Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Uploaded by

nadeem shaikhCopyright:

Available Formats

Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Uploaded by

nadeem shaikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Saudi Aramco Test Report: Ultraviolet (UV) Light Intensity Log 24-Jul-18 NDE

Uploaded by

nadeem shaikhCopyright:

Available Formats

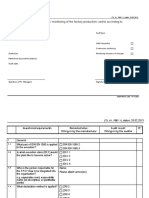

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.

00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

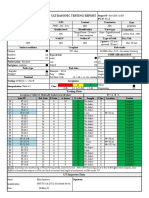

Ultraviolet (UV) Light Intensity Log SATR-NDE-2010 24-Jul-18 NDE

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

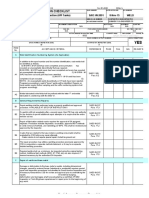

SAEP-1145 Section 7

7.1 Lighting and lighting intensity shall meet the requirements of ASME V, Article 6, T-676.3 for color contrast (visible) PT examination, and T-676.4 for fluorescent PT examinations,

unless otherwise specified in this procedure.

7.2 Visible and UV light sources and meter specifications and requirements shall meet the requirements of ASTM E2297.

7.3 Color Contrast (Visible) PT indications can be examined in either natural or artificial white light. PT examinations performed in the field or at shop with color contrast require a

minimum of 1000 lux (100 fc) of white light illumination at the examination surface for adequate evaluation of indications. The reading shall be recorded on the PT Inspection report.

7.4 Every attempt shall be made to darken the area as much as possible prior to conducting a fluorescent penetrant examination through the use of a blanket, hood, or portable booth.

7.5 Ultraviolet light intensity shall be measured at the examination surface prior to the fluorescent penetrant examination. The light sensor shall be placed on the surface to be tested.

The black light should be centered perpendicular (90°) to the light sensor at a distance of 381 mm (15 inches). The light should be maneuvered in such a manner as to monitor the light

meter and achieve the highest intensity reading. The reading shall be recorded on the PT Inspection report.

7.7 Examinations requiring the use of ultraviolet light shall be conducted in a darkened area of 21 lux (2 fc) or less of white light intensity as measured at the surface to be tested, as per

ASTM E1417, paragraph 6.6.1.

7.8 The ultraviolet light intensity at the examination surface shall be measured:

• Prior to use

• After completion of examinations

• At least every 4 hours.

• Whenever the work location is changed.

• After changing a component of the unit such as a filter or bulb.

• After a black light unit failure.

• Whenever power source is interrupted or changes.

7.9 The light meters shall be calibrated every 1 year and bear an authentic seal which presents the date calibration was accomplished and the next due date, as per ISO 3059, Section 8.

7.10 A minimum of 3000 μW/cm² is required for field inspections in areas of ambient white light which exceed 21 lux (2 fc) as measured at the examination surface. A minimum value of

1000 μW/cm² is required for work in a darkened area of 21 lux or less, as per ASTM E165, paragraph 8.9.1 and ISO 3059, Section 6.3.

7.11 The UV light must be allowed to warm-up a minimum for 5 minutes prior to use as per ASTM E165, paragraph 8.9.1.2. In the event power is lost, many lights require 20 minutes

before they will restart. Regardless, if the power is lost, an additional warm-up time of 10 minutes is required to assure proper performance of the UV light.

7.12 The inspector should be in the darkened examination area for at least 5 minutes prior to examination to allow the eyes to adapt to the dark viewing, as per ASME V, Article 6, T-

676.4(b).

NDT Service Provider / Contractor Saudi Aramco

Technician Performing Test* PMT Representative

Saudi Aramco: Company General Use

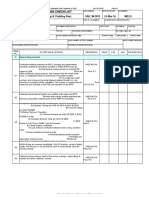

SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018) Rev.2018.06.00 30-Jun-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

Ultraviolet (UV) Light Intensity Log SATR-NDE-2010 24-Jul-18 NDE

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Saes R 004Document8 pagesSaes R 004nadeem shaikh100% (1)

- Nitrogen PowerpointDocument24 pagesNitrogen PowerpointArnis JapinsNo ratings yet

- Saic H 2024Document2 pagesSaic H 2024usmanNo ratings yet

- Saes S 040Document22 pagesSaes S 040nadeem shaikhNo ratings yet

- Saes S 007Document17 pagesSaes S 007nadeem shaikhNo ratings yet

- 175 045600Document2 pages175 045600Abu Anas M.Salaheldin0% (1)

- Phanikumar TransportPhenomenaNotes 01feb2010Document109 pagesPhanikumar TransportPhenomenaNotes 01feb2010aalisafa50% (2)

- MPT Procedure No:: Saudi Aramco Test ReportDocument2 pagesMPT Procedure No:: Saudi Aramco Test Reportnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEDocument1 pageSaudi Aramco Test Report: Ultrasonic Testing (SAEP-311 Hot Tap/Tie In) Report 24-Jul-18 NDEnadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatDocument2 pagesSaudi Aramco Test Report: Adhesion Test of Fbe Coating SATR-H-2010 CoatnasirNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report (Weld Overlay UT Examination) SATR-NDE-2006 24-Jul-18 NdeDocument9 pagesSaudi Aramco Test Report: Ultrasonic Test Report (Weld Overlay UT Examination) SATR-NDE-2006 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 NdeDocument3 pagesSaudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Saudi Aramco Test Report: Re-Instatement Punch List Form (Punch List by The Contractor) SATR-A-2011 25-May-05 MechDocument1 pageSaudi Aramco Test Report: Re-Instatement Punch List Form (Punch List by The Contractor) SATR-A-2011 25-May-05 MechAnonymous S9qBDVkyNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)Document2 pagesSAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)nadeem shaikhNo ratings yet

- SAIC-W-2015 Select Welds For NDE (On-Plot)Document3 pagesSAIC-W-2015 Select Welds For NDE (On-Plot)KirubhakarPooranamNo ratings yet

- SAIC-A-2025 Rev 6 Pre Test Pressure VesselDocument4 pagesSAIC-A-2025 Rev 6 Pre Test Pressure Vesselpookkoya thangal100% (1)

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDocument13 pagesFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischGabriel StoichitaNo ratings yet

- NDT Terminology Glossary Reference ComparativeDocument38 pagesNDT Terminology Glossary Reference ComparativeDavid RodriguezNo ratings yet

- Saudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldDocument4 pagesSaudi Aramco Inspection Checklist: Weld Repair Verification and Inspection (API Tanks) SAIC-W-2091 8-Nov-15 WeldAbdul Khaleem KhanNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdeDocument1 pageSaudi Aramco Inspection Checklist: Review of Radiographic Testing Procedure SAIC-RT-2001 25-May-05 NdephilipyapNo ratings yet

- Adw TR RTCF QP Me 002, Rev.1Document38 pagesAdw TR RTCF QP Me 002, Rev.1Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- 5 Things Surface Prep 1Document40 pages5 Things Surface Prep 1Jesus De la RosaNo ratings yet

- Iqwq Ce1091 Vphyt D7 9005 - 0Document5 pagesIqwq Ce1091 Vphyt D7 9005 - 0Bello Friday JacksonNo ratings yet

- RDSO NDT 109 For Magnetic Particles Used in MPIDocument4 pagesRDSO NDT 109 For Magnetic Particles Used in MPISâñthøßh Päwãr100% (1)

- Visual Inspection PV FormDocument2 pagesVisual Inspection PV FormGibson FisherNo ratings yet

- BV Italy January 2007 Introduction PDFDocument79 pagesBV Italy January 2007 Introduction PDFKadri HelmiNo ratings yet

- G3 Application Paint FINAL DRAFT 07-10-2016-MMDocument132 pagesG3 Application Paint FINAL DRAFT 07-10-2016-MMalemayehu tesfayeNo ratings yet

- Iqwq Ce1091 VPNDT D7 4562 - 0Document49 pagesIqwq Ce1091 VPNDT D7 4562 - 0Bello Friday JacksonNo ratings yet

- NDT & Rbi: Ultrasonic Test: Departemen Teknik Material & Metalurgi Institut Teknologi Sepuluh Nopember (ITS) 2022Document63 pagesNDT & Rbi: Ultrasonic Test: Departemen Teknik Material & Metalurgi Institut Teknologi Sepuluh Nopember (ITS) 2022Naufal RafiNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SATIP F 001 02 Forced Draft FanDocument3 pagesSATIP F 001 02 Forced Draft FanhossamalsherbinyNo ratings yet

- ?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'CesDocument33 pages?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'Cesvijay padaleNo ratings yet

- SATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Document2 pagesSATIP-NDE-LPT-01 Liquid Penetrant Testing-Rev1Sivaram KottaliNo ratings yet

- SAIC-W-2043 Rev 0Document3 pagesSAIC-W-2043 Rev 0philipyapNo ratings yet

- Radiography Examination ProcedureDocument8 pagesRadiography Examination ProcedureSivaraman SelvarajNo ratings yet

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 pageSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWNo ratings yet

- PA UTR 2021 053 (Final)Document1 pagePA UTR 2021 053 (Final)Elias JarjouraNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldDocument9 pagesSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Dec-09 WeldIrshad IqbalNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestDocument4 pagesSaudi Aramco Inspection Checklist: SAIC-W-2022 24-Mar-16 Weld-In-Process Welding Insp - Weld Overlay & Cladding RestRijwan MohammadNo ratings yet

- Thermax Limited: Inspection Procedure For GalvanizingDocument14 pagesThermax Limited: Inspection Procedure For GalvanizingNsidibe Michael EtimNo ratings yet

- Visual TestingDocument39 pagesVisual TestingLeon Heart FCNo ratings yet

- Heat Treatment of Welded StructuresDocument25 pagesHeat Treatment of Welded Structuresjohn powerNo ratings yet

- 09 Samss 035Document8 pages09 Samss 035NASIR SYEDNo ratings yet

- Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BDocument15 pagesAin Tsila Development Main EPC Contract A-CNT-CON-000-00282 Subcontract N°: JI-2045/07-002BAslaouiNo ratings yet

- SAIC-W-2007 Rev 8Document6 pagesSAIC-W-2007 Rev 8saravananmenmathiNo ratings yet

- Ultrasound v. Radiography For ThermowellsDocument1 pageUltrasound v. Radiography For ThermowellsChristian R. TaylorNo ratings yet

- Specifications - NDT Contract - SPGDocument7 pagesSpecifications - NDT Contract - SPGTechnical A-Star Testing & Inspection Malaysia0% (1)

- Saudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Weld Overlay Chemical Composition Testing & Results SAIC-W-2025 24-Mar-16 WeldRijwan MohammadNo ratings yet

- 09 Samss 087 PDFDocument8 pages09 Samss 087 PDFMohamed SolimanNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Welding Procedure Specification (WPS) : Date: 2017/04/09Document1 pageWelding Procedure Specification (WPS) : Date: 2017/04/09akalNo ratings yet

- VMW 2 OP 007 Rev.6 UncontrolledDocument8 pagesVMW 2 OP 007 Rev.6 Uncontrolledsyasha humairaNo ratings yet

- 175 014300Document1 page175 014300Abu Anas M.SalaheldinNo ratings yet

- Satr H 2004Document1 pageSatr H 2004ravi ajithNo ratings yet

- P 11 CNDT JP39 LPI-ASME Sec VIII Dye Penetrant Testing R11Document15 pagesP 11 CNDT JP39 LPI-ASME Sec VIII Dye Penetrant Testing R11Vimal MenonNo ratings yet

- 175-026600 10312016Document2 pages175-026600 10312016Prasanna UmapathyNo ratings yet

- Radiography of Welds Using Selenium 75, Ir 192 and X-Rays: TH TH THDocument5 pagesRadiography of Welds Using Selenium 75, Ir 192 and X-Rays: TH TH THSundar KumarNo ratings yet

- Repair of Single Coat Inorganic Zinc SilDocument8 pagesRepair of Single Coat Inorganic Zinc SilLuís PiresNo ratings yet

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- Saep 310Document38 pagesSaep 310paul cafeNo ratings yet

- Satr H 2008Document2 pagesSatr H 2008Moghal AliNo ratings yet

- Saudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)Document4 pagesSaudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)nadeem shaikhNo ratings yet

- SAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)Document2 pagesSAUDI ARAMCO ID/PIEU-24-July-2018 - REV.2018.06.00 (Standards Cutoff - June 30,2018)nadeem shaikhNo ratings yet

- Satr Nde 2002Document1 pageSatr Nde 2002nadeem shaikhNo ratings yet

- Satr A 2010Document2 pagesSatr A 2010nadeem shaikhNo ratings yet

- Saes Q 004Document25 pagesSaes Q 004nadeem shaikhNo ratings yet

- Saes S 020Document33 pagesSaes S 020nadeem shaikhNo ratings yet

- Saes T 101Document6 pagesSaes T 101nadeem shaikhNo ratings yet

- Saes S 010Document28 pagesSaes S 010nadeem shaikh0% (1)

- Saes P 121Document19 pagesSaes P 121nadeem shaikhNo ratings yet

- Saep 306Document15 pagesSaep 306nadeem shaikh100% (1)

- Explanation of Maxon EC Motor TerminologyDocument1 pageExplanation of Maxon EC Motor TerminologyfurkanfurkanfurkanNo ratings yet

- Facility Management System (FMS)Document14 pagesFacility Management System (FMS)Sarfraz LocusNo ratings yet

- Search Algorithms in Artificial IntelligenceDocument13 pagesSearch Algorithms in Artificial IntelligencenandhiniNo ratings yet

- Sap Budget ProceduresDocument17 pagesSap Budget ProceduresAnonymous ywBR5hF4No ratings yet

- VP Director Land Development Acquisition in Dallas FT Worth TX Resume Jon FeatherstonDocument2 pagesVP Director Land Development Acquisition in Dallas FT Worth TX Resume Jon FeatherstonJon FeatherstonNo ratings yet

- Sim Civil-Engineering-1930 1959-08 29 8Document149 pagesSim Civil-Engineering-1930 1959-08 29 8Riccardo CavalliniNo ratings yet

- Elastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresDocument4 pagesElastic Support Up To 25 KV AC: Sicat 8WL4200 For Overhead Contact Line Systems in Tunnels and Under StructuresVictor Manuel BonettoNo ratings yet

- Holiday Inn Express Paris - Velizy: Your Confirmation Number Is: 85701768Document3 pagesHoliday Inn Express Paris - Velizy: Your Confirmation Number Is: 85701768amal alruqi100% (1)

- International Business Plan Sample DecaDocument6 pagesInternational Business Plan Sample Decagtc7b7dh100% (1)

- Politics of Globalisation QP 2019 - TutorialsDuniyaDocument5 pagesPolitics of Globalisation QP 2019 - TutorialsDuniyasatyam kumarNo ratings yet

- Microwave AntennaDocument100 pagesMicrowave AntennaJhill-Jhill Jimenez Dela PeñaNo ratings yet

- 10th English Questions Answers and Objective NotesDocument26 pages10th English Questions Answers and Objective NotesI the only soulNo ratings yet

- Usace / Navfac / Afcec / Nasa UFGS-23 64 26 (August 2009) Change 6 - 11/22 - Preparing Activity: NAVFAC Superseding UFGS-23 64 26 (April 2008)Document54 pagesUsace / Navfac / Afcec / Nasa UFGS-23 64 26 (August 2009) Change 6 - 11/22 - Preparing Activity: NAVFAC Superseding UFGS-23 64 26 (April 2008)Ramon De los ReyesNo ratings yet

- Iron and SteelmakingDocument139 pagesIron and SteelmakingRajatSehgal100% (1)

- Lijia BlogDocument12 pagesLijia Bloglijia ann joseNo ratings yet

- 1 CHEN401 - First Day Package - Prof. N.S. MainaDocument5 pages1 CHEN401 - First Day Package - Prof. N.S. Mainasaminumusa217No ratings yet

- Apc smx3000lv User ManualDocument10 pagesApc smx3000lv User ManualColour BlindNo ratings yet

- Beeswax Tensile Properties and Water Vapor Permeability of Sodium PDFDocument8 pagesBeeswax Tensile Properties and Water Vapor Permeability of Sodium PDFElkyn BohórquezNo ratings yet

- IP QB (Itscholar - Codegency.co - In)Document2 pagesIP QB (Itscholar - Codegency.co - In)faiyaz pardiwalaNo ratings yet

- Model 549: General & Small Parts PhantomDocument3 pagesModel 549: General & Small Parts PhantomMiguel De Los Santos PavisicNo ratings yet

- Hydraulic Crane Bumpers IntroductionDocument2 pagesHydraulic Crane Bumpers IntroductionManu Gimenez100% (1)

- Die and MoldDocument120 pagesDie and MoldEr Faiyaz AhmedNo ratings yet

- 1 s2.0 S0360544223005960 MainDocument14 pages1 s2.0 S0360544223005960 MainFrank Joel Herrera ApaesteguiNo ratings yet

- Le Microcrédit Au Maroc - Tensions Entre Finalités Sociales Et Performances CommercialesDocument23 pagesLe Microcrédit Au Maroc - Tensions Entre Finalités Sociales Et Performances Commercialesabdhafid meftahiNo ratings yet

- Psychosocial Status and Quality of Life of Adolescent Girls in Karnataka, IndiaDocument8 pagesPsychosocial Status and Quality of Life of Adolescent Girls in Karnataka, Indiavarunendra pandeyNo ratings yet

- Condition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBDocument2 pagesCondition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBloulou_beNo ratings yet

- No Contact RuleDocument10 pagesNo Contact RuleExBackExpertiseNo ratings yet

- Articulo de Investigacion Sobre Digitalizacion 3DDocument20 pagesArticulo de Investigacion Sobre Digitalizacion 3DAlex HillarNo ratings yet