Manual Serviço Volvo D49 A MT

Manual Serviço Volvo D49 A MT

Uploaded by

Lucas MarquesCopyright:

Available Formats

Manual Serviço Volvo D49 A MT

Manual Serviço Volvo D49 A MT

Uploaded by

Lucas MarquesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Manual Serviço Volvo D49 A MT

Manual Serviço Volvo D49 A MT

Uploaded by

Lucas MarquesCopyright:

Available Formats

Workshop Manual H

2(0)

D49A MS, D49A MT

Plus d'informations sur : www.dbmoteurs.fr

Plus d'informations sur : www.dbmoteurs.fr

Marine Engines

D49A MS/MT

Contents

Safety Information ................................................. 5 Group 22:Lubrication system

Warning labels ....................................................... 8 Oil Pump and Safety Valve

Disassembly ...................................................... 137

General Information ............................................ 10

Inspection .......................................................... 138

Presentation ........................................................ 16

Reassembly ....................................................... 140

Identification numbers ......................................... 18

Oil filter, Relief Valve,Left Cooler and Thermostat

Specifications ...................................................... 19

Disassembly ...................................................... 141

Maintenance Standards Table ............................. 22

Inspection .......................................................... 142

Tightening torques ............................................... 39

Reassembly ....................................................... 143

Sealants and Lubricants Table ............................ 45

Right Side Oil Cooler and Oil Thermostat

Special Tools ....................................................... 46 Disassembly ...................................................... 144

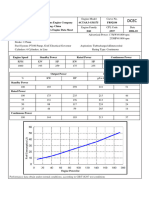

Determination of overhaul timing ...................... 49 Inspection .......................................................... 144

Reassembly ....................................................... 144

Adjustment and Benchtesting ............................ 50

Group 23:Fuel System

Engine auxiliaries removal ................................. 60

Fuel Filters

Engine auxiliaries installation ............................ 71 Disassembly ...................................................... 145

Reassembly ....................................................... 146

Group 21:Engine Body

Fuel Injectors

Cylinder heads and valve mechanism

Disassembly ...................................................... 147

Disassembly ........................................................ 75

Inspection and Adjustment ................................ 148

Inspection and Repair .......................................... 78

Reassembly ....................................................... 150

Reassembly ......................................................... 85

Fuel Injection Pump

Cylinder liners, Pistons and Connecting rods

Disassembly ...................................................... 151

Disassembly ........................................................ 89

Inspection .......................................................... 157

Inspection and Repair .......................................... 93

Reassembly ....................................................... 160

Reassembly ....................................................... 102

Adjustment of Injection Timing ........................... 169

Viscous damper and front gears

Feed Pump

Disassembly ...................................................... 106

Disassembly ...................................................... 171

Inspection and Repair ........................................ 109

Reassembly ....................................................... 172

Reassembly ....................................................... 111

Testing .............................................................. 172

Oil pan and Oil strainer ...................................... 113

PSG Woodward Governor and Drive

Flywheel, Timing gears, and Camshaft

Disassembly ...................................................... 173

Disassembly ...................................................... 115

Inspection .......................................................... 174

Inspection and Repair ........................................ 118

Reassembly ....................................................... 175

Reassembly ....................................................... 122

Crankcase, Crankshaft and Main bearings

Disassembly ...................................................... 126

Inspection and Repair ........................................ 128

Reassembly ....................................................... 135

Plus d'informations sur : www.dbmoteurs.fr

Group 25:Inlet and Exhaust System Group 30:Electrical System

Air Cooler Starter

Disassembly ...................................................... 176 Disassembly ...................................................... 203

Inspection .......................................................... 177 Inspection and Repair ........................................ 206

Turbocharger ..................................................... 178 Reassembly ....................................................... 210

Disassembly ...................................................... 179 Alternator

Inspection .......................................................... 182 Disassembly ...................................................... 213

Reassembly ....................................................... 184 Inspection and repair ......................................... 214

Group 26:Cooling System Reassembly ....................................................... 214

Fresh Water Pump

Disassembly ...................................................... 191

Inspection .......................................................... 193

Reassembly ....................................................... 194

Thermostats ...................................................... 196

Heat Exchanger ................................................. 197

Raw Water Pump

Disassembly ...................................................... 198

Inspection .......................................................... 199

Reassembly ....................................................... 200

Plus d'informations sur : www.dbmoteurs.fr

Safety information

Safety Information

Introduction

The Manual contains technical data, descriptions, and repair instructions for the designated Volvo Penta engines

or engine versions. Make sure that the correct workshop literature is used.

Read the following safety information and the General Information and Repair Instructions in the Workshop Man-

ual carefully before starting service work.

Important

The following special warning symbols are used in the Workshop Manual and on the engine.

WARNING! Warns of risk of bodily injury, serious damage to product or property, or that a serious malfunc-

tion can occur if the instructions are not followed.

IMPORTANT! Used to attract attention to things that can cause damage or malfunction to product or prop-

erty.

NOTE! Used to attract attention to important information, to simplify work procedures or handling.

The following list provides an overview of the risks and cautionary procedures that should always be observed.

Prevent the engine from being started by dis- Make sure that the warning or information de-

connecting the power with the main switch cals on the product are always clearly visible.

(switches) and locking it (them) in the discon- Replace labels that have been damaged or

nected position. Post warning signs stating painted over.

“Work in progress!” in every position from wich

the engine can be started. Never start the engine unless the air filter is fit-

ted. The rotating compressor wheel in the turbo

Maintenance and service should be performed can cause severe injury. Foreign objects in the

on a stationary engine. However, some proce- inlet pipe can also damage the machine.

dures, e.g. certain adjustments, require the en-

gine to be running. Approaching an engine that Never use starter spray or the like. Risk of in

is running is a safety risk. Remember that loose the inlet pipe. Risk of personal injury.

clothes or long hair can fasten in rotating parts

and cause severe injury. Avoid opening the coolant filler cap when the

A careless movement or dropped tool while engine is hot. Steam or hot coolant can spray

working in the vicinity of an engine that is run- out, and built up pressure will be lost. Open the

ning, can in the worst case lead to injury. Ob- filler cap slowly and release the overpressure in

serve caution with hot surfaces (exhaust pipe, the cooling system if the filler cap or cock must

turbo, charge air pipe, starter element etc.) and be opened, or if a plug or coolant pipe must be

hot fluids in the lines and hoses of an engine removed when the engine is hot. Steam or hot

that is running, or has just been stopped. Refit coolant can flow out in an unpredicted direction.

all guards dismantled during service work be-

fore starting the engine.

Plus d'informations sur : www.dbmoteurs.fr

Safety information

Hot oil can cause burn injuries. Avoid skin con- All fuels, as well as many chemicals, are inflam-

tact with hot oil. Make sure that the oil system is mable. Make sure no naked flames or sparks

not pressurised before working on it. Never can cause ignition. Petrol, certain thinners, and

start, or run the engine with the oil filler cap re- hydrogen from batteries are extremely inflam-

moved due to the risk of ejecting oil. mable and explosive when mixed with air.

Smoking is prohibited! Ventilate well and take

Stop the engine and close the bottom valve be- the necessary precautions before welding or

fore working on the cooling system. grinding in the immediate vicinity. Always have

a fire extinguisher handy in the workshop.

Only start the engine in a well-ventilated area.

Exhaust fumes and crankcase gases should be Make sure that rags drenched in oil and petrol,

bled out of the engine compartment or work- including old fuel and lubricant filters, are stored

shop when working in closed environments. safety. Oil drenched rags can in certain condi-

tions self-ignite. Old fuel and oil filters are envi-

Always use protective glasses for work where ronmentally hazardous waste, and together with

there is a risk of splintering, sparks, or splash- spent lubricant, contaminated fuel, paint resi-

ing of acid or other chemicals. The eyes are ex- due, solvent, degreasing agent and suds,

tremely sensitive, and an injury could cause should be handed in to a waste-handling unit for

blindness! destruction.

Avoid skin contact with oil! Prolonged or fre- Batteries must never be exposed to naked

quent skin contact with oil can degrease the flames or electrical sparks. Never smoke in the

skin, resulting in irritation, drying out, eczema, vicinity of batteries. Hydrogen develops when

and other skin complaints. Used oil is more batteries are charged, which in combination

dangerous than new oil from a health care point with air forms an explosive gas. This gas is

of view. Use protective gloves and avoid oil- highly inflammable and very explosive. One

drenched clothes and rags. Wash your hands spark from connecting the batteries incorrectly

regularly, especially before meals. Use special is sufficient to cause the battery to explode and

hand cream to counteract drying out, and to cause injury. Do not touch the connection when

simplify cleaning the skin. starting (risk of spark) and do not lean over the

batteries.

The majority of chemicals intended for the prod-

uct (e.g. engine and timing gear oils, glycol, Never confuse the plus and minus terminals

petrol and diesel oil) or chemicals for workshop when fitting the batteries. This can cause seri-

use (e.g. degreasing agent, enamels and sol- ous damage to the electrical equipment. Check

vents) are hazardous to health. Read the in- the wiring diagram.

structions on the pack carefully. Always follow

the given safety instructions (e.g. the use of Always use protective glasses when charging

breathing protection, protective glasses, or and handling batteries. The battery electrolyte

gloves, etc.) Make sure that other personnel are contains strongly corrosive sulphuric acid. Upon

not exposed to hazardous substances, e.g. by contact with the skin, wash with soap and plen-

inhaling the air. Make sure there is adequate ty of water. If battery acid gets into the eyes,

ventilation. Handle consumed and surplus rinse immediately with water, and contact a

chemicals in the prescribed manner. doctor without delay.

Observe extreme caution when tracing fuel Stop the engine and turn off the power with the

leaks in fuel systems and when testing fuel noz- main switch (switches) before working on the

zles. Wear protective glasses. The jet from a electrical system.

fuel nozzle has a very high pressure and pene-

trating force. The fuel can penetrate deeply into The clutch should be adjusted when the engine

bodily tissue and cause serious injury. Risk of is idle.

blood poisoning.

Plus d'informations sur : www.dbmoteurs.fr

Safety information

Use the lifting hooks mounted on the engine/re- WARNING! The components in the electrical

versing gear when lifting the drive unit. Always system and fuel system on Volvo Penta prod-

check that the lifting equipment is in good con- ucts are designed and manufactured to mini-

dition and has the correct capacity for the lift mise the risks of explosion and fire. The engine

(weight of engine plus reversing gear and extra must not be run in environments surrounded by

equipment where appropriate). explosive media.

For safe handling, and to avoid damaging the Pressure pipes must not bent, turned, or ex-

components mounted on top of the engine, the posed to other strain. Replace damaged pres-

engine should always be lifted with a lifting bar sure pipes.

adjusted to the engine. All chains or wires

should run in parallel with each other and as Observe the following when cleaning with high-

perpendicular to the top of the engine as possi- pressure wash: Never point the jet of water at

ble. Special lifting equipment may be required to seals, rubber hoses, or electrical components.

ensure the right balance and safe handling if Never use the high-pressure function when

other equipment connected to the engine alters washing the engine.

its centre of gravity.

Always use Volvo Penta recommended fuel.

Never work on an engine supported only by lift- See the instruction manual. The use of inferior

ing equipment. quality fuel could damage the engine. The use

of inferior fuel in a diesel engine could cause

Never work alone when heavy components are the control rod to jam and the engine to over-

to be dismantled, even when safe lifting (e.g. speed, with the risk of personal injury or dam-

lockable block and tackle) equipment is used. In age to the machine. Inferior fuel can also lead

most cases, two persons are required even to higher maintenance costs.

when lifting equipment is used: one to handle

the equipment and one to make sure that com-

ponents are not damaged. When working on-

board a boat always make sure in advance that

there is sufficient space to allow dismantling in

situ, without the risk of personal injury or materi-

al damage.

Plus d'informations sur : www.dbmoteurs.fr

Safety information

Warning labels D49A MS

The engine carries ‘Warning Labels’ at places where you are required to pay special attention. Please read them

carefully and make sure you understand the content of each label and the meaning of their position.

1. Make sure the labels are legible. If you find any letter or picture illegible in a label, remove soil from the label,

or replace it.

2. Clean the label with cloth and water or cleanser. Do not use organic solvent or gasoline, this would dissolve

the label’s adhesive and cause the label to fall off.

3. If any label is damaged, lost or illegible, replace it. When replacing a label, make sure the new label is

identical to the old one. For new labels, please contact your dealer.

Plus d'informations sur : www.dbmoteurs.fr

8

Safety information

Warning labels D49A MT

The engine carries ‘Warning Labels’ at places where you are required to pay special attention. Please read them

carefully and make sure you understand the content of each label and the meaning of their position.

1. Make sure the labels are legible. If you find any letter or picture illegible in a label, remove soil from the label,

or replace it.

2. Clean the label with cloth and water or cleanser. Do not use organic solvent or gasoline, this would dissolve

the label’s adhesive and cause the label to fall off.

3. If any label is damaged, lost or illegible, replace it. When replacing a label, make sure the new label is

identical to the old one. For new labels, please contact your dealer.

Plus d'informations sur : www.dbmoteurs.fr

9

General information

General Information

About the Workshop Manual

This Workshop Manual contains technical information, descriptions, and instructions for the standard versions of

the D49A MS and D49A MT engines. The engine designation and numbers are to be found on the engine identifi-

cation plate, refer to section “Identification numbers”. The motor designation and number should always be given

during all correspondence with Volvo Penta.

The Workshop Manual is primarily produced for Volvo Penta service workshops and their qualified personnel. It

is therefore assumed that persons using this manual have a basic knowledge of marine drive systems, and are

able to carry out the related mechanical and electrical nature. Volvo Penta is continuously developing their prod-

ucts. We therefore reserve the right to make changes. All the information contained in this book is based on

product data available prior to publication. Any essential changes or modifications in production or updated or re-

vised service methods introduced after publication will be communicated by means of Service Bulletins.

Spare parts

Spare parts for the electrical and fuel systems are subject to different national safety requirements, e.g. U.S.

Coast Guard Safety Regulations. Volvo Penta Genuine Spare Parts comply with these requirements. All types of

damage resulting from the use of non genuine Volvo Penta spare parts for the product in question will not be reg-

ulated by the warranty undertakings of Volvo Penta.

Certified engines

For service and repair on an engine certificated for any area where exhaust emissions are regulated by law, the

following is important:

Certification means that an engine type is inspected and approved by the authorities. The engine manufacturer

guarantees that all engines manufactured of that type correspond to the certified engine.

This places special requirements on maintenance and service as follows:

● The maintenance and service intervals recommended by Volvo Penta must be observed.

● Only genuine Volvo Penta replacement parts may be used.

● The service of injection pumps and injectors or pump settings must always be carried out by an authorized

Volvo Penta workshop.

● The engine must not be modified in any way except with accessories and service kits approved by Volvo

Penta.

● No modifications to the exhaust pipes and air supply ducts for the engine may be undertaken.

● Seals may only be broken by authorized personnel.

Otherwise the general instructions contained in the Operator’s manual concerning operation, service and mainte-

nance must be followed.

IMPORTANT! Neglected or deficient maintenance/service and the use of non-original spare parts will entail

Volvo Penta renouncing any responsibility for the engine corresponding to the certified version. Volvo Pen-

ta will not compensate for damage and/or costs arising from the above.

10

Plus d'informations sur : www.dbmoteurs.fr

General information

Repair instructions

The working methods described in the Service Manual apply to work carried out in a workshop. The engine has

been removed from the boat and is installed in an engine fixture. Unless otherwise stated reconditioning work

which can be carried out with the engine in place follows the same working method.

Warning symbols occurring in the Workshop Manual (refer to section “Safety information”) are not in any way

comprehensive since it is impossible to predict every circumstance under which service work or repairs may be

carried out. For this reason we can only highlight the risks that can arise when work is carried out incorrectly in a

well-equipped workshop using working methods and tools developed by us.

All procedures for which there are Volvo Penta special tools in this Workshop Manual are carried out using

these. Special tools are developed to rationalize working methods and make procedures as safe as possible. It is

therefore the responsibility of any person using tools or working methods other than the ones recommended by

us to ensure that there is no danger of injury, damage or malfunction resulting from these.

In some cases there may be special safety precautions and instructions for the use of tools and chemicals con-

tained in this Workshop Manual. These special instructions should always be followed if there are no separate in-

structions in the Workshop Manual.

Certain elementary precautions and common sense can prevent most risks arising. A clean workplace and en-

gine eliminates much of the danger of injury and malfunction.

It is of the greatest importance that no dirt or foreign particles get into the fuel system, cooling system, lubrication

system, intake system, turbocharger, bearings and seals when they are being worked on. The result can be mal-

function or a shorter operational life.

Our joint responsibility

Each engine consists of many connected systems and components. If a component deviates from its technical

specification the environmental impact of an otherwise good engine may be increased significantly. It is therefore

vital that wear tolerances are maintained, that systems that can be adjusted are adjusted properly and that Volvo

Penta Genuine Parts as used. The engine Maintenance Schedule must be followed.

Some systems, such as the components in the fuel system, require special expertise and special testing equip-

ment for service and maintenance. Some components are sealed at the factory for environmental reasons. No

work should be carried out on sealed components except by authorized personnel.

Bear in mind that most chemicals used on boats are harmful to the environment if used incorrectly. Volvo Penta

recommends the use of biodegradable degreasing agents for cleaning engine components, unless otherwise

stated in a workshop manual. Take special care when working on-board, that oil and waste is taken for destruc-

tion and is not accidentally pumped into the environment with bilge water.

11

Plus d'informations sur : www.dbmoteurs.fr

General information

How to Use This Manual Terms used in this manual

1. Parts in illustrations are numbered to correspond Before you read this manual, note that the following

with references to these numbers in text. special terms are used in dimensional and other

specifications.

2. Items or conditions to be inspected during disas-

sembly are listed in the disassembled views. Assembly standard

Indicates the dimension of a part, the dimension to be

3. Maintenance standards for inspection and repair attained at the time of reassembly or the standard

are described in text where relevant. For a quick performance.

summary of maintenance standards refer to sec-

tion “Maintenance Standards” of this manual. Norminal value

4. The sequence in which parts are to be reassem- Indicates the standard dimension of a part.

bled is summarized below each assembled view.

Repair limit

Such as:

A part which has reached this limit must be repaired.

Service limit

5. Tightening torque under wet conditions is indicat- A part which has reached this limit must be replaced.

ed as “(wet)” in text, drawings, and tables. When

so indicated, apply engine oil to the threaded por- Standard clearance

tion of the fastener. Unless indicated as (wet), the Indicates the clearance to be obtained between mat-

tightening torque should be dry. ing parts at reassembly.

12

Plus d'informations sur : www.dbmoteurs.fr

General information

Disassembly and Reassembly

This service manual covers recommended procedures to be followed when servicing diesel engines. It also con-

tains information on special tools required and basic safety precautions.

It is the responsibility of service personnel to be familiar with these requirements, precautions, and potential haz-

ards and to discuss these points with their foreman or supervisor.

Study this manual carefully and observe the following general precautions to prevent serious personal injury and

to avoid damage to the engine, equipment, and parts.

WARNING! Use the correct tools and instruments. Serious injury or damage to the engine can result from

using the wrong tools and instruments

WARNING! When lifting or carrying heavy parts, get someone to help you if the part is too awkward for one

person to handle. Use jacks and chain blocks when necessary.

IMPORTANT! Use an overhaul stand or work bench if necessary.

IMPORTANT! Always read the Service Bulletins to learn about changes in procedures and/or technical data.

NOTE! Pay attention to the marks on assemblies, components, and parts for positions or directions. Put on your

own marks, if necessary, to aid reassembly.

NOTE! Carefully check each part for faults during removal or cleaning. Signs of abnormal wear will tell if parts or

assemblies are functioning improperly.

NOTE! Use assembly bins to keep the parts in order of removal and lay down disassembled or cleaned parts in

the order in which they were removed. This will save you time at reassembly

NOTE! Wash all engine parts, except oil seals, O-rings, rubber seals, etc. in cleaning solvent and dry them with

compressed air

NOTE! Use a torque wrench to tighten parts when specified tightening torques are required.

NOTE! Use only good quality lubricating oils and greases. Be sure to apply a coat of oil, grease, or sealant be-

fore reassembly, to parts as specified.

NOTE! Replace all gaskets and packing. Apply appropriate amount of adhesive or liquid gasket when required.

13

Plus d'informations sur : www.dbmoteurs.fr

General information

Oil Seals

When installing oil seals, carefully observe the follow-

ing points.

Driving oil seals into housings

1. Check the seal lip for damage, and be sure to po-

sition correctly in the housing.

2. Apply a smear of grease to the surface of the oil

seal (to be fitted into the housing bore).

3. Use an oil seal driver shown to guide the seal lip

and drive the outer diameter squarely. To avoid

damage to the oil seal and leaking, never ham-

mer on it directly.

Driving oil seals onto shafts

1. Apply a smear of grease to the oil seal lip.

2. Use an oil seal guide of the type shown when

driving the oil seal over the stepped portion,

splines, threads, or key way to prevent damage

to the oil seal lip.

O-rings

Use an O-ring guide to install an O-ring over stepped

parts, splines, threads, or key way to prevent damage

to the ring. Apply a smear of grease to the O-ring be-

fore installation.

14

Plus d'informations sur : www.dbmoteurs.fr

General information

Bearings

1. When installing a rolling bearing, be sure to push

the inner or outer race by which the bearing is fit-

ted. Be sure to use a bearing driver like the one

shown.

2. Whenever possible, use a press to minimize

shock to the bearing and to assure proper instal-

lation.

Lock Plates

Bend lock plates against the flats of the nuts or bolt

heads as shown.

Split Pins and Spring Pins

Generally, split pins are to be replaced once dis-

turbed. Insert the pin fully and spread it properly.

Drive each spring pin into position to hold it in place

after later installation of parts has been completed.

15

Plus d'informations sur : www.dbmoteurs.fr

General information

Presentation D49 MS

D49A MS

1. Fuel filters

2. Oil cooler

3. Fuel injection pump

4. Governor oil filter

5. Manual stop lever

6. Governor

7. Stop solenoid

8. Oil dipstick

9. Fuel feed pump

10. Oil filler cap

11. Fresh water pump

12. Lifting eye

13. Intake air silencer

14. Turbocharger

15. Alternator

16. Oil filters

17. Engine oil drain pipe

18. Starter motor

19. Manual speed control knob

16

Plus d'informations sur : www.dbmoteurs.fr

General information

Presentation D49 MT

D49A MT

1. Fuel filters

2. Oil cooler

3. Fuel injection pump

4. Governor oil filter

5. Manual stop lever

6. Governor

7. Stop solenoid

8. Oil dipstick

9. Fuel feed pump

10. Oil filler cap

11. Fresh water pump

12. Lifting eye

13. Intake air silencer

14. Turbocharger

15. Heat exchanger

16. Oil filters

17. Starter motor

18. Engine oil drain pipe

19. Sea water pump

20. Alternator

21. Manual speed control knob

17

Plus d'informations sur : www.dbmoteurs.fr

General information

Identification numbers D49A

Type plates with identification numbers can be found on the engine and the transmission or generator. This infor-

mation must always be used as a reference when ordering service and spare parts.

Engine ........................................................................................................................................

Product designation ....................................................................................................................

Serial and basic engine number .................................................................................................

Product number ..........................................................................................................................

Certification, IMO ........................................................................................................................

Decal, part No. ...........................................................................................................................

Approval No. ...............................................................................................................................

Transmission / Generator ...........................................................................................................

Product designation ....................................................................................................................

Serial number .............................................................................................................................

Product number ..........................................................................................................................

18

Plus d'informations sur : www.dbmoteurs.fr

General information

Specification D49A MS & MT

General specification

Model ........................................................................... Water-cooled,4-stroke, turbocharged diesel with air-cooled intercooler

No. of cylinders ............................................................ 12

Arrangement ................................................................ vertical V type

Combustion type .......................................................... Direct injection

Valve mechanism ........................................................ Overhead

Cylinder bore,mm [in.] .................................................. 170[6.70]

Cylinder stroke,mm [in.] ............................................... 180 [7.10]

Displacement, litres [U.S. gal] ..................................... 49.03 [12.95]

Compression ratio ........................................................ 14.0:1

Firing order ................................................................... 1-12-5-8-3-10-6-7-2-11-4-9

Rotational direction ...................................................... Counterclockwise as viewed from flywheel

Weight (Dry)(without marine gear), kg [lb] ................... MS: 4820[10626] MT: 5000 [11025]

Engine main parts

Cylinder liner type ........................................................ Wet type

Piston rings:

Compression rings, pcs ............................................... 2

Oil ring(w/expander), pcs ............................................. 1

Valve timing (when warm):

Inlet valve ..................................................................... open BTDC 37°

Inlet valve ..................................................................... close ABDC 44°

Exhaust valve .............................................................. open BBDC 57°

Exhaust valve .............................................................. close ATDC 24°

Engine support method ................................................ 4 point support

Fuel system

Fuel

JIS K2204 .................................................................... TYPE 1, TYPE 2, TYPE 3

ASTM. D975 ................................................................ No.1-D, No.2-D

BS2869 ........................................................................ CLASS-A1, CLASS-A2,

DIN51601 ..................................................................... DIESEL-FUEL

ISO8217 ....................................................................... DMX-CLASS

Injection pump

Model ........................................................................... PS6 type

Manufacturer ................................................................ Mitsubishi Heavy Industries, Ltd.

Plunger outside diam., mm [in.] ................................... 17 [0.67]

Plunger lead, mm [in.] .................................................. Counterclockwise, left-hand 35 [1.38] lead

Cam lift, mm [in.] .......................................................... 15 [0.59]

Fuel feed pump

Model ........................................................................... Zexel

Manufacturer ................................................................ Zexel

Cam lift, mm [in.] .......................................................... 12 [0.47]

Governor

Control system ............................................................. Woodward Hydraulic PSG

19

Plus d'informations sur : www.dbmoteurs.fr

General information

Fuel system cont.

Fuel injector

Type ............................................................................. Hole type

Manufacturer ................................................................ Zexel

No. of spray holes ........................................................ 10

Spray hole diameter, mm [in.] ...................................... 0.325 [0.013]

Spray angle, deg. ......................................................... 160°

Injection press., Mpa(kgf/cm²)[psi] .............................. 34.32 to 34.81 (350 to 355) [4979 to 5050]

Fuel filter

Type ............................................................................. Paper element cartridge changeover, spin-on type

Oil system

Lubricating type ........................................................... Forced circulation type (pressure feed by oil pump)

Engine oil Standard ...................................................... CF oil (API service classification)

Engine oil volume:

Oil sump,liter [U.S. gal] ................................................ 200 [52.8] approx

Complete engine, liter [U.S. gal] .................................. 230 [60.8] approx

Oil pump

Type ............................................................................. Gear pump

Delivery capacity, liter [U.S. gal] .................................. 240 [63.4] (at engine speed 800 rpm)

Relief valve

Type ............................................................................. Piston valve type

Opening press., MPa(kgf/cm³)[psi] .............................. 0.51 +/-0.02 (5.2 +/-0.2) [73.97+/-2.84}

Oil cooler

Type ............................................................................. Water-cooled, multi-plate type (housed in the crankcase)

Full-flow oil filter

Type ............................................................................. Paper element changeover type (spin on)

Oil thermostat

Type ............................................................................. Wax type

Valve opening temp., °C [°F] ....................................... 80 to 84 [176 to 183.2]

Cooling system

Cooling type ................................................................. Water-cooled, forced circulation

Coolant capacity (whole engine), liter [U.S. gal] .......... MS: 125 [33.0] MT: 235 [62.1]

Fresh water pump

Type ............................................................................. Centrifugal

Pump capacity, liter [U.S. gal]/min. .............................. 1600 [423], Total head 0.20 MPa (20 mAq) (at 3292 rpm pump speed)

Thermostat

Type ............................................................................. Wax

Valve opening temp.,°C [°F] ........................................ 71+/-2 [159.8 +/- 3.6]

Raw water pump (only on MT)

Type ............................................................................. Rubber rotor

Pump capacity, liter [U.S. gal]/min. .............................. 800 [211], Total head 0.10 MPa (10 mAq)(at 1600 rpm pump speed)

Pump drive belt type .................................................... V-belt

Outside circumference, mm [in] ................................... 2085 [82] or 2115 [83]

20

Plus d'informations sur : www.dbmoteurs.fr

General information

Inlet and exhaust system

Turbocharger

Type ............................................................................. MS: TD13 or TD15 MT: TD15

No. of units ................................................................... 2

Electrical system

Voltage-polarity ............................................................ 24V each float

Starter

Manufacturer ................................................................ Nikko Electric Industry

Pinion mesh type ......................................................... Pinion shift (Reduction type)

Output .......................................................................... V (kW) 24 (7.5)

No. of starters .............................................................. 2

No. of pinion tooth/ring gear tooth ............................... 15 / 182

Alternator

Type ............................................................................. 3-Phase alternating generator, Internal IC regulator

Manufacturer ................................................................ Mitsubishi Electric

Output .......................................................................... V-A 24-35

Rated generated .......................................................... min-1 5000 (at 27V, 35A)

Regulated voltrage ....................................................... V 28.5 +/- 0.5

Drive belt type .............................................................. V-belt

Outside circumference, mm [in.] .................................. 1000 [39.4]

21

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Maintenance Standards Table

General

Maximum rpm

Nominal Value ........... 5 – 10 % higher than rated rpm

Repair limit ................ Lower or 20 % higher than rated rpm

NOTE! Rated rpm stamped on the nameplate. Check governor setting.

Minimum rpm

Nominal value ........... 600 to 650 rpm

Compression pressure MPa (Bar) [psi]

Nominal Value ........... 2.85 (28.5) [263] minimum (at 120 rpm)

Repair limit ................ 2.30 (23.0) [185] or lower

NOTE! Oil and water temp. 20 to 30°C [68 to 86°F]

Lube oil pressure MPa (Bar) [psi]

Nominal Value ........... 0.20 – 0.29 (2.0 – 2.9) [28 to 43] at idling

Repair limit ................ 0.10 (1.0) [14] or lower

NOTE! Oil temp. 60 to 70°C [140 to 158°F]

Valve timing (2 mm[0.8 in.] clearance valve side, cold)

Nominal Value:

Inlet valve opens ....... 2.5° BTDC ±2° (crank angle)

Inlet valve closes ...... 13° ABDC ±2° (crank angle)

Exh. valve opens ...... 26° BBDC ±2° (crank angle)

Exh. valve closes ...... 10.5° BTDC ±2° (crank angle)

NOTE! Values are only for checking valve timing and are different from the actual ones.

Valve clearance (cold), mm [in.]

Inlet valves:

Standard Clearance .. 0.6 [0.024]

Exhaust valves:

Standard Clearance .. 0.8 [0.031]

Injection timing

Nominal Value ........... XX° BTDC ±1° (crank angle)

NOTE! XX varies according to specifications. Refer to caution plate on No. 1 rocker cover.

Engine main parts

Valves

Valve stem diameter, mm [in.]

Nominal Value ........... Ø10 [0.39]

Assembly Standard ... 9.940 to 9.960 [0.39134 to 0.39213]

Service Limit ............. 9.910 [0.39016]

NOTE! The same for both inlet and exhaust valves.

22

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Valve guide inside diameter, mm [in.]

Nominal Value ........... Ø10 [0.39]

Assembly Standard ... 10.000 to 10.015 [0.39370 to 0.39429]

Service Limit ............. 10.060 [0.39606]

NOTE! The same for both inlet and exhaust valves.

Valve seat angle(A)

Nominal Value ........... 30°

Valve depth(B), mm [in.]

Nominal value ........... 0

Assembly Standard ... -2.0 – 0.2 [-0.008 – 0.008]

Repair Limit ............... 1.0 [0.039]

Seat width(C), mm [in.]

Nominal value ........... 2.3 [0.091]

Assembly Standard ... 2.15 to 2.45 [0.0846 to 0.0965]

Repair Limit ............... 2.8 [0.110]

Valve margin(D), mm [in.]

Nominal Value ........... 3.0 [0.12]

Assembly Standard ... 2.8 – 3.2 [0.110 to 0.126]

NOTE! Refacing permissible up to 2.5 [0.098]

Cylinder head bore and valve seat diameter, mm [in.]

Nominal Value ........... Ø60 [2.36]

Assembly Standard ... -0.070 – -0.130 [-0.00276 – -0.00512]

NOTE! - (minus) indicates interference

Valve push rods

Deflection, mm [in.]

Assembly Standard ... 0.5 [0.020] maximum

Service Limit ............. 0.5 [0.020]

Valve springs

Free length (A), mm [in.]

Assembly standard ... 73 [2.87]

Service limit .............. 71 [2.80]

Perpendicularity (B), mm [in.]

Service limit .............. 2.2 [0.087] (at end)

Length under test force, mm [in.]

Assembly standard ... 66.0 [2.6]

Test force, N (kgf) [lbf]

Assembly standard ... 289–319 (29.45 to 32.55) [65 to 72]

23

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Rockers

Rocker bushing inside diameter, mm [in.]

Nominal Value ........... Ø36 [1.42]

Assembly Standard ... 36.000 to 36.040 [1.41732 to 1.41889]

Service Limit ............. 36.090 [1.42086]

Rocker shaft diameter, mm [in.]

Nominal Value ........... Ø36 [1.42]

Assembly Standard ... 35.966 to 35.991 [1.41598 to 1.41697

Service Limit ............. 35.940 [1.41496]Cylinder heads

Flatness of gasket surface, mm [in.]

Assembly Standard ... 0.03 [0.0012] or less

Repair Limit ............... 0.07 [0.0028]

Service Limit ............. 0.50 [0.0197]

NOTE! Reface if necessary

Thickness of gasket when tightened, mm [in.]

Nominal Value ........... 1.8 [0.07]

Assembly Standard ... 1.77 to 1.83 [0.0697 to 0.0720]

Cylinder liners

Inside diameter, mm [in.]

Nominal Value ........... Ø170 [6.69]

Assembly Standard ... 170.000 to 170.040 [6.69290 to 6.69447]

Repair Limit ............... 170.200 [6.70078]

Service Limit ............. 170.500 [6.71259]

Roundness, mm [in.]

Assembly Standard ... 0.02 [0.0008] or less

Cylindricity, mm [in.]

Assembly Standard ... 0.02 [0.0008] or less

Squareness of flange lower face to liner center line, mm [in.]

Assembly Standard ... 0.03 [0.0012] or less

Protrusion of cylinder liner at flange, mm [in.]

Assembly Standard ... 0.11 to 0.20 [0.0043 to 0.0089]

Pistons and cylinderheads

Clearance between piston top and cylinder head, mm [in.]

Standard Clearance .. [1.22 to 1.95) ([0.0480 to 0.0768])

Pistons

Outside diameter, mm [in.]

Nominal Value ........... Ø170 [6.69]

Assembly Standard ... 169.76 to 169.80 [6.6835 to 6.6850]

Service Limit ............. 169.66 [6.6795]

NOTE! Meaure diameter perpendicular to pin at piston skirt.

24

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Weight difference between pistons in one engine

Assembly Standard ... ±10 g [±0.35 oz]

Pin bore diameter, mm [in.]

Nominal Value ........... Ø70 [2.76]

Assembly Standard ... 70.002 to 70.015 [2.75598 to 2.75649]

Service Limit ............. 70.040 [2.75747]

Protrusion, mm [in.]

Assembly Standard ... 0.06 to 0.65 [0.0024 to 0.0256]

NOTE! From the cylinder block

Piston rings

Gaps Top ring, mm [in.]

Assembly Standard ... (0.6 to 0.8) ([0.024 to 0.031])

Service Limit ............. (2.0) ([0.079])

NOTE! If gauge is not available, the general value can be obtained at the cylinder bore.

Gaps Second ring, mm [in.]

Assembly Standard ... (0.6 to 0.8) ([0.024 to 0.031])

Service Limit ............. (2.0) ([0.079])

NOTE! If gauge is not available, the general value can be obtained at the cylinder bore.

Gaps Oil ring, mm [in.]

Assembly Standard ... (0.3 to 0.45) ([0.012 to 0.018])

Service Limit ............. (2.0) ([0.079])

NOTE! If gauge is not available, the general value can be obtained at the cylinder bore.

Piston pins

Diameter, mm [in.]

Nominal Value ........... Ø70 [2.76]

Assembly Standard ... 69.987 to 70.000 [2.75539 to 2.75590]

Service Limit ............. 69.970 [2.75472]

Connecting rods

Bushing inside diameter, mm [in.]

Nominal Value ........... Ø70 [2.76]

Assembly Standard ... 70.020 to 70.040 [2.75669 to 2.75747]

Service Limit ............. 70.070 [2.75866]

Bend and twist, mm [in.]

Assembly Standard ... 0.05/100 [0.0020/3.9] or less

End play (rod and crankpin widths), mm [in.]

Nominal Value ........... 60 [2.36] x 2

Assembly Standard ... (0.4 to 0.9) ([0.016 to 0.035])

Service Limit ............. (1.4) ([0.055])

Weight difference between connecting rods in one engine

Assembly Standard ... ±30 g [±1.06 oz]

25

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Big end bore diameter, mm [in.]

Nominal Value ........... Ø131 [5.16]

Assembly Standard ... 131.000 to 131.025 [5.15747 to 5.15845]

Service Limit ............. 131.050 [5.15944]

NOTE! To be measured in combination with caps. Roundness less than (0.1 mm [0.004 in.] - service limit)

Connecting rod bearings

Thickness of center, STD, mm [in.]

Nominal Value ........... 3.000 [0.11811]

Assembly Standard ... 2.972 to 2.985 [0.11701 to 0.11752]

Service Limit* ............ 2.930 [0.11535]

Thickness of center, –0.25 [–0.0098], mm [in.]

Nominal Value ........... 3.125 [0.12303]

Assembly Standard ... 3.097 to 3.110 [0.12193 to 0.12244]

Service Limit* ............ 3.055 [0.12028]

Thickness of center, –0.50 [–0.0197], mm [in.]

Nominal Value ........... 3.250 [0.12795]

Assembly Standard ... 3.222 to 3.235 [0.12685 to 0.12736]

Service Limit* ............ 3.180 [0.12520]

Thickness of center, –0.75 [–0.0295], mm [in.]

Nominal Value ........... 3.375 [0.12287]

Assembly Standard ... 3.347 to 3.360 [0.13177 to 0.13228]

Service Limit* ............ 3.305 [0.13012]

Thickness of center, –1.00 [–0.0394], mm [in.]

Nominal Value ........... 3.500 [0.13780]

Assembly Standard ... 3.472 to 3.485 [0.13669 to 0.13720]

Service Limit ............. 3.430 [0.13504]

*NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if necessary.

Oil pump drive

Cover bearing journal inside diameter, mm [in.]

Nominal Value ........... Ø110 [4.33]

Assembly Standard ... 110.000 to 110.035 [4.33070 to 4.33208]

Plate bearing journal inside diameter, mm [in.]

Nominal Value ........... Ø110 [4.33]

Assembly Standard ... 109.987 to 110.022 [4.33019 to 4.33157]

Bearing, Outside diameter, mm [in.]

Nominal Value ........... Ø110 [4.33]

Assembly Standard ... 109.985 to 110.000 [4.33012 to 4.33071]

Bearing, Inside diameter, mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 49.988 to 50.000 [1.96803 to 1.96850]

Gear shaft bearing journal diameter, mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 49.993 to 50.013 [1.96822 to 1.96901]

26

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Flywheel

Face runout, mm [in.]

Assembly Standard ... 0.336 [0.0132] to less

Radial runout, mm [in.]

Assembly Standard ... 0.13 [0.0051] or less

Injection pump accessory drive

Bearing bore inside diameter, mm [in.]

Nominal Value ........... Ø90 [3.54]

Assembly Standard ... 89.987 – 90.022 [3.54279 – 3.54417]

Bearing bore inside diameter, mm [in.]

Nominal Value ........... Ø100 [3.94]

Assembly Standard ... 99.987– 100.022 [3.93649 – 3.93787]

Bearing, Outside diameter, mm [in.]

Nominal Value ........... Ø90 [3.54]

Assembly Standard ... 89.985 – 90.000 [3.54272 – 3.54331]

Bearing, Outside diameter, mm [in.]

Nominal Value ........... Ø100 [3.94]

Assembly Standard ... 99.985 – 100.000 [3.93642 – 3.93701]

Bearing, Inside diameter, mm [in.]

Nominal Value ........... Ø45 [1.77]

Assembly Standard ... 44.988 to 45.000 [1.77118 to 1.77165]

Bearing, Inside diameter , mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 49.988 to 50.000 [1.96803 to 1.96850]

Drive shaft bearing journal diameter, mm [in.]

Nominal Value ........... Ø45 [1.77]

Assembly Standard ... 45.002 to 45.013 [1.77173 to 1.77216]

Drive shaft bearing journal diameter, mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 50.002 to 50.013 [1.96858 to 1.96901]

Damper

Radial runout (at periphery), mm [in.]

Assembly Standard ... 0.5 [0.020] or less

Service Limit ............. 1.5 [0.059]

Radial runout (at periphery), mm [in.]

Assembly Standard ... 0.5 [0.020] or less

Service Limit ............. 1.5 [0.059]

27

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Front gears

Backlash, mm [in.]

Assembly Standard ... (0.12 to 0.18) ([0.0047 to 0.0071])

Repair Limit ............... (0.30) ([0.0118])

Service Limit ............. (0.50) ([0.0197])

NOTE! Replace gears, if necessary

Idle gear shaft bushing inside diameter, mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 50.000 to 50.025 [1.96850 to 1.96948]

Service Limit ............. 50.060 [1.97086]

Idle gear shaft diameter, mm [in.]

Nominal Value ........... Ø50 [1.97]

Assembly Standard ... 49.950 to 49.975 [1.966553 to 1.96752]

Service Limit ............. 49.900 [1.96456]

Idle gear end play, mm [in.]

Assembly Standard ... (0.2 to 0.4) ([0.008 to 0.016])

Service Limit ............. (0.6) ([0.024])

Timing gears

Backlash, mm [in.]

Assembly Standard ... (0.12 to 0.18) ([0.0047 to 0.0071])

Repair Limit ............... (0.30) ([0.0118])

Service Limit ............. (0.50) ([0.0197])

Idle gear shaft bushing inside diameter, mm [in.]

Nominal Value ........... Ø65 [2.56]

Assembly Standard ... 65.000 to 65.030 [2.55906 to 2.56024]

Service Limit ............. 65.060 [2.56142]

Idle gear shaft diameter, mm [in.]

Nominal Value ........... Ø65 [2.56]

Assembly Standard ... 64.951 to 64.970 [2.55713 to 2.55787]

Service Limit ............. 64.900 [2.55512]

Idle gear end play, mm [in.]

Assembly Standard ... (0.3 to 0.6) ([0.118 to 0.236])

Service Limit ............. (1.0) ([0.0397])

28

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Camshaft

Cam lift (A-B), mm [in.]

Nominal Value ........... 9.247 [0.36405]

Assembly Standard ... 9.197 to 9.297 [0.36209 to 0.36602]

Service Limit ............. 8.45 [0.3327]

Deflection, mm [in.]

Assembly Standard ... 0.05 [0.0020] or less

Repair Limit ............... 0.08 [0.0031]

NOTE! Deflection at center bushing measured with both ends supported. Repair or replace, if necessary.

Journal diameter, mm [in.]

Nominal Value ........... Ø84 [3.31]

Assembly Standard ... 83.92 to 83.94 [3.3039 to 3.3047]

Service Limit ............. 83.87 [3.3020]

Camshaft bushing inside diameter (as installed in crank case), mm [in.]

Nominal Value ........... Ø84 [3.31]

Assembly Standard ... 84.00 to 84.035 [3.30708 to 3.30846]

Service Limit ............. 84.10 [3.3110]

NOTE! Replace bushings and ream them, if necessary

End play, mm [in.]

Nominal Value ........... 8 [0.3]

Assembly Standard ... 0.10 to 0.25 [0.0039 to 0.0098]

Service Limit ............. 0.40 [0.0157])

NOTE! Replace thrust bearing, if necessary.

Crankshaft

Crankpin diameter, mm [in.]

Nominal Value ........... Ø125 [4.92]

Assembly Standard ... -0.050 – -0.070 [0.00197 – -0.00276]

Repair Limit ............... -0.110 [-0.00433]

Crankpin journal diameter, mm [in.]

Nominal Value ........... Ø170 [6.69]

Assembly Standard ... -0.060 – -0.080 [0.00236 – -0.00315]

Repair Limit ............... -0.110 [-0.00433]

Journal and crankpin center to center distance, mm [in.]

Nominal Value ........... 90 [3.54]

Assembly Standard ... ±0.1 [±0.004]

Parallelism between journals and crankpins, mm [in.]

Assembly Standard ... 0.01 [0.0004] or less at pin length

Repair Limit ............... 0.03 [0.0012]

Roundness of journals and crankpins, mm [in.]

Assembly Standard ... 0.01 [0.0004] or less in diameters

Repair Limit ............... 0.03 [0.0012]

Cylindricity of journals and crankpins, mm [in.]

Assembly Standard ... 0.02 [0.0008] or less in diameters

Repair Limit ............... 0.03 [0.0012]

29

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Fillet radius of crankpins, mm [in.]

Nominal Value ........... 7 [0.28]

Assembly Standard ... 7.0 – 7.2 [0.268 – 0.276]

Fillet radius of journals, mm [in.]

Nominal Value ........... 8.5 [0.33]

Assembly Standard ... 8.3 – 8.5 [0.327 – 0.335]

Hardness of journals and crankpins

Assembly Standard ... Hv>590

Angularity

Assembly Standard ... ±0°20’

Deflection, mm [in.]

Assembly Standard ... 0.04 [0.0016] or less

Repair Limit ............... 0.10 [0.0039]

NOTE! Repair or replace if necessary

Crankshaft end play, mm [in.]

Nominal Value ........... 67 [2.64]

Assembly Standard ... 0.20 to 0.40 [0.0079 to 0.0157]

Service Limit ............. 0.50 [0.0197] + 1.18[0.0465] (crank shaft width)

NOTE! Replace thrust bearings if worn down to service limit. Use oversize thrust bearings if worn beyond repair limit.

Main bearing

Thickness of center, STD, mm [in.]

Nominal Value ........... 4.500 [0.17717]

Assembly Standard ... 4.467 to 4.480 [0.17587 to 0.17638]

Service Limit ............. 4.425 [0.17421]

NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if worn beyond service limit.

Thickness of center, –0.25 [–0.0098], mm [in.]

Nominal Value ........... 4.625 [0.18209]

Assembly Standard ... 4.592 to 4.605 [0.18079 to 0.18130]

Service Limit ............. 4.550 [0.17913]

NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if worn beyond service limit.

Thickness of center, –0.50 [–0.0197], mm [in.]

Nominal Value ........... 4.750 [0.18701]

Assembly Standard ... 4.717 to 4.730 [0.18571 to 0.18622]

Service Limit ............. 4.675 [0.18405]

NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if worn beyond service limit.

Thickness of center, –0.75 [–0.0295], mm [in.]

Nominal Value ........... 4.875 [0.19193]

Assembly Standard ... 4.842 to 4.855 [0.19063 to 0.19114]

Service Limit ............. 4.800 [0.18898]

NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if worn beyond service limit.

Thickness of center, –1.00 [–0.0394], mm [in.]

Nominal Value ........... 5.000 [0.19685]

Assembly Standard ... 4.967 to 4.980 [0.19555 to 0.19606]

Service Limit ............. 4.925 [0.19390]

NOTE! Replace bearings if worn down to service limit. Regrind crankpins and use undersize bearings if worn beyond service limit.

30

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Crankcase

Flatness of gasket surface, mm [in.]

Assembly Standard ... 0.1 [0.004] or less

Repair Limit ............... 0.2 [0.008]

NOTE! Reface if necessary

Main bearing bore diameter, mm [in.]

Nominal Value ........... Ø179 [7.05]

Assembly Standard ... 179.000 to 179.025 [7.04723 to 7.04821]

Service Limit ............. 179.045 [7.04900]

Inlet and exhaust system

Turbocharger TD13 (only on D49 MS)

Inside diameter of bearing-fitted housing section, mm [in.]

Nominal Value ........... 30 [1.18]

Service Limit ............. 30.006 [1.18134]

Bearing outside diameter, mm [in.]

Service Limit ............. 29.876 [1.17622]

Bearing inside diameter, mm [in.]

Service Limit ............. 18.050 [0.71063]

Bearing length, mm [in.]

Service Limit ............. 17.440 [0.68661]

Shaft journal diameter, mm [in.]

Nominal Value ........... 18 [0.709]

Service Limit ............. 17.996 [0.70850]

Shaft deflection, mm [in.]

Service Limit ............. 0.015 [0.00059]

Ring gap clearance, mm [in.]

Standard Clearance .. 0.05 to 0.25 [0.00197 to 0.00984]

Shaft & turbine wheel and turbine housing clearance, mm [in.]

Standard Clearance .. 0.29 to 0.91 [0.01142 to 0.03583]

Shaft end play, mm [in.]

Assembly Standard ... 0.075 to 0.135 [0.00295 to 0.00531]

Turbine backplate and turbine wheel clearance, mm [in.]

Standard Clearance .. 0.55 to 1.15 [0.02165 to 0.05315]

Turbocharger TD15

Inside diameter of bearing-fitted housing section, mm [in.]

Nominal Value ........... Ø34 [1.34]

Service Limit ............. 34.016 [1.33921]

31

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Bearing outside diameter, mm [in.]

Service Limit ............. 33.882 [1.33393]

Bearing inside diameter, mm [in.]

Service Limit ............. 19.929 [0.78460]

Bearing length, mm [in.]

Service Limit ............. 19.440 [0.76535]

Shaft journal, mm [in.]

Nominal Value ........... Ø20 [0.79]

Service Limit ............. 19.863 [0.78201]

Shaft deflection, mm [in.]

Service Limit ............. 0.015 [0.00059]

Ring gap clearance, mm [in.]

Standard Clearance .. 0.05 to 0.20 [0.00197 to 0.00787]

Shaft & turbine wheel and turbine housing clearance, mm [in.]

Standard Clearance .. 0.63 to 1.18 [0.02480 to 0.04646]

Shaft end play, mm [in.]

Assembly Standard ... 0.075 to 0.135 [0.00295 to 0.00531]

Turbine backplate and turbine wheel clearance, mm [in.]

Standard Clearance .. 0.85 to 1.35 [0.03346 to 0.04528]

Lubrication system

Oil Pump

Backlash between drive gear and driven gear, mm [in.]

Assembly Standard ... (0.10 to 0.20) [0.0039 to 0.0079]

Service Limit ............. (0.4) [0.0157]

Drive gear and driven gear clearance, mm [in.]

Nominal Value ........... Ø60 [2.36]

Standard Clearance .. (0.100 to 0.148) [0.00394 to 0.00583]

Clearance .................. Tip clearance (0.35) [0.0138]

Gear and clearance in case, mm [in.]

Nominal Value ........... 72.5 [2.854]

Standard Clearance .. (0.040 to 0.116) [0.00157 to 0.00457]

Clearance .................. [0.21] [0.0083]

NOTE! Remove the cover packing (width of 0.04 [0.0016]) for mesurement.

Shaft diameter, Drive shaft, mm [in.]

Nominal Value ........... Ø30 [1.18]

Assembly Standard ... 29.887 to 29.000 [1.17665 to1.17717]

Service Limit ............. 29.840 [1.17480]

32

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Shaft diameter, Driven shaft, mm [in.]

Nominal Value ........... Ø30 [1.18]

Assembly Standard ... 29.947 to 29.960 [1.17901 to 1.17953]

Service Limit ............. 29.900 [1.17716]

Bushing inside diameter, mm [in.]

Nominal Value ........... Ø30 [1.18]

Assembly Standard ... 30.000 to 30.021 (1.18110 to 1.18193)

Service Limit ............. 30.055 [1.18327]

Safety valve

Valve opening pressure MPa (Bar) [psi]

Assembly Standard ... 1.27±0.13 (12.7±1.3) [185±18.5]

Spring set length/load mm [in.]/N (kgf) [lbf]

Assembly Standard ... 65.8 [2.59]/359 (36.6) [80.7]

Service Limit ............. 65.8 [2.59]/314 (32) [70.5]

Relief valve

Valve opening pressure, MPa (Bar) [psi]

Assembly Standard ... 0.5±0.02 (5±0.2) [71.1±2.84]

Oil thermostat

Temperature at which valve starts opening

Assembly Standard ... 80 to 84°C [176 to 183°F]

Temperature at which valve lift more than 11 mm [0.43 in.]

Assembly Standard ... 95°C [203°F]

Piston cooling nozzle

Valve opening pressure, MPa (Bar) [psi]

Assembly Standard ... 0.26 to 0.32 2.6 to 3.2 [38 to 47]

Cooling system

Fresh water pump

Bearing bore inside diameter, mm [in.]

Nominal value ........... Ø120 [4.72]

Assembly Standard ... 119.987 to 120.022 [4.72389 to 4.72527]

Bearing bore inside diameter, mm [in.]

Nominal value ........... Ø110 [4.33]

Assembly Standard ... 110.005 to 110.040 [4.33090 to 4.33227]

NOTE! Same as the bearing cover.

Bearing, Outside diameter, mm [in.]

Nominal value ........... Ø120 [4.72]

Assembly Standard ... 119.985 to 120.000 [4.72381 to 4.72441]

33

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Bearing, Outside diameter, mm [in.]

Nominal value ........... Ø110 [4.33]

Assembly Standard ... 109.985 to 110.000 [4.33012 to 4.33071]

Bearing, Inside diameter, mm [in.]

Nominal value ........... Ø55 [2.17]

Assembly Standard ... 54.985 to 55.000 [2.16476 to 2.16535]

Bearing, Inside diameter, mm [in.]

Nominal value ........... Ø50 [1.97]

Assembly Standard ... 49.988 to 50.000 [1.96803 to 1.96850]

Shaft bearing journal diameter, mm [in.]

Nominal value ........... Ø55 [2.17]

Assembly Standard ... 55.011 to 55.024 [2.16578 to 2.16629]

Shaft bearing journal diameter, mm [in.]

Nominal value ........... Ø50 [1.97]

Assembly Standard ... 50.011 to 50.024 [1.96893 to 1.96944]

Vane front face clearance, mm [in.]

Nominal value ........... 1.04 [0.041]

Standard Clearance .. (0.58 to 1.5) ([0.023 to 0.059])

Thermostat

Temperature at which valve starts opening

Assembly Standard ... 71±2°C [159.8±3.6°F]

NOTE! Check in atmospheric pressure

Temperature at which valve lift is more than 11 mm [0.43 in.]

Assembly Standard ... 85°C [185°F]

NOTE! Check in atmospheric pressure

Sea water pump

Impeller

Repair Limit ............... Replace if cracked.

Pump seals

Repair Limit ............... Replace if water leaks.

Bearing

Repair Limit ............... Replace if worn excessively.

Holder bearing bore inside diameter, mm [in.]

Nominal value ........... Ø110 [4.33]

Assembly Standard ... 109.995 to 110.030 [4.33050 to 4.33188]

Service Limit ............. 110.030 [4.33188]

34

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Bearing, Outside diameter, mm [in.]

Nominal value ........... Ø110 [4.33]

Assembly Standard ... 109.985 to 110.000 [4.33011 to 4.3307]

Bearing, Inside diameter, mm [in.]

Nominal value ........... Ø50 [1.97]

Assembly Standard ... 49.985 to 50.000 [1.96791 to 1.9685]

Shaft bearing journal, mm [in.]

Nominal value ........... Ø50 [1.97]

Assembly Standard ... 50.002 to 50.013 [1.96858 to 1.96901]

Service Limit ............. 50.000 [1.96858]

Fuel system

Fuel injector

Valve opening pressure, MPa (kgf/cm2) [psi]

Nominal value ........... 34.32 (350) [4977]

Assembly Standard ... 34.32 to 34.81 350 to 355 [4977 to 5048]

Spray cone angle

Nominal value ........... 160°

NOTE! Check nozzle with a hand tester (at fuel oil temperature 20°C [68°F]. Replace the nozzle if the spray pattern is still bad after

washing in clean fuel oil.

Injection pump

Overall clearance at tappet roller, mm [in.]

Service Limit ............. 0.2 [0.00787]

Wear of contact surface between tappet and plunger, mm [in.]

Service Limit ............. 0.2 [0.00787]

Outside diameter at contact surface of camshaft oil seal, mm [in.]

Nominal value ........... Ø35 [1.378]

Assembly Standard ... 34.963 to 34.938 [1.37649 to 1.37551]

Service Limit ............. 34.800 [1.37001]

Camshaft deflection, mm [in.]

Assembly Standard ... 0.05 [0.00197]

Repair Limit ............... 0.15 [0.00591]

35

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Plunger Spring, mm [in.]

Free length (A), mm[in.]

Assembly Standard ... 70.8 [2.787]

Perpendicularity (B), mm[in.]

Service Limit ............. 1.8 [0.071]

Length under test force, mm [in.]

Assembly standard ... 60.0 [2.36]

Test force, N (kgf) [lbf]

Assembly standard ... 299–366 (30.5–37.3) [67.2–82.2]

Delivery valve spring, mm [in.]

Free length (A)

Assembly Standard ... 18 [0.71]

Perpendicularity (B)

Service Limit ............. 0.6 [0.024]

Length under test force, mm [in.]

Assembly standard ... 14.15 [0.56]

Test force, N (kgf) [lbf]

Assembly standard ... 51.6-61.4 (5.26–6.26) [11.60–13.80]

Camshaft thrust clearance, mm [in.]

Standard Clearance .. 0.02 to 0.06 [0.00079 to 0.00236]

Resistance in rack movement

Assembly Standard ... 500 g [1.102 lb]

NOTE! Make sure rack moves smoothly. Total rack stroke should be 36 mm [1.42 in.].

Injection start interval

Assembly Standard ... 60°±0.5°

NOTE! Camshaft angle

Nozzle valve opening pressure MPa (Bar) [psi]

Assembly Standard ... 34.3 (343) [4978.75]

Feed pressure MPa (Bar) [psi]

Assembly Standard ... 0.16 (1.6) [22.76]

Feed pump

Feed pump discharge start time

Assembly Standard ... 20 sec or less

Priming pump discharge start

Assembly Standard ... No. of pumping operations: 30 strokes or less

Feed pump feed rate (pump at 600 rpm)

Assembly Standard ... 900 cm3 [54.9 cu.in.]/15 sec

36

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

PSG governor drive

Diameter of case bore, drive shaft-side bearing section, mm [in.]

Nominal Value ........... 52 [2.05]

Assembly Standard ... 51.988–52.018 [2.04677–2.04795]

Drive shaft side bearing

Outside diameter, mm [in.]

Nominal Value ........... 52 [2.05]

Assembly Standard ... 51.987–52.000 [2.04673–2.04742]

Inside diameter, mm [in.]

Nominal Value ........... 25 [0.98]

Assembly Standard ... 24.990–25.000 [0.98386–0.98425]

Drive shaft diam., bearing section, mm [in.]

Nominal Value ........... 25 [0.98]

Assembly Standard ... 25.002–25.011 [0.98433–0.98468]

Case bore diam., idler shaft-side bearing section, mm [in.]

Nominal Value ........... 47 [1.85]

Assembly Standard ... 46.989–47.014 [1.84996 –1.85094]

Idler shaft side bearing diameter

Outside diameter, mm [in.]

Nominal Value ........... 47 [1.85]

Assembly Standard ... 46.988–47.000 [1.84992–1.85039]

Inside diameter, mm [in.]

Nominal Value ........... 20 [0.79]

Assembly Standard ... 19.990–20.000 [0.78701–0.78740]

Idler shaft diam., bearing section, mm [in.]

Nominal Value ........... 20 [0.79]

Assembly Standard ... 20.002–20.011 [0.78749–0.78783]

Electric system

Starter

Diameter of commutator, mm [in.]

Nominal Value ........... Ø43 [1.69]

Service Limit ............. Ø42 [1.65]

Runout of commutator, mm [in.]

Assembly Standard ... 0.06 [0.0024], or less

Service Limit ............. 0.10 [0.0039]

Mica depth in commutator, mm [in.]

Assembly Standard ... 0.7–0.9 [0.028–0.035]

Service Limit ............. 0.2 [0.0079]

Height of brushes, mm [in.]

Assembly Standard ... 21–22 [0.83–0.87]

Service Limit ............. 13 [0.51]

37

Plus d'informations sur : www.dbmoteurs.fr

Maintenance Standards

Tension of brush springs, N (kgf) [lbf]

Nominal Value ........... 44.13 [4.5] [10]

Assembly Standard ... 39.23–49.03 (4.0–5.0) [9–11]

Service Limit ............. 39.23 (4.0) [9], maximum

Armature shaft diameter (rear), mm [in.]

Nominal Value ........... Ø14 [0.55]

Assembly Standard ... 13.941–13.968 [0.54886–0.54992]

+0.25

Repair Limit ............... Ø10 +0.15 [0.39 +0.0098

+0.0059]

Armature shaft diameter (front), mm [in.]

Nominal Value ........... Ø25 [0.98]

Assembly Standard ... 25.002–25.011 [0.98433–0.98468]

Reapir Limit ............... Ø25 +0.25 +0.0098

+0.15 [0.98 +0.0059]

Armature shaft deflection, mm [in.]

Assembly Standard ... 0.06 [0.00236]

Pinion shaft diameter (rear), mm [in.]

Nominal Value ........... Ø30 [1.8]

Assembly Standard ... 30.002 to 30.011 [1.18118 to 1.1853]

Reapir Limit ............... Ø30 +0.011 +0.0043

+0.002 [1.18 +0.0008]

Pinion shaft diameter (front), mm [in.]

Nominal Value ........... Ø19 [0.75]

Assembly Standard ... (18.90 to 18.94) ([0.7441 to 0.7457])

Reapir Limit ............... Ø19 +0.06 +0.00236

+0.10 [0.75 +0.00394]

Metal, Pinion

Nominal Value ........... Ø19 [0.75]

Assembly Standard ... 19.000 to 19.033 [0.7480 to 0.7493]

Reapir Limit ............... Ø19 +0.033

0 [0.75 +0.00130

0 ]

Service Limit ............. 0.25 [0.0098]

NOTE! Clearance between shaft and metal.

End play of armature, mm [in.]

Assembly Standard ... 0.3 to 0.7 [0.012 to 0.028]

End play of pinion shaft, mm [in.]

Assembly Standard ... 0.2 to 0.8 [0.008 to 0.031]

Alternator

Output current (27 V), 2500 rpm

At 2500 rpm:

Assembly Standard ... 30 A or higher when cold

At 5000 rpm:

Assembly Standard ... 35 A or higher, when hot

Regulator adjusting voltage (alternator at 5000 rpm, load at 5 A or lower)

Assembly Standard ... 28.5±0.5 V

Field coil resistance (at 20°C [68°F])

Assembly Standard ... 7.3 to 8.6 W

38

Plus d'informations sur : www.dbmoteurs.fr

General information

Tightening torques D49A MS

Thread Torque

Description Diam.xPitch Nm kpm lbf.ft Notes

(M-Thread)

Cylinder Head 22 x 2,5 539 55 398 (a) (b) (c)

Cylinder head nozzle gland (studs) 14 x 2,0 69-78 7-8 51-58

Rocker case 12 x 1,25 108 11 80

Rocker shaft 14 x 2,0 147 15 108

Rocker arm lock nuts 12 x 1,25 64 6,5 47

Bridge lock nuts 10 x 1,25 55 5,6 40

Camshaft gear 12 x 1,25 108 11 80

Camshaft thrust plate 12 x 1,25 59 6 43

Main bearing caps 22 x 2,5 588 60 434 (a)

Main bearing cap side bolts 20 x 2,5 392 40 289

Hanger 12 x 1,25 392 40 289

Hanger 16 x 1,5 216 22 159

Piston cooling nozzle 12 x 1,75 34 3,5 25 (d)

Timing gear case 16 x 1,5 255 26 188

Rear plate 12 x 1,25 108 11 80

Rear plate 16 x 1,5 216 22 159

Oil pan 12 x 1,25 59 6 43

Front mounting bracket 20 x 1,5 392 40 289

Rear mounting bracket 20 x 1,5 392 40 289

Connecting rod metal caps 22 x 1,5 539 55 398 (a) (e)

Flywheel 22 x 1,5 539 55 398 (a)

Balance weight 22 x 1,5 490 50 362

Viscous damper 22 x 1,5 490 50 362

Ring gears 10 x 1,25 59 6 43

Rear idler shaft 20 x 1,25 392 40 289

Rear idler shaft (nuts) 18 x 1,5 196 20 145

Front gear case 12 x 1,25 59 6 43

Front gear case 16 x 1,5 216 22 159

Front plate 12 x 1,25 59 6 43

Front idler shaft 12 x 1,25 108 11 80

Front idler gear thrust plate 10 x 1,25 29 3 22

Exhaust manifold V-clamp nuts 6 x 1,0 9 0,9 6,5

Exhaust manifold mounting bolts 10 x 1,5 98 10 72

Fresh water pump 12 x 1,25 108 11 80

Fresh water pump shaft pulley (nuts) 30 x 1,5 392 40 289 For alternator drive.

(a) Wet , apply lubrication oil to the threads of the nut and bolt.

(b) 2-step tightening method

(c) Tighten cylinder head bolts according to the angle method, tighten to 294 Nm [30 kpm; 217 lbf.ft], then tighten 60° more.

(d) Extremely important to use torque wrench in tightening the piston cooling nozzles. Failure to do so may result in excessive tightening

torque, which may cause valve malfunctions that could lead to seizing of pistons due to insufficient lubrication.

(e) Tighten connecting rod caps according to the angle method, tighten to 245 Nm [25 kpm; 181 lbf.ft], then tighten 60° more.

39

Plus d'informations sur : www.dbmoteurs.fr

General information

Tightening torques D49A MS

Thread Torque

Description Diam.xPitch Nm kpm lbf.ft Notes

(M-Thread)

Oil pump 12 x 1,25 108 11 80

Oil pump cover 10 x 1,25 26,3-39,7 2,7-4,1 18-32

Oil & Water pump mounting plates 12 x 1,25 59 6 43

Bearing cover (oil & water pump) 12 x 1,25 108 11 80

Injection pump 12 x 1,25 108 11 80

Injection pump bracket 12 x 1,25 108 11 80

Injection pump drive case 12 x 1,25 108 11 80

Injection pump gear (nuts) 30 x 1,5 392 40 289

Injection pump laminate plate 12 x 1,25 103-113 10,5-11,5 76-83

Injection pump flywheel (nuts) 24 x 1,5 392 40 289

Injection pump coupling shaft 14 x 1,5 167-177 17-18 123-130 Tighten the slit part.

Injection pump plunger assembly 12 x 1,25 78-83 8-8,5 58-61

Injection pump delivery valve holder 30 x 1,5 235-255 24-26 174-188

Injection nozzle gland (nut) 14 x 1,5 98 10 72

Injection nozzle chip (nut) 28 x 1,5 177-196 18-20 130-145