Lab Manual - PRPC

Uploaded by

Kaushal BaldhaLab Manual - PRPC

Uploaded by

Kaushal BaldhaDepartment of Chemical Engineering

Experiment No. 1

Determination of viscosity by Saybolt Viscometer

AIM: -

To determine the viscosity (in Saybolt Universal Seconds) of a liquid hydrocarbon and also

the effect of temperature on the viscosity.

PRINCIPLE

The absolute viscosity of fluid oil can be determined by measuring the rate of flow of the oil

through a capillary tube kept at a uniform temperature. But in case of lubricating oils specific

viscosity is generally determined by measuring the time taken for a given quantity of oil to

flow through an orifice or jet of standard dimension under standard conditions. Three types

of standard viscometers namely Redwood, Engler and Saybolt viscometer are of common

use.

This test method covers the empirical procedures for determining the Saybolt Universal or

Saybolt Furol viscosities of petroleum products at specified temperatures between 21 and

99°C (70 and 210°F). It is referred to as the Saybolt viscosity and written as Saybolt second

universal (SSU). The dynamic viscosity can be obtained by multiplying the kinematic

viscosity by the density of the liquid.

APPARATUS

PROCEDURE

Clean and dry the oil cylinder of viscometer. Insert the cork tightly. Fill the

cylinder up to mark with oil.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 1

Department of Chemical Engineering

Take out excess oil with the help of pipette. Insert a thermometer both in oil bath

and in the paraffin bath.

Start heating at a controlled rate and stir the oil and paraffin bath continuously for

uniform heating.

As the oil sample comes at desired temperature open the cork at bottom and note

the seconds for collection of 60 ml oil at specified temperature.

Repeat the process for a constant reading. Find out a constant flow time at

different temperatures

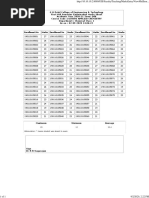

EXPERIMENTAL RESULTS

Room Temperature:

Temperature of water bath

Collection time Mean time

Volume collection Sr. No

(s) (s)

60 ml. 1

2

3

Plot a graph of flow time versus Kinematic viscosity

Updated on 1st January 2021 by Dr. Kaushik Nath Page 2

Department of Chemical Engineering

The following formula may be used to convert centistokes (cSt) units to approximate Saybolt

universal seconds unit.

For SUS values between 32 and 100

195

cSt 0.226 SUS

SUS

For SUS values greater than 100

135

cSt 0.220 SUS

SUS

Also refer the attached conversion table of centistokes, stokes and SSU.

The viscosity of a given sample using Saybolt viscometer should be denoted with

Saybolt seconds at the specified temperature.

Repeatability of the experiments should be duly compared at low and high

temperatures.

Convert the Saybolt seconds to cSt with the empirical formulation 1cSt as 31 Saybolt

seconds and compare with standard values.

INDUSTRIAL APPLICATIONS

This is used for the empirical measurement of Saybolt Viscoisty of petroleum products at

specified temperatures between 07° F and 210°F. This is also used for determining the

Saybolt Furol Viscosity of bituminous materials at temperature of 250, 275, 300, 350, 400

and 450° F.

DISCUSSIONS

The result obtained from this test method is dependent upon the behavior of the sample and is

intended for application to liquids for which primarily the shear stress and shear rates are

proportional (Newtonian flow behavior). If, however, the viscosity varies significantly with

the rate of shear, different results may be obtained from viscometers of different capillary

diameters. The range of kinematic viscosities covered by this test method is from 0.2 to 300

000 mm²/s at all temperatures.

SHORT QUESTIONS

1. How does the viscosity of gas/liquid vary with temperature?

2. Define kinematic viscosity?

3. How do you improve the viscosity index of lubricating oil?

4. How viscosity is expressed in Saybolt Viscometer?

5. Name a few other viscometers for testing of viscosities of lube oils.

6. Name a few lubricants with high viscosity index.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 3

Department of Chemical Engineering

Experiment No. 2

Determination of Flash Point by Pensky Marten Apparatus

AIM

To find out the Flash point of fuel oils or lubricating oils ranging above 49oC by Pensky

Marten Close cup apparatus.

PRINCIPLE

Flash point is defined as the temperature at which an oil gives sufficient vapor to form an

inflammable mixture with air and catches fire momentarily flashes when flame is applied.

Flash point gives the idea about the nature of the boiling point diagram of the system,

amount of low boiling fraction present in the liquid fuel, explosion hazards, volatility of

the liquid fuels. Beside oil‟s volatility and inflammability limits of the vapor-air mixture

the flash point also depends on the design of the apparatus, the test procedure and

barometric pressure.

APPARATUS

There are two basic types of flash point measurement: open cup and closed cup. In open

cup devices the sample is contained in an open cup (hence the name) which is heated, and

at intervals a flame is brought over the surface. The measured flash point will actually

vary with the height of the flame above the liquid surface, and at sufficient height the

measured flash point temperature will coincide with the fire point. Examples include

Cleveland Open Cup and Pensky-Martens open cup. The main difference being that the

former is heated from below, while the later is heated from the sides as well as below.

Closed cup testers, of which the Pensky-Martens closed cup is one example, are sealed

with a lid through which the ignition source can be introduced periodically. The vapour

above the liquid is assumed to be in reasonable equilibrium with the liquid.

The apparatus consists of the following:

(1) Cast iron bath provided with bras cup cover

(2) Flame arrangement

(3) Shutter mechanism

(4) Hand operated stirrer

Updated on 1st January 2021 by Dr. Kaushik Nath Page 4

Department of Chemical Engineering

Pensky-Marten Flash Point Apparatus

PROCEDURE

Clean and dry the brass cup. Fill the cup with sample exactly to the mark. Adjust the

micro flame. Heat the cup slowly at a controlled rate of 2oC per minute. Pass the test

flame across the center of the cup at every degree in temperature rise. Record the lowest

temperature at which flame is observed at any point over the liquid.

OBSERVATION TABLE

Room Temperature:

Atmospheric pressure:

Sample Given:

Characteristics of the sample:

Sample Serial Number Temperature (oC) Observation

Updated on 1st January 2021 by Dr. Kaushik Nath Page 5

Department of Chemical Engineering

Observed Flash Point: --------------- oC

Since the pressure varies from place to place there is a pressure correction required to

be applied. The following correlation is used:

Δtp = 0.0346 (760P) oC

Where P = atmospheric pressure under test conditions.

Actual Flash point = Observed flash point + Pressure correction factor.

TASK

1) Draw the profile of time vs. temperature.

2) Compare the results with the literature value.

3) Can the experiment be conducted to determine the fire point?

INDUSTRIAL APPLICATION

Flash and fire point are important when oil is exposed to high temperature service.

This test provides safe guard against decomposition and fire hazard during

storage, transportation, handling and other uses.

Flash point is used to assess the overall hazard of a material and is used in

shipping and safety regulations to define "flammable" and "combustible"

materials.

DISCUSSION

The flash point is an empirical measurement rather than a fundamental physical

parameter. The measured value will vary with equipment and test protocol variations,

including temperature ramp rate (in automated testers), time allowed for the sample to

equilibrate, sample volume and whether the sample is stirred.

Methods for determining the flash point of a liquid are specified in many standards. For

example, testing by the Pensky-Martens closed cup method is detailed in ASTM D93,

IP34, ISO 2719, DIN 51758, JIS K2265 and AFNOR M07-019. Determination of flash

point by the Closed Cup Equilibrium method is specified in ISO 1523:2002.

REFERENCE

I.S 1448 – 1970 Methods of test for petroleum and its products (P: 21) Flash Point(

Closed) by Pensky Martin apparatus.)

Updated on 1st January 2021 by Dr. Kaushik Nath Page 6

Department of Chemical Engineering

SHORT QUESTIONS

1. Define Flash point and Fire point of petroleum oil.

2. What are the factors that affect flash and fire point?

3. What should be the flash point of a good lubricant?

4. What is the difference between Abel‟s and Pensky Marten‟s Apparatus?

5. What is the permissible flash point value of marketable kerosene?

6. Arrange the following fuels in order of increasing flash point

Kerosene, Gasoline, Diesel, lube oil

7. Is there any relationship between flash point and IBP of oil?

8. What is the significance of flash point determination of petroleum oil?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 7

Department of Chemical Engineering

Experiment No: 3

Determination of Aniline point of petroleum oil

AIM

To determine the aniline point of the supplied oil samples using aniline point apparatus

and to find out the diesel index number of the diesel oil.

APPARATUS & CHEMICALS

Two micro burettes, Test tube, Thermometer, Heating bath, Aniline, Kerosene, Diesel,

Ethyl alcohol / Acetone.

PRINCIPLE

The aniline point is called the "aniline point temperature," which is the lowest

temperature (°F or °C) at which equal volumes of aniline (C6H5NH2) and the oil form a

single phase. The aniline point (AP) correlates roughly with the amount and type of

aromatic hydrocarbons in an oil sample. A low AP is indicative of higher aromatics,

while a high AP is indicative of lower aromatics content.

Aniline point is defined as the minimum temperature at which equal volumes of

anhydrous aniline and oil mix together.

Diesel index, (I.P 21/I.S P: 17) a derivative of aniline point is defined as

[0.018 A.P oC + 0.32] API

Aniline being an aromatic compound freely mixes with aromatics; so a low aniline point

indicates low diesel index, because of high percentage of aromatics.

PROCEDURE

Wash the micro burettes and beakers with ethyl alcohol/acetone.

Take 5ml of aniline and diesel/kerosene to each of the two burettes and

hold in stands.

Collect two mixers in a test tube. Heat it by placing in a water bath, with a

thermometer kept inside.

Heat the test tube with continuous shaking.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 8

Department of Chemical Engineering

After some time you will find that the layers will disappear and form

turbidity.

Then the mixture was cooled and at some instant it was noticed that the

layer again appeared. Temperature at this point was noted.

The same procedure was applied for diesel but for petrol the mixture was

cooled in an ice bath and aniline point was found out by taking it out of ice

bath.

Take the reading in 0C , then convert in to 0F

OBSERVATION TABLE

Volume Volume Average Average

Aniline Aniline Aniline

of of oil Aniline Aniline

Oil sample point 0C point 0C point 0C

aniline sample point in point in

1 2 3 0 0

(ml) (ml) C F

Kerosene

Diesel

Petrol

DIESEL INDEX

RESULTS

DISCUSSION

INDUSTRIAL APPLICATION

Aniline point is used to characterize pure hydrocarbons and to indicate the

aromatic content of hydrocarbon mixtures.

The value gives an indication of the aromatic content of diesel oil, since aniline is

an aromatic compound, which is dissolved on heating by the aromatics in diesel

oil. The greater the aniline point, the lower the aromatics in diesel oil. A lower

aniline point also indicates a higher proportion of paraffin.

A higher aniline point (and therefore a lower aromatic content) in diesel oil is

desirable, in order to prevent auto ignition in diesel engines.

The auto ignition temperature or kindling point of a substance is the lowest

temperature at which it will spontaneously ignite in a normal atmosphere without

Updated on 1st January 2021 by Dr. Kaushik Nath Page 9

Department of Chemical Engineering

an external source of ignition, such as a flame or spark. This temperature is

required to supply the activation energy needed for combustion. The temperature

at which a chemical will ignite decreases as the pressure increases or oxygen

concentration increases. It is usually applied to a combustible fuel mixture.

PRECAUTIONS

The whole apparatus and all the reagents must be perfectly dry as the presence of

even traces of moisture shows high results.

Aniline being hygroscopic so the test tube used must be dried.

Aniline being highly toxic the care should be observed while sucking it through

pipette and perfectly it should be taken with a pipette provided with a rubber

suction bulb.

EXERCISE

1. Mention the formula for Deg. API & characterization factor and explain their

significance.

2. Define Aniline point & explain its significance.

3. Why Aniline has been selected as a solvent for the determination of aniline point?

4. Is there any similarity between aniline point and smoke point?

5. What is Diesel index?

6. Define Cetane number and give its significance.

7. Define Octane number and give its significance.

8. Name the various antiknocking agents with their importance.

9. Which types of oil have the highest aniline point?

10. How is aniline point related to the ignition quality of a diesel fuel?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 10

Department of Chemical Engineering

Experiment No. 4

Determination of viscosity by Redwood Viscometer

AIM

To determine the viscosity (in „Redwood seconds‟) of a liquid hydrocarbon and also the

effect of temperature on the viscosity.

PRINCIPLE

The absolute viscosity of a fluid oil can be determined by measuring the rate of flow of the

oil through a capillary tube kept at a uniform temperature. But in case of lubricating oils

specific viscosity is generally determined by measuring the time taken for a given quantity of

oil to flow through an orifice or jet of standard dimension under standard conditions. Three

types of standard viscometers namely Redwood, Engler and Saybolt viscometer are of

common use.

The viscosity of a hydrocarbon can be expressed as the number of seconds taken for the

collection of 50ml. of the liquid when flowing under standard conditions through a jet of

standard dimensions. The equipment specified is the Redwood Viscometer. The Redwood

apparatus measures viscosity in empirical units and not in absolute unit such as centistoke.

These viscometers are designed for viscosity tests of petroleum Products. They confirm to

requirements of IP 70

APPARATUS

The viscometer consists of an oil cup furnished with a pointer, which ensures a constant head

of oil, and an agate jet, which is drilled with a central hole. The upper end of the agate jet is

closed with a ball, which is lifted to allow the flow of oil during the experiment. The outer

jacket which is for maintaining the oil at a constant temperature is electrically heated and

normally contains water, though if a higher temperature is required, cylinder oil is used. The

temperature is maintained at a uniform level by rotating the stirrer. A wire stirrer is also

provided for mixing the oil samples.

Viscometer No.1 or No.2 is used depending on whether the time of flow of the oil at the

desired temperature, is greater or less than 2000 seconds. The difference between the two

viscometers is the diameter of the orifice.

Redwood No. 1 Capillary diameter.1.62 mm, length. 10.0 mm

Redwood No. 2 Capillary diameter. 3.5 mm, length. 5.0 mm

Updated on 1st January 2021 by Dr. Kaushik Nath Page 11

Department of Chemical Engineering

This means there is a factor of ten between the two viscometers, i.e. a liquid that takes

100 seconds to flow through a No1 viscometer will take 10 seconds in a No2 viscometer.

For oil samples with Redwood seconds less than 2000, Redwood No.1 is

recommended. For highly viscous fluids with greater than 2000 Redwood seconds,

Redwood No.2 is recommended.

Redwood Viscometer

PROCEDURE

The sample of oil, filtered if necessary, is transferred to the container cup of the

viscometer until the pointer just breaks the surface of the oil. It is most

important that the test is always started with the pointer just emerging through

the liquid surface. This ensures that the head of oil above the orifice is always the

same and therefore that the pressure forcing the oil through is the same in each

test using the same oil.

Whilst slowly rotating the jacket stirrer, the water in the jacket is heated to a

temperature of 41oC. When the sample of oil in the cup reaches 40oC., the ball is

lifted and at the same time a stop-watch is started.

Allow oil to run through into the collecting flask until the 50 ml mark on the flask

is reached, at which point the clock should be stopped and the ball pushed back

onto the orifice to halt the oil flow.

The time taken for the passage of 50 ml of oil through the jet into the collecting

flask, in seconds, should be noted. For Redwood 1 do three tests per sample and

for the Redwood 2 do one test per sample. Determination of viscosity in this way

Updated on 1st January 2021 by Dr. Kaushik Nath Page 12

Department of Chemical Engineering

should be made at the following temperatures:- 30oC, 40oC, 60oC, 90oC. The

temperatures suggested do not have to be exactly these values but you must

record the actual values used accurately.

EXPERIMENTAL RESULTS

Room Temperature:

Time Required to Mean

Temperature Kinematic

Sr. No o collect 50 ml of oil Time

C viscosity

(s) (s)

RESULTS

The viscosity of an oil sample with the help of Redwood Viscometer at ----oC is ----------

- Redwood seconds

Updated on 1st January 2021 by Dr. Kaushik Nath Page 13

Department of Chemical Engineering

Redwood viscosity obtained as above can be converted in to kinematic viscosity by using

formula given below:

V = At B/t; where V = kinematic viscosity of the oil in centistokes.

t = time of flow (efflux time) in seconds

A & B are instrument constant

(A) = 0.264 and (B) = 190, when t = 40 to 85 seconds

(A) = 0.247 and (B) = 65, when t = 85 to 2000 seconds.

100 centistokes = 1 stoke

Unit conversions: Stoke Density = Poise (Absolute density)

1/Poise = Centipoise

Kinematic viscosity = Viscosity absolute/Sp. Gravity

The viscosity of a given sample using Redwood viscometer should be denoted with

Redwood seconds at the specified temperature.

b) Repeatability of the experiments should be duly compared at low and high

temperatures.

c) Convert the Redwood seconds to cSt with the empirical formulation 100 Redwood

seconds as 24.5cSt and compare with the standard values.

INDUSTRIAL APPLICATIONS

Redwood viscometer apparatus are widely used in Petroleum Laboratories, Industries, Oil

Refineries, Educational Institutions, Research Organizations for standardization and

determines the Viscosity of Petroleum products, which flows in a Newtonian liquid

except cut back Bitumens and road oils at the set temperature. They confirm to

requirement of IP 70.

SHORT QUESTIONS:

1. How does the viscosity of liquid vary with temperature?

2. Define viscosity. Mention its units in various systems.

3. What is viscosity index?

4. How do you improve the viscosity index of lubricating oil?

5. What is the difference between the Redwood Viscometer No 1 and Redwood No.

2?

6. Name a few lubricants with high viscosity index.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 14

Department of Chemical Engineering

Difference between Redwood and Saybolt Viscometer

Sr. No. Saybolt Viscometer Redwood Viscometer

1 The experiment is held and a 60ml of oil In this experiment is held and a

is passed through a standard orifice. The 50ml of oil is passed through a

total time duration is then noted. standard orifice. The total time

duration is then noted.

2 A stopper is provided at the bottom of The stopper is replaced with a ball

the tube for the liquid not to flow. It is valve and orifice.

released during the experiment.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 15

Department of Chemical Engineering

Experiment No. 5

Determination of Flash Point by Abel’s Apparatus

AIM

To find out the Flash point of petroleum products and mixtures above 19oC and below

70oC ranging by Abel‟ apparatus (as per IP: 33 and 1448 [part 1, p.20], 1982).

PRINCIPLE:

Flash point is defined as the temperature at which an oil gives sufficient vapor to form an

inflammable mixture with air and catches fire momentarily flashes when flame is applied.

Flash point gives the idea about the nature of the boiling point diagram of the system,

amount of low boiling fraction present in the liquid fuel, explosion hazards, volatility of

the liquid fuels. Beside oil‟s volatility and inflammability limits of the vapor-air mixture

the flash point also depends on the design of the apparatus, the test procedure and

barometric pressure.

APPARATUS

There are two basic types of flash point measurement: open cup and closed cup. In open

cup devices the sample is contained in an open cup (hence the name) which is heated, and

at intervals a flame is brought over the surface. The measured flash point will actually

vary with the height of the flame above the liquid surface, and at sufficient height the

measured flash point temperature will coincide with the fire point.

The apparatus is made of brass /gun metal machined cup cover fitted with shutter

mechanism, test flame arrangement, stirrer and thermometer socket. The total assembly

of the apparatus rests in stainless double jacketed copper/stainless steel water bath. Other

components like a funnel, an overflow pipe, and split thermometer socket are fixed on the

top of the heating bath and its outer jacket of the bath is fitted with a stand. At the bottom

of the apparatus, an electric heater is fitted with a flexible cord.

PROCEDURE

The test portion is placed in the test cup of an Abel apparatus and heated to give a

constant temperature increase with continuous stirring.

A small test flame is directed through an opening in the test cup cover at regular

temperature intervals with simultaneous interruption of stirring.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 16

Department of Chemical Engineering

The lowest temperature at which application of the test flame causes the vapour of

test portion to ignite and propagate over the surface of the liquid is recorded as the

flash point at the ambient barometric pressure.

The temperature is corrected to standard atmospheric pressure using an equation.

Separate test procedures are defined for liquids with expected flash points

between –30 °C and 18,5 °C inclusive, and between 19 °C and 70 °C inclusive.

Abel’s Flash Point Apparatus: Assembly plus heating Vessel

Updated on 1st January 2021 by Dr. Kaushik Nath Page 17

Department of Chemical Engineering

OBSERVATION TABLE

Room Temperature:

Atmospheric pressure:

Sample Given:

Characteristics of the sample:

Sample Serial Number Temperature (oC) Observation

Observed Flash Point: --------------- oC

Since the pressure varies from place to place there is a pressure correction required to

be applied. The following correlation is used:

Δtp = 0.0346 (760 P) oC

Where P = atmospheric pressure under test conditions.

Actual Flash point = Observed flash point + Pressure correction factor.

TASK

4) Draw the profile of time vs. temperature.

5) Compare the results with the literature value.

6) Can the experiment be conducted to determine the fire point?

INDUSTRIAL APPLICATION

Updated on 1st January 2021 by Dr. Kaushik Nath Page 18

Department of Chemical Engineering

Flash and fire point are important when oil is exposed to high temperature service.

This test provides safe guard against decomposition and fire hazard during

storage, transportation, handling and other uses.

Flash point is used to assess the overall hazard of a material and is used in

shipping and safety regulations to define "flammable" and "combustible"

materials.

DISCUSSION

The flash point is an empirical measurement rather than a fundamental physical

parameter. The measured value will vary with equipment and test protocol variations,

including temperature ramp rate (in automated testers), time allowed for the sample to

equilibrate, sample volume and whether the sample is stirred.

Flash point values may be used in shipping, storage, handling and safety regulations, as a

classification property to define “flammable” and “combustible” materials. Precise

definition of the classes is given in each particular regulation. A flash point value may

indicate the presence of highly volatile material(s) in a relatively non-volatile or

nonflammable material and flash point testing may be a preliminary step to other

investigations into the composition of unknown materials.

SHORT QUESTIONS

1. Define Flash point and Fire point of petroleum oil.

2. What are the factors that affect flash and fire point?

3. What should be the flash point of a good lubricant?

4. What is the difference between Abel‟s and Pensky Marten‟s Apparatus?

5. What is the permissible flash point value of marketable kerosene/diesel/gasoline?

6. Arrange the following fuels in order of increasing flash point

a. Kerosene, Gasoline, Diesel, lube oil

7. Is there any relationship between flash point and IBP of oil?

9. What is the significance of flash point determination of petroleum oil?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 19

Department of Chemical Engineering

Experiment No. 6

Determination of Carbon residue by Conradson carbon Apparatus

AIM

To find out the carbon residue of supplied sample of fuel oil using Conradson carbon

apparatus (As per IP-13 & ASTM D 189).

PRINCIPLE

Carbon residue of oil is defined as percentage of carbon left after complete evaporation

and pyrolysis of the oil taken, heated under standard condition in a Conradson‟s

apparatus. The result gives information about relative carbon forming property of oil

which is useful for its use as a lubricant. The carbon residue of a crude oil product gives

an indication of the propensity for that product to form a carbonaceous residue under

thermal conditions. The carbonaceous residue is correctly referred to as the carbon

residue but is also often referred to as coke or thermal coke.

Carbon residue is an indication of the fuel to decompose and form carbonaceous

material that can plug diesel fuel injection nozzles. The carbon residue provides

information on the carbonaceous deposits which will result from combustion of the fuel.

For fuels with a high carbon- high carbon/hydrogen ratio, it is proved more difficult to

burn them fully, which results in increased deposits in the combustion and exhaust

spaces. Fuels with a high carbon residue value may cause problems in older engines

when they are operating under part load conditions. The carbon residue value of a fuel

depends on the refinery processes employed in its manufacture.

Ramsbottom Carbon Residue (RCR), Conradson Carbon Residue (CCR), Micro

Carbon Residue (MCR) are the most commonly used indexes for estimation of carbon

residue.

APPARATUS

It consists of the following:

i) Porcelain crucible

ii) Iron crucible (skidmore)

iii) Spun sheet iron crucible

iv) Hood

v) Burner

Updated on 1st January 2021 by Dr. Kaushik Nath Page 20

Department of Chemical Engineering

The Conradson apparatus mainly consists of three crucibles kept one inside other. The

inner most is a silica crucible which consists of the oil along with two glass beads. This is

provided with a lid, having a small tube type opening for the escape of volatile matter.

The combination is then placed inside a spun sheet crucible covered with a chimney

shaped iron hood.

PROCEDURE

About 1 gm of oil under test is to be taken in a porcelain or silica crucible with one or

two of glass beads to prevent bumping during heating. The crucible is then placed in a

skidmore iron crucible of capacity 65-82 ml, containing sand so that the levels of the two

crucibles are same. Initially it is to be heated strongly so that ignition starts within 10±1

min, marking the pre-ignition period. When smoke appears over the chimney, burner is to

be switched on so that the sides of crucible are heated and vapors are formed. The flame

is adjusted so that the vapors burn uniformly and the burning period is 13 ± 1min when

the vapor ceases to burn and no more blue smoke is observed, the burner is readjusted to

heat at the bottom as in beginning and heating is continued to red hot for exactly 7 min.

Thus the total heating period is 30 ± 2 min. After heating the arrangement is cooled until

no smoke appears. The hood is then removed and silica crucible is cooled is desiccator

and weighed.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 21

Department of Chemical Engineering

OBSERVATIONS

Weight of the crucible with glass beads = __________

Weight of crucible + Glass bead + Oil = _______________

Weight of crucible with glass bead and residue after cooling = _______________

% age of Carbon residue in oil = (weight of Carbon residue/weight of oil taken) ×

100.

RESULT

TASK

Compare the results with literature value.

INDUSTRIAL APPLICATION

Propensity of thermal cracking in petroleum refining is an outright function of Conradson

carbon residue (CCR). Industrially a concise analogical term Conradson Decarbonizing

Efficiency (CDE) is more familiar; it is given by

carbon residue in feedstock carbon residue in liq products

CDE

Carbon residue in feedstock

The carbon residue value of burner fuel serves as a rough approximation of the

tendency of the fuel to form deposits in vaporizing pot-type and sleeve-type

burners. Similarly, provided alkyl nitrates are absent (or if present, provided the

test is performed on the base fuel without additive) the carbon residue of diesel

fuel correlates approximately with combustion chamber deposits.

The carbon residue value of motor oil, while at one time regarded as indicative of

the amount of carbonaceous deposits a motor oil would form in the combustion

chamber of an engine, is now considered to be of doubtful significance due to the

presence of additives in many oils. For example, an ash-forming detergent

additive may increase the carbon residue value of oil yet will generally reduce its

tendency to form deposits.

The carbon residue value of gas oil is useful as a guide in the manufacture of gas

from gas oil, while carbon residue values of crude oil residuum‟s, cylinder and

bright stocks, are useful in the manufacture of lubricants.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 22

Department of Chemical Engineering

Exercise: -

1. Name the various methods to determine the carbon residue in petroleum fractions.

2. For which fraction carbon residue is an importance specification.

3. What are the constituents of LPG?

4. What is the difference between gross calorific value and net calorific value of

fuel?

5. What are the different types of fuel gases? Give their detail composition and

heating value.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 23

Department of Chemical Engineering

Experiment No. 7

ASTM Distillation

(As per IS – 1448 (Part.1) 1960 (P: 18) and As per IP 18 Specification)

AIM:

This test is intended for the determination of the distillation characteristics of natural,

gasoline, aviation and motor fuel special boiling point spirit, white spirit and petroleum

distillation having volatities intermediate between those of kerosene and lubricating oil.

PRINCIPLE:

This test method covers the determination of the boiling range distribution of petroleum

products. This test method is applicable to petroleum distillates having an initial boiling

point greater than 100°C and a final boiling point less than 615°C at atmospheric pressure

as measured by this test method. ASTM stands for American Society for Testing and

Materials.

Dry point: The temperature indicated by the distillation thermometer when the last drop

of liquid leaves the bottom of the distillation flask.

Final boiling point (FBP): Maximum temperature indicated during the distillation.

Initial boiling point (IBP): The temperature indicated by the distillation thermometer at

the instant the first drop of condensate leaves the end of the condenser tube.

APPARATUS:

The sample is distilled in specified apparatus under prescribed conditions of heat input

and rate of distillation. One hundred milliliters of the sample are distilled in method A

and method B and 200 ml in method C. Temperature are observed on the specified total

immersion thermometer in order to obtain the initial and final boiling points of the

distillation and the dry point, if required. Either the percentage of distillate recovered at

prescribed temperature intervals or the temperatures at which prescribed percentage of

distillate are collected in the receiver are recorded. Correction of the observed

temperatures for incomplete immersion of the thermometer is not made.

Collect the sample in a previously cooled bottle preferably by immersing the bottle in the

liquid and discarding the first sample. When immersion is not possible draw off the

sample into a previously cooled bottle keeping agitation at a minimum. Close the bottle

immediately with a tight stopper and place it in a ice bath or a refrigeration to bring the

sample to a temperature between 0 to 5 oC.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 24

Department of Chemical Engineering

PROCEDURE:

Cool the distillation flask, the receiver and the sample to 0 to 5 oC. Measure 100

ml of the sample into the distillation flask by means of the receiver taking care

that none of the liquid flows into the vapour tube.

Cool the thermometer to between 0 and 5oC and dry it before fitting it tightly into

the flask by means of a cork. Adjust it so that it will be in the middle of the neck

and so that the lower and of the capillary is level with the bottom of the inside of

the vapor tube at its junction with the neck of the flask.

Ensure that the heating apparatus, including the draught screen and flask support

are all at room temperature at the start of each distillation. Place the flask with its

contents on the 32 mm opening the upper asbestos board with the vapour tube

inserted into condenser.

Make the connection tight by means of a cork through which the vapour tube

passes and adjust the position of the flask so that the vapour tube extends into the

condenser not less than 25 mm and not more than 50 mm.

Without drying it, place the graduated receiver used in measuring the charge at

the outlet of the condenser in such a position that the condenser tube extends into

the receiver at least 25 mm but not below the 100 mm mark. Immerse the receiver

up to the level of the outlet of the condenser tube in transparent liquid bath

maintained between the temperatures of 0 to 1 oC. Cover the top of the receiver

closely during the

Updated on 1st January 2021 by Dr. Kaushik Nath Page 25

Department of Chemical Engineering

RESULTS

Room Temperature:-

Observation table: -

Condensate Collected in Temperature of the test

Sr

ml sample in

No. 0

C

1 First drop 54

2 5 56

3 10 58

4 15 60

5 20 62

6 25 64

7 30 66

8 35 70

9 40 72

10 45 79

11 50 88

12 55 104

13 60 118

14 65 126

15 70 136

16 75 142

17 80 150

18 85 159

19 90 172

20 95 230

21 Last drop 260

Graph: -

Temperature of the test sample vs. Condensate Collected (Find the true boiling point and

final boiling point of the sample from graph)

INDUSTRIAL APPLICATIONS

Updated on 1st January 2021 by Dr. Kaushik Nath Page 26

Department of Chemical Engineering

It is generally known in petrochemical industry to perform a distillation analysis

of a hydrocarbon-containing compound such as a petroleum product (e.g. gasoline

and/or naphta) in order to obtain distillation data such as boiling point range and

the like. The boiling range distribution of light and medium petroleum distillate

fractions provides an insight into the composition of feed stocks and products

related to petroleum refining process.

This test method covers the atmospheric distillation of petroleum products using a

laboratory batch distillation unit to determine quantitatively the boiling range

characteristics of such products as light and middle distillates, automotive spark-

ignition engine fuels, automotive spark-ignition engine fuels containing up to 10

% ethanol, aviation gasolines, aviation turbine fuels, 1-D and 2-D diesel fuels,

biodiesel blends up to 20 %, marine fuels, special petroleum spirits, naphthas,

white spirits, kerosene, and Grades 1 and 2 burner fuels.

Exercise: -

1. What do you understand from ASTM distillation and True Boiling Point (TBP)

overlap? Also explain their significance with respect to motor spirit.

2. State any four thermal properties of petroleum fractions.

3. What is the elemental and chemical Composition of petroleum?

4. What are the various types of gases obtained during production and refining of

crude oil?

5. Define the terms cracking, reforming and hydro treating.

6. Name the catalysts used in catalytic cracking and reforming and explain the

mechanisms.

7. What is the purpose of visbreaking process in petroleum refinery?

8. Name the various petroleum refinery products and mention their applications.

9. What do you understand by stabilization of crude oil and how is it carried out?

10. State and discuss the various methods for dehydration of crude.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 27

Department of Chemical Engineering

Experiment No. 8

Determination of Cloud and Pour point of Petroleum oil

AIM:

This test method is intended to determine the cloud and pour point of petroleum oils used

in the softening and stuffing of leather, as well as those used in the manufacture of

products for such purpose. The pour point of petroleum oils is measured for the purpose

of quality assurance. (ASTM D5346 - 93(2003) e1

PRINCIPLE:

Some petroleum fractions, particularly middle distillate petroleum fuels and dark oils

typically contain varying quantities of dissolved wax. Waxes are hydrocarbons of high

molecular weight which are solids at about 70° F. or less such as paraffin and

microcrystalline. Wax has a tendency to crystallize within a petroleum fraction as the

petroleum fraction temperature decreases. Crystallized wax causes the petroleum fraction

to cloud, become viscous and, as the temperature drops, to solidify. The cloud point of a

fuel oil is the temperature at which the fuel becomes hazy or cloudy because of the

appearance of wax crystals. Cloud & pour point are indicators of the lowest temperature

of utility for petroleum products. The sample is periodically examined while it is being

cooled in the cloud & pour point apparatus. The highest temperature at which haziness is

observed (cloud point) or the lowest temperature at which movement of the oil is

observed (pour point) is reported as the test result.

PROCEDURE

If required dry the test oil by shaking it with a small amount of anhydrous sodium

sulphate and filter it through lintless filter paper.

Fill the oil up to the mark inside the flat bottomed glass tube and fit the tube with

a cork in to which a thermometer is inserted. The bulb of the thermometer should

dip inside the oil.

Keep the tube in the cooling air jacket surrounded by the cooling bath containing

the cooling mixture. The temperature of the oil will start falling down.

After every 1oC fall in temperature of oil, take out the test jar from the jacket and

inspect for cloudiness. If no cloudiness appears, immediately replace it in the

jacket.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 28

Department of Chemical Engineering

Record the temperature at which such inspection first reveals a distinct cloudiness

in the oil near the bottom of the jar.

Continue the cooling and take out the tube after every 3 oC fall of temperature and

tilt it just enough to see any movement or flow of oil. If the movement or flow is

there, replace it immediately in the jar.

Continue the test until no movement of oil is observed when the test jar is held in

a horizontal position for exactly 5 seconds. Note down the temperature and report

it as pour point.

OBSERVATION TABLE

Room Temperature:

Sample Given:

Cloud Point:

Pour Point:

Cloud and Pour Point Apparatus

TASK: Collect the pour point values of various lube oils from literature. Compare your

result with literature value.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 29

Department of Chemical Engineering

INDUSTRIAL APPLICATION:

The lowest temperature (in °F or °C) at which a liquid remains pourable (meaning it still

behaves as a fluid). Oil or synthetic muds with high pour points may suffer from poor

screening and excessive pressure, surges in deepwater wells or other operations subject to

low temperatures. In oils, the pour point is generally increased by a high paraffin content.

The pour point of liquid additives is an important consideration for arctic drilling

operations.

DISCUSSION:

A particular problem exists during the winter months when wax crystallization caused by

low outdoor temperatures can cause fuel lines, filters and the like to clog in diesel engines

and furnaces which burn petroleum fractions. Pour point depressants such as kerosene

and polymerized higher esters of acrylic acid derivatives are well known. When added to

a petroleum fraction, pour point depressants lower the cloud point and the pour point

temperature of the petroleum fraction. Kerosene is also used as a diluent to lower the

cloud point of petroleum fractions. However, wax content within a petroleum fraction

often varies with the distillation conditions under which the fraction was produced and

with the source of crude oil from which the fraction was distilled. Thus, the amount of

pour point depressant needed to achieve a desired pour point in a petroleum fraction will

vary.

SHORT QUESTIONS:

1. Define cloud and pour point of a liquid lubricant.

2. How can the pour point of an oil be lowered?

3. What is the significance of pour point and cloud point determination?

4. Name a few pour point depressants.

5. What are the factors for pour point fixation of a fuel?

6. Name a few freezing mixtures used for pour point analysis.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 30

Department of Chemical Engineering

Experiment No. 9

Determination of surface tension of a given liquid by Stalagmometer

AIM: To determine the surface tension of a given liquid at ambient temperature.

PRINCIPLE:

Surface tension is the characteristic property of every liquid and it is due to

intermolecular attractions among molecules of liquid. It is defined as the force in dynes

acting at right angles to the surface of a liquid or a solution along one centimeter length

of surface. The surface tension of a given liquid is determined relative to water at the

room temperature by using stalagmometer. The number of drops for the same volume of

water and the given liquid are counted and let these be as n1 and n2 respectively. Now if

d1 and d2 are densities of water and the given liquid at the room temperature as

determined separately by using pyknometer, then the surface tension 2 of the given

liquid can be calculated by using simplified relationship as:

1 n 1 d1

2 n2 d2

MATERIALS:

Stalagmometer, distilled water, unknown liquid, beaker, rubber tube with screw pinch

cock, clamp stand, pyknometer.

DESCRIPTION OF APPARATUS

The stalagmometer consists of a bulbed dropping tube with a capillary. The lower end of

capillary is well ground, polished and flattened in order to provide large dropping

surface. There are two marks above and below the bulb. The upper end of the apparatus is

connected with a rubber tube with a screw pinch cock in order to control the rate of flow

so that spherical drop may be formed. Hence by simply counting the number of drops for

the given liquid and water and knowing their density, we can find the relative surface

tension of the liquid. The advantages of the drop pipette method are that it is very

convenient and quick. It can also be employed for determination at different temperatures

by placing the whole apparatus in thermostat.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 31

Department of Chemical Engineering

PROCEDURE

Clean the stalagmometer and pyknometer thoroughly first with chromic acid

solution and wash finally with distilled water and then dry.

By immersing the lower end in a beaker containing the distilled water, suck up

water until it rises above the mark and tighten the screw of the screw pinch.

Now loosen the screw of the screw pinch carefully so that the liquid drops

start falling at the interval of about 2-3 seconds in successive drops. Counting

of drops is started when the water meniscus just reaches the upper mark and

stopped when the meniscus just passes the lower mark. Repeat to get three

readings and take the mean value.

Clean the stalagmometer and dry it. Fill it with liquid until it rises above the

upper mark and count the number of drops as before.

OBSERVATINS & CALCULATIONS

Room Temperature = oC

Density of water at room temperature = d1

Weight of empty pyknometer = w1 g

Weight of pyknometer with water = w2 g

Weight of pyknometer with liquid under test (same volume as water) = w2

Weight of water = ( w2-w1) = m1 g (say)

Weight of liquid = (w3-w1) = m2 g (say)

Updated on 1st January 2021 by Dr. Kaushik Nath Page 32

Department of Chemical Engineering

Surface tension of water at room temperature =

Liquid Number of drops Mean value

(1) (2) (3)

n1

n2

n3

CALCULATIONS

Density of the given liquid relative to water at room temperature

m1

d2

m2

n d

Also 1 2 2

2 n 1 d1

n1 d 2

2 1

n 2 d1

where 1 = surface tension of water at room temperature.

Substituting the values of 1, n1, n2, d1 and d2 , the surface tension of the given liquid at

room temperature thus becomes known.

Result: -

Discussion: -

Precautions: -

a. The stalagmometer and specific gravity bottle or pyknometer should be

cleaned properly and dried before use.

b. Fit the stalagmometer vertically.

c. The rate of the fall of the drops should be adjusted in a way of having

interval of at least 2 – 3 seconds in successive drops. The number of drops

per minute must be in between 15 – 20.

d. The drops should fall from the tip of the stalagmometer under their own

weight rather than pushing them by force.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 33

Department of Chemical Engineering

e. Wash and dry the stalagmometer after use.

Exercise: -

1. How do you define the term surface tension?

2. What method do you use in laboratory for determination of surface tension?

Briefly explain that method.

3. What formula is used for the calculation of surface tension?

4. How do you measure the density of the liquid?

5. What is the shape of a liquid drop falling from a capillary?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 34

Department of Chemical Engineering

Experiment No. 10

Methods for testing Tar and Bitumen determination of softening point

(IP-198and IS 1208 specifications)

Aim: -

To determine the softening point of a given bituminous material

Apparatus and Chemicals: -

1. 1000 mi of Beaker with cover

2. Thermometer

3. Heating mental

4. Asphaitic material and water

Theory: -

This standard covers the method for the determination of softening point of asphaltic

bitumen & fluxed native asphalt road tar coal tar pitch and blown type bitumen. The

temperature at which the substance attains a particular degree of softening under

specified condition of test.

Procedure: -

Preparation of test sample: -Heat the material to a temperature between 75 0C &

100 0C above its softening point stir until It is completely fluid and free from air

bubbles and water, and filter, if necessary through IS sieve 30(see IS: 460-1953).

Place the rings, previously heated to a temperature approximating to that of

molten material, on a metal plate, which has been coated with mercury and filled

with sufficient melt to give excess above the level of the ring when cooled. After

cooling for 30mins in air, level the material in the ring by removing the excess

with warmed sharp knife.

For material of softening point below 80 0C: -Assemble the apparatus with the

rings, thermometer and ball guides in position; and fill the bath to a height of

50mm. Above the upper surface of the ring with freshly boiled distilled water at a

temperature of 50 0C for 15mins after which place a ball previously cooled to a

temperature of 50C by mean of forceps in each ball guide. Apply heat to the bath

and stir the liquid so that the temperature rises at uniform rate of 50+ 0.50 0C per

minutes until the material softens and allows the ball to pass through the ring. The

Updated on 1st January 2021 by Dr. Kaushik Nath Page 35

Department of Chemical Engineering

rate of temperature rise shall not be averaged over the period of test, & any test in

which the rate of temp rise does not fall within the specified limits after the first 3

mins shall be rejected. Make the determination in duplicate.

For materials of softening above 800 0C: -The procedure for materials of

softening point above 800 0C is similar to that described under 3.2 with the

difference that glycerin is used in place of water in the bath and the starting temp.

of the test is 350 0C. Make the determination in duplicate.

Report:

a. Record, for each ring and ball, the temp, shown by the thermometer at the instant

the sample surrounding the ball touches the bottom plate of the support. If any, or

the bottom of the bath.

b. Report to the nearest 0.50 0C the mean of the temp recorded in duplicate

determination, without correction for the emergent stem of the thermometer, as

the softening point.

Observation table:

Softening point Softening point Softening point Average

Sample in 0C in 0C in 0C Softening point

1 2 3 in 0C

Result: -

Industrial Application: -

Exercise: -

1. What is the difference between asphalt, bitumen and asphaltenes? How are they

produced?

2. Write the significance of softening point.

3. What are the uses of bitumen?

4. What is dewaxing? Name the solvent used for dewaxing.

Updated on 1st January 2021 by Dr. Kaushik Nath Page 36

Department of Chemical Engineering

Experiment No: 11

Determination of smoke point of kerosene by smoke point apparatus

Aim: -

To determine the smoke point of a given sample of kerosene

Apparatus: -

1) Standard lamp with wick.

2) Wick height adjuster.

3) Linear scale to denote the flame height.

Principle: -

Smoke point is an indication of clean burning quality of kerosene. Illumination depends

upon the flame dimensions although it is not related to flame height. Smoke point is

defined as the maximum height of flame in millimeters at which the given oil will burn

without giving smoke. Thus smoke point test enables the burning quality to be measured

by adjusting the wick height to give proper non-smoky flame. Different flame heights are

obtained due to the presence of the different components such as paraffin, naphthenes,

and aromatics. Mainly aromatics contribute smoke; hence removal of aromatics increases

smoke point.

Smoke Point Lamp: -

Updated on 1st January 2021 by Dr. Kaushik Nath Page 37

Department of Chemical Engineering

Specifications: -

Conforms to ASTM D1322; ISO 3014; IP 57; DIN 51406; FTM 791-2107

Included Accessories Cotton Wicks, non-extracted (6)

Dimensions (Dia x H) 7 x 18.5 in. (18 x 47 in.)

Net Weight 10 lbs (4.5kg)

Shipping Weight 16 Ibs (7.3kg)

Shipping Dimensions 5 Cu. ft.

Procedure: -

Take out the lamp & wick from the stand.

Fill the container with given sample of kerosene.

Fix the container into the jacket & light up the wick.

Observe the formation of black smoke from the top.

Observe the color and luminosity of the flame.

Note down the initial height.

Now adjust the wick height slowly by rotating the adjuster & wait for few minutes

to observe the formation of smoke.

Note down the height in millimeter.

Adjust the flame to a non-smoky & luminous condition. Measure the height

which corresponds to actual smoke point of kerosene

Observation Table:-

Flame height Smoke characteristics Luminosity

(In mm.) (Whether smoky / non smoky) (Luminous / non-luminous)

Result: -

Significance and Use: -

This test method provides an indication of the relative smoke producing properties of

kerosene and aviation turbine fuels in a diffusion flame. The smoke point is related to the

Updated on 1st January 2021 by Dr. Kaushik Nath Page 38

Department of Chemical Engineering

hydrocarbon type composition of such fuels. Generally the more aromatic the fuel the

smokier the flame. A high smoke point indicates a fuel of low smoke producing

tendency.

The smoke point (and Luminometer number with which it can be correlated) is

quantitatively related to the potential radiant heat transfer from the combustion products

of the fuel. Because radiant heat transfer exerts a strong influence on the metal

temperature of combustor liners and other hot section parts of gas turbines, the smoke

point provides a basis for correlation of fuel characteristics with the life of these

components.

Exercise: -

1. State the standard tests prescribed for kerosene

2. Define Smoke point and name the processes, which are used to improve smoke

point.

3. What do you meant by ignition temperature of the fuel?

4. What is the difference between lube oil, lubricating oil &gas oil?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 39

Department of Chemical Engineering

Experiment No: 12

Determination of Viscosity by Oswald Viscometer

Aim: -

To determine the relative viscosity of a given liquid with respect to water at different

temperature using Oswald‟s viscometer

Apparatus:

Oswald‟s Viscometer, thermometer, thermostat, pipette, Sp. Gr. Bottle, weight box and a

stop watch.

The apparatus consists of a U-tube with a glass bulb A, made from a thick-walled

capillary glass tube. The two limbs of the U-tube are bent at right angles and end in

narrow bores. One of the ends is shorter and thicker, and the other narrower and longer.

Two glass caps to prevent loss due to evaporation close the ends. The pyknometer is

weighed by suspending it with a wore from the hook of the balance.

Theory:

Viscosity of a solution varies with its concentration. If the viscosities are plotted against

the corresponding concentration, a curve (depending on the nature of the solution) is

obtained by determining the viscosity of the unknown solution, its concentration may be

found out from the curve.

Consider a column of liquid, in a capillary glass tube, flowing downward due to a

pressure difference P. The liquid column in the tube may be considered as being

composed of a large number of concentric cylindrical layers which slides over one

another and moves downward due to the pressure difference. As the liquid layer in

contact with the glass wall tends to move, a shearing effect is produced by the glass wall

and destroys the relative motion of the moving layer. Similarly, each of the moving liquid

layer experiences a shearing effect by its preceding liquid layer. Thus the velocity of the

different liquid layers are not the same, but change uniformly according to their distance

from the glass wall, and its maximum at the center and minimum at the surface of the

wall. The shearing effect or the internal friction which is produced by the glass wall and

the different liquid layers, when a liquid flows, and which opposes the flow of the liquid

is called „viscosity‟ of the liquid. Newton supposed that the force which opposes the

Updated on 1st January 2021 by Dr. Kaushik Nath Page 40

Department of Chemical Engineering

movement of a particular cylindrical liquid layer is proportional to the velocity gradient

du

and to area A of the liquid layer. Thus:

dx

du du

F A or F A --------------------------- (1)

dx dx

When is the co-efficient of viscosity, which is constant for a particular substance at a

du

definite temperature and pressure? When = 1 and A = 1, equation (1) reduces to F =

dx

. Thus from this, coefficient of viscosity may be defined as the force per unit area in

dynes / cm 2 required to maintain a difference of viscosity of 1 cm between two parallel

liquid layers flowing at a distance of 1 cm. The unit of co-efficient of viscosity is called 1

poise.

When the driving force (i.e., the force due to the pressure difference (P) becomes equal to

the viscous-drag, the liquid flows steadily.

For the determination of co-efficient of viscosity of a liquid by Oswald‟s Viscometer the

following equation of Poisculle is employed

P x4 t

------------------------------------- (2)

8lV

When is the co-efficient of viscosity of a liquid which flows uniformly through a

capillary tube of radius x cm and length l cm at the rate of V ml of the liquid in t seconds

and P represents the driving pressure in dynes / cm 2 .

In the Oswald‟s Viscometer the relative viscosity of a liquid is measured. So if t1 and t 2

represent the times required for the same volume of two different liquids to flow through

the same capillary tube, we have for the two liquids

P x 4 t1

1 --------------------------------- (3)

8lV

and

P x 4 t2

2 ------------------------------------- (4)

8lV

Thus dividing eqn. (3) by (4) we get the ratio of the viscosity co-efficient of the two

liquids:

1 p t

1 1 ----------------------------------------- (5)

2 p2 t 2

Since p1 and p2 are proportional to 1 and 2 , the densities of the two liquids

[because p1 h 1 g and p2 h 2 g ] the eqn. (5) becomes

Updated on 1st January 2021 by Dr. Kaushik Nath Page 41

Department of Chemical Engineering

1 1 t1

----------------------------------------- (6)

2 2 t2

Where 2 , 1 , 2 , t1 and t 2 are known 1 can be calculated from eqn. (6).

Procedure:

Clean the Oswald‟s Viscometer thoroughly with chromic acid and water. Drop from a

measuring pipette a definite volume of water into the viscometer through the right hand

limb, D. Maintain a thermostat at constant temperature and note the temperature.

Immerse the viscometer into the thermostat and keep it for sometime, so that it can attain

the constant temperature of the bath. Suck the water with the rubber tube up to a level

above the mark „a‟. Allow the water to flow down the tube. Start the stopwatch when the

level of water is at „a‟ and stop it when the level falls at „b‟. Note the time of fall and

repeat the experiment at least five times. [Difference of time must not exceed 0.2 to 0.3

seconds.]

Dry the viscometer by passing hot air and repeat the experiment at least three times with

the same volume of liquid, whose viscosity is to be determined.

Determine the density of the liquid by a specific gravity bottle in the usual way.

Observations: -

1. Room temperature: --------------

2. Time of flow between two marks: --------------

3. Density of liquid (d1) and of water (d2): ---------------

(Using Specific gravity bottle)

Observation Table: -

Sr Temperature Water Liquid under Experiment

No. in C Time of Time of Mean Time of Time of Mean

flow - 1 flow - 2 time flow - 1 flow - 2 time

1

2

3

4

Updated on 1st January 2021 by Dr. Kaushik Nath Page 42

Department of Chemical Engineering

Calculations:

1. Density of liquid (d1) / Density of water (d2) = Weight of liquid / Weight of

water

2. Relative viscosity of liquid = n1 / n2 = d1t1 / d2t2

Result: -

Discussion: -

Industrial Applications: -

Precautions:

1. The viscometer should be thoroughly cleared (grease free).

2. The viscometer should be held exactly vertical during the experiment.

3. Volume of water and the experimental liquid taken in the viscometer should be

equal.

4. The temperature should be maintained constant during the experiment with the

help of a thermostat. If a thermostat be not available, the temperature at the

beginning as well as at the end of the experiment should be noted carefully, and if

there be any difference, the mean should be recorded as the room temperature.

5. If the experimental liquid be volatile, a pyknometer, instead of a Sp. Gr. Bottle

should be used for determination of density.

Exercise: -

1. What is the principle of Ostwald viscometer?

2. What is viscosity? What are the different units of viscosity?

3. What is the effect of temperature on viscosity?

4. What are the different types of viscometers? Explain their principle.

5. What is the importance of determination of viscosity?

6. What are the viscoelastic fluids? What are their applications?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 43

Department of Chemical Engineering

Experiment No: 13

Determination of Chemical oxygen demand (COD)

Aim: To determine the COD value of a given sample of wastewater.

Apparatus and reagents: -

(1) Standard potassium dichromate solution, 0.04167 M. 12.259 g of K2Cr2O7 was

dissolved in distilled water and diluted to 1000 ml. This reagent undergoes a

six-electron reduction reaction; the equivalent concentration is 0.2500 N.

(2) Ferroin indicator solution: 1.485 g/1, 10 phenanthroline monohydrate and 695

mg FeSO4. 7H2O in distilled water and was diluted to 100 ml.

(3) Standard ferrous ammonium sulfate (FAS) titrant, approximately 0.25 M: 98 g

of Fe (NH4) 2(SO4)2.6H2O was dissolved in distilled water. 20 ml of

concentrated H2SO4 was added to it. The mixture was cooled and diluted to

1000 ml. This solution was standardized against standard K2Cr2O7 solution as

follows:

25 ml of standard K2Cr2O7 was diluted to about 100 ml. 30 ml of concentrated

H2SO4 was added to it and was cooled. It was titrated against FAS titrant using 2-

3 drops ferroin indicator.

Principle:

COD (Chemical oxygen demand) is a measure of any kind of oxidizable impurities

present in the sewage. COD is a measure of both the biologically oxidizable and

biologically inert organic matter present in the sewage sample. It is an important and

quickly measured parameter for stream and industrial waste water analysis and water

treatment plants. A boiling mixture of chromic and sulfuric acids oxidizes most types of

organic matter. A sample is refluxed in strongly acid solution with a known excess of

potassium dichromate (K2Cr2O7). After digestion, the remaining unreduced dichromate is

titrated with ferrous ammonium sulfate to determine the amount of K2Cr2O7 consumed

and the oxidizable matter is calculated in terms of oxygen equivalent.

Procedure: -

For samples with a COD of > 900 mg O2/l, a smaller portion was diluted to 50 ml. 1 g of

Hg SO4 and a few glass beads were added. Then 5 ml of H2SO4 reagent was added very

slowly. The mixture was cooled in ice bath to avoid possible loss of volatile materials. 25

ml of standard K2Cr2O7 solution was added and mixed. The flask was attached to the

condenser and the cooling water was turned on. Remaining sulfuric acid (70 ml) was also

added slowly into the flask with continued swirling. Reflux was carried out for 2 hours. It

was cooled and the condenser was washed down with distilled water. The reflux

condenser was disconnected and the mixture was diluted to about twice its volume with

distilled water. It was cooled down to room temperature and the excess K2Cr2O7 was

Updated on 1st January 2021 by Dr. Kaushik Nath Page 44

Department of Chemical Engineering

titrated against standard FAS, using 2-3 drops of ferroin indicator. The first sharp color

change fro blue-green to reddish-brown was noted which persisted for more than one

minute. In the same manner a blank containing the reagents and a volume of distilled

water equal to that of the sample was also refluxed and titrated.

(A B) M 8000

COD as mg O2/l =

ml of sample

Where

A = ml of FAS used for blank

B= ml of FAS used for sample

M = molarity of FAS and 8000 = milli equivalent weight of oxygen × 1000 ml/l

Precautions: -

1. Adding of suphuric acid reagent to reflux flask should be done slowly and by

shaking the flask. As it is an exothermic reaction the flask should be cooled

during mixing.

2. Smaller volume of sample should be taken in the flask, if it has high COD.

3. End point of the titration should be carefully observed.

Commercial Application: -

COD (Chemical oxygen demand) is one of the most important characteristic parameters

of wastewater. For any wastewater treatment process, the knowledge of COD helps in

determining the amenability of the waste water towards its treatment process.

Exercise: -

1. What is chemical oxygen demand?

2. What do you meant by BOD?

3. Name the impurities, which may interfere in COD determination.

4. Correlate BOD with COD.

5. Discuss the significance of COD determination.

6. How do you define the pollution strength of waste water and industrial waste?

Updated on 1st January 2021 by Dr. Kaushik Nath Page 45

You might also like

- Acropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryNo ratings yetAcropolis Institute of Technology & Research, Indore: BT101 Engg Chemistry7 pages

- Experiment 1: Specific Gravity Determination of Liquids: Physical Pharmacy Laboratory: PrelimNo ratings yetExperiment 1: Specific Gravity Determination of Liquids: Physical Pharmacy Laboratory: Prelim15 pages

- Indian Standard: Methods of Test For Petroleum and Its ProductsNo ratings yetIndian Standard: Methods of Test For Petroleum and Its Products8 pages

- Lecture 3: Petroleum Refining Overview: 3.1 Crude Oil100% (1)Lecture 3: Petroleum Refining Overview: 3.1 Crude Oil2 pages

- To Determine The Melting Point of Organic Compounds Like Naphthalene and Benzoic AcidNo ratings yetTo Determine The Melting Point of Organic Compounds Like Naphthalene and Benzoic Acid7 pages

- Experiment No:1: Determination of Reid Vapour Pressure AimNo ratings yetExperiment No:1: Determination of Reid Vapour Pressure Aim26 pages

- Standard Test Method For Carbon Residue: University of Zakho School of Engineering Petroleum Eng. DepNo ratings yetStandard Test Method For Carbon Residue: University of Zakho School of Engineering Petroleum Eng. Dep5 pages

- Toluene Toluene Toluene Hydrogen Chromium PlatinumNo ratings yetToluene Toluene Toluene Hydrogen Chromium Platinum6 pages

- 2210 - Melting Points and Mixed Melting Points0% (1)2210 - Melting Points and Mixed Melting Points13 pages

- Design Project "Glycerol": Srinivas Reddy Cherukula (09bch020) Sanath Kumar Vellanki (09bch066)100% (1)Design Project "Glycerol": Srinivas Reddy Cherukula (09bch020) Sanath Kumar Vellanki (09bch066)38 pages

- High Density Polyethylene and Low Density PolyethyleneNo ratings yetHigh Density Polyethylene and Low Density Polyethylene10 pages

- Aniline Point Test Apparatus: Instruction Manual FORNo ratings yetAniline Point Test Apparatus: Instruction Manual FOR4 pages

- University of Kirkuk College of Pharmacy: Partition CoefficientNo ratings yetUniversity of Kirkuk College of Pharmacy: Partition Coefficient4 pages

- Furfural A Selective Solvent Petroleum Refining: Kemp, JR.No ratings yetFurfural A Selective Solvent Petroleum Refining: Kemp, JR.8 pages

- Petroleum Refinery Lab. Kinematic Viscosity100% (1)Petroleum Refinery Lab. Kinematic Viscosity11 pages

- Presentation Lecture Slides Petroleum Refinery Engineering100% (1)Presentation Lecture Slides Petroleum Refinery Engineering49 pages

- Determination of Aniline Point of Petroleum SamplesNo ratings yetDetermination of Aniline Point of Petroleum Samples4 pages

- Industrial Hygiene: Instructor - Dr. Tamaghna Chakraborti Ph. No. - (0) 9892770980No ratings yetIndustrial Hygiene: Instructor - Dr. Tamaghna Chakraborti Ph. No. - (0) 989277098037 pages

- Azeotropic Mixtures and Their Separation - PPT Outline Seminar 2No ratings yetAzeotropic Mixtures and Their Separation - PPT Outline Seminar 26 pages

- Boley - 1980 - Determination of Foods Synthetic Colours Using HPLCNo ratings yetBoley - 1980 - Determination of Foods Synthetic Colours Using HPLC11 pages

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnNo ratings yetKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. Sohn6 pages

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut100% (1)Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut38 pages

- Preliminary Distillation of Crude Oil 25No ratings yetPreliminary Distillation of Crude Oil 2519 pages

- Petrochemical Industry: Eng/Bassem FathallaNo ratings yetPetrochemical Industry: Eng/Bassem Fathalla45 pages

- Caking Phenomena in Amorphous Food Powders: M. Aguilera, M. DD Valle and Marcus Ka LNo ratings yetCaking Phenomena in Amorphous Food Powders: M. Aguilera, M. DD Valle and Marcus Ka L7 pages

- CPB30503 Petrochemicals & Petroleum Refining Technology Experiment 4: Determination of Reid Vapor Pressure Full Lab Report100% (2)CPB30503 Petrochemicals & Petroleum Refining Technology Experiment 4: Determination of Reid Vapor Pressure Full Lab Report11 pages

- 3130507-Group Wise Topics For Online PresentationNo ratings yet3130507-Group Wise Topics For Online Presentation2 pages

- Performance and Mechanical Running Tests of Centrifugal Compressors PDF100% (2)Performance and Mechanical Running Tests of Centrifugal Compressors PDF9 pages

- Face Seal Glands: Parker O-Ring HandbookNo ratings yetFace Seal Glands: Parker O-Ring Handbook1 page

- chm150_v5_wk4_debrief_memo_template copyNo ratings yetchm150_v5_wk4_debrief_memo_template copy4 pages

- Osb - Chemical Bonding MCQ With SolutionsNo ratings yetOsb - Chemical Bonding MCQ With Solutions18 pages

- Centrifugal Pump Calculation SpreadsheetNo ratings yetCentrifugal Pump Calculation Spreadsheet8 pages

- Fluid Mechanics and Hydraulic Machines DR R K Bansal PDFNo ratings yetFluid Mechanics and Hydraulic Machines DR R K Bansal PDF287 pages

- Section 5 Equipment Selection, Sizing & Design100% (1)Section 5 Equipment Selection, Sizing & Design43 pages

- Acropolis Institute of Technology & Research, Indore: BT101 Engg ChemistryAcropolis Institute of Technology & Research, Indore: BT101 Engg Chemistry

- Experiment 1: Specific Gravity Determination of Liquids: Physical Pharmacy Laboratory: PrelimExperiment 1: Specific Gravity Determination of Liquids: Physical Pharmacy Laboratory: Prelim

- Indian Standard: Methods of Test For Petroleum and Its ProductsIndian Standard: Methods of Test For Petroleum and Its Products

- Lecture 3: Petroleum Refining Overview: 3.1 Crude OilLecture 3: Petroleum Refining Overview: 3.1 Crude Oil

- To Determine The Melting Point of Organic Compounds Like Naphthalene and Benzoic AcidTo Determine The Melting Point of Organic Compounds Like Naphthalene and Benzoic Acid

- Experiment No:1: Determination of Reid Vapour Pressure AimExperiment No:1: Determination of Reid Vapour Pressure Aim

- Standard Test Method For Carbon Residue: University of Zakho School of Engineering Petroleum Eng. DepStandard Test Method For Carbon Residue: University of Zakho School of Engineering Petroleum Eng. Dep

- Toluene Toluene Toluene Hydrogen Chromium PlatinumToluene Toluene Toluene Hydrogen Chromium Platinum

- Design Project "Glycerol": Srinivas Reddy Cherukula (09bch020) Sanath Kumar Vellanki (09bch066)Design Project "Glycerol": Srinivas Reddy Cherukula (09bch020) Sanath Kumar Vellanki (09bch066)

- High Density Polyethylene and Low Density PolyethyleneHigh Density Polyethylene and Low Density Polyethylene

- Aniline Point Test Apparatus: Instruction Manual FORAniline Point Test Apparatus: Instruction Manual FOR

- University of Kirkuk College of Pharmacy: Partition CoefficientUniversity of Kirkuk College of Pharmacy: Partition Coefficient

- Furfural A Selective Solvent Petroleum Refining: Kemp, JR.Furfural A Selective Solvent Petroleum Refining: Kemp, JR.

- Presentation Lecture Slides Petroleum Refinery EngineeringPresentation Lecture Slides Petroleum Refinery Engineering

- Determination of Aniline Point of Petroleum SamplesDetermination of Aniline Point of Petroleum Samples

- Industrial Hygiene: Instructor - Dr. Tamaghna Chakraborti Ph. No. - (0) 9892770980Industrial Hygiene: Instructor - Dr. Tamaghna Chakraborti Ph. No. - (0) 9892770980

- Azeotropic Mixtures and Their Separation - PPT Outline Seminar 2Azeotropic Mixtures and Their Separation - PPT Outline Seminar 2

- Boley - 1980 - Determination of Foods Synthetic Colours Using HPLCBoley - 1980 - Determination of Foods Synthetic Colours Using HPLC

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. Sohn

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, CalicutEvaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut