Lamella Gravity Settler

Lamella Gravity Settler

Uploaded by

Iwan KenichiwaCopyright:

Available Formats

Lamella Gravity Settler

Lamella Gravity Settler

Uploaded by

Iwan KenichiwaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Lamella Gravity Settler

Lamella Gravity Settler

Uploaded by

Iwan KenichiwaCopyright:

Available Formats

Lamella Gravity Settler ®

Inclined Plate Settler

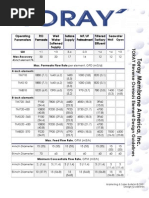

Conventional clarification equipment requires settling area becomes available for each

10 times more physical area to even begin to square foot of physical area occupied by the

approach the same settling capacity of a Lamella ®

unit. Loading rates normally used for the design of

Gravity Settler. This means faster settling in one conventional settlers can be applied to the sizing

tenth the space because the effective gravity of a Lamella settler by substituting projected area

settling area of the inclined plate design equals for the surface settling area

each plate’s area projected on a horizontal of a conventional clarifier.

surface. Up to ten square feet of

The most significant aspect of the gravity

settler’s design is its available settling area

Lamella Gravity Settler package unit

®

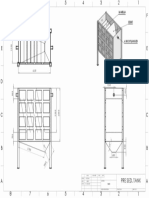

Lamella Gravity Settler/Thickener

®

The compact design minimizes hydraulic

disturbances caused by wind or temperature

Lamella Applications

changes. Balanced flow distribution ensures equal • Potable water

flow to each plate and across the plate surface • Filter Backwash

area preventing short-circuiting. • Industrial process water

• Clarification

Units and plate packs arrive at the job site factory

• Effluent treatment in Pulp and

assembled which reduces installation time and Paper

lowers installed costs. Minimal moving parts Lamella® plate packs in concrete basin

• Biological purification processes

means low maintenance costs.

• Washwater recirculation systems

Principle of Operation • Wet-scrubbed and slaking

Influent enters the Lamella Gravity Settler and

®

effluents

flows downward through the inlet chamber in the

center of the unit and enters the plates through

side-entry plate slots. The countercurrent design,

unlike typical bottom feed designs, reduces the The Lamella Gravity Settler teamed up with

®

Process Knowledge

the SuperScraper sludge removal system The knowledge gained from 4,000

risk of disturbing previously settled solids.

installations, 6,000 laboratory tests,

As the liquid flows upward, the solids settle on and 900 pilot tests is the Parkson

and/or solids loadings beyond the capacity of a guarantee.

the inclined, parallel plates and slide into the

packaged settler unit. It produces unprecedented

sludge hopper at the bottom. Further thickening

sludge concentrations and provides sludge

of the sludge is achieved in the hopper due to

storage providing flexibility for further sludge

compression in the quiescent zone achieved by

dewatering equipment. Underflow sludge

the side feed design.

concentrations are up to 5 times higher.

The clarified liquid leaves the plate assembly

In addition to self-contained designs, the LGS

through orifices or weirs at the top and is distributed

plate pack assembly is appropriate for installation

into collection channels leading to the clarified

in concrete basins or steel tanks. This can be a

water outlet. This creates a pressure drop across

low maintenance, cost-effective means of

the collection channels which ensures uniform

increasing existing basin capacity. The plate pack

flow distribution across the plates in order to

assemblies operate in the same manner as the

utilize the full area for settling.

free-standing units. The basins can be equipped

Three Standard Designs with Parkson’s SuperScraper™ hydraulic sludge

The LGS design is a self-contained, packaged scraper for sludge removal and thickening.

settling unit with a conical sludge hopper and

optional sludge scraper. Both designs can be equipped with a flash mixing

and flocculation tank upstream of the inlet pipe.

The LGST design is a high-rate gravity settler The chemical flocculant is added in a separate

combined with a circular, picket-fence sludge flash mixing compartment.

thickener/scraper. The settler section utilizes the

same counter-current flow principle and the

inclined plate design used in packaged Lamella

Gravity Settlers. The LGST handles flow rates

Fort Lauderdale Chicago Montreal Dubai

ISO 9001:2008 Certified www.parkson.com

Quality Management System technology@parkson.com

AN AXEL JOHNSON INC. COMPANY

1.888.PARKSON

1.954.974.6610 CLAR-LGS020109 ©2009 Parkson Corporation

You might also like

- 2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20Document10 pages2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20mgalphamrn100% (1)

- Biological Wastewater Treatment PDFDocument1,096 pagesBiological Wastewater Treatment PDFKhang Trần100% (2)

- WWT Secondary Clarifier PDFDocument15 pagesWWT Secondary Clarifier PDFdzari6738No ratings yet

- Hoja Completa UASBDocument12 pagesHoja Completa UASBAlex Ignacio Andrade100% (1)

- Benenv Products CatalogueDocument40 pagesBenenv Products CataloguePham Nguyen Phuc100% (3)

- DewateringDocument123 pagesDewateringHoseaNo ratings yet

- UNICEL Vertical Gas Flotation PDFDocument2 pagesUNICEL Vertical Gas Flotation PDFJessika LópezNo ratings yet

- Dissolved Air Flotation (DAF) SystemDocument8 pagesDissolved Air Flotation (DAF) Systemneeraj sharmaNo ratings yet

- Asp Vs MBRDocument8 pagesAsp Vs MBRStanPuneetNo ratings yet

- Data Sheet: Clarifier 13000: Description Lamella SeparatorDocument2 pagesData Sheet: Clarifier 13000: Description Lamella SeparatorTuesou Machere100% (1)

- JohnsonandBoltz2013 IFAS MBBRAirSystemDesign PDFDocument28 pagesJohnsonandBoltz2013 IFAS MBBRAirSystemDesign PDFBong BongarNo ratings yet

- Zero Liquid DischargeDocument28 pagesZero Liquid DischargegunjanatulbansalNo ratings yet

- Boehmite - 2020 PDFDocument7 pagesBoehmite - 2020 PDFSangyun SeoNo ratings yet

- Sludge ThickenerDocument10 pagesSludge ThickenerKharisma NataliaNo ratings yet

- Cyclone CalculationDocument151 pagesCyclone CalculationBANGGANo ratings yet

- Cyclone Excel Calculation - Google SearchDocument2 pagesCyclone Excel Calculation - Google SearchFucKerWengie100% (1)

- De Oiler WEMCODocument6 pagesDe Oiler WEMCONicolas RehNo ratings yet

- Bardenpho ProcessDocument8 pagesBardenpho ProcessAnonymous 8ooQmMoNs1100% (4)

- Dick Mechanisms of Sludge Thickening PDFDocument316 pagesDick Mechanisms of Sludge Thickening PDFpixulinoNo ratings yet

- Ozone PaDocument8 pagesOzone PaAmbar AmKaNo ratings yet

- Sismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsDocument5 pagesSismat Externally Fed Drum Screen (DAT) Brochure A4 - SpreadsasddNo ratings yet

- Design of A Screw Press For Dewatering of Cattle Dung SlurryDocument7 pagesDesign of A Screw Press For Dewatering of Cattle Dung SlurrycamsagNo ratings yet

- SFC Belt Filter Press IntroductionDocument38 pagesSFC Belt Filter Press Introductionthinh phanNo ratings yet

- Deliverable-1.10 Guideline Design Granular Sludge ReactorDocument19 pagesDeliverable-1.10 Guideline Design Granular Sludge ReactorCatalina Nicoleta RoscaNo ratings yet

- DegasifierDocument2 pagesDegasifierSumit Kaushik100% (1)

- G-5 Cyanide and Removal Options From Effluents in Gold Mining and Metallurgical Processes PDFDocument17 pagesG-5 Cyanide and Removal Options From Effluents in Gold Mining and Metallurgical Processes PDFCristian Galleguillos Cortes100% (1)

- Belt Filter PressDocument4 pagesBelt Filter PressPukhraj Daga100% (1)

- Coal Stockyard Storm Water TreatmentDocument23 pagesCoal Stockyard Storm Water TreatmentRajaram Jayaraman100% (1)

- Wastewater LagoonsDocument49 pagesWastewater LagoonsMatthew BennettNo ratings yet

- P0408 HM TP M TS 003Document79 pagesP0408 HM TP M TS 003SurangaGNo ratings yet

- Environmental Ionex II (Principle & Design)Document163 pagesEnvironmental Ionex II (Principle & Design)Moski KeljynNo ratings yet

- Pre Sedimentasi - Sheet1Document1 pagePre Sedimentasi - Sheet1milesNo ratings yet

- 5 Sludge Treatment & DisposalDocument28 pages5 Sludge Treatment & DisposalLeena Marashdeh100% (1)

- RHDHV Nereda EN PDFDocument8 pagesRHDHV Nereda EN PDFdmnNo ratings yet

- Cartridge Filter CartridgeDocument32 pagesCartridge Filter CartridgeTrần Quang TuyếnNo ratings yet

- 1326 Leopold TypeS FiltrationDocument5 pages1326 Leopold TypeS Filtrationgea alifa amorynaNo ratings yet

- Anaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandDocument9 pagesAnaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandPurnama Muhlis KaimunNo ratings yet

- Filter Design ParameterDocument3 pagesFilter Design ParameteruemaaplNo ratings yet

- Pump Selection For Filter PressesDocument8 pagesPump Selection For Filter Pressessangeeksub100% (1)

- Magra High-Rate Thickener Presentation 2011Document5 pagesMagra High-Rate Thickener Presentation 2011Eder SalcedoNo ratings yet

- Filtration ProcessDocument3 pagesFiltration Processannyi chamorroNo ratings yet

- IWATER Product Brochure MBBRDocument4 pagesIWATER Product Brochure MBBRAbderrazak AmiriNo ratings yet

- Oki Aerator PDFDocument10 pagesOki Aerator PDFDikky SukmayadiNo ratings yet

- Fume Scrubber Maintenance PDFDocument4 pagesFume Scrubber Maintenance PDFherikNo ratings yet

- Alum Stick ProductionDocument4 pagesAlum Stick ProductionMehreen shehzadiNo ratings yet

- Design of A Filtration System For A Small Scale Water Treatment Plant For A Rural Community Around Maiduguri Area in Borno State, NigeriaDocument5 pagesDesign of A Filtration System For A Small Scale Water Treatment Plant For A Rural Community Around Maiduguri Area in Borno State, NigeriainventionjournalsNo ratings yet

- Sludge Drying PDFDocument10 pagesSludge Drying PDFdanndiamondNo ratings yet

- Apex Manual 5.10.2013Document101 pagesApex Manual 5.10.2013Suresh KumarNo ratings yet

- Design Guidelines-TorayDocument2 pagesDesign Guidelines-TorayIrshad SondeNo ratings yet

- Sludge ProcessDocument16 pagesSludge ProcessArun Gupta0% (1)

- 21850, Issue 17 Flotation DAF, IAF, SAFDocument3 pages21850, Issue 17 Flotation DAF, IAF, SAFSyariful Maliki NejstaršíNo ratings yet

- Consider Wet Scrubbers For Pollution Control: Environmental ManagementDocument5 pagesConsider Wet Scrubbers For Pollution Control: Environmental ManagementAnkur GavaiNo ratings yet

- Filter PressDocument2 pagesFilter PressAnshuman Choudhury0% (1)

- Document Lamella Gravity Settler 1796Document2 pagesDocument Lamella Gravity Settler 1796fitomoh624No ratings yet

- Document Lamella Ecoflow Print Version 1798Document4 pagesDocument Lamella Ecoflow Print Version 1798fitomoh624No ratings yet

- Separator Internals Data SheetDocument13 pagesSeparator Internals Data SheetPreeda PawaranaNo ratings yet

- Failure Causes of Tray and PackingsDocument18 pagesFailure Causes of Tray and PackingsSatyam MadameNo ratings yet

- Document Lamella Ecoflow Brochure 482Document4 pagesDocument Lamella Ecoflow Brochure 482Zerihun Alemayehu0% (1)

- Halliburtos SAND TRAPDocument2 pagesHalliburtos SAND TRAPAnonymous JdPYHGmW100% (1)

- Alfa Laval Decanter PDFDocument16 pagesAlfa Laval Decanter PDFdaniel adamNo ratings yet

- Lamella Clarifier Leopold TexlerDocument4 pagesLamella Clarifier Leopold TexlerAntony ThanosNo ratings yet

- Avicci SANITARY WARE CatalogueDocument3 pagesAvicci SANITARY WARE CatalogueNyuku MasiloNo ratings yet

- CH 2 Land, Soil, Water, Natural Vegetation and Wildlife ResourcesDocument3 pagesCH 2 Land, Soil, Water, Natural Vegetation and Wildlife Resourcesxx yyNo ratings yet

- 3 Steps To Home Flood ProtectionDocument1 page3 Steps To Home Flood ProtectionAlison SandstromNo ratings yet

- Ce Syllabus-1 PDFDocument8 pagesCe Syllabus-1 PDFmadhav narayanNo ratings yet

- Potable WaterDocument19 pagesPotable Waterroshan034No ratings yet

- Investigatory ChemistryDocument16 pagesInvestigatory ChemistryRajat KumbharNo ratings yet

- Full Report Wastewater Paling Latest BiaDocument44 pagesFull Report Wastewater Paling Latest BiaSyazwi HakimiNo ratings yet

- For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-011: Otak InternationalDocument1 pageFor Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-011: Otak InternationalnaveenNo ratings yet

- BLD307 Newly CompiledDocument85 pagesBLD307 Newly CompiledAbdulazeez Habeebllah OlaitanNo ratings yet

- Ultrafiltration, Nanofiltration and Reverse Osmosis - Safe Drinking Water FoundationDocument7 pagesUltrafiltration, Nanofiltration and Reverse Osmosis - Safe Drinking Water FoundationJimmy Hend KhratNo ratings yet

- Unit 5.13 SedimentationDocument17 pagesUnit 5.13 SedimentationMutale InongeNo ratings yet

- BMB TB No2022 02Document43 pagesBMB TB No2022 02Darwin MacalisangNo ratings yet

- Form 2 ODCD (LGU LEGAZPI)Document7 pagesForm 2 ODCD (LGU LEGAZPI)Dominic CareoNo ratings yet

- Ramboll Session 1 - Understanding WSUD StrategyDocument25 pagesRamboll Session 1 - Understanding WSUD Strategypepelepiew76No ratings yet

- Electrocoagulation Electroflotation MethDocument10 pagesElectrocoagulation Electroflotation MethBagas FairuzNo ratings yet

- Chapter 9 - Highway Drainage: 020ROUGS4 - Road and Pavement EngineeringDocument50 pagesChapter 9 - Highway Drainage: 020ROUGS4 - Road and Pavement Engineeringfadi eidNo ratings yet

- Sanitary Engineering Chapter 7Document82 pagesSanitary Engineering Chapter 7nisha chimariyaNo ratings yet

- Engineering Utilities 2 Midterm Exam ReviewerDocument1 pageEngineering Utilities 2 Midterm Exam ReviewerGLANIE LEE CLARONo ratings yet

- Hydrologic Cycle and Water BudgetDocument29 pagesHydrologic Cycle and Water BudgetLarissa RiveraNo ratings yet

- Kurita Waste Water 04 15 en WebDocument2 pagesKurita Waste Water 04 15 en WebdanielNo ratings yet

- Field Exercise On Hydraulic Structure: Lecture in ChargeDocument10 pagesField Exercise On Hydraulic Structure: Lecture in ChargeMadura HasarangaNo ratings yet

- MC Layout PlanDocument1 pageMC Layout PlanMd SuruzzamanNo ratings yet

- Journey To ManasarovarDocument7 pagesJourney To ManasarovarHimanshi KumarNo ratings yet

- CDPHE On NoosaDocument3 pagesCDPHE On NoosaColoradoanNo ratings yet

- MSIG Volume 4Document288 pagesMSIG Volume 4Chung Yee Yong100% (1)

- LG Water Solutions - Brochure - ENGDocument10 pagesLG Water Solutions - Brochure - ENGCesiMartínezNo ratings yet

- Plate Settler Presentation 140415Document26 pagesPlate Settler Presentation 140415Raya SNo ratings yet

- Sargodha WSS RDP (13-04-2022)Document121 pagesSargodha WSS RDP (13-04-2022)Ahmed ButtNo ratings yet

- Hydrographic Surveying: - Uses of Hydrographic SurveyDocument7 pagesHydrographic Surveying: - Uses of Hydrographic SurveyShahid AliNo ratings yet