Alarmas Chiller Serie CH

Alarmas Chiller Serie CH

Uploaded by

Eliezer GonzalezCopyright:

Available Formats

Alarmas Chiller Serie CH

Alarmas Chiller Serie CH

Uploaded by

Eliezer GonzalezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Alarmas Chiller Serie CH

Alarmas Chiller Serie CH

Uploaded by

Eliezer GonzalezCopyright:

Available Formats

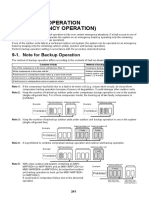

Piovan Chiller

CH series

Alarms List

85 L@G Ch-start-uk 11/00 rev.03

Alarm E01 HIGH PRESSURE ALARM

(Blocking alarm)

Condensation temperature too high.

• CAUSES:

• Ventilator stopped / blocked.

• Ambient temperature too high.

• Lateral panel of the chiller open (only air condenser type)

• Condenser air filters and ducts clogged.

• Incorrect position of the chiller (see indications in the manual).

• Ventilation obstructed or re-circulation of hot air expelled from the chiller or heat sources in

proximity to the chiller air inlets.

• Condensation air ducts incorrectly constructed (too small, long distances with great loss of

charge).

• Process water temperature higher than 22-30°C.

• Dirty or clogged condensers.

• Fan pressure switch or high pressure switch broken.

• Excessive load of refrigerant fluid, or insufficient discharge/vacuum of the system before

loading the gas. This causes a considerable presence of air in the condenser.

• Chiller under-sized as regards the thermic load applied.

86 L@G Ch-start-uk 11/00 rev.03

1/2

Alarm E01 High pressure alarm

• REMEDY:

• Check the functioning of the fan (thermal relay,

motor current, etc.).

• Close all lateral panels of the chiller.

• Clean and replace the condenser air filters if

necessary.

• Eliminate any heat source in the proximity of the

chiller.

• Ensure that the fan does not suck back in the hot

air that it has expelled and eliminate the possible

re-circulation of air.

• Try to improve the circulation of air in the area

surrounding the chiller, removing any obstacles

which could impede condenser ventilation.

• Check the functioning of the fan pressure switch

and replace if necessary.

• Ensure that the chiller is positioned according to

the manual instructions, respecting the prescribed

distance from walls and with the air intakes and

ducts correctly sized.

87 L@G Ch-start-uk 11/00 rev.03

2/2

Alarm E01 High pressure alarm

Automatic Reset • Remedy:

• If the process water temperature is higher

than 22-30°C it must be lowered to around

20°C otherwise the alarm will be activated.

• Reset the alarm on the high pressure switch

(the mode of reset can change from model

to model).

• If necessary clean the condenser fins in

order to increase the heat exchange.

• If a centrifugal fan is used, check the state

Manual Reset of the transmission belts between the motor

and the ventilator (the V-belts).

• A refrigeration expert should be consulted

for the possible discharge of some of the

gas (optimal sub-cooling around 8 - 10°C)

and for the control of the functioning of the

chiller.

• Try to reduce the thermic load applied to

the chiller.

88 L@G Ch-start-uk 11/00 rev.03

Alarm E02 LOW PRESSURE ALARM

(Blocking alarm - compressor)

• CAUSE: • REMEDY

• Gas leakage in the system. • Consult a refrigeration expert for the control of the functioning of

• Gas filter clogged. the chiller.

• Control and repair possible refrigerant leakage in the circuit and

• Low pressure switch faulty. then provide for the reloading of the refrigerant.

• Gas solenoid valve closed. • Check the inlet and outlet temperatures of the gas filter. If there

• Insufficient water flow. is a significant difference, replace it as it could be clogged.

• Gas expansion valve or hot gas • Check the calibration (if possible) and functioning of the low

pressure switch and replace if necessary.

valve (if present) incorrectly

calibrated. • Check the functioning of the gas solenoid valve and replace if

necessary.

• Check the calibration of the gas expansion valve. It must be

remembered that the possible re-calibration of this requires time

since any change has times of inertia before stabilising at the

set point (optimal overheating is around 5°C, which must be

stable. If higher than 5°C, it will cause a reduction in the chiller

cooling capacity).

• Check that there are no problems in the water circuit that could

reduce the water flow in the evaporator, consequently risking its

icing.

89 L@G Ch-start-uk 11/00 rev.03

Alarm E03 OVERLOAD CUTOUT COMPRESSOR

(Blocking alarm)

• CAUSE: REMEDY:

• Excessive electrical current of • Check the compressor contactor and

compressor motor. electrical connections, and replace the

• Compressor electrical connections, damaged or broken components if

contactor or thermal relay faulty. necessary.

• Compressor mechanically blocked. • Reset the magnetic thermal relay and

• If the process temperature is high but not check the motor current if the

high enough to trip the high pressure compressor restarts.

switch, the compressor could • Check that the evaporation temperature

progressively overheat until its thermal on the low pressure manometer returns

relay trips. This is due to the insufficient within the limits foreseen.

cooling in suction. • Contact Piovan Service Department if

the problem persists.

90 L@G Ch-start-uk 11/00 rev.03

Alarm E04 OVERLOAD CUTOUT SWITCH TRIPPED ON FAN MOTOR

(Blocking alarm)

• CAUSE: • REMEDY:

• Excessive electric current of fan • Check the fan contactor and the

motor. electrical connections and

replace the damaged or broken

• Fan electrical connections,

components if necessary.

contactor or thermal relay faulty.

• Reset the magnetic thermal

• Fan blocked mechanically.

relay and check the motor

current after the restart of the

fan.

91 L@G Ch-start-uk 11/00 rev.03

Alarm E05 ANTIFREEZE ALARM

(Blocking alarm)

• CAUSE: • REMEDY:

• The antifreeze probe reads a • Check the real process water temperature and

temperature lower than that set on check the set-point on the antifreeze

the antifreeze thermostat. thermostat.

• The set point of the process • Reset the antifreeze thermostat (excluding

temperature is too close to the set models with automatic reset).

point of the antifreeze thermostat. • Check the trend of the process temperature

• Considerable variation in the process with respect to that set.

temperature. • If it is necessary to work with a process

• Low water flow in the evaporator or temperature lower than 5-6°C Piovan must be

evaporator clogged. contacted for the appropriate

recommendations (calibration of antifreeze

thermostat and addition of glycol antifreeze to

the water circuit).

• Check that the process water flow is regular

and that there are no obstructions.

• Check that the evaporator is clean.

92 L@G Ch-start-uk 11/00 rev.03

Alarm E06 - Alarm E40

(Blocking alarms)

• CAUSE: • CAUSE:

• Antifreeze probe broken • Process probe broken

• REMEDY: • REMEDY:

• Check the terminal • Check the terminal

strips connections and strips connections and

the condition of the cable replace the probe if

and replace the probe if necessary.

necessary.

93 L@G Ch-start-uk 11/00 rev.03

Alarm E41

(Blocking alarm)

• Intervention of water pressure

switch or flow-switch, or the pump

thermal relay

• CAUSE:

• Water flow:

– Insufficient or absent water flow.

– Obstructions or clogging in the water circuit.

– Interception valves closed.

– By-Pass valve to be regulated (if present).

– Presence of air in the water piping.

– Water pressure switch or flow-switch faulty.

• Water pump:

– Excessive electric current of the pump motor.

– Pump electrical connections, contactor or thermal

relay faulty.

– Pump blocked mechanically (typically this is due to

Water circuit differential the system being stopped for a long time).

pressure switch

94 L@G Ch-start-uk 11/00 rev.03

Alarm E41

• REMEDY:

• Water flow:

– Check that there is no obstruction or clogging in

the water circuit (for example, the filters).

– Check that possible interception valves are not

closed.

– Check the pressure on the water manometer,

usually 2-3 bar in standard machines.

– If present, open or close the by-pass valve in

Flow-switch the water circuit as necessary.

– Eliminate the presence of air inside the water

piping.

– Check the functioning of the water pressure

switch or flow-switch and replace if necessary.

– Check that the evaporator is not clogged.

• Water pump:

– Check the pump contactor and electrical

connections and replace damaged or broken

components as necessary.

– Check that the pump is turning freely.

– Reset the magnetic thermal relay and check the

motor current if the pump restarts.

95 L@G Ch-start-uk 11/00 rev.03

Alarm E45 Alarm E46

(Blocking Alarm) (Blocking Alarm)

• Configuration Error • Water process temperature too high.

• CAUSE: • CAUSE:

• Configuration problems on the • Exceeded the safety limit of the

microprocessor. maximum process water temperature.

• Remedy: (To prevent too high an evaporation

• Replace the microprocessor. temperature).

• Remedy:

Extra note: • Close all the utilities and let the chiller

Indications displayed on the chiller function to gradually reduce the water

with remote control : process temperature.

When ”E00” is displayed in the • When the process water temperature

microprocessor, it means that the chiller reaches the set point, begin to open the

has been stopped by the on-off remote utilities gradually and check the chiller

selector. functioning.

To reactivate the chiller, select ‘on’ on

the remote selector.

96 L@G Ch-start-uk 11/00 rev.03

End of presentation

Thank you for

your attention

97 L@G Ch-start-uk 11/00 rev.03

You might also like

- Stress Cracking in PET BottlesDocument93 pagesStress Cracking in PET BottlesEliezer Gonzalez100% (3)

- Hitachi Mini VRFDocument37 pagesHitachi Mini VRFMohamed ShomanNo ratings yet

- TraneDocument33 pagesTranejake1000100% (1)

- Annexure 3 - SCP Ajmer - Round 2Document21 pagesAnnexure 3 - SCP Ajmer - Round 2Shailendra Kumar RoshanNo ratings yet

- Antony C. Sutton & Viktor Suvorov - Technology Transfer From The West To The Soviet UnionDocument72 pagesAntony C. Sutton & Viktor Suvorov - Technology Transfer From The West To The Soviet Unionpillulful100% (3)

- MF S21C GBDocument210 pagesMF S21C GBnenad100% (7)

- Pco Xs ManualDocument30 pagesPco Xs ManualpabloabelgilsotoNo ratings yet

- End User-Technical Sheet: 7 Units of Air CurtainsDocument41 pagesEnd User-Technical Sheet: 7 Units of Air CurtainsAngelica Sta. MariaNo ratings yet

- Samsung Scroll Compressor: Samsung Electronics Co. Ltd. HQ SeDocument9 pagesSamsung Scroll Compressor: Samsung Electronics Co. Ltd. HQ SeJose Manuel AlfaroNo ratings yet

- RTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsDocument2 pagesRTWD Series R (TM) 70-250 Ton Water-Cooled Chiller Dimension DrawingsJhon LewisNo ratings yet

- KR - MV IDU - WallMountedUnit (4series) - R410A - 5060Hz - Global - MFL55028426W - 0CVP0-01A (Mar.2017) PDFDocument62 pagesKR - MV IDU - WallMountedUnit (4series) - R410A - 5060Hz - Global - MFL55028426W - 0CVP0-01A (Mar.2017) PDFFelipe BabugiaNo ratings yet

- Product - Data - 30XW - Enfriado Agua Tornillo 150 A 400 PDFDocument52 pagesProduct - Data - 30XW - Enfriado Agua Tornillo 150 A 400 PDFJONATHAN MENDEZNo ratings yet

- MT50HK3CVE MT050 Series DanfossDocument26 pagesMT50HK3CVE MT050 Series DanfossPaulo Roberto SouzaNo ratings yet

- WCFX EvDocument31 pagesWCFX EvhjmmNo ratings yet

- Room Air Conditioner: SVC MANUAL (Exploded View)Document8 pagesRoom Air Conditioner: SVC MANUAL (Exploded View)Virgilio B. CañizaresNo ratings yet

- PREMTB100Document1 pagePREMTB100Edgard Chara Carhuayo0% (1)

- Inverter Multi Split System (60Hz, R22)Document58 pagesInverter Multi Split System (60Hz, R22)Педро СлеваNo ratings yet

- Códigos de Erores Aires SamsungDocument39 pagesCódigos de Erores Aires SamsungANDRES MALDONADONo ratings yet

- 3900 - Trane Ccud 104Document6 pages3900 - Trane Ccud 104HoàngViệtAnhNo ratings yet

- CATALOGUE-Set Free Kyosho Brochure PDFDocument20 pagesCATALOGUE-Set Free Kyosho Brochure PDFShubham PopliNo ratings yet

- LGMV Total ENG PDFDocument42 pagesLGMV Total ENG PDFJorge alfredo Villarreal triviñoNo ratings yet

- AirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)Document110 pagesAirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)alexNo ratings yet

- 30HX 14PDDocument56 pages30HX 14PDDaniel TaveiraNo ratings yet

- 256 Copeland Scroll Motor Technical Information PDFDocument11 pages256 Copeland Scroll Motor Technical Information PDFDianichtrNo ratings yet

- ATS - Com VSD - TEC-manual-ATS PDFDocument76 pagesATS - Com VSD - TEC-manual-ATS PDFg3qwsfNo ratings yet

- Mini Compressor & Cooling Units - Rigid CoolingDocument16 pagesMini Compressor & Cooling Units - Rigid CoolingronaldmarcelleNo ratings yet

- Z0012048 Rcuf-Wzpy TC1-1Document53 pagesZ0012048 Rcuf-Wzpy TC1-1Ferry SantosoNo ratings yet

- Catalogo Técnico DVM SamsungDocument90 pagesCatalogo Técnico DVM Samsungfabioleite06No ratings yet

- Daikin VRV III (Q Series) Installation ManualDocument33 pagesDaikin VRV III (Q Series) Installation ManualirfanNo ratings yet

- Guia Tecnica Ydv Modular DC Inverter R-410a 60 HZ Tech SVC Manual 1 PartDocument100 pagesGuia Tecnica Ydv Modular DC Inverter R-410a 60 HZ Tech SVC Manual 1 PartSony CNo ratings yet

- DCS303A51Document51 pagesDCS303A51mquaiottiNo ratings yet

- Chiller CarrierDocument40 pagesChiller CarrierNicolas MatiasNo ratings yet

- Alarmes Piovan Dryer Kd002700aDocument31 pagesAlarmes Piovan Dryer Kd002700amarioNo ratings yet

- KR - MV IDU - 4series - R410A - 5060Hz - Global - MFL55028426 - 0CVP0-05B - Jul.2016 PDFDocument474 pagesKR - MV IDU - 4series - R410A - 5060Hz - Global - MFL55028426 - 0CVP0-05B - Jul.2016 PDFEmmanuel MartínezNo ratings yet

- Nuevo Brochure VRF FY2012Document20 pagesNuevo Brochure VRF FY2012Sony CNo ratings yet

- KR - MV5 - R410A - 220VMFL67474052 - 20170728 - Al ISO PDFDocument441 pagesKR - MV5 - R410A - 220VMFL67474052 - 20170728 - Al ISO PDFFelipe Babugia0% (1)

- Manual de Serviços VRF Toshiba SMMSi - Inibir Condensadora RevDocument16 pagesManual de Serviços VRF Toshiba SMMSi - Inibir Condensadora RevHeitor Prudente CorreaNo ratings yet

- Pro-Dialog Control: 30RB/30RQDocument36 pagesPro-Dialog Control: 30RB/30RQSergeNo ratings yet

- Solar/DC Air Conditioner: 12,000 BTU 48V DC Heat PumpDocument2 pagesSolar/DC Air Conditioner: 12,000 BTU 48V DC Heat PumpUbaid Ur Rehman100% (1)

- CVGF Svu02a E4 Iom Ch530Document88 pagesCVGF Svu02a E4 Iom Ch530Emerson PenaforteNo ratings yet

- Icematic E Series Instruction Manual (Page 6 of 72) ManualsLibDocument1 pageIcematic E Series Instruction Manual (Page 6 of 72) ManualsLibEnnio CherinNo ratings yet

- User Manual - YCZ-A003 PDFDocument37 pagesUser Manual - YCZ-A003 PDFEdward ToroNo ratings yet

- VRF - Heat Recorvery (FSXNP & FSXNS Series)Document108 pagesVRF - Heat Recorvery (FSXNP & FSXNS Series)Cường NguyễnNo ratings yet

- Acpsb-Pqp: Mobile Utility Energy Package Cooling Only UnitDocument2 pagesAcpsb-Pqp: Mobile Utility Energy Package Cooling Only UnitEduardo Luis SouzaNo ratings yet

- Technical - Manual HITACHI RAS-2HVRNE y OtrasDocument220 pagesTechnical - Manual HITACHI RAS-2HVRNE y OtrasFrancisco Martin Burgos100% (1)

- System 48V Solar AC BookDocument12 pagesSystem 48V Solar AC BookFran Garsos100% (1)

- YORK KLIMA Sro Klimatizacie Katalog 2010 VRFDocument69 pagesYORK KLIMA Sro Klimatizacie Katalog 2010 VRFeddyx66No ratings yet

- 201.28-EG1Document56 pages201.28-EG1Time To Use BrainNo ratings yet

- Control Manual 30RB RQ - 008 040Document28 pagesControl Manual 30RB RQ - 008 040alex alexandruNo ratings yet

- FDV Carrier 30RBDocument56 pagesFDV Carrier 30RBSantiago Fernandez de CastroNo ratings yet

- RHXYQ8-66AYL: Heat Pump 60HzDocument508 pagesRHXYQ8-66AYL: Heat Pump 60HzClayton VeronezNo ratings yet

- (TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529Document109 pages(TDB) VRF ODU DVM S (R410A, 230V, 60Hz, CO) For LA - Ver.2.0 - 190529jefferson100% (1)

- Catalogo Chiller Trane CGAD Cg-prc002e-En - 07012012Document38 pagesCatalogo Chiller Trane CGAD Cg-prc002e-En - 07012012Leandro P SilvaNo ratings yet

- TC - Rcue 40 - 240 WG2 (TCGB0045 (12-06)Document88 pagesTC - Rcue 40 - 240 WG2 (TCGB0045 (12-06)arif1993100% (1)

- Toshiba-Quick Reference - Smms-E-Eu Model - q18-001 - en 180627 PDFDocument96 pagesToshiba-Quick Reference - Smms-E-Eu Model - q18-001 - en 180627 PDFGingubaNo ratings yet

- SE7000FCUAPPGUIDEDocument60 pagesSE7000FCUAPPGUIDEKardos ZoltanNo ratings yet

- York Rooftops EngDocument14 pagesYork Rooftops EngBulclimaNo ratings yet

- 3304100Document51 pages3304100Erdinc Klima100% (1)

- Carrier Scroll CompressorDocument16 pagesCarrier Scroll Compressorzulkifli.sulimanNo ratings yet

- ALARMES - SMMSi Service ManualDocument370 pagesALARMES - SMMSi Service ManualSprinlg100% (1)

- LG LBUM7280BL Exploded View PDFDocument55 pagesLG LBUM7280BL Exploded View PDFmazacotesNo ratings yet

- Ot VentilationDocument24 pagesOt Ventilationjyoti gaudNo ratings yet

- Engine Cooling SystemDocument11 pagesEngine Cooling SystemKNo ratings yet

- Relief Valves - NCCDocument26 pagesRelief Valves - NCCNour HNo ratings yet

- Maier DPDocument54 pagesMaier DPEliezer GonzalezNo ratings yet

- Catalogo IgludurDocument156 pagesCatalogo IgludurEliezer GonzalezNo ratings yet

- GoTo Roller Rail-Spring 2013Document5 pagesGoTo Roller Rail-Spring 2013Eliezer GonzalezNo ratings yet

- Gi355 Data SheetDocument4 pagesGi355 Data SheetEliezer GonzalezNo ratings yet

- RLK 131 1234Document2 pagesRLK 131 1234Eliezer GonzalezNo ratings yet

- Megadyne MegapowerDocument38 pagesMegadyne MegapowerEliezer GonzalezNo ratings yet

- Arx AutocadDocument857 pagesArx Autocadecobo243075No ratings yet

- Qu Brochure AP9457 5 WebDocument24 pagesQu Brochure AP9457 5 WebFrancisco Infante R.No ratings yet

- TAIM WESER Test EquipmentDocument1 pageTAIM WESER Test EquipmentBenny YacilaNo ratings yet

- Abb Motors For Cog en PDFDocument340 pagesAbb Motors For Cog en PDFNguyen Anh TuNo ratings yet

- Sap MTBR & MTTR BackgroundDocument3 pagesSap MTBR & MTTR BackgroundSallar QaziNo ratings yet

- Dragon Age Chargenmorph Compiler V1.1.0 - Mini Guide Coded by Terra - ExDocument6 pagesDragon Age Chargenmorph Compiler V1.1.0 - Mini Guide Coded by Terra - ExBrigit CollinsNo ratings yet

- Piping Spec (24-08-2017)Document7 pagesPiping Spec (24-08-2017)Muhammad Moeed AlamNo ratings yet

- User's Manual: GC1000 Mark II Process Gas Chromatograph Basic Operation and StartupDocument51 pagesUser's Manual: GC1000 Mark II Process Gas Chromatograph Basic Operation and StartupMohammad AbbasiNo ratings yet

- Customer Relationship Management in Banking SectorDocument4 pagesCustomer Relationship Management in Banking SectorkalamsoftwareNo ratings yet

- 275kw Diesel Generator Datasheet J275u (English)Document4 pages275kw Diesel Generator Datasheet J275u (English)giapy0000No ratings yet

- Cloud MigrationDocument12 pagesCloud MigrationPrashant PanseNo ratings yet

- 33kv 400a On Load Ab SwitchDocument2 pages33kv 400a On Load Ab SwitchSharafat AliNo ratings yet

- IQ41x Series ControllersDocument20 pagesIQ41x Series ControllersZill RafiNo ratings yet

- Assignment-1 Water PurifierDocument10 pagesAssignment-1 Water PurifierSurya TejaNo ratings yet

- Examen AdcDocument5 pagesExamen AdcValeria_Andree_2513No ratings yet

- 1993 Chevrolet Astro Owners ManualDocument345 pages1993 Chevrolet Astro Owners ManualastrolinNo ratings yet

- Semi DetachedDocument1 pageSemi DetachedDhumal Mangesh DhumalNo ratings yet

- MR - Wilson Cubos JBD Telecom Hubpoint: Batangas State UniversityDocument3 pagesMR - Wilson Cubos JBD Telecom Hubpoint: Batangas State UniversityAdlibitumNo ratings yet

- Rit 51Document1 pageRit 51Nagasreenivasarao PNo ratings yet

- Nanoelectronics AbstractDocument1 pageNanoelectronics AbstractAmrit PattnaikNo ratings yet

- Chemline Actuation Price ListDocument39 pagesChemline Actuation Price Listnuno.aparicio93No ratings yet

- Catalogue Hitachi Lift OUG ON1Document30 pagesCatalogue Hitachi Lift OUG ON1Dak SerikNo ratings yet

- SD-S5564-XX-SGA0 - Rev.6 (Beams)Document3 pagesSD-S5564-XX-SGA0 - Rev.6 (Beams)Anonymous koR9VtfNo ratings yet

- 153300012-ZW, CR, PUMP HOUSE-Drawing (Enclosure)Document2 pages153300012-ZW, CR, PUMP HOUSE-Drawing (Enclosure)mauriciolopeztepsiNo ratings yet

- Factors Affecting Delays in Construction Projects PDFDocument11 pagesFactors Affecting Delays in Construction Projects PDFmeetshaileshshahNo ratings yet

- CallRecord LogDocument37 pagesCallRecord LogAntonio Castellanos100% (1)

- 08 Cylinder-PistonDocument14 pages08 Cylinder-PistonDidier GarciaNo ratings yet