Lab Manual

Uploaded by

Sultana AlmansooriLab Manual

Uploaded by

Sultana AlmansooriFaculty of Engineering Technology and Science

Chemical Engineering Technology

CHE 4433- Petroleum and Petrochemical Processing

LABORATORY MANUAL

-:SCTL:-

Dr. Zin-Eddine Dadach

-:LI:-

Yasir Mahmood

CHE 4433- Petroleum and Petrochemical Processing Page 1 of 29

Table of Contents

Laboratory Safety ....................................................................................................................................................3

Academic Honesty Statement .................................................................................................................................5

Grading Rubric .........................................................................................................................................................6

Lab 1: Measure the Density and API gravity of petroleum products using a density meter. .................................8

Lab 2: Atmospheric distillation of crude oil and measuring API gravity of distillation fractions. .........................10

Lab 3: Determine Cloud Point of Petroleum Products. .........................................................................................13

Lab 4: Determine Pour Point of Petroleum Products. ...........................................................................................15

Lab 5: Determination of octane number of gasoline. ...........................................................................................17

Lab 6: Determine Flash Point of Petroleum Products. ..........................................................................................19

Lab 7: Determine the Freezing Point of the petroleum Products. ........................................................................21

Lab 8: Determination of Kinematic Viscosity of lube oils. .....................................................................................23

Lab 9: Determination of dropping point of lubricating greases. ...........................................................................26

Lab 10: Analyze the evaporation loss tendencies of lubricating oils.....................................................................28

CHE 4433- Petroleum and Petrochemical Processing Page 2 of 29

Laboratory Safety

Introduction

Laboratory Conduct Code should be followed, to minimize the risk of hazards to human health.

People who work in laboratories are required to be suitably trained, informed, instructed, and

supervised, and to ensure that equipment used is fit for purpose, maintained, inspected, and used in

accordance with recommended requirements.

Rules and Regulations:

Besides the General Rules of Labs and the Computer Utilization Policy, other specific rules apply

to this lab:

− Proper PPE is required in physical labs which includes lab coat, gloves, close shoes and

goggles if needed.

− Unauthorized personnel are not allowed in the laboratory without special permission.

− Smoking, eating, and drinking are not allowed.

− Horseplay or other acts of carelessness are prohibited.

− Students are not allowed to work alone in the laboratory.

− Understand the operation of apparatus before using them. Prior permission from the Lab

Supervisor must be obtained if any change is to be made.

− If in doubt about the operation of apparatus, electrical safety, etc, consult the laboratory

instructor.

− Handle all apparatus with care. Turn OFF the apparatus when not in use.

− All equipment, apparatus, and stools must be RETURNED to their original place after use.

− Do not take any things out of the laboratory without special permission.

− The experiment must be completed within the given time.

− Clean up laboratory work areas before leaving the workplace.

− Report immediately to the laboratory engineer or instructor any injury incurred.

− Report to the laboratory engineers any damage to equipment, hazards, and potential hazards.

Know the location of all safety equipment (e.g. eyewash, fire extinguisher, fire blanket, safety

showers, and spill kit) and how to use them.

− Consumption of food or beverages in the laboratory is forbidden. Food may not be stored in

refrigerators located in a laboratory.

− Wash hands before leaving the lab and before eating.

CHE 4433- Petroleum and Petrochemical Processing Page 3 of 29

− Read labels carefully.

− Keep the work area clear of all materials except those needed for your work. Coats should be

hung in the hall or placed in a locker. Extra books, purses, etc. should be kept away from

equipment that requires air flow or ventilation to prevent overheating.

− Disposal - Students are responsible for the proper disposal of used material if any in the

appropriate containers.

Safety Precautions in general:

− Do not touch any exposed wires.

− Do not unplug the cable while the power is switched on.

− Make sure that long hairs are tied.

− Always keep the door close.

CHE 4433- Petroleum and Petrochemical Processing Page 4 of 29

Academic Honesty Statement

In accordance with HCT policy LP201- Academic Honesty

• Students are required to refrain from all forms of academic dishonesty as defined and explained in HCT

procedures and directions from HCT personnel.

• A student found guilty of having committed acts of academic dishonesty may be subject to one or more of

the disciplinary measures as outlined in Article 33 of the Student and Academic Regulations.

إﻓﺎدة اﻷﻣﺎﻧﺔ اﻷﻛﺎدﯾﻤﯿﺔ

اﻷﻣﺎﻧﺔ اﻷﻛﺎدﯾﻤﯿﺔ- LP201 وﻓﻘًﺎ ﻟﺴﯿﺎﺳﺔ ﻛﻠﯿﺎت اﻟﺘﻘﻨﯿﺔ اﻟﻌﻠﯿﺎ

ﻛﻤﺎ ھﻮ ﻣﺒﯿّﻦ وﻣﻮﺿﺢ ﻓﻲ اﻟﺴﯿﺎﺳﺎت واﻹﺟﺮاءات اﻟﺨﺎﺻﺔ ﺑﻜﻠﯿﺎت اﻟﺘﻘﻨﯿﺔ،• ﯾُﻄﻠﺐ ﻣﻦ اﻟﻄﻠﺒﺔ اﻻﻣﺘﻨﺎع ﻋﻦ ﻛﺎﻓﺔ أﺷﻜﺎل ﺳﻮء اﻷﻣﺎﻧﺔ اﻷﻛﺎدﯾﻤﯿﺔ

. واﻟﺘﻮﺟﯿﮭﺎت اﻟﺼﺎدرة ﻣﻦ ﻣﻮظﻔﻲ اﻟﻜﻠﯿﺎت،اﻟﻌﻠﯿﺎ

• ﻓﻲ ﺣﺎﻟﺔ ارﺗﻜﺎب اﻟﻄﺎﻟﺐ أي ﺷﻜﻞ ﻣﻦ أﺷﻜﺎل ﺳﻮء اﻷﻣﺎﻧﺔ اﻷﻛﺎدﯾﻤﯿﺔ ﺳﻮف ﯾﺘﻌﺮض اﻟﻰ واﺣﺪ أو أﻛﺜﺮ ﻣﻦ اﻟﺘﺪاﺑﯿﺮ اﻟﺘﺄدﯾﺒﯿﺔ ﻋﻠﻰ اﻟﻨﺤﻮ اﻟﻤﺒﯿﻦ

. ﻣﻦ اﻷﻧﻈﻤﺔ اﻷﻛﺎدﯾﻤﯿﺔ33 ﻓﻲ اﻟﻤﺎدة

Declaration: Group/Individual

1. No part of this assignment has been copied from another source, (not from another group or

student, an internet source or a book).

2. No late submission will be accepted.

3. When another person’s words are used, this is shown in the text with “…” and referenced.

4. No part of this assignment has been written by anyone other than the member(s) of the group

named below.

5. We/I have a copy of this assignment that we/I can produce if the first copy is lost or damaged.

N.B. The marker may choose not to mark this assignment if the above declaration is not signed.

If the declaration is found to be false, appropriate action will be taken.

Plagiarism is copying and handing in someone’s work as your own. Any student found guilty of this type

of cheating will be dismissed from the college.

Student Name: ____________________ Signature: _____________

CHE 4433- Petroleum and Petrochemical Processing Page 5 of 29

Grading Rubric

Part I: Individual assessment (40%)

Each student will be evaluated individually during the lab time according to the following aspects

PI- Marks Obtained

S. Aspect for PLO Maximum

No. Evaluation Marks Student 1 Student 2 Student 3 Student 4

Health & Safety

1. Housekeeping and 5%

organization

Participation/ Work

2. independently/ Oral 10%

questions

Set up the

experiment/ using

3. 10%

equipment and

measuring tools

Troubleshooting and

4. 10%

problem solving.

Time management/

5. 5%

Late/ finish on time

Total

CHE 4433- Petroleum and Petrochemical Processing Page 6 of 29

Part II: Group assessment (60%)

Each group will be evaluated as a team based on their submitted report according to the following

aspects

Introduction/ Objective/

1. 5%

Procedure

Calculations /Codes/

2. 5%

Theory.

Data collection/ Findings /

3. 5%

observations

Diagrams / Charts / Figures

4. 10%

and Plots with Captions

Analysis & Discussion /

5. 15%

(theory vs actual)

Conclusions/ Summary

6. 15%

/self-reflection

Quality of work performed

7. including quality of lab 5%

report, neatness etc.

Total

CHE 4433- Petroleum and Petrochemical Processing Page 7 of 29

Lab 1: Measure the Density and API gravity of petroleum products using a density

meter.

1. Objective:

Determination of Density and API Gravity of Crude Petroleum Products by Density Meter

2. Apparatus and Materials

1. Density meter (RUDOLPH DDM 2909)

2. Test Tubes

3. Cleaning Solvents

4. Thermometer

5. Petroleum Products Samples

3. Introduction

Density or API gravity is a factor governing the quality and pricing of crude petroleum. However, this

property of petroleum is an uncertain indication of its quality unless correlated with other properties.

Density is an important quality indicator for automotive, aviation and marine fuels, where it affects

storage, handling and combustion.

API gravity express the gravity or density of crude oil and liquid petroleum products. The American

Petroleum Institute and the NIST - National Institute of Standards and Technology, devise API jointly.

The measuring scale is calibrated in terms of degrees API.

API Gravity can be calculated as:

°API = (141.5 / SG) - 131.5 (1)

°API = Degrees API Gravity

SG = Specific Gravity (at 60oF)

Specific gravity can be calculated from API gravity:

SG = 141.5 / (°API+131.5) (2)

Note! Oil with the least specific gravity has the highest API gravity

4. Procedure

1. Turn ON the Density Meter and wait until it is stabilized.

2. Clean the sample line with a cleaning solvent such as Toluene or Acetone.

3. Inject the sample into the Density Meter manually by the use of a syringe.

4. Select the desired temperature to measure the density of the sample fuel.

CHE 4433- Petroleum and Petrochemical Processing Page 8 of 29

5. Click on START button and wait until the Density Meter displays a reading.

6. Note down the Density and calculate the API Gravity by using formula.

7. Repeat the test for all the test samples.

Experimental Results

Density Meter Reading

No.

Sample Density Specific Gravity API Gravity

@ 15 0C (S.G)

(g/cm3)

1

Diesel

2

Gasoline

3

Heavy Gas Oil

4

Light Gas Oil

5

Aviation Fuel

CHE 4433- Petroleum and Petrochemical Processing Page 9 of 29

Lab 2: Atmospheric distillation of crude oil and measuring API gravity of distillation

fractions.

1. Objective:

To understand the atmospheric distillation of petroleum using a laboratory batch distillation unit to

determine quantitatively the boiling range characteristics of the petroleum products.

2. Apparatus & Resources:

1. Atmospheric Distillation Unit with accessories

2. Measuring cylinders

3. Samples

4. Density meter

3. Introduction

The basic test method of determining the boiling range of a petroleum product by performing a simple

batch distillation has been in use as long as the petroleum industry has existed. The distillation

(volatility) characteristics of hydrocarbons have an important effect on their safety and performance,

especially in the case of fuels and solvents. The boiling range gives information on the composition,

the properties, and the behavior of the fuel during storage and use. Volatility is the major determinant

of the tendency of a hydrocarbon mixture to produce potentially explosive vapors.

The distillation characteristics are critically important for both automotive and aviation gasolines,

affecting starting, warm-up, and tendency to vapor lock at high operating temperature or at high altitude,

or both. The presence of high boiling point components in these and other fuels can significantly affect

the degree of formation of solid combustion deposits. Also, volatility, as it affects rate of evaporation, is

an important factor in the application of many solvents, particularly those used in paints.

Figure 1. Atmospheric Distillation Unit

CHE 4433- Petroleum and Petrochemical Processing Page 10 of 29

4. Procedure

1. Measure and pour 100 mL of the crude oil sample into a distillation flask and allow the sample

to drain into the flask for about 30 seconds.

2. Put three 3-4 boiling chips into the distillation flask.

3. Place the flask in the distillation apparatus, fix the temperature measuring probe and cork into

the top of the distillation flask.

4. Get eight (8) clean 10 mL measuring cylinders and label them 1 to 8.

5. Record the temperature when the first drop of distillate comes out (initial boiling point) in the

data table.

6. Keep on adjusting the heater setting so that the distillate comes out at a rate of 4 or 5 mL/min

(about two drops per second).

7. Record the temperature reading of the distillation thermometer after collecting 5, 10, 20, 30,

40, 50, 60 and 70 mL of distillate, in the data table.

8. Stop heating the crude oil when the temperature reaches 2750C. Turn OFF the heater.

Continue collecting the remaining distillate in the last measuring cylinder used.

9. Measure the density of each collected sample.

5. Experimental Results

Sample Description: …………….. Sample charge:…………………

Condensate

Cut Number Cut Temperature (0C) Density Colour Smell

Volume (ml)

1 0-5

____˚C to ______˚C

2 5 - 10

_____˚C to ______˚C

3 10 - 20

_____˚C to ______˚C

CHE 4433- Petroleum and Petrochemical Processing Page 11 of 29

4 20 – 30

_____˚C to ______˚C

5 30 – 40

_____˚C to ______˚C

6 40 – 50

_____˚C to ______˚C

7 50 - 60

_____˚C to ______˚C

8 60 - 70

_____˚C to ______˚C

7. Results

Initial boiling point (IBP)………………….

End point (EP)……………………..

Dry point……………..

Percent recovery……………..

Front end loss…………….

Percent residue……………

CHE 4433- Petroleum and Petrochemical Processing Page 12 of 29

Lab 3: Determine Cloud Point of Petroleum Products.

1. Objective

To determine the Cloud point of the given petroleum product sample.

2. Apparatus and Resources

• Cloud Point Apparatus with accessories

• Temperature Measuring Device

• Constant temperature bath

3. Introduction

In petroleum products and biodiesel fuels, the temperature of a liquid specimen when the smallest

observable cluster of wax crystals first occurs upon cooling under prescribed conditions, this is called

cloud point.

The cloud point and the pour point are related to the flow conditions of crude and its products at low

temperature.The cloud point gives the rough idea of the temperature above which the oil can be handled

safely, without any fear of congealing or filter clogging.The pour point is determined to estimate the

temperature at which a sample of oil becomes sufficiently solid to prevent its movement by pumping.

The pour point temperature depends to a large extent on the thermal history of the sample. Also the pour

point indicates the waxy nature of the sample.

FIGURE. 1 Apparatus for Cloud Point Test

CHE 4433- Petroleum and Petrochemical Processing Page 13 of 29

4. Procedure:

1.Pour the specimen into the test jar to the level mark.

2.Adjust the position of the cork and temperature measuring device so the cork fits tightly..

3.For liquid-in-glass, the thermometer bulb should be immersed so the beginning of the capillary is

3 mm below the surface of the specimen.

4.. Place the disk in the bottom of the jacket.

5.After the specimen has cooled to allow the formation of paraffin wax crystals, take great care not

to disturb the mass of specimen nor permit the thermometer to shift in the specimen.

6.Cloud points are expressed in integers that are positive or negative multiples of 3 °C. Begin to

examine the appearance of the specimen when the temperature of the specimen is 9 °C above the

expected Cloud point (estimated as a multiple of 3 °C).

7.The test tube is cooled continuously. The test tube is withdrawn often for 5 0C fall of temperature

to observe the flow or Cloud point of the sample.

8.The temperature at which the oil does not flow in the tube even when kept horizontal for 5sec is

recorded as Cloud point.

5. Data Collection & Results

Sample Description Observed Cloud Point (°C) Comments

CHE 4433- Petroleum and Petrochemical Processing Page 14 of 29

Lab 4: Determine Pour Point of Petroleum Products.

1. Objective

To determine the pour point of the given petroleum product sample.

2. Apparatus and Resources

• Pour Point Apparatus with accessories

• Temperature Measuring Device

• Constant temperature bath

3. Introduction

The pour point is related to the flow conditions of crude and its products at low temperature. In

petroleum products, this the lowest temperature at which movement of the test specimen is observed

under prescribed conditions of test. The cloud point gives the rough idea of the temperature above

which the oil can be handled safely, without any fear of congealing or filter clogging. The pour point is

determined to estimate the temperature at which a sample of oil becomes sufficiently solid to prevent

its movement by pumping. The pour point of a petroleum specimen is an index of the lowest temperature

of its utility for certain applications.

FIGURE. 1 Apparatus for Pour Point Test

CHE 4433- Petroleum and Petrochemical Processing Page 15 of 29

4. Procedure:

1. Pour the specimen into the test jar to the level mark.

2. Adjust the position of the cork and temperature measuring device so the cork fits tightly..

3. For liquid-in-glass, the thermometer bulb should be immersed so the beginning of the capillary

is 3 mm below the surface of the specimen.

4. . Place the disk in the bottom of the jacket.

5. After the specimen has cooled to allow the formation of paraffin wax crystals, take great care

not to disturb the mass of specimen nor permit the thermometer to shift in the specimen.

6. Pour points are expressed in integers that are positive or negative multiples of 3 °C. Begin to

examine the appearance of the specimen when the temperature of the specimen is 9 °C above

the expected pour point (estimated as a multiple of 3 °C).

7. The test tube is cooled continuously. The test tube is withdrawn often for 5 0C fall of

temperature to observe the flow or pour point of the sample.

8. The temperature at which the oil does not flow in the tube even when kept horizontal for 5sec

is recorded as pour point.

5. Data Collection & Results

Sample Description Observed Pour Point (°C) Comments

CHE 4433- Petroleum and Petrochemical Processing Page 16 of 29

Lab 5: Determination of octane number of gasoline.

1. Objective:

To determine octane number of gasoline.

2. Introduction

Octane number is one of the main parameters used in quality control of gasoline and provides

information about the resistance to auto ignition. This phenomenon occurs when the temperature of the

fuel–air mixture under the effect of compression, leading to sufficiently increased self-detonation of

the mixture without the help of a spark . Fuel self-detonation generates pressure pulses in the engine

cylinder and causes an increase in fuel consumption, loss of engine power and, at worst, may even

damage the engine. Octane number is mainly affected by the presence of aromatic hydrocarbons,

isoparaffins, olefins and additives such as ethanol and esters. The chemical structure of hydrocarbons

in gasoline has great influence on detonation. Paraffins that have many ramifications, olefins and

aromatics (benzene, toluene, xylenes) are very resistant to self-detonation, and conversely the long

chains paraffins with less ramifications and olefins, with more than four carbon atoms, are more

susceptible to the phenomena of self detonation.

Apparatus & Resources

1. Octane Number Analyzer

2. Fuel samples

3. Cleaning solvents

4. Sample holder

Octane Number Analyzermeasures octane number via near-infrared (NIR) transmission spectroscopy

utilizing 14 near-infrared emitting diodes with narrow bandpass filters, a silicon detector system, and a

fully integrated microprocessor. Simple octane number determination requires three easy steps:

sampling a background signal, acquiring two absorption spectra of the gas sample, and then acquiring a

second background signal. Analyzer is pre-calibrated for unleaded gasoline and ethanol-blended fuels,

and can be calibrated for up to eight additional fuel types.

CHE 4433- Petroleum and Petrochemical Processing Page 17 of 29

3. Procedure

1. Compression ratio and fuel-air ratio are adjusted to produce standard K.I. for the sample fuel,

as measured by a specific electronic detonation measurement system

2. The fuel-air ratio for the sample fuel and each of the primary reference fuel blends is adjusted

to maximize K.I. for each fuel.

3. The engine is calibrated to operate at standard K.I. in accordance with the guide table.

4. The fuel-air ratio of the sample fuel is adjusted to maximize the K.I.

5. Bracketing procedure ratings may be determined using either the equilibrium or dynamic fuel-

air ratio approach.

6. A calibration is performed to establish standard K.I. using the cylinder height specified by the

guide table for the O.N. of the selected PRF

4. Result and Observations

No. Sample Flash Point Comments

(0C)

1 Diesel

2 Kerosene

3 Jet Fuel

CHE 4433- Petroleum and Petrochemical Processing Page 18 of 29

Lab 6: Determine Flash Point of Petroleum Products.

1. Objective:

To determine the Flash point of the petroleum products by Pensky Martens Closed Cup Flash Point

Tester.

2. Introduction

The flash point of a volatile material is the lowest temperature at which vapors of the material will ignite,

when given an ignition source. The flash point may sometimes be confused with the auto-ignition

temperature, which is the temperature at which the vapor ignites spontaneously without an ignition

source. The fire point is the lowest temperature at which vapors of the material will keep burning after

being ignited and the ignition source removed. The fire point is higher than the flash point, because at

the flash point more vapor may not be produced rapidly enough to sustain combustion.

The flash point is a descriptive characteristic that is used to distinguish between flammable fuels, such

as petrol (gasoline in the US), and combustible fuels, such as diesel. It is also used to characterize the

fire hazards of fuels. Fuels which have a flash point less than 37.8 °C (100.0 °F) are called flammable,

whereas fuels having a flash point above that temperature are called combustible.

3. Resources

1. Pensky-Martins closed cup tester

2. Gas supply source with igniter

3. Fuel Samples

4. Cleaning Solvents

Figure 1. Pensky Martens Closed Cup Flash Point Tester.

CHE 4433- Petroleum and Petrochemical Processing Page 19 of 29

4. Procedure

1. Fill the cup with the sample to be tested, up to the fill mark, on the inside of the cup.

2. Put the cup into the tester, put the lid on the cup, make sure it is on properly, and make sure the

locking device is properly engaged.

3. Insert the thermometer and connect the stirrer driver shaft.

4. Turn the heater ON and bring the sample to a temperature of 110C lower than the estimated flash

point.

5. Light the pilot flame to give approximately 4mm diameter flame.

6. Adjust the heater controller so that it heats the sample at about 5 to 6 0C per minute.

7. Turn the stirrer motor ON.

8. If you know the sample will have a flash point of 1100C or less, start the flash test when the

sample temperature is 17 to 28 0C below the expected flash point.

9. Keep on testing the sample for every 10C in temperature until it flashes.

10. If you know that the flash point is above 1100C, begin testing the flash point 17 to 280C below

the expected flash point and keep on testing the flashpoint at every 20C.

11. Record as the observed flash point, the temperature shown on the thermometer at the time the

test flame application caused the flash on the Data Sheet.

5. Result and Observations

No. Sample Flash Point Flammable or Combustible

(0C)

1 Diesel

2 Kerosene

3 Jet Fuel

6. Answer the following question and include in section 11 (Conclusion Reference) of Lab report.

Identify at least two sources of error when carrying out the above experiment, and explain how one

would eliminate or minimize the above sources of error.

CHE 4433- Petroleum and Petrochemical Processing Page 20 of 29

Lab 7: Determine the Freezing Point of the petroleum Products.

1. ObjectiveThe aim of an experiment or test explains why it was done.

To determine the Freezing Point of Petroleum Fuels.

2. Introduction

The freezing point of an aviation fuel is the lowest temperature at which the fuel remains free of solid

hydrocarbon crystals that can restrict the flow of fuel through filters if present in the fuel system of the

aircraft. The temperature of the fuel in the aircraft tank normally falls during flight depending on aircraft

speed, altitude, and flight duration. The freezing point of the fuel must always be lower than the

minimum operational tank temperature. Crystallization point is the temperature at which crystals of

hydrocarbons first appear when the test sample is cooled.

Figure 1. Freezing Point Apparatus.

4. Resources

5. Freezing Point Apparatus

6. Fuel Thermometer

7. Carbon Dioxide (Solid) or Dry Ice

8. Cleaning Solvents

9. Samples

CHE 4433- Petroleum and Petrochemical Processing Page 21 of 29

5. Procedure

1. Measure out 25 mL of the fuel and transfer it to the clean, dry, jacketed sample tube. Close the

tube tightly with the cork holding the stirrer, thermometer, and moisture proof collar and adjust the

thermometer position so that its bulb does not touch the walls of the tube flask and is approximately

in the center. The bulb of the thermometer should be 10 to 15 mm from the bottom of the sample

tube.

2. Clamp the jacketed sample tube so that it extends as far as possible into the vacuum flask. The

surface of the sample should be approximately 15 to 20 mm below the level of the coolant. Unless

the medium is cooled by mechanical refrigeration, add solid carbon dioxide as necessary

throughout the test to maintain the coolant level in the vacuum flask.

3. Stir the fuel continuously, moving the stirrer up and down at the rate of 1 to 1.5 cycles/s, except

when making observations, taking care that the stirrer loops approach the bottom of the flask on

the down stroke and remain below the fuel surface on the upstroke.

4. Disregard any cloud that appears at approximately − 10°C and does not increase in intensity as the

temperature is lowered, because this is due to water.

5. Remove the jacketed sample tube from the coolant and allow the sample to warm, stirring it

continuously at 1 to 1.5 cycles/s.

6. Record the temperature at which the hydrocarbon crystals completely disappear.

6. Result and Observations

No. Sample Observed Observed Literature

Crystallization Point Freezing Point Freezing Point

(0C) (0C) (0C)

1 Diesel 48 -42

2 Jet Fuel-Jet A1 59 -53

3 Kerosene-Jet B 70 -65

6. Post Lab Question.

Answer the following questions, add them in section 11 (Conclusion/Reference) of the lab report.

1. Explain the term Freezing Point and state why it is important.

2. Identify at least two sources of error when carrying out the above experiment, and explain how

one would eliminate or minimize the above sources of error.

CHE 4433- Petroleum and Petrochemical Processing Page 22 of 29

Lab 8: Determination of Kinematic Viscosity of lube oils.

1.Objective

To determine the Kinematic and Dynamic viscosity of Transparent and Opaque Liquids by ASTM

D445 Method.

2.Introduction

Viscosity is a measure of a fluid’s resistance to flow. It is one of the most important properties of a

fluid and plays a very prominent role in the petroleum industry. The viscosity of a crude oil affects

our ability to pump it out of the ground; the viscosity and volatility of a fuel affect how easy it is to

atomize in the fuel injector; the viscosity of a lubricant affects its ability to protect an engine. It is an

important measurement characteristic in the food, paint, polymer coating and other industries where

flow is a critical product or use characteristic.

Small changes in viscosity can have a dramatic impact on the properties of petroleum fluids.

Kinematic means that the measurement is made while fluid is flowing under the force of gravity. It

is determined by measuring the time it takes for a volume of fluid to flow under gravity through a

calibrated glass capillary viscometer.

3.Apparatus:

1. Constant temperature Kinematic Viscosity bath

2. Stop watch

3. Calibrated viscometers

4. Oil samples

Fig. 1. Constant temperature Kinematic Viscosity bath with viscometer.

CHE 4433- Petroleum and Petrochemical Processing Page 23 of 29

4. Procedure:

1.1. Turn the oil bath main switch ON.

Turn the oil bath light ON.

Turn the pump/stirrer ON.

Turn the heater ON.

1.2. Use the hand pump to suck the oil up into the viscometer.

1.3. The Technician has placed two viscometers with oil samples into the oil bath for you. Write

the type of oil samples in your data sheet.

1.4. The viscometers are held in position using holders.

1.5. When the oil bath and samples are at the correct temperature, start taking the viscosity

measurements. Use your left hand to grip the holder. Squeeze the air out of the hand pump

then put it over the right hand side of the viscometer and suck

the oil into the viscometer until it fills part of the bulb above the

top line. (see the diagram)

1.6. Use a stopwatch to time how long it takes for the oil to flow

from the top line to the bottom line.

1.7. Repeat the test 3 times for each oil sample. Write the results in

the Data Sheet each time. Calculate the average time and enter

this into the table.

1.8. When you finish inform the technician, before you turn the oil

bath off.

5.Readings and calculations:

1.9. Calculate the kinematic viscosity, ν (centiStokes, cSt), from the

measured flow time, t (sec) and the instrument constant, C

(taken from the certificate for your viscometer at 40 0C in cSt/s), by using the equation: 𝜈𝜈 = 𝐶𝐶𝐶𝐶

1.10. Calculate the dynamic viscosity, μ (cP or mPa/s), from the calculated kinematic viscosity, ν

(cSt), and the density, ρ (g/mL), by using the equation: 𝜇𝜇 = 𝜌𝜌𝜌𝜌

Density of ADNOC Light Lube Oil #32 = 0.8342 g/mL

Density of ADNOC Special Gasoline Engine Oil = 0.857 g/mL

Density of ADNOC Heavy Lube Oil = 0.87719 g/mL

1.11. You will need to be told the density of each oil or use a hydrometer to find it if it is not on the

list above.

CHE 4433- Petroleum and Petrochemical Processing Page 24 of 29

6.Experimental Data:

Report your results for kinematic and dynamic viscosity to 3 decimal places on the data sheet.

Average

Flow Flow Flow

Test flow

Oil Sample & Viscosity time in time in time in Kinematic Dynamic

Temperat time

Density constant seconds seconds seconds Viscosity Viscosity

ure (Second

#1 #2 #3

s)

ADNOC 40˚C

BRONZE

Density:_______ 100˚C

_ g /cc

ADNOC

VOYEGER 40˚C

Density:_______ 100˚C

_ g /cc

ADNOC

40˚C

SPECIAL

Density:_______ 100˚C

_ g /cc

ADNOC

HEAVY LUBE 40˚C

OIL

Density:_______ 100˚C

_ g /cc

ADNOC LIGHT

LUBE 40˚C

Density:_______

_ g /cc 100˚C

CHE 4433- Petroleum and Petrochemical Processing Page 25 of 29

Lab 9: Determination of dropping point of lubricating greases.

1. Objective:

Determination of the dropping point of lubricating oils.

2. ResourcesWrite down all the tools and instruments used to conduct the experiment. Add your

apparatus below:

The apparatus consist of the following:

1. Dropping Point Apparatus

2. Grease oil

3. Thermometer

4. Test tube

3. Introduction

The dropping point is the temperature at which the grease passes from a semisolid to a liquid state under

the conditions of test. This change in state is typical of greases containing as thickeners soaps of

conventional types. Greases containing as thickeners materials other than conventional soaps can,

without change in state, separate oil. This test method is useful to assist in identifying the grease as to

type and for establishing and maintaining bench marks for quality control.

Dropping point determinations are used for identification and quality control purposes, and can be an

indication of the highest temperature of utility for some applications. The sample is heated at a prescribed

rate in a precision machined cup whose sides slope toward an opening at its center. The temperature at

which a liquid drop first falls from the cup is the dropping point of the sample.

Dropping Point Apparatus performs dropping point determinations on lubricating greases at

temperatures of up to 550°F (288°C). Consists of dropping point cup, test cell with accessories and oil

bath with stirrer and heater. Test cell is immersed in a 400mL Borosilicate Glass bath for heating at the

prescribed rate. A 750W variable stepless control heater and 1⁄40hp stirrer permit accurate, uniform

control of bath temperature rate of rise. Heater assembly includes refractory top plate and reference dial.

Fig. 1. Dropping Point Apparatus.

CHE 4433- Petroleum and Petrochemical Processing Page 26 of 29

4. Procedure

7. Thoroughly clean the cup and test tube with mineral spirits

8. Use only cups that are clean and free from any residue from previous runs. When the interior

plating of the cup shows indications of wear, discard.

9. Test tube shall be clean and free of residues. Inspect the tube for evidence of chipping or

cracking, particularly the points of indentation. Replace when necessary.

10. Inspect both cork ring guide and upper cork for charring or distortions in shape. Total clearance

between the cork ring guide and the inside wall of the test tube is 1.5 mm. When either cork is

abnormal, replace.

11. Inspect the bulb end of the thermometer to be used in the test tube. Clean if there is any residue

build-up.

12. Note down the temperature at which the grease passes from a semisolid to a liquid state under

the conditions of test.

5. Data Collection & Results

No. Sample Softening Point Dropping Point

(0C) (0C)

1 Diesel

2 Kerosene

3 Jet Fuel

CHE 4433- Petroleum and Petrochemical Processing Page 27 of 29

Lab 10: Analyze the evaporation loss tendencies of lubricating oils.

Objective

To determine the Evaporation Loss of Lubricating Oils by the Noack Method.

2. Introduction

The evaporation loss is of particular importance in engine lubrication. Where high temperatures occur,

portions of an oil can evaporate. Evaporation may contribute to oil consumption in an engine and can

lead to a change in the properties of an oil. Many engine manufacturers specify a maximum allowable

evaporation loss. Engine manufacturers, when specifying a maximum allowable evaporation loss, quote

this test method along with the specifications.

3. Resources

1. Noack Evaporative Apparatus

2. Cleaning solvents

3. Drying paper

4. Gloves

Evaporation Loss of Lubricating Oils by the Noack Method

6.Procedure

1. Prepare the automated apparatus for operation in accordance with the manufacturer's

instructions for calibrating, checking, and operating the equipment.

2. Clean the glass bottles, the glass tubing, and the Y-piece to prevent a build-up of condensate

3. Condensate should not be allowed to build up in the 2 L glass bottles. These should be washed

out with solvent and dried before a maximum 2 cm of condensate collects

CHE 4433- Petroleum and Petrochemical Processing Page 28 of 29

4. Locate the instrument on a laboratory bench if possible (rather than a hood) to minimize

atmospheric pressure fluctuation. Vent the vacuum pump outlet provided on the back of the

instrument with a metal or plastic tube leading to a suitable exhaust outlet.

5. Insert the thermocouple connector into the thermocouple receptacle on the back of the cabinet.

Be sure that the inside of the reactor vessel is clean and that the other hardware and tubing are

free of any oil residue.

6. If collection of the volatilized oil is desired, clean the coalescing filter housing with a

hydrocarbon solvent, dry, and install new filter cartridge.

5. Data Collection & Results

No. Sample Softening Point Evaporation Losses

(0C)

1 Diesel

2 Kerosene

3 Jet Fuel

CHE 4433- Petroleum and Petrochemical Processing Page 29 of 29

You might also like

- Lubrizol® 5370C Grease Additive - Grease Additives - The Lubrizol CorporationNo ratings yetLubrizol® 5370C Grease Additive - Grease Additives - The Lubrizol Corporation4 pages

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut100% (1)Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut38 pages

- Indian Standard: Methods of Test For Petroleum and Its ProductsNo ratings yetIndian Standard: Methods of Test For Petroleum and Its Products8 pages

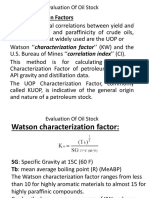

- Characterization Factors: Evaluation of Oil StockNo ratings yetCharacterization Factors: Evaluation of Oil Stock65 pages

- ASTM Distillation Curve Dr. Khalid FarhodNo ratings yetASTM Distillation Curve Dr. Khalid Farhod13 pages

- Presentation Lecture Slides Petroleum Refinery Engineering100% (1)Presentation Lecture Slides Petroleum Refinery Engineering49 pages

- Lecture 3: Petroleum Refining Overview: 3.1 Crude Oil100% (1)Lecture 3: Petroleum Refining Overview: 3.1 Crude Oil2 pages

- Experiment No:1: Determination of Reid Vapour Pressure AimNo ratings yetExperiment No:1: Determination of Reid Vapour Pressure Aim26 pages

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324No ratings yetProduction of Synthesis Gas: Caalysis Today, 18 (1993) 305-32420 pages

- CHE 331: Petroleum Refinery Engineering: Refining: Technology and EconomicsNo ratings yetCHE 331: Petroleum Refinery Engineering: Refining: Technology and Economics101 pages

- Determination of Aniline Point of Petroleum SamplesNo ratings yetDetermination of Aniline Point of Petroleum Samples4 pages

- Process Dynamics & Control: Muhammad Rashed JavedNo ratings yetProcess Dynamics & Control: Muhammad Rashed Javed33 pages

- Experiment Number (7) Determination of Octane Number by Shatox Sx-100M InstrumentalNo ratings yetExperiment Number (7) Determination of Octane Number by Shatox Sx-100M Instrumental8 pages

- Crude Oil Refining (Crude Oil DistillationNo ratings yetCrude Oil Refining (Crude Oil Distillation12 pages

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnNo ratings yetKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. Sohn6 pages

- ASTM D611 Standard Test Methods For Aniline Point and Mixed Aniline Point of Petroleum ProductsNo ratings yetASTM D611 Standard Test Methods For Aniline Point and Mixed Aniline Point of Petroleum Products8 pages

- Elemental Analysis: Sajad Mohammad AkloNo ratings yetElemental Analysis: Sajad Mohammad Aklo23 pages

- Furfural A Selective Solvent Petroleum Refining: Kemp, JR.No ratings yetFurfural A Selective Solvent Petroleum Refining: Kemp, JR.8 pages

- 1 - CL619 RPD - Properties Calculation PDFNo ratings yet1 - CL619 RPD - Properties Calculation PDF166 pages

- Technical Support Section in The Preface To This ManualNo ratings yetTechnical Support Section in The Preface To This Manual19 pages

- State The Top Two Crude Oil Producers in The Years 2012 and 2019 ? What Was Their Production Each Year ?No ratings yetState The Top Two Crude Oil Producers in The Years 2012 and 2019 ? What Was Their Production Each Year ?6 pages

- Characterization of Feed and Product in Crude RefienryNo ratings yetCharacterization of Feed and Product in Crude Refienry22 pages

- CLO5 CHE4413 Chemical Process HAZOP and Risk Analysis-202220-2No ratings yetCLO5 CHE4413 Chemical Process HAZOP and Risk Analysis-202220-241 pages

- Gas Processing (CHE4403) : Different Types of GasesNo ratings yetGas Processing (CHE4403) : Different Types of Gases27 pages

- D6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesNo ratings yetD6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating Greases9 pages

- Dropping Point of Lubricating Grease: Standard Test Method ForNo ratings yetDropping Point of Lubricating Grease: Standard Test Method For5 pages

- Lubrizol® 5370C Grease Additive - Grease Additives - The Lubrizol CorporationLubrizol® 5370C Grease Additive - Grease Additives - The Lubrizol Corporation

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, CalicutEvaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicut

- Indian Standard: Methods of Test For Petroleum and Its ProductsIndian Standard: Methods of Test For Petroleum and Its Products

- Presentation Lecture Slides Petroleum Refinery EngineeringPresentation Lecture Slides Petroleum Refinery Engineering

- Lecture 3: Petroleum Refining Overview: 3.1 Crude OilLecture 3: Petroleum Refining Overview: 3.1 Crude Oil

- Experiment No:1: Determination of Reid Vapour Pressure AimExperiment No:1: Determination of Reid Vapour Pressure Aim

- Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324Production of Synthesis Gas: Caalysis Today, 18 (1993) 305-324

- CHE 331: Petroleum Refinery Engineering: Refining: Technology and EconomicsCHE 331: Petroleum Refinery Engineering: Refining: Technology and Economics

- Determination of Aniline Point of Petroleum SamplesDetermination of Aniline Point of Petroleum Samples

- Experiment Number (7) Determination of Octane Number by Shatox Sx-100M InstrumentalExperiment Number (7) Determination of Octane Number by Shatox Sx-100M Instrumental

- Kerosene Isosiv Process For Production of Normal Paraffins: Stephen W. SohnKerosene Isosiv Process For Production of Normal Paraffins: Stephen W. Sohn

- ASTM D611 Standard Test Methods For Aniline Point and Mixed Aniline Point of Petroleum ProductsASTM D611 Standard Test Methods For Aniline Point and Mixed Aniline Point of Petroleum Products

- Furfural A Selective Solvent Petroleum Refining: Kemp, JR.Furfural A Selective Solvent Petroleum Refining: Kemp, JR.

- Technical Support Section in The Preface To This ManualTechnical Support Section in The Preface To This Manual

- State The Top Two Crude Oil Producers in The Years 2012 and 2019 ? What Was Their Production Each Year ?State The Top Two Crude Oil Producers in The Years 2012 and 2019 ? What Was Their Production Each Year ?

- Characterization of Feed and Product in Crude RefienryCharacterization of Feed and Product in Crude Refienry

- CLO5 CHE4413 Chemical Process HAZOP and Risk Analysis-202220-2CLO5 CHE4413 Chemical Process HAZOP and Risk Analysis-202220-2

- Gas Processing (CHE4403) : Different Types of GasesGas Processing (CHE4403) : Different Types of Gases

- D6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesD6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating Greases

- Dropping Point of Lubricating Grease: Standard Test Method ForDropping Point of Lubricating Grease: Standard Test Method For