínezNo ratings yet

- 4Inch DP SpecsDocument3 pages4Inch DP SpecsDhrubajyoti BoraNo ratings yet

- Datasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1Document2 pagesDatasheet 312 EU-x-1330-x-S135-x-R2-31.5-ft - 478-x-2916-x-TSDS38-x-135-ksi-SMYS - 1412-Box-12-Pin - HB-Box - 60-70-MUT - 1.0-FF-and-1.15-FF - TSC-DP-Web-Site-1oscarNo ratings yet

- Drillpipe 3.500 110KSI 225 ID NC38Document1 pageDrillpipe 3.500 110KSI 225 ID NC38Lucas Paul Perez HernandezNo ratings yet

- 5.875 HWDP With XT57 (7.000 X 4.000 TJ) Tri-SpiralDocument1 page5.875 HWDP With XT57 (7.000 X 4.000 TJ) Tri-SpiralRonaldNo ratings yet

- 3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Document5 pages3-1/2'', 13.30#, 0.368'', S135, EU, R2: Delta377 - 4.750'' X 2.563''Jcchcc JcchccNo ratings yet

- 3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralDocument1 page3.500 HWDP With HT38 (4.875 X 2.250 TJ) Tri-SpiralLuis A G. C.No ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.500 X 3.000 TJ) Integral SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.500 X 3.000 TJ) Integral SpiraljosephbenettonNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetGaona industrial PetroleroNo ratings yet

- 4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated PipeDocument3 pages4 DP VX-39 Dogis Pipe. Drift ID. With Int. Coated Pipeyatinbhat100% (2)

- 3,5 in Drill Pipe Performance Data SS 105Document1 page3,5 in Drill Pipe Performance Data SS 105mustafaNo ratings yet

- Specification Sheet: 2 7/8" P 110 7.90 LBS/FT, PH 6 HYDRIL TUBINGDocument1 pageSpecification Sheet: 2 7/8" P 110 7.90 LBS/FT, PH 6 HYDRIL TUBINGAlberto CárdenasNo ratings yet

- 2.875in P 110 7 - 9PPF PH6 0 - 875WT PDFDocument1 page2.875in P 110 7 - 9PPF PH6 0 - 875WT PDFAlberto CárdenasNo ratings yet

- 5.5in Hwdp Ht55质量文件包裹模板Document20 pages5.5in Hwdp Ht55质量文件包裹模板zhaibo666No ratings yet

- PS PTECH55 - 6.625 X 4.250 - 5.500 - 21.90 S135 RG2 Rev5 - TSC Drill PipeDocument3 pagesPS PTECH55 - 6.625 X 4.250 - 5.500 - 21.90 S135 RG2 Rev5 - TSC Drill Pipe11tkt11No ratings yet

- PS PTECH55 - 6.625 X 4.250 - 5.500 - 24.70 S135 RG2 Rev3 - TSC Drill PipeDocument3 pagesPS PTECH55 - 6.625 X 4.250 - 5.500 - 24.70 S135 RG2 Rev3 - TSC Drill Pipe11tkt11No ratings yet

- TSS DP 5.875 0.415 S-135 VAM Express VX57 TJ 7.000 4.250Document2 pagesTSS DP 5.875 0.415 S-135 VAM Express VX57 TJ 7.000 4.250Carlos SanchezNo ratings yet

- 5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)Document2 pages5.5 Inch 24.70 VX54 6625 4000 2 (Landing String)humberto Nascimento100% (1)

- 2-7/8'', 10.40#, 0.362'', S135, EU, R2: 2-3/8''HT-SLH90 - 3.125'' X 1.975''Document2 pages2-7/8'', 10.40#, 0.362'', S135, EU, R2: 2-3/8''HT-SLH90 - 3.125'' X 1.975''Ko LinNo ratings yet

- 4.000 HWDP With XT39 (4.875 X 2.5625 TJ) ConventionalDocument1 page4.000 HWDP With XT39 (4.875 X 2.5625 TJ) Conventionalsurendra kumarNo ratings yet

- Drill Pipe Performance Characteristics SheetDocument1 pageDrill Pipe Performance Characteristics SheetDheeraj KapoorNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Swiggy Order 43333379786Document2 pagesSwiggy Order 43333379786Bhargav VekariaNo ratings yet

- Kmart PPTDocument40 pagesKmart PPTKarthik RanganathanNo ratings yet

- Atlas Copco Air Compressor Parts CatalogDocument591 pagesAtlas Copco Air Compressor Parts CatalogYacine CherifiNo ratings yet

- Supervision and Follow Up of AdvancesDocument28 pagesSupervision and Follow Up of Advancesr.jeyashankar9550No ratings yet

- Daddy No 2Document5 pagesDaddy No 2Darshani RajkumarNo ratings yet

- Salam Financing Question 11.5Document2 pagesSalam Financing Question 11.5cik bungaNo ratings yet

- Agency Under Indian Contract Act, 1872Document21 pagesAgency Under Indian Contract Act, 1872Naveen ArraboluNo ratings yet

- DepreciationDocument9 pagesDepreciationPriyank JainNo ratings yet

- Study of Non Fund Banking Business - Naiya Atul Mehta - Sachin P Xalxo - Vaishnavi S - Utkarsh - Syed Ahmer RizviDocument2 pagesStudy of Non Fund Banking Business - Naiya Atul Mehta - Sachin P Xalxo - Vaishnavi S - Utkarsh - Syed Ahmer RizviUtkarsh PrasadNo ratings yet

- CHAPTER 4 SUMMARY (The Revenue Cycle)Document6 pagesCHAPTER 4 SUMMARY (The Revenue Cycle)Janica GaynorNo ratings yet

- Chapter 9 VisualsDocument56 pagesChapter 9 VisualsOscar G. SoteroNo ratings yet

- Format Description Mt103 RCM v1 0 RCCDocument10 pagesFormat Description Mt103 RCM v1 0 RCCharirk1986No ratings yet

- Your BillDocument3 pagesYour Billniyaznadaf689No ratings yet

- GodrejDocument364 pagesGodrejmohammedrahees18No ratings yet

- Philadelphia Business Journal/Feb. 2, 2018Document32 pagesPhiladelphia Business Journal/Feb. 2, 2018Craig EyNo ratings yet

- Accounting Cycle Journal Entries With Chart of AccountsDocument3 pagesAccounting Cycle Journal Entries With Chart of AccountsMay Rojas MortosNo ratings yet

- Thanos Industries Case StudyDocument48 pagesThanos Industries Case StudyWJ TanoNo ratings yet

- Module 13 - Inventories: IFRS Foundation: Training Material For The IFRSDocument47 pagesModule 13 - Inventories: IFRS Foundation: Training Material For The IFRSSamantha DionisioNo ratings yet

- Content: Review Test Submission: Exercise - 1Document6 pagesContent: Review Test Submission: Exercise - 18085roNo ratings yet

- Lec 31Document14 pagesLec 31venkatachalapathy.thNo ratings yet

- Dedy ISTANTO - CV 2021Document13 pagesDedy ISTANTO - CV 2021Viki HermawatiNo ratings yet

- Practice Problems For Managing InventoryDocument7 pagesPractice Problems For Managing InventoryKholoudBenSaidNo ratings yet

- FM101 Group Assignment QuestionDocument2 pagesFM101 Group Assignment QuestionReenal100% (1)

- Fnma 1004Document3 pagesFnma 1004michaelc84No ratings yet

- Exhibit E - Contract of Legal ServicesDocument2 pagesExhibit E - Contract of Legal ServicesRjay SorianoNo ratings yet

- Red Hat Enterprise Linux-5-Tuning and Optimizing Red Hat Enterprise Linux For Oracle 9i and 10g Databases-en-US PDFDocument134 pagesRed Hat Enterprise Linux-5-Tuning and Optimizing Red Hat Enterprise Linux For Oracle 9i and 10g Databases-en-US PDFNinjaDragonXNo ratings yet

- Role of New Age Entrepreneurs in Shaping India-1Document12 pagesRole of New Age Entrepreneurs in Shaping India-1Shashank ShenoyNo ratings yet

- Iesco Online Billl PDFDocument1 pageIesco Online Billl PDFIrfan Shah0% (1)