Asp Vs MBR

Asp Vs MBR

Uploaded by

StanPuneetCopyright:

Available Formats

Asp Vs MBR

Asp Vs MBR

Uploaded by

StanPuneetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Asp Vs MBR

Asp Vs MBR

Uploaded by

StanPuneetCopyright:

Available Formats

www.ijraset.

com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

Study of Industrial Wastewater Treatment

Comparison between Conventional Activated

Systems (CAS) and Membrane Bioreactor (MBR)

Systems

Manoj Kumar T1, Nilavuneasan D, Thiruvengadaravi KV, Baskaralingam P, Sivanesan S*2

1

Department of chemical Engineering, Anna University, Chennai

2

Department of Applied Science and Technology, Anna University, Chennai

Abstract--This paper provides a detailed literature review of waste water treatment in a membrane bioreactor process (MBR).

Here the MBR system is compared with conventional wastewater treatment system. The characteristics of the bioreactor

treatment process (biomass loading rates, etc.) and the membrane separation of microorganisms from the wastewater is

discussed in detail. The present study has been undertaken to evaluate the performance of the 60 KLD Beverages industrial

sewage treatment plant located at Nemam, Poonamallee, Thiruvallur District, Tamilnadu. The plants are designed and

constructed with an aim to manage wastewater in order to minimize and/or remove organic matter, solids, nutrients, disease-

causing organisms and other pollutants, before it reenters a water body. It is revealed from this performance study that the

efficiency of the conventional treatment method in analyzing the different removal/reduction parameters (TSS, BOD, COD,

HRT, SRTand F/M ratio) is poor on comparison with the MBR system.

Keywords--Industrial wastewater, Membrane Bioreactor, wastewater treatment.

I. INTRODUCTION

In India, most residential sewage treatment plants are expected to have zero liquid discharge (ZLD). Water is a source of life and

regarded as the most essential of natural resources. Existing freshwater resources are gradually becoming polluted and unavailable

due to human or industrial activities. The increasing contamination of freshwater systems with thousands of industrial and natural

chemical compounds is one of the key environmental problems facing humanity worldwide. A growing number of contaminants are

entering water supplies from industrialization like heavy metals, dyes, pharmaceuticals, pesticides, fluoride, phenols, insecticides

and detergents may have adverse effects on human health and aquatic ecosystems. In view of the aforesaid problems, recent

attention has been focused on the development of more effective, lower-cost, robust methods for wastewater treatment.

II. UNIT OPERATIONS IN SEWAGE TREATMENT PROCESS

The pollutants in waste water are removed by physical, chemical and biological means.

A. Physical Operations

In earlier days, treatment methods used were physical unit operations in which physical forces are applied to remove pollutants.

Some of the basic physical operations are given Screening, Comminuting, flow equalization, sedimentation etc.

B. Chemical Operations

Treatment methods in which the removal or conversion of contaminants is brought about by the addition of chemicals or by other

chemical reactions are known as chemical unit process. Precipitation and adsorption are the most common examples used in waste

water treatment. In chemical precipitation, treatment is accomplished by producing flocks that will settle.

C. Biological Operations

Biological treatment is used primarily to remove the biodegradable organic substance (colloidal or dissolved) in waste water. The

substances are converted into gases that can escape to the atmosphere and into biological cell tissue that can be removed by settling.

Biological treatment is also used to remove the nutrients such as nitrogen and phosphorous in waste water.

©IJRASET 2013: All Rights are Reserved 587

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

III. METHODS OF SEWAGE TREATMENT

Various methods for waste water treatment are given below:

Conventional method

Membrane Bioreactor (MBR)

Moving bed Bioreactor (MBBR)

Sequencing batch reactor (SBR)

A. Membrane Bioreactor

The mechanism of biodegradation is successfully used in the conventional activated sludge process for waste water treatment, and

also in advanced technologies as Membrane Bioreactor (MBR).Membrane bioreactor (MBR) technology is a combination of the

conventional activated sludge process characterized by a suspended growth of biomass and the membrane filtration system. The

biological unit is responsible for the biodegradation of the waste compounds and the membrane module for the physical separation

of the waste from the mixed liquid. The pore diameter of the membranes range between 0.01–0.1 μm so that particulates and

bacteria can be removed. The membrane system replaces the gravity sedimentation unit (clarifier) in the conventional activated

sludge process. Hence the MBR offers the advantage of higher product water quality and low footprint.

IV. PLANT LOCATION

The wastewater sample was collected from Beverages (Nemam) Poonamallee Sewage treatment plant in Tamilnadu. This plant was

based on the conventional treatment method (pre-treatment method) till DEC 2014, after which the plant is to be revamped to

Membrane bioreactor same capacity 60 m3/day. The conventional method of the sewage treatment plant lay out shown in Fig 1. Fig

2 shows the Membrane Bioreactor method of sewage treatment plant lay out.

Fig 1 Conventional method sewage treatment plant layout

ee

Collection Bar Equalization Aeration Tank

tank

Screen Tank

Permeate Secondary

Outlet

Settling Tank

Tank

Fig 2 Membrane Bioreactor method sewage treatment plant layout

In this plant revamping membrane bioreactor is installed manufactured by GE.

©IJRASET 2013: All Rights are Reserved 588

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

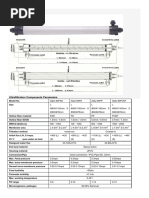

V. MEMBRANE SPECIFICA1TIONS

Specification of membrane used in the Beverages sewage treatment plant given in table 2

Membrane model Zee Weed 500D (Hollow Fiber)

Membrane material PVDF

Membrane module surface area 340ft2 (31.6m2)

Membrane pore size 0.04 micron

Operating pH range 5 to 9.5

VI. MATERIALS AND METHODS

The experimental method involved the collection of composite samples in clean plastic containers of 5 liters capacity at four

different units of treatment plant, namely, a) Influent to the treatment plant, b) Effluent of aeration tank (considered for the influent

of secondary clarifiers) and c) treated water from conventional method, d) treated water from MBR method

The samples were analyzed using the standard methods (APHA, EPA, and USEPA). IS 3025 (PART44-Reaffirmed 2003)The

primary parameters included pH,total dissolved solids(TDS),total suspended solids (TSS),Biological Oxygen Demand (BOD),

Chemical Oxygen Demand (COD), Sludge Volume index (SVI), MLSS, SRT, HRT.

A. Performance of MBR in Sewage Treatment Plant

1) Sludge Volume Index Method (SVI): 1lit of sewage inlet water sample taken beaker 10 min settle bottom.

The SVI of the process was 360 mg/L

2) Hydraulic Residence Time (HRT: HRT is the average residence time of wastewater in the aeration tank

HRT =24*Vat / Q units: hr

Where

Vat = Volume of aeration tank (m3)

Q = Flow rate of wastewater influent to aeration tank (m3/hr)

©IJRASET 2013: All Rights are Reserved 589

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

HRT = (24* 27)/ (9m3/hr)

= 72 hrs

3) Food-To-Microorganism (F/M) Ratio): F/M is the amount of BOD to which a unit mass of bio solids is exposed on a daily

basis (loading based on microorganisms)

F/M = (Q • So) / (MLVSS • Vat)

Where

Q = Influent flow (m3/hr)

So = Influent BOD concentration (mg/L)

MLVSS = Mixed liquor volatile suspended solids concentration in aeration tank (mg/L)

Vat = Volume of aeration tank (m3)

Influent flow = 9 m3/hr

Volume of aeration tank =27 m3

So = 128 mg/L

MLVSS = (A-B)*1000/ (Sample of volume mL)

= (1.6-0.8)*1000/ (10)

= 80

= 80*27

MLVSS = 2160 mg/L

(F/M) ratio =1152/2160

= 0.533

4) Solids Retention Time (SRT):

MLSS* Aeration Volume *8.34

SRT =

(WAS TSS)*(WAS Q)*8.34 + (Effluent TSS)*(Q) *8.34

2160*27*8.34

= -----------------------------

(92*7*8.34) + (104*9)*8.34

= 486388.8/ (5370.96 +7806.24)

= 36.911 hrs.

5) Volumetric BOD Loading: BOD applied to a unit volume of aeration tank:

VBL = 8.34 • (Q • So) / Vat

Where

Q = Influent flow

So = Influent BOD5 (mg/L)

Vat = Volume of aeration tank

VBL = 8.34*(9*122)/2

= 339.16 lb/1000ft3.day

6) Density:

©IJRASET 2013: All Rights are Reserved 590

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

= Mass/ Volume

= 800 / 1000

=0.800 g/L

= 800 kg/m3

VII. RESULTS AND DISCUSSION

Determined the general efficiency indicator to compare overall performances of the different plants in terms of average TSS, COD,

BOD, CHLORIDE removal efficiencs.Similarly,the, the efficiency of plants is generally measured in terms of removal of organic

matter. The pH directly affects the performance of a Secondary treatment process (Metcalf and Eddy, 1991 &2003) Because the

existence of most biological life is dependent upon narrow and critical range of pH .since, the solids removal is an important

measure for the success of a primary treatment unit (McGhee, 1991) and the dissolved solids content of the wastewater is of concern

as it affects the reuse of wastewater for agricultural purposes.

Physico – Chemical properties of sewage water of coca cola sewage treatment plant for conventional and MBR method

LOCATION

SAMPLING

CHLORIDE

COD(mg/l)

BOD(mg/l)

TDS(mg/l)

METHOD

TSS(mg/l)

TS(mg/l)

(mg/l)

pH

Initial 7.24 480 108 90 1050 1140 623

After aeration 7.18 304 52 82 1058 1140 486

CONVENTIONAL

Final 7.05 192 29 24 850 874 425

Initial 7.48 462 128 95 1025 1120 595

BIO REACTOR

MEMBRANE

After aeration 7.24 325 76 82 1008 1090 420

Final 6.98 36 8 12 514 526 280

After membrane revamped process continuous monitoring inlet and outlet for every 72 hrs because HRT design 72 hrs, SRT design

37 hrs, F/M ratio 0.533 to be calculate

©IJRASET 2013: All Rights are Reserved 591

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

Days condition pH COD BOD Cl TSS TDS TS

(mg/L) (mg/L) (mg/L) (mg/L) (mg/L) (mg/L)

Initial 7.48 462 128 595 95 1025 1120

After 7.24 325 76 420 82 1008 1090

1

aeration

Final 6.98 36 8 280 9 514 523

Initial 7.49 460 126 590 104 1086 1190

After 7.20 340 70 432 88 1068 1156

3

aeration

Final 7.03 32 6 272 10 528 538

Initial 7.52 486 130 586 102 1098 1200

After 7.33 358 68 438 90 1077 1167

6

aeration

Final 7.1 30 9 286 9 534 543

Initial 7.48 478 136 572 99 1076 1175

After 7.28 364 74 425 83 1036 1119

9

aeration

Final 6.95 34 10 278 8 518 526

Initial 7.48 470 120 570 94 1056 1150

After 7.19 332 71 418 80 1021 1101

12

aeration

Final 6.92 28 8 268 7 498 505

Table 3 Physico – Chemical properties of sewage water of coca cola sewage treatment plant for MBR method

VIII. BIOLOGICAL OXYGEN DEMAND

Days vs BOD

150

BOD(mg/l)

100

initial

50

after

0

1 3 6 9 12 final

Days

CHEMICAL OXYGEN DEMAND

©IJRASET 2013: All Rights are Reserved 592

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

Days vs COD

1000

COD(mg/L)

Initial

0

After

1 3 6 9 12

Days Final

TOTAL SUSPENDED SOLIDS

Days vs TSS

150

TSS(mg/L)

100 initial

after

50

final

0

1 3 6 9 12

A. Characteristics of Wastewater Influent to Inlet Of Treatment Plant

Coca Cola (Nemam) Poonamallee Sewage treatment plant in Tamilnadu, at the inlet, performance study of 7 months collected and

analysis the concentration ranges of total dissolved solids, total suspended solids, BOD and COD were 1025 – 1096 mg/L, 90 – 104

mg/L, 120 – 136 mg/L, 460 – 486 mg/, While the average chlorides were 570 – 595 mg/L.The pH varied from 7.24 to 7.52.

B. Characteristics of Wastewater Effluent To Aeration Tank

Aeration tank in the both the treatment plant is considered a most important step in activate sludge process and the priority was

intended to increase the dissolved oxygen level of sewage so that the aerobic digestion facilitates decomposition of organic matter

this has to be ensured because of low dissolved oxygen content (nil) in the influent. The DO in aeration tank range from 1.2 to 2.6

mg/L.

MLSS Concentration in the aeration tank range between 2160 -2380 mg/L. Conforming suitability in terms of microbial content. A

SVI value 100 – 350 indicates good settling of suspended solids that can be achieved for proper MLSS Concentration. The SVI was

320 mg/L.

C. Characteristics of Wastewater Effluent to Treated Tank

Treated water tank in most important for wastewater treatment in this effluent treated conventional method was calculated by

considering the BOD, COD and TSS were 29 - 35 mg/L, 190 -202 mg/L, and 25 – 32mg/L. Sewage Treatment Plant after revamped

conventional system to MBR systems Samples were collected and analysis MBR method was calculated by considering the BOD,

COD and TSS were 7 - 9 mg/L, 28 -36 mg/L, and 9 – 11mg/L.pH varied from 6.98 – 7.12

D. Overall Efficiency of the Two Treatments Methods

The overall efficiency of the two treatments methods was calculated by considering the TDS, TSS, COD and BOD of the influent

and final effluent from conventional method and MBR Method. The percentage reduction in COD is 192 - 202 mg/L and 58% -

60% in Conventional Method, MBR Method reduction of COD is 28 - 36 mg/L and 92.5% - 94% respectively. The percentage

reduction in BOD is 29 -35 mg/L and 74% -76% in Conventional Method, MBR Method reduction of BOD is 6 - 9 mg/L and 93% -

95 % satisfactory. The percentage reduction in TSS is 25- 32 mg/L and 69% -72% in Conventional Method, MBR Method reduction

of TSS is 7 - 10 mg/L and 90% - 92% satisfactory.

©IJRASET 2013: All Rights are Reserved 593

www.ijraset.com Volume 4 Issue II, February 2016

IC Value: 13.98 ISSN: 2321-9653

International Journal for Research in Applied Science & Engineering

Technology (IJRASET)

OVER ALL EFFICIENCY FOR CONVENTIONAL SYSTEM AND MEMBRANE BIOREACTOR SYTEM

EFFICIENCY

95 94 92

100 76 72

60

50

0

BOD COD TSS

CONVENTIONAL MBR

IX. CONCLUSION

The maximum COD and BOD, TSS, TDS removal was observed at 72hrs the optimum HRT is assessed for every 72hrs, for

effective Removal of COD, BOD, TDS, and TSS, Removal BOD, COD (Microorganism and organic contamination) optimum for 6

to 9 days, Removal of TSS, TDS optimum for 6 days. MBR maximum efficiency 30 to 35 % compared to conventional method.

Comparison between industrial wastewater treatment conventional Method and Membrane Bioreactor System, so this process

conventional method treated wastewater using garden purpose only. Sewage Treatment Plant after revamped conventional system to

MBR systems treated water reuse gardening, flushing, cooling tower.

REFERENCES

[1] Sudhakar, Muniswami, Vijayalakshmi, Ponnusamy and Sivanesan Subramanian, Preventing membrane bio-fouling in a full-scale plant by textile effluent pre-

treatment to produce near zero biological oxygen demand, Research Journal of Chemistry and Environment.185(2014) 369 -368

[2] Elango.D, Pulikesi.M, Baskaralingam.P, Ramamurthi.V and Sivanesan.S, Production of Biogas from Municipal solid waste with domestic sewage, Journal of

Hazardous Materials, 141 (2007) 301 – 304.

[3] Takao Murakami, Membrane Bioreactors for Waste water Reuse”, Senior Researcher, Dept., Japan Sewage Works Agency, 5141 shimo-sasame, Toda, 335-

0037 Japan

[4] Stacy Scott, Application of Membrane Bioreactor Technology to Wastewater Treatment and Reuse.589-04589

[5] ZakirHirani, James Decarolis,Larry Wasserman,Joe Jacangelol,Hal Schmidt, and George Simon, Feasibility of Selected MBR Systems For Water

Reclamation.896-896,2010.

[6] Melhem, K. B, Edward Smith. ‘Grey water treatment by a continuous process of an electrocoagulation unit and a submerged membrane bioreactor system’,

Chemical Engineering Journal, Vol.198-199, pp. 201–210, 2012.

[7] Govindasamy P., Madhavan SD., Revathi S and Shanmugam P., ‘Performance Evaluation of Common Effluent Treatment Plant for Tanneries at Pallavaram

CETP’, Journal Of environ. Science &engg. Vol. 47, No. 4, P. 326-335

[8] Ram Kumar Kushwah., AvinashBajpai and Suman Malik., ‘Wastewater Quality Studies of Influent and Effluent Water at Municipal Wastewater Treatment

plant, Bhopal (India)’ International journal of chemical, environmental and pharmaceutical research (CEPR) Vol. 2, No.2-3, 131-134 May-December, 2011

[9] Office of Wastewater Management, Washington DC 20460., ‘Primer for Municipal Wastewater Treatment Systems’EPA 832-R-04-001, September 2004

[10] Marrot,Barrios-Martinez,Mouin,Roche, Industrial Wastewater treatment from Membrane Bioreactor, online publication Wiley interscience , Vol 23,No1,2004.

[11] McGhee.T.1991 water supply and sewerage; McGraw-Hill International Editions, 6th edition, New York.

[12] Metcalf and Eddy Inc., (1991), “Wastewater Engineering: Treatment, Disposal and Reuse”3rd edition Tata McGraw-Hill Publishing co.Ltd, New Delhi.

[13] Metcalf and Eddy Inc., (2003), “Wastewater Engineering: Treatment, Disposal and Reuse”4th edition Tata McGraw-Hill Publishing co.Ltd, New Delhi.

©IJRASET 2013: All Rights are Reserved 594

You might also like

- Questionnaire For ETPDocument4 pagesQuestionnaire For ETPdhruvfuturaNo ratings yet

- 25 KLD - STPDocument12 pages25 KLD - STPranjeet.globalgreenNo ratings yet

- ReviewerDocument13 pagesReviewerElden Kyle Billones100% (3)

- Manual ENG - Kristal 600ER0820 V1.3b (221110)Document49 pagesManual ENG - Kristal 600ER0820 V1.3b (221110)merifie renegado67% (3)

- Rubber Wastewater Treatment ProcessDocument2 pagesRubber Wastewater Treatment ProcessStan MacapiliNo ratings yet

- Environmental Fluid Dynamics: Handbook ofDocument577 pagesEnvironmental Fluid Dynamics: Handbook ofStanPuneetNo ratings yet

- Design of 50KLD MBBR Based Sewage Treatment For Hostel Building, NagpurDocument7 pagesDesign of 50KLD MBBR Based Sewage Treatment For Hostel Building, NagpurIJRASETPublicationsNo ratings yet

- Aquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvDocument5 pagesAquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvNitin GajmalNo ratings yet

- DMI 65 Technical Data SheetDocument7 pagesDMI 65 Technical Data Sheetalexmuchmure2158No ratings yet

- Chemical Consumption DBDocument3 pagesChemical Consumption DBkemas biruNo ratings yet

- Perhitungan Kebutuhan ChemicalDocument49 pagesPerhitungan Kebutuhan ChemicalDavid LambertNo ratings yet

- Technical Datasheet of SBRDocument13 pagesTechnical Datasheet of SBRKSPCB KalaburagiNo ratings yet

- The Treatment Fo Fluorescent Penetrant WastewaterDocument9 pagesThe Treatment Fo Fluorescent Penetrant WastewaterWONG TSNo ratings yet

- Bio STP Final PrintDocument11 pagesBio STP Final PrintChauhan UjjvalNo ratings yet

- IWATER Product Brochure MBBRDocument4 pagesIWATER Product Brochure MBBRAbderrazak AmiriNo ratings yet

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocument7 pagesA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNo ratings yet

- MBR Membrane BioreactorDocument3 pagesMBR Membrane Bioreactorjpsingh75No ratings yet

- Report of Membrane Bioreactor System (MBR) For Wastewater TreatmentDocument10 pagesReport of Membrane Bioreactor System (MBR) For Wastewater TreatmentJulie MahadiNo ratings yet

- CLARIFIERDocument3 pagesCLARIFIERsumit_7285No ratings yet

- Fs-Bio-010-Mbr A20160202Document25 pagesFs-Bio-010-Mbr A20160202GREENLAB ECL TECH100% (1)

- MBR OPEX - The Theory of Running CostsDocument6 pagesMBR OPEX - The Theory of Running CostsJeremy DudleyNo ratings yet

- Membrane Bio-Reactor Membrane Sheets With The Material of PVDFDocument2 pagesMembrane Bio-Reactor Membrane Sheets With The Material of PVDFsong gongNo ratings yet

- Primary Treatment Secondary TreatmentDocument2 pagesPrimary Treatment Secondary TreatmentMiftah MasrurNo ratings yet

- Karnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemDocument7 pagesKarnaphuli Water Supply Project Phase 2: P&Id For Chlorine Neutralization SystemJahangir AlamNo ratings yet

- Reverse Osmosis Design GuidelinesDocument2 pagesReverse Osmosis Design Guidelineswacsii ccasullaNo ratings yet

- TMF Lime SofteningDocument2 pagesTMF Lime SofteningRachel HechanovaNo ratings yet

- Bike Wash ETP OfferDocument11 pagesBike Wash ETP OfferMuhammadHanifa100% (1)

- Containerisedmbrsystem EngDocument12 pagesContainerisedmbrsystem EngNermeen ElmelegaeNo ratings yet

- Membrane Bioreactors For Municipal Wastewater TreatmentDocument154 pagesMembrane Bioreactors For Municipal Wastewater TreatmentYONGSEOK CHOINo ratings yet

- Co2 Degasifier To Adjust The PHDocument2 pagesCo2 Degasifier To Adjust The PHGhuna UcihaNo ratings yet

- UPVC Chemical Resistance ChartDocument5 pagesUPVC Chemical Resistance ChartPravin BoteNo ratings yet

- Anaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandDocument9 pagesAnaerobic Ponds Treatment of Starch Wastewater Case Study in ThailandPurnama Muhlis KaimunNo ratings yet

- Ozone PaDocument8 pagesOzone PaAmbar AmKaNo ratings yet

- MBR DesignDocument5 pagesMBR DesignDavid LambertNo ratings yet

- Water PDFDocument12 pagesWater PDFONE DNo ratings yet

- 3Document66 pages3Nikhil AroraNo ratings yet

- WAVE Courseware 2019Document33 pagesWAVE Courseware 2019patryk001No ratings yet

- MBBR STP - WastreatDocument2 pagesMBBR STP - WastreatA3S ENVIRONo ratings yet

- Efficiency Comparison of Various Sewage Treatment Plants in BangaloreDocument36 pagesEfficiency Comparison of Various Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocument8 pages04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNo ratings yet

- ETP Combined Spec - R0Document60 pagesETP Combined Spec - R0Pravash Chandra Senapaty100% (1)

- 50 Cum/day Capacity Softener System Sl. No. Particulars Specification Feed Pump / Backwash Pump With MotorDocument8 pages50 Cum/day Capacity Softener System Sl. No. Particulars Specification Feed Pump / Backwash Pump With MotorkoppinenipraneethNo ratings yet

- Hydraulic Calculation Sheet Influent DataDocument18 pagesHydraulic Calculation Sheet Influent DataMagic Master0% (1)

- MemstarDocument3 pagesMemstarAo Thành Tuấn100% (1)

- Kuliah MBR ITB 14 Nov 2022 - For PrintDocument31 pagesKuliah MBR ITB 14 Nov 2022 - For PrintEni RohkayatiNo ratings yet

- Lamella Clarifier Leopold TexlerDocument4 pagesLamella Clarifier Leopold TexlerAntony ThanosNo ratings yet

- Project Profile On Battery Water PDFDocument2 pagesProject Profile On Battery Water PDFSuresh KaushikNo ratings yet

- Treatment of Tannery WastewaterDocument11 pagesTreatment of Tannery Wastewatersadakeling90% (1)

- JohnsonandBoltz2013 IFAS MBBRAirSystemDesign PDFDocument28 pagesJohnsonandBoltz2013 IFAS MBBRAirSystemDesign PDFBong BongarNo ratings yet

- History of Nano FiltrationDocument42 pagesHistory of Nano FiltrationKieran Sexton100% (2)

- Trehan STPDocument2 pagesTrehan STPsoma_sharadNo ratings yet

- Old Formula MBBRDocument190 pagesOld Formula MBBRRoland LumpasNo ratings yet

- MBBR Pack - GB - 1.0 - 06-10-2015Document8 pagesMBBR Pack - GB - 1.0 - 06-10-2015SvetlanaNo ratings yet

- AOP + ElectrocoagulationDocument53 pagesAOP + ElectrocoagulationShri ShriNo ratings yet

- Wastewater Treatment Plant Options and Design CriteriaDocument14 pagesWastewater Treatment Plant Options and Design Criteriaahmed elbazNo ratings yet

- Mini Project ReportDocument5 pagesMini Project ReportSaj BhaiNo ratings yet

- Laundry Wastewater Treatment Using CoaguDocument20 pagesLaundry Wastewater Treatment Using CoaguAnggy de Rincon100% (1)

- Zero Liquid DischargeDocument28 pagesZero Liquid DischargegunjanatulbansalNo ratings yet

- Moving Bed Biofim Reactor Sewage TreatmentDocument9 pagesMoving Bed Biofim Reactor Sewage TreatmentchemitechengineerNo ratings yet

- Brosur - UF Membrane (A) PDFDocument8 pagesBrosur - UF Membrane (A) PDFigo badr100% (1)

- Unesco - Eolss Sample Chapters: Amounts and Composition of Municipal Solid WastesDocument8 pagesUnesco - Eolss Sample Chapters: Amounts and Composition of Municipal Solid WastesStanPuneetNo ratings yet

- Annex 31 Tool Design Extended AerationDocument5 pagesAnnex 31 Tool Design Extended AerationKalyca Nazhifa SalwaNo ratings yet

- Himachal Pradesh Public Service Commission: Asstt Environmental Engineer - 2019Document1 pageHimachal Pradesh Public Service Commission: Asstt Environmental Engineer - 2019StanPuneetNo ratings yet

- Multi-Criteria Decision-Making Using GIS-AHP For Air Pollution Problem in Igdir Province/TurkeyDocument17 pagesMulti-Criteria Decision-Making Using GIS-AHP For Air Pollution Problem in Igdir Province/TurkeyStanPuneetNo ratings yet

- 114' Mapping of Vehicular Noise Pollution Using GISDocument7 pages114' Mapping of Vehicular Noise Pollution Using GISStanPuneetNo ratings yet

- A GIS-based Spatial Correlation Analysis For AmbieDocument16 pagesA GIS-based Spatial Correlation Analysis For AmbieStanPuneetNo ratings yet

- Mapping of Air Pollution Using GIS: A Case Study of HyderabadDocument7 pagesMapping of Air Pollution Using GIS: A Case Study of HyderabadStanPuneetNo ratings yet

- Some Methods of Tidal Analysis: Mosetti MancaDocument14 pagesSome Methods of Tidal Analysis: Mosetti MancaStanPuneetNo ratings yet

- Ultrasonic Disintegration of Sewage Sludge To Increase Biogas GenerationDocument7 pagesUltrasonic Disintegration of Sewage Sludge To Increase Biogas GenerationStanPuneetNo ratings yet

- Hydrodynamic Modelling of An UASB Reactor: November 2015Document3 pagesHydrodynamic Modelling of An UASB Reactor: November 2015StanPuneetNo ratings yet

- A Study of Decentralized Wastewater Systems in IndiaDocument1 pageA Study of Decentralized Wastewater Systems in IndiaStanPuneetNo ratings yet

- Viewdoc PDFDocument57 pagesViewdoc PDFStanPuneetNo ratings yet

- Ashok Kumar Gude Test Engineer - TraineeDocument3 pagesAshok Kumar Gude Test Engineer - TraineeSourabh SinhaNo ratings yet

- Express 1A (FWS) PDFDocument226 pagesExpress 1A (FWS) PDFyusdi afandiNo ratings yet

- GOODYEAR PHILIPPINES v. SyDocument5 pagesGOODYEAR PHILIPPINES v. SyShiela MagnoNo ratings yet

- Comparative Design of Biaxial RC ColumnsDocument14 pagesComparative Design of Biaxial RC ColumnsMouhamad WehbeNo ratings yet

- Ang Kasaysayan NG Paglikha-Aralin 4 (Regular SSC) : Review: Bible Lesson Introduction: Review of Creation Day One To FourDocument6 pagesAng Kasaysayan NG Paglikha-Aralin 4 (Regular SSC) : Review: Bible Lesson Introduction: Review of Creation Day One To FourWize DeeNo ratings yet

- Grade 10 Math Performance Task Practice Test Scoring Guide Lights Candles ActionDocument20 pagesGrade 10 Math Performance Task Practice Test Scoring Guide Lights Candles ActionMaychelle TañezaNo ratings yet

- GS HS Math 2012 ParticipantDocument224 pagesGS HS Math 2012 Participanthairey947594No ratings yet

- Letter WritingDocument31 pagesLetter WritingMuazNo ratings yet

- Patriotic Oath (Philippines) : CustomDocument3 pagesPatriotic Oath (Philippines) : CustomReynalynne Caye MagbooNo ratings yet

- Deliverance - 3 - P Holliday PDFDocument67 pagesDeliverance - 3 - P Holliday PDFCHRISTIAN BOOKSNo ratings yet

- Sherwood - Prostitute & Prophet, Hosea's Marriage in Literary-Theoretical Perspective - JSOTS 212Document361 pagesSherwood - Prostitute & Prophet, Hosea's Marriage in Literary-Theoretical Perspective - JSOTS 212Silviu Dorin100% (2)

- Car Racing Games TemplateDocument40 pagesCar Racing Games TemplateCarm Gonzales100% (1)

- House (Individual House/Apartment) Rental Management SystemDocument6 pagesHouse (Individual House/Apartment) Rental Management SystemjanscarletTM uzamakiNo ratings yet

- Jamila S Khalil Complete ProjectDocument57 pagesJamila S Khalil Complete ProjectEmmanuelNo ratings yet

- Double TakeDocument3 pagesDouble TakeKip PygmanNo ratings yet

- Atkins Madison E-PortfolioDocument1 pageAtkins Madison E-Portfolioapi-622043707No ratings yet

- Thesis Airport SecurityDocument8 pagesThesis Airport SecurityNicole Adams100% (2)

- Are Lawyers Liars?: (Short Paper No. 2)Document5 pagesAre Lawyers Liars?: (Short Paper No. 2)Windy Awe Malapit100% (1)

- Capilla of The Campito de San José: M - Arch - T History ClassDocument1 pageCapilla of The Campito de San José: M - Arch - T History ClassSantiago Sánchez RodríguezNo ratings yet

- Choir & Organ - September 2021Document86 pagesChoir & Organ - September 2021崔艺道No ratings yet

- Bahai Child Rape Court Case - Implications For IranDocument33 pagesBahai Child Rape Court Case - Implications For IranNasserbBahaiNo ratings yet

- 5 Strategies To Beat The Philippine Stock Market - Juanis BarredoDocument61 pages5 Strategies To Beat The Philippine Stock Market - Juanis BarredoDon Quijote de la ManchaNo ratings yet

- Advance Power Electronics - GTU Paper - April2010Document1 pageAdvance Power Electronics - GTU Paper - April2010be6351No ratings yet

- Lunch Set Menu: Available Sunday To Thursday From 12 PM To 3 PMDocument1 pageLunch Set Menu: Available Sunday To Thursday From 12 PM To 3 PMNT TankyaNo ratings yet

- Archdiocesan Spelling Bee Word List GR High SchoolDocument4 pagesArchdiocesan Spelling Bee Word List GR High Schoolanaba2926No ratings yet

- Ancient Architecture (A Visual Dictionary)Document54 pagesAncient Architecture (A Visual Dictionary)Elaiza Ann TaguseNo ratings yet

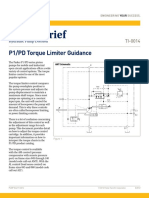

- P1PD Torque Limiter GuidanceDocument5 pagesP1PD Torque Limiter GuidancexxshNo ratings yet

- P N M S: PNMSJ+ Installation Manual (Windows Server 2008, Windows Server 2008 R2, Windows Server 2012 R2)Document113 pagesP N M S: PNMSJ+ Installation Manual (Windows Server 2008, Windows Server 2008 R2, Windows Server 2012 R2)sergioNo ratings yet

- Reicon Realty vs. DiamondDocument15 pagesReicon Realty vs. DiamondAlexNo ratings yet