Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Uploaded by

JagdishCopyright:

Available Formats

Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Uploaded by

JagdishOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Saudi Aramco Test Report: Positive Material Identification (PMI) Report 30-Oct-17 Mech

Uploaded by

JagdishCopyright:

Available Formats

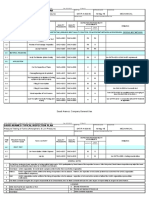

SAUDI ARAMCO ID/PIEU-30-Oct-2017- REV. 2017.06.00 (Standards Cutoff -June 30, 2017) Rev. 2017.06.

00 30-Jun-17

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Positive Material Identification (PMI) Report SATR-A-2012 30-Oct-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Material Type: (Weld, Valve, Pipe, Weld, etc.) Item Description: (Material Spec/Grade)

Type Of Instrument Used:

Model:

Serial No:

Date Of Calibration:

Required Element Composition per Spec ____

(Verify against ASME IIC Spec Tables) C Cr Ni Mo Nb Ti Cu Z

_____ _____ _ _____ _____ _____ ___ _____

Analysis Result: (Evaluate Results in conjunction with SAIC-L-2010 Checklist & Attachments)

Equipment/

Weld Elements Verified (per SAES-A-206, Table 1) Results of Chemical Analysis Color Code

or

Line Number/ Part

00-SAIP-07 Att III

Pending & PFI ES-22

No C Cr Ni Mo Nb Ti Cu Zn Accept Reject

Analysis

P.O. & line item

NOTES: C=Carbon, Cr=Chrome, Cu=Copper, Ni=Nickel, Mo=Molybdenum, Nb=Niobium, Ti=Titanium, Zn=Zinc

1. Alloys are acceptable if the alloying elements are each within 10% of the specified range of values. (SAES-A-206, Para. 10.1)

2. Welds with consumables that match, or nearly match, the base metal composition shall be within ±12.5% of the ranges allowed in ASME SEC IIC

for each element. (SAES-A-206, Para. 10.2). Chemical Composition of Material specs must be verified/available.

3. For weld overlays, the chemistry on the surface of overlays shall be in accordance with SAES-W-014. (SAES-A-206, Para. 10.3)

4. For dissimilar metal alloy welds (other than weld overlays), the effects of dilution from the different base metals and the filler metal shall be taken

into account for determining the nominal as-deposited weld metal composition. (SAES-A-206, Para. 10.4)

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-206, Positive Material Identification, (5 May 2016)

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

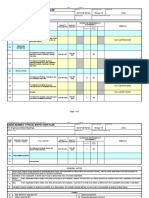

SAUDI ARAMCO ID/PIEU-30-Oct-2017- REV. 2017.06.00 (Standards Cutoff -June 30, 2017) Rev. 2017.06.00 30-Jun-17

SAUDI ARAMCO TEST REPORT SATR NUMBER DATE APPROVED QR NUMBER

Positive Material Identification (PMI) Report SATR-A-2012 30-Oct-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

Material Type: (Weld, Valve, Pipe, Weld, etc.) Item Description: (Material Spec/Grade)

Type Of Instrument Used:

Model:

Serial No:

Date Of Calibration:

Required Element Composition per Spec ____

(Verify against ASME IIC Spec Tables) C Cr Ni Mo Nb Ti Cu Z

_____ _____ _ _____ _____ _____ ___ _____

Analysis Result: (Evaluate Results in conjunction with SAIC-L-2010 Checklist & Attachments)

Equipment/

Weld Elements Verified (per SAES-A-206, Table 1) Results of Chemical Analysis Color Code

or

Line Number/ Part

00-SAIP-07 Att III

Pending & PFI ES-22

No C Cr Ni Mo Nb Ti Cu Zn Accept Reject

Analysis

P.O. & line item

NOTES: C=Carbon, Cr=Chrome, Cu=Copper, Ni=Nickel, Mo=Molybdenum, Nb=Niobium, Ti=Titanium, Zn=Zinc

1. Alloys are acceptable if the alloying elements are each within 10% of the specified range of values. (SAES-A-206, Para. 10.1)

2. Welds with consumables that match, or nearly match, the base metal composition shall be within ±12.5% of the ranges allowed in ASME SEC IIC

for each element. (SAES-A-206, Para. 10.2). Chemical Composition of Material specs must be verified/available.

3. For weld overlays, the chemistry on the surface of overlays shall be in accordance with SAES-W-014. (SAES-A-206, Para. 10.3)

4. For dissimilar metal alloy welds (other than weld overlays), the effects of dilution from the different base metals and the filler metal shall be taken

into account for determining the nominal as-deposited weld metal composition. (SAES-A-206, Para. 10.4)

REMARKS:

REFERENCE DOCUMENTS:

1. SAES-A-206, Positive Material Identification, (5 May 2016)

Quality Record Approved:

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium Weldingvishal bailur50% (2)

- CBT CoatingDocument23 pagesCBT CoatingJagdish100% (1)

- Saudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report: Internal Cleanliness Report (Piping Systems & Equip) SATR-A-2008 30-Oct-17 MechJagdishNo ratings yet

- SATR-W-2006 Rev 6Document1 pageSATR-W-2006 Rev 6Manoj KumarNo ratings yet

- Inspection Release Certificate For Part Shipment 3021&3022Document1 pageInspection Release Certificate For Part Shipment 3021&3022Mohammed NouzalNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.Salaheldin100% (1)

- Saic L 2003Document9 pagesSaic L 2003MAZHARULNo ratings yet

- SAIC-A-2003 Rev 0Document3 pagesSAIC-A-2003 Rev 0bluelions_19No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistjunaidNo ratings yet

- Satip W 014 01Document12 pagesSatip W 014 01spravin231No ratings yet

- SAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpDocument2 pagesSAIC-A-2008 Rev 6 Verify Test Medium For Hydrostatic Testing and Lay UpAhdal NoushadNo ratings yet

- SATIP-P-104-01 Rev 7 FinalDocument4 pagesSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- SAIC-A-2008 Rev 0Document3 pagesSAIC-A-2008 Rev 0Kristine Caye DatarioNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saic L 2007 PDFDocument7 pagesSaic L 2007 PDFHesham HelalNo ratings yet

- Saudi Aramco Test Report Pre-Test Punch List Form: Testing Mech-SATR-A-2007Document1 pageSaudi Aramco Test Report Pre-Test Punch List Form: Testing Mech-SATR-A-2007Anonymous S9qBDVky100% (2)

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

- 6.method Statement - Pneumatic Test - MS - 410 - 006Document9 pages6.method Statement - Pneumatic Test - MS - 410 - 006mohiuddin149No ratings yet

- Satr S 4001Document1 pageSatr S 4001Noor Mohamed AzeezNo ratings yet

- Satip G 006 0122Document10 pagesSatip G 006 0122Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection ChecklistManoj KumarNo ratings yet

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Document2 pagesSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanNo ratings yet

- Saudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechDocument27 pagesSaudi Aramco Inspection Checklist: Review Procedure - Pressure Testing (All Applications) SAIC-A-2001 15-Nov-17 MechNaushad AlamNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanJagdishNo ratings yet

- Satr-W-2010Document1 pageSatr-W-2010Joni Carino SuniNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection Plankarthi51289No ratings yet

- Saic J 6001Document7 pagesSaic J 6001sureshNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacDocument2 pagesSaudi Aramco Inspection Checklist: Receiving, Storage, Handling and Preservation of Filters SAIC-K-4028 HvacshahzadaNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanDomie Neil Bucag SalasNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- 1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1Document1 page1 SATIP-NDE-RT-01 Radiographic Testing-Rev 1KirubhakarPooranamNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Satip Sair Satr LogDocument35 pagesSatip Sair Satr LograhulrkurupNo ratings yet

- Satip A 004 03Document3 pagesSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDocument3 pagesSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNo ratings yet

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Nov-17 MechanicalRijwan MohammadNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- SATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)Document2 pagesSATR-A-2009 Rev 2 - System Lay-Up Report (Certificate)deepa narayan100% (1)

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- Satr A 2011Document3 pagesSatr A 2011JagdishNo ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Satip G 005 01Document11 pagesSatip G 005 01Rijwan MohammadNo ratings yet

- PID ResponsibilityDocument2 pagesPID Responsibilityimurugan06No ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.No ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeDocument7 pagesSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2016 Rev 0Document2 pagesSAIC-A-2016 Rev 0philipyapNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- SATIP-P-104-01 Rev 8 Final LV Cables PDFDocument2 pagesSATIP-P-104-01 Rev 8 Final LV Cables PDFSabheeh AliNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- SATIP S 070 03 ThermoplasticDocument2 pagesSATIP S 070 03 ThermoplasticMuhammad Farukh Manzoor100% (1)

- 175 320300Document1 page175 320300sridhar100% (1)

- Saudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Report 24-Jul-18 MechnadeemNo ratings yet

- Satr-A-2012 Rev 7Document1 pageSatr-A-2012 Rev 7Eswari AnandNo ratings yet

- Saudi Aramco Test Report: Positive Material Identification (PMI) Log Sheet SATR-A-2013 22-Jan-18 MechDocument2 pagesSaudi Aramco Test Report: Positive Material Identification (PMI) Log Sheet SATR-A-2013 22-Jan-18 MechaneeshNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKDocument2 pagesSaudi Aramco Test Report: Liquid Penetrant Test Report Mech-Nde Kapsarc BI-25-00013 MRKshaikhbwcNo ratings yet

- Saudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 NdeDocument3 pagesSaudi Aramco Test Report: Ultrasonic Test Report - TKY Joints SATR-NDE-2005 24-Jul-18 Ndenadeem shaikhNo ratings yet

- Hempalin Enamel 52140 MSDSDocument13 pagesHempalin Enamel 52140 MSDSJagdishNo ratings yet

- TH THDocument7 pagesTH THJagdishNo ratings yet

- en-US 6823Document5 pagesen-US 6823JagdishNo ratings yet

- Physio Synopsis FinalDocument23 pagesPhysio Synopsis FinalJagdishNo ratings yet

- A. 2 CHDocument46 pagesA. 2 CHJagdishNo ratings yet

- ThesisiiiiiDocument7 pagesThesisiiiiiJagdishNo ratings yet

- A. IntroductionDocument3 pagesA. IntroductionJagdishNo ratings yet

- QC SkillDocument31 pagesQC SkillJagdish100% (3)

- IntroDocument3 pagesIntroJagdishNo ratings yet

- MaterialsDocument2 pagesMaterialsJagdishNo ratings yet

- Saudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Oct-17 MechanicalDocument11 pagesSaudi Aramco Typical Inspection Plan: Hydrostatic Testing of Pipelines SATIP-A-004-03 30-Oct-17 MechanicalJagdishNo ratings yet

- Safety Data Sheet: Hempathane Topcoat 55219 BaseDocument13 pagesSafety Data Sheet: Hempathane Topcoat 55219 BaseJagdishNo ratings yet

- Hempadur XP87559 MSDSDocument20 pagesHempadur XP87559 MSDSJagdishNo ratings yet

- Hempel Curing 98550 MSDSDocument14 pagesHempel Curing 98550 MSDSJagdishNo ratings yet

- Satr A 2009Document2 pagesSatr A 2009JagdishNo ratings yet

- Saudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestDocument9 pagesSaudi Aramco Test Report: SATR-B-6103 30-Oct-17 Inst Fire Alarm System - Smoke / Heat Detector - Pre-Commissioning TestJagdishNo ratings yet

- Satr A 2011Document3 pagesSatr A 2011JagdishNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechDocument2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form) : SATR-A-2007 30-Oct-17 MechJagdishNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanJagdishNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanJagdishNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistJagdishNo ratings yet

- Apcs SystemDocument2 pagesApcs SystemJagdishNo ratings yet

- Saudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Alignment Inspection Record-Horizontal Vessel SATR-D-2001 30-Oct-17 MechJagdishNo ratings yet

- Saic A 1004Document3 pagesSaic A 1004JagdishNo ratings yet

- Cempol SBR: Bonding AdmixtureDocument2 pagesCempol SBR: Bonding AdmixtureJagdishNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- EBOOK Masonry Design and Detailing Sixth Edition 6Th Edition Ebook PDF Download Full Chapter PDF KindleDocument61 pagesEBOOK Masonry Design and Detailing Sixth Edition 6Th Edition Ebook PDF Download Full Chapter PDF Kindleraymond.cobb946100% (45)

- Dimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Document2 pagesDimensions of Weldolets Reducing, Standard Weight (STD), NPS 1 - 2 (3 - 4) - NPS (20) 24, MSS-SP97Qiuniu100% (1)

- Vanessa Basic DatasheetDocument20 pagesVanessa Basic DatasheetM Azri Zulkipli100% (1)

- Spiral Arc Welding PipesDocument44 pagesSpiral Arc Welding PipesomdkhaleelNo ratings yet

- Method Statement For Placing of Embedded Hook Bars To Slab For RCC Structures Supporting System - Submittal No. 167 PDFDocument15 pagesMethod Statement For Placing of Embedded Hook Bars To Slab For RCC Structures Supporting System - Submittal No. 167 PDFThilan SenarathneNo ratings yet

- Rate Analysis (2016) - Cpwd-Part1Document4,174 pagesRate Analysis (2016) - Cpwd-Part1dreamspacearchitects100% (1)

- Sikarep - 100: 1-Component Polymer Modified Ultra-Fine Fairing CoatDocument3 pagesSikarep - 100: 1-Component Polymer Modified Ultra-Fine Fairing CoatSudhanshuGuptaNo ratings yet

- Cylinders 2007-04 Lo PDFDocument14 pagesCylinders 2007-04 Lo PDFXaviNo ratings yet

- Sound Absorbing Materials: Floor and RoofDocument6 pagesSound Absorbing Materials: Floor and RoofLakshmi MenonNo ratings yet

- Stainless Steel Fittings Index: SwagetailsDocument2 pagesStainless Steel Fittings Index: SwagetailsvipulNo ratings yet

- Bonded AnchorDocument26 pagesBonded AnchorrmqkrdNo ratings yet

- S6 - Concrete 01 Material Aspects Strength Design - WBDocument164 pagesS6 - Concrete 01 Material Aspects Strength Design - WBShantonu DeyNo ratings yet

- Welding Rod Price N-7018Document7 pagesWelding Rod Price N-7018jremptymakNo ratings yet

- Valves PresentationDocument36 pagesValves PresentationFareedee100% (3)

- Cetamine f3100 enDocument1 pageCetamine f3100 enatlagh ayoubNo ratings yet

- What Is The Minimum Slope Requirement For Drains?Document14 pagesWhat Is The Minimum Slope Requirement For Drains?Jerome D. EdullantesNo ratings yet

- Air Admittance ValveDocument3 pagesAir Admittance ValvejituplanojrNo ratings yet

- J61H yDocument3 pagesJ61H yFallo SusiloNo ratings yet

- PLASCON-ARCHI-TEXTURE-MARBLE-TEXDocument3 pagesPLASCON-ARCHI-TEXTURE-MARBLE-TEXlydiakawaggaNo ratings yet

- Electoral List of EOU UnitsDocument60 pagesElectoral List of EOU UnitsBhumika vatsNo ratings yet

- DENSOLEN R - AS50 Product Information PR00131517Document2 pagesDENSOLEN R - AS50 Product Information PR00131517mokbelNo ratings yet

- Utilization of Aluminum Sludge and Aluminum Slag (Dross) For The Manufacture of Calcium Aluminate CementDocument8 pagesUtilization of Aluminum Sludge and Aluminum Slag (Dross) For The Manufacture of Calcium Aluminate CementNitin RautNo ratings yet

- Unbrako US Product Guide PDFDocument144 pagesUnbrako US Product Guide PDFVilas m ChinkeNo ratings yet

- Aircraft Gas Turbine MaterialsDocument10 pagesAircraft Gas Turbine MaterialsCaio Fazzioli TavaresNo ratings yet

- State of Art: The Fire Resistance of RC Members Strengthened With CFRP LaminatesDocument36 pagesState of Art: The Fire Resistance of RC Members Strengthened With CFRP LaminatesKhalid Abdel Naser Abdel RahimNo ratings yet

- 30 11 Solenoid Valves InstallationDocument12 pages30 11 Solenoid Valves InstallationWitthaya ThanakhotNo ratings yet

- Materials and Techniques Used in Expansion JointsDocument1 pageMaterials and Techniques Used in Expansion JointsSunidhi VermaNo ratings yet

- Me3393 Manufacturing Processes Question BankDocument46 pagesMe3393 Manufacturing Processes Question BankstezenmNo ratings yet

- Wire and Bar DrawingDocument6 pagesWire and Bar DrawingPrincess NobleNo ratings yet